Advertisement

Quick Links

Translated from German to English - www.onlinedoctranslator.com

D

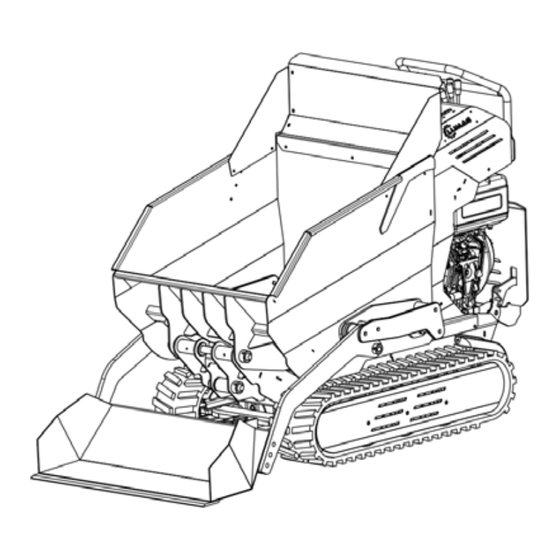

Mini dumper VH-500A / VH500PROA –

series

original operating instructions

mini-dumper

VH500A / VH500PROA series

VH500A series

VH500PROA series

DANGER!

The engine and hydraulic oil were drained for shipping.

Before first use, the engine and hydraulic oil must be topped up (see chapters 10

+ 13)

For diesel versions

The operating hours counter must be activated before initial commissioning! (See

Chapter 10.1)

Model:

Serial number:

Both the model number and the serial number can be found on the mini dumper's nameplate. You should keep both

numbers safe for future reference. This manual explains the machine's functions and applications.

Before commissioning, read the operating

instructions and observe the safety and warning

instructions!

1

original operating

Page

instructions

Advertisement

Summarization of Contents

5. SAFETY INSTRUCTIONS

5.1 General Safety

Observe instructions to minimize risks. Comply with regulations. Check machine before use.

5.2 Work and Danger Area

User responsible for third parties. Stay clear of danger zone. Adapt speed. Keep area tidy.

5.3 Personal Safety

Proper training prerequisite. No fatigue/intoxication. Dress appropriately, wear PPE.

5.4 Combustion Engine Safety

Danger from engines and refueling. Avoid exhaust fumes, hot parts. Observe warnings.

5.5 Machine Use and Maintenance Safety

Do not overload. Operate on firm ground. Avoid hot parts. Use approved parts. Clean machine.

5.6 Service Security

Proper maintenance ensures safety. Remove spark plug before maintenance. Check fuel/hydraulic systems.

5.9 Emergency Behavior

Initiate first aid, request medical assistance. Provide essential information.

6. WARNING AND NOTE SYMBOLS

Mandatory Safety Gear

Follow instructions, wear protective gear (helmet, gloves, shoes), and observe safety practices.

Operational Safety Risks

Tipping, flying objects, hot surfaces, rotating parts. Maintain safe distances.

7. TECHNICAL DATA

7.1 VH500A Series Specs

Specifications for VH500A series: weight, dimensions, engine, performance.

7.2 VH500PROA Series Specs

Specifications for VH500PROA series: weight, dimensions, engine, performance.

7.3 Noise Level Data

Noise levels according to EU directive, including sound power and pressure.

7.4 Permissible Inclination

Maximum inclination limits to prevent tipping. Diagrams show angles.

8. DELIVERED CONTENT

8.1 Fluid Filling

Fill engine/hydraulic oil before use. Risk of damage if operated without oil.

8.2 Transport

Machine transport requires care. Empty fuel tank before transport.

8.3 Turn Off Procedure

Procedure for turning off the machine safely.

9. CONTROLS

Control Lever A

Controls left crawler track rotation. Operates when engine is running.

Control Lever B

Controls right crawler track rotation. Operates when engine is running.

Shift Lever C (Tipping)

Activates tipping trough hydraulics. Can be moved with engine off.

Shift Lever D (Self-loading)

Operates self-loading bucket hydraulics. Operates when engine is running.

Accelerator Lever

Controls engine speed and power output.

10. WORK PREPARATION

10.1 Initial Commissioning

Read manual, fill tanks. Machine delivered ready for use.

10.3 Start Engine

Start engine outdoors only. Read engine manual. Check fuel/oil levels.

10.5 Refueling

Refuel machine before operating. Follow safety instructions carefully. Danger of fire.

10.5.1 Operating Resources

Fuel and oil types and quantities for different models.

10.5.2 Refill Engine Oil

Check and refill engine oil. Low oil causes serious damage.

10.5.3 Refueling

Refueling procedure. Use correct fuel, store properly, do not overfill.

11. MACHINE OPERATION

11.1 Operating Instructions

Do not overload. Tracked vehicle tilts. Warm up engine/hydraulics.

11.2 Operating Position

Maintain position. Drive at walking pace. Secure operator platform on slopes.

11.3 Forward Motion

Push both levers forward to move. Not for public roads.

11.4 Reversing

Pull both levers backward to reverse. Avoid uphill reversing.

11.5 Driving on Inclines/Declines

Avoid steep gradients. Driving on slopes requires special techniques.

11.7 Cornering

Release lever on steering side. Right turns: release B, Left turns: release A.

11.8 Rotations

Rotate on own axis for tight spaces. Clockwise: A forward, B back. Counterclockwise: B forward, A back.

11.9 Stopping and Parking

Secure machine against unauthorized use. Park on level surface.

11.11.1 Unloading Material

Tip slowly, evenly on firm ground. Do not move during tipping.

13. MAINTENANCE

13.1 Preventive Measures

Switch off engine. Cool down. Check machine condition, clean, lubricate.

13.2 Maintenance Intervals

Schedule by operating hours for oil, hydraulics, tracks, filters.

13.3 Motor

Refer to engine manual for motor maintenance. Proper maintenance ensures performance.

13.4 Hydraulic Oil Operations

Check, refill, change hydraulic oil. Safety warnings about hot oil.

13.4.4 Hydraulic Oil Filter

Change hydraulic oil filter at prescribed intervals.

13.5 Caterpillar Tracks

Information on caterpillar tracks, including replacement and adjustment.

13.5.1 Tightening Crawler Tracks

Adjust track tension every 50 hours. Sag approx. 3 cm.

13.7 Recommended Materials

Lists recommended engine oil, hydraulic oil, grease with specs and intervals.

15. WARRANTY AND GUARANTEE

Warranty

Statutory warranty for material/assembly defects. Excludes wear, improper use, modifications.

Guarantee

LUMAG guarantee: 24 months private, 12 months commercial. Proof of purchase required.

Customer Service

Contact service for technical help, parts. Provides contact details.

Need help?

Do you have a question about the VH500PROA Series and is the answer not in the manual?

Questions and answers