Advertisement

Quick Links

Translated from German to English - www.onlinedoctranslator.com

D

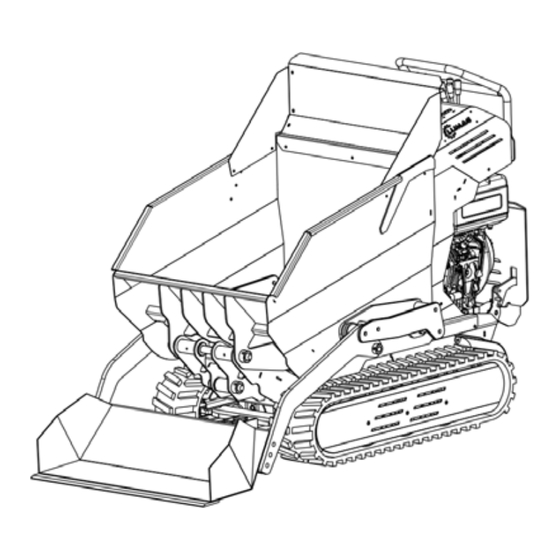

Mini dumper VH-500A / VH500PROA –

series

original operating instructions

mini-dumper

VH500A / VH500PROA series

VH500A series

VH500PROA series

DANGER!

The engine and hydraulic oil were drained for shipping.

Before first use, the engine and hydraulic oil must be topped up (see chapters 10

+ 13)

For diesel versions

The operating hours counter must be activated before initial commissioning! (See

Chapter 10.1)

Model:

Serial number:

Both the model number and the serial number can be found on the mini dumper's nameplate. You should keep both

numbers safe for future reference. This manual explains the machine's functions and applications.

Before commissioning, read the operating

instructions and observe the safety and warning

instructions!

1

original operating

Page

instructions

Advertisement

Summarization of Contents

Information on Operating Instructions

Intended Use

Defines the purpose and scope of the VH-500 series mini dumpers for transporting bulk and general cargo.

Safety Instructions

General Safety Instructions

Provides fundamental safety rules, hazard symbols, and precautions for operating the machine safely.

Work and Danger Area Safety

Outlines responsibilities and safety measures for the work zone and proximity to the machine.

Personal Safety Guidelines

Details essential personal protective equipment and conduct for safe operation.

Combustion Engine Safety

Highlights specific hazards and safety precautions related to engine operation and refueling.

Machine Use and Maintenance Safety

Covers safe practices for operating, maintaining, and handling the machine and its components.

Service Security Procedures

Emphasizes safety during maintenance, cleaning, and electrical system handling.

Electrical System Safety

Notes for individuals with pacemakers regarding the ignition system.

Special Security Measures

Highlights a specific security measure relevant to operation.

Emergency Procedures

Provides guidance on actions to take and information to provide in case of an accident or emergency.

Warning and Note Symbols

Mandatory Signs and Hazard Warnings

Details essential mandatory signs, tipping risks, passenger restrictions, and warnings for flying objects and hot surfaces.

Machine Identification Plate

Describes the information found on the machine's nameplate for identification and service.

Technical Data

VH500A Series Specifications

Provides detailed technical specifications for the VH500A series mini dumpers.

VH500PROA Series Specifications

Provides detailed technical specifications for the VH500PROA series mini dumpers with self-loading shovel.

Noise Level Data

Details the guaranteed sound power level and sound pressure level of the machine.

Permissible Inclination Limits

Specifies the maximum safe longitudinal and transverse inclination angles for operating the machine.

Delivered Content

Engine, Transmission, and Hydraulic Oil

Instructions on filling engine, transmission, and hydraulic oil and initial transport considerations.

Machine Transport

Provides safety and procedural advice for transporting the mini dumper.

Machine Controls

Control Lever A Function

Details the operation of the control lever for the left crawler track.

Control Lever B Function

Details the operation of the control lever for the right crawler track.

Shift Lever C (Tipping Trough)

Explains the function of the lever for tipping the trough.

Shift Lever D (Self-Loading)

Details the operation of the lever for the self-loading bucket (VH500PROA series).

Accelerator Lever (Throttle)

Controls engine speed and power output.

Work Preparation

Initial Commissioning

Guides through the crucial first steps before operating the machine.

Running-in Phase

Details how to operate the machine during its initial period for optimal performance.

Starting the Engine

Provides instructions on how to safely start the engine.

Turning Off the Engine

Explains the correct procedure for shutting down the engine.

Refueling Procedures

Details the correct procedures and safety precautions for refueling the machine.

Operating Resources

Specifies required fuels and engine oil for different models.

Refilling Engine Oil

Provides procedures for checking and refilling the engine oil level.

Fueling the Machine

Explains the process for safely filling the fuel tank with the correct fuel type.

Operation of the Machine

Operating Instructions

Offers essential guidelines for safe and efficient operation of the mini dumper.

Operating Position

Describes the correct and safe position for the operator while working with the machine.

Forward Motion

Explains how to move the machine forward using the control levers.

Reversing and Slope Driving

Details reversing procedures and warnings for operating the machine on slopes and inclines.

Stopping and Cornering

Explains how to stop, turn, and secure the machine safely, especially on slopes.

Machine Rotations

Explains how to rotate the machine on its axis for tight space maneuvers.

Parking, Load Transport, and Tipping

Covers safe parking, load transport guidelines, and procedures for unloading the tipping trough.

Self-Loading Device Operation

Instructions for operating the self-loading shovel feature on the VH500PROA series.

Maintenance

Preventive Measures

Details actions to take before and after operation to ensure machine longevity and safety.

Maintenance Intervals

Outlines the recommended maintenance schedule based on operating hours or time.

Motor Maintenance

Refers to the engine manual for specific maintenance tasks related to the engine.

Hydraulic Oil System

Covers checking and refilling the hydraulic oil, including safety precautions.

Changing Hydraulic Oil and Filter

Provides procedures and intervals for changing hydraulic oil and replacing the oil filter.

Caterpillar Track Maintenance

Explains how to check and adjust the tension of the crawler tracks for optimal performance.

Track Replacement, Lubrication, and Materials

Details track replacement, lubrication points, and recommended operating materials.

Warranty, Guarantee, and Service

Warranty Information

Outlines warranty exclusions and conditions for claims.

Guarantee and Customer Service

Provides guarantee details, contact information, and service hours for support.

Need help?

Do you have a question about the VH500/GXA and is the answer not in the manual?

Questions and answers