Table of Contents

Advertisement

Quick Links

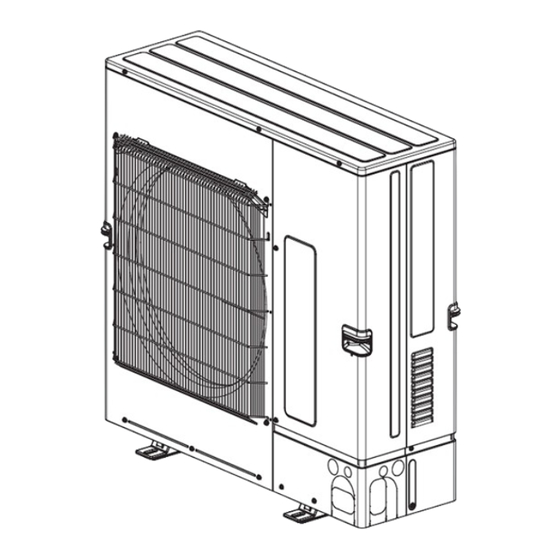

SPLIT-TYPE AIR CONDITIONERS

SERVICE MANUAL

Outdoor unit

[Model Name]

PUZ-M100VKA2

PUZ-M100VKA2-ET

PUZ-M100VKA2-ER

PUZ-M125VKA2

PUZ-M125VKA2-ET

PUZ-M125VKA2-ER

PUZ-M140VKA2

PUZ-M140VKA2-ET

PUZ-M140VKA2-ER

PUZ-M100YKA2

PUZ-M100YKA2-ET

PUZ-M100YKA2-ER

PUZ-M125YKA2

PUZ-M125YKA2-ET

PUZ-M125YKA2-ER

PUZ-M140YKA2

PUZ-M140YKA2-ET

PUZ-M140YKA2-ER

[Service Ref.]

PUZ-M100VKA2.TH

PUZ-M100VKA2-ET.TH

PUZ-M100VKA2-ER.TH

PUZ-M125VKA2.TH

PUZ-M125VKA2-ET.TH

PUZ-M125VKA2-ER.TH

PUZ-M140VKA2.TH

PUZ-M140VKA2-ET.TH

PUZ-M140VKA2-ER.TH

PUZ-M100YKA2.TH

PUZ-M100YKA2-ET.TH

PUZ-M100YKA2-ER.TH

PUZ-M125YKA2.TH

PUZ-M125YKA2-ET.TH

PUZ-M125YKA2-ER.TH

PUZ-M140YKA2.TH

PUZ-M140YKA2-ET.TH

PUZ-M140YKA2-ER.TH

R32

PUZ-M100YKA2R1.TH

PUZ-M100YKA2-ETR1.TH

PUZ-M125YKA2R1.TH

PUZ-M125YKA2-ETR1.TH

PUZ-M140YKA2R1.TH

PUZ-M140YKA2-ETR1.TH

CONTENTS

1. REFERENCE MANUAL ······················· 2

2. SAFETY PRECAUTION ······················· 2

3. SPECIFICATIONS ···························· 13

4. DATA ·············································· 14

5. OUTLINES AND DIMENSIONS ··········· 17

6. WIRING DIAGRAM ··························· 18

7. WIRING SPECIFICATIONS ················ 22

9. TROUBLESHOOTING ······················· 29

10. FUNCTION SETTING ························ 77

BY THE REMOTE CONTROLLER ······· 78

12. EASY MAINTENANCE FUNCTION ······ 86

13. DISASSEMBLY PROCEDURE ············ 88

14. REMOTE CONTROLLER ··················· 95

PARTS CATALOG (OCB773)

January 2024

No.OCH773

REVISED EDITION-B

Revision:

• Connectable indoor units

have been added

in REVISED EDITION-B.

OCH773A is void.

Note:

• This service manual

describes technical data

of the outdoor units only.

Advertisement

Table of Contents

Summarization of Contents

REFERENCE MANUAL

INDOOR UNIT SERVICE MANUAL

Manual for indoor unit service operations.

SAFETY PRECAUTIONS AND REFRIGERANT HANDLING

SYMBOLS AND SAFETY OBSERVANCE

Meanings of unit symbols and general safety rules.

NEW REFRIGERANT CAUTIONS

Specific safety precautions for new refrigerants like R32.

SERVICE PROCEDURES AND WARNINGS

SERVICE WARNINGS AND CAUTIONS

General warnings and cautions for service operations and refrigerant handling.

SERVICE CAUTIONS AND REFRIGERANT CHARGING

Cautions for service and procedures for additional refrigerant charging.

R32 REFRIGERANT HANDLING CAUTIONS

Detailed cautions for units using R32 refrigerant during servicing.

R32 REFRIGERANT SERVICE AND RECOVERY

REPAIRS AND PROCEDURES FOR R32 UNITS

Cautions for repairs, detection methods, removal, evacuation, and charging.

REFRIGERANT RECOVERY AND DECOMMISSIONING

Procedures for refrigerant recovery, labeling, and decommissioning.

SERVICE TOOLS AND PIPE REUSE

EXCLUSIVE TOOLS FOR R32 REFRIGERANT

List of specialized tools required for R32 refrigerant.

REUSING EXISTING REFRIGERANT PIPES

Precautions and flowchart for reusing R22/R410A refrigerant pipes.

REFRIGERANT PIPING WORK CAUTIONS

REFRIGERANT PIPING WORK CAUTIONS

Cautions for refrigerant piping work including tool compatibility and dimensions.

INSTALLATION LOCATION GUIDELINES

OUTDOOR UNIT INSTALLATION LOCATION

Guidelines for choosing the correct installation location for outdoor units.

MINIMUM INSTALLATION AREA REQUIREMENTS

Requirements for minimum installation space to ensure safety.

MINIMUM INSTALLATION AREA FOR INDOOR UNITS

MINIMUM INSTALLATION AREA FOR INDOOR UNITS

Installation area requirements for various indoor unit types.

FLOOR STANDING UNIT INSTALLATION AREA

FLOOR STANDING UNIT INSTALLATION AREA

Specific installation area requirements for floor standing units.

SPECIFICATIONS

TECHNICAL SPECIFICATIONS OVERVIEW

General technical specifications for the outdoor units.

DATA

REFILLING REFRIGERANT CHARGE DATA

Data on refrigerant charge based on piping length.

COMPRESSOR TECHNICAL DATA

Technical data specific to the compressor unit.

NOISE CRITERION CURVES

NOISE CRITERION CURVES

Noise level data presented in criterion curves.

STANDARD OPERATION DATA

STANDARD OPERATION DATA

Standard operational data for various modes and conditions.

OUTLINES AND DIMENSIONS

UNIT DIMENSIONS AND PIPING/WIRING DETAILS

Physical dimensions and connection details for the unit.

WIRING DIAGRAM

WIRING DIAGRAM FOR PUZ-M100VKA2(-ET/-ER).TH

Electrical wiring diagram for a specific model.

WIRING DIAGRAMS FOR PUZ-M125/140VKA2 MODELS

Electrical wiring diagrams for PUZ-M125/140VKA2 models.

WIRING DIAGRAMS FOR PUZ-M100/125/140YKA2 MODELS

Electrical wiring diagrams for PUZ-M100/125/140YKA2 models.

WIRING DIAGRAMS FOR PUZ-M100/125/140YKA2R1 MODELS

Electrical wiring diagrams for PUZ-M100/125/140YKA2R1 models.

WIRING SPECIFICATIONS

FIELD ELECTRICAL WIRING SPECIFICATIONS

Power wiring specifications for different outdoor unit models.

SEPARATE INDOOR/OUTDOOR UNIT POWER SUPPLIES

Wiring patterns for separate indoor and outdoor unit power supplies.

INDOOR – OUTDOOR CONNECTING CABLE SPECIFICATIONS

Specifications for indoor and outdoor unit connecting cables.

M-NET WIRING METHOD AND EARTHING

Guidelines for M-NET wiring and proper earthing methods.

M-NET ADDRESS AND REFRIGERANT ADDRESS SETTINGS

Procedures for setting M-NET and refrigerant addresses.

REFRIGERANT SYSTEM DIAGRAM

REFRIGERANT FLOW AND COMPONENTS

Diagram illustrating the refrigerant system and its components.

REFRIGERANT COLLECTING (PUMP DOWN) PROCEDURE

Step-by-step procedure for collecting refrigerant (pump down).

TEST RUN START AND FINISH

Procedures for starting and finishing a test run operation.

TROUBLESHOOTING

SELF-DIAGNOSIS AND CHECK CODE SUMMARY

Overview of self-diagnosis codes and actions for troubleshooting.

TEST RUN CHECKPOINTS AND ERROR INFO

Checkpoints before test run and references for error information.

INDOOR UNIT ERROR CODES (OUTPUT PATTERN A)

List of error codes detected by indoor units with symptoms.

OUTDOOR UNIT ERROR CODES (OUTPUT PATTERN B)

List of error codes detected by outdoor units with symptoms.

SELF-DIAGNOSIS ACTION TABLE

ACTIONS FOR POWER ON ABNORMALITIES

Actions for abnormalities detected when the power is ON.

MISWIRING AND STARTUP TIME OVER ERRORS

Troubleshooting for miswiring and startup time over errors.

HIGH PRESSURE AND DISCHARGE TEMPERATURE ERRORS

Troubleshooting for high pressure and discharge temperature related errors.

THERMISTOR AND FAN MOTOR RELATED ERRORS

Troubleshooting for thermistor and fan motor errors.

POWER SUPPLY VOLTAGE AND CURRENT ERRORS

Troubleshooting for overvoltage, undervoltage, and current sensor errors.

REFRIGERANT AND PRESSURE RELATED ERRORS

Troubleshooting for low pressure and overheat protection errors.

COMPRESSOR AND REMOTE CONTROLLER ERRORS

Troubleshooting for compressor and remote controller communication errors.

COMMUNICATION ERRORS BETWEEN UNITS

Troubleshooting for indoor/outdoor unit communication errors.

REFRIGERANT AND PIPE TEMPERATURE ERRORS

Troubleshooting for refrigerant circuit and pipe temperature errors.

M-NET COMMUNICATION ERRORS

Troubleshooting for M-NET communication errors and address issues.

M-NET COMMUNICATION ERRORS (NO ACK SIGNAL)

Troubleshooting for M-NET "No ACK" signal errors.

TROUBLESHOOTING OF PROBLEMS

REMOTE CONTROLLER DISPLAY ISSUES

Troubleshooting for remote controller display problems.

M-NET COMMUNICATION RESPONSE ERRORS

Troubleshooting for M-NET response errors.

REMOTE CONTROLLER OPERATION ISSUES

Troubleshooting for remote controller operation and sound issues.

"PLEASE WAIT" DISPLAY TROUBLESHOOTING

Troubleshooting for the "Please Wait" display on the remote controller.

REMOTE CONTROLLER NO DISPLAY TROUBLESHOOTING

Troubleshooting for when the remote controller display shows no output.

REMOTE CONTROLLER NO DISPLAY TROUBLESHOOTING

Troubleshooting steps for a blank remote controller display.

REMOTE CONTROLLER NO DISPLAY TROUBLESHOOTING

Final troubleshooting steps for a blank remote controller display.

FREQUENT CUSTOMER CALLS AND RESPONSES

UNIT OPERATION AND REMOTE CONTROLLER ISSUES

Common customer issues regarding unit operation and remote controller.

COOLING PERFORMANCE AND SOUND ISSUES

Customer issues related to cooling performance and normal operational sounds.

SOUND AND AIRFLOW DIRECTION ISSUES

Troubleshooting for unusual sounds and airflow direction problems.

UNINTENDED OPERATION AND AIRFLOW ISSUES

Troubleshooting for unintended operation and fan speed mismatches.

MIST, WATER, AND REMOTE CONTROLLER DISPLAY ISSUES

Troubleshooting for mist, water expulsion, and dim/blank remote controller displays.

HOW TO CHECK THE PARTS

THERMISTOR RESISTANCE CHECK

Procedures for checking thermistor resistance values.

SOLENOID VALVE COIL AND MOTOR RESISTANCE

Checking resistance of solenoid valve coils and compressor motors.

DC FAN MOTOR AND CIRCUIT BOARD CHECK

Methods for checking DC fan motor and related circuit boards.

HOW TO CHECK THE COMPONENTS

THERMISTOR CHARACTERISTIC CHARTS

Charts showing thermistor resistance vs. temperature.

LINEAR EXPANSION VALVE OPERATION AND CHECK

Operation summary and connection details for the linear expansion valve.

LINEAR EXPANSION VALVE COIL ATTACHMENT/DETACHMENT

Procedures for attaching and detaching the linear expansion valve coil.

EMERGENCY OPERATION

CONDITIONS AND PROCEDURES FOR EMERGENCY OPERATION

When to use and how to perform emergency operation.

TEST POINT DIAGRAM

OUTDOOR CONTROLLER CIRCUIT BOARD DIAGRAM

Diagram showing test points on the outdoor controller circuit board.

OUTDOOR NOISE FILTER CIRCUIT BOARD LAYOUT

Layout of the outdoor noise filter circuit board.

OUTDOOR POWER CIRCUIT BOARD DIAGRAM

Diagram showing components on the outdoor power circuit board.

FUNCTION OF SWITCHES, CONNECTORS AND JUMPERS

DIP SWITCH FUNCTIONS AND OPERATION

Explanation of DIP switch functions and their actions.

CONNECTOR FUNCTIONS AND SPECIAL FEATURES

Explanation of connector functions and special features like low noise mode.

OUTDOOR UNIT INSPECTION INDICATORS

NORMAL AND ABNORMAL OPERATION INDICATIONS

Interpretation of LED indicators for normal and abnormal unit conditions.

DETAILED ERROR CODE INTERPRETATION

Detailed interpretation of error codes indicated by LED blinking patterns.

OUTDOOR UNIT OPERATION MONITOR FUNCTION

DIGITAL INDICATOR LED1 AND ERROR POSTPONEMENT

Explanation of LED1 indicators and error postponement displays.

BLINKING INDICATORS FOR INSPECTION CODES

Explanation of blinking indicators for various inspection codes.

MONITORING OPERATION DATA VIA REMOTE CONTROLLER

MONITORING TEMPERATURE AND CURRENT DATA

Display details for temperature, current, and history data.

MONITORING OPERATION AND POSTPONEMENT CODES

Display details for operation modes and postponement codes.

MONITORING ERROR HISTORY AND THERMISTOR DATA

Display details for error history and thermistor readings.

MONITORING THERMOSTAT TIME AND TEST RUN TIME

Display details for thermostat and test run times.

MONITORING INDOOR SETTING AND PIPE TEMPERATURES

Display details for indoor settings and pipe temperatures.

MONITORING CONNECTED UNITS AND CAPACITY SETTINGS

Display details for connected units and capacity settings.

MONITORING DEFROST CYCLES AND INPUT CURRENT

Display details for defrost cycles and input current.

MONITORING DISCHARGE SUPERHEAT AND OPENING PULSE

Display details for discharge superheat and LEV opening pulse.

MONITORING CAPACITY SAVE AND ERROR HISTORY

Display details for capacity save and error history.

MONITORING THERMISTOR AND OPERATION FREQUENCY ERRORS

Display details for thermistor and operation frequency errors.

MONITORING PIPE TEMPERATURE AND SUPERHEAT ERRORS

Display details for pipe temperature and discharge superheat errors.

MONITORING THERMOSTAT TIME UNTIL ERROR STOPS

Display details for thermostat time until error stops.

MONITORING INDOOR PIPE TEMPERATURES AND COMPRESSOR STATUS

Display details for indoor pipe temperatures and compressor status.

MONITORING COMPRESSOR SURFACE TEMPERATURE

Display details for compressor surface temperature.

FUNCTION SETTING

UNIT FUNCTION SETTING VIA REMOTE CONTROLLER

How to set unit functions using the remote controller.

SELECTING FUNCTIONS USING REMOTE CONTROLLER

How to select functions via the remote controller menus.

HOW TO MONITOR OPERATION DATA

HOW TO MONITOR OPERATION DATA USING REMOTE CONTROLLER

Guide on how to monitor operation data via the remote controller.

REQUEST CODE LIST FOR OPERATION DATA

REQUEST CODE LIST FOR OPERATION DATA

List of request codes to retrieve specific operation data.

REQUEST CODE LIST FOR OPERATION DATA

List of request codes to retrieve specific operation data.

REQUEST CODE LIST FOR OPERATION DATA

List of request codes to retrieve specific operation data.

OPERATION AND CONTROL STATE DETAILS

Detailed content for operation and control state request codes.

COMPRESSOR FREQUENCY CONTROL STATE DETAILS

Detailed content for compressor frequency control state request codes.

FAN CONTROL AND ACTUATOR OUTPUT STATE DETAILS

Detailed content for fan control and actuator output state request codes.

ERROR CONTENT (U9) DETAILS

Detailed content for error code U9 request codes.

DEMAND CAPACITY AND EXTERNAL INPUT STATE DETAILS

Detailed content for demand capacity and external input state request codes.

CAPACITY SETTING AND UNIT SETTING INFORMATION DETAILS

Detailed content for capacity setting and unit setting information request codes.

INDOOR UNIT CAPACITY SETTING INFORMATION DETAILS

Detailed content for indoor unit capacity setting information request codes.

WIRELESS PAIR NUMBER SETTING INFORMATION DETAILS

Detailed content for wireless pair number setting information request codes.

EASY MAINTENANCE FUNCTION

SMOOTH MAINTENANCE FUNCTION OVERVIEW

Overview of the Smooth Maintenance function for easier servicing.

OPERATION CONDITION GUIDE AND INSPECTION CRITERIA

OPERATION CONDITION GUIDE AND INSPECTION CRITERIA

Guide for operation conditions and criteria for inspection.

DISASSEMBLY PROCEDURE

REMOVING SERVICE PANEL AND TOP PANEL

Steps to remove the service and top panels of the unit.

REMOVING THE FAN MOTOR

Steps to remove the fan motor assembly.

REMOVING THE ELECTRICAL PARTS BOX

Steps to remove the electrical parts box.

DISASSEMBLING THE ELECTRICAL PARTS BOX (VKA2 TYPE)

Steps for disassembling the electrical parts box for VKA2 type units.

DISASSEMBLING THE ELECTRICAL PARTS BOX (YKA2 TYPE)

Steps for disassembling the electrical parts box for YKA2 type units.

DISASSEMBLING THE ELECTRICAL PARTS BOX (YKA2R1 MODEL)

Steps for disassembling the electrical parts box for YKA2R1 models.

REMOVING THE THERMISTOR <2-PHASE PIPE> (TH6)

Steps to remove the 2-phase pipe thermistor (TH6).

REMOVING THE THERMISTOR (TH7)

Steps to remove the ambient thermistor (TH7).

REMOVING THERMISTORS , ,

Steps to remove liquid, discharge, and comp. surface thermistors.

REMOVING THE LEV COIL

Steps to remove the LEV coil.

REMOVING THE LEV

Steps to remove the Linear Expansion Valve (LEV).

REMOVING THE HIGH PRESSURE SWITCH (63H)

Steps to remove the high pressure switch (63H).

REMOVING THE 4-WAY VALVE COIL (21S4)

Steps to remove the 4-way valve coil.

REMOVING THE 4-WAY VALVE

Steps to remove the 4-way valve.

REMOVING THE COMPRESSOR (MC)

Steps to remove the compressor unit.

REMOTE CONTROLLER

REMOTE CONTROLLER FUNCTIONS OVERVIEW

Explanation of the functions of the remote controller buttons.

REMOTE CONTROLLER DISPLAY MODES AND ICONS

Explanation of the remote controller's display modes and icons.

REMOTE CONTROLLER MENU STRUCTURE

MAIN MENU NAVIGATION AND SECTIONS

Overview of the remote controller's main menu structure and sections.

MAINTENANCE, SERVICE, SETTINGS, AND CHECK MENUS

Detailed breakdown of the maintenance, service, settings, and check menus.

REMOTE CONTROLLER MAIN MENU LIST

OPERATION AND TIMER FUNCTION SETTINGS

Details on setting operation modes and timer functions via remote.

ENERGY SAVING AND RESTRICTION SETTINGS

Details on setting energy saving, restriction, and silent modes.

INITIAL, DISPLAY, AND OPERATION SETTINGS

Details on initial, display, and operation settings via remote.

MAINTENANCE, SERVICE, SETTINGS, AND CHECK MENUS

Details on maintenance, service, settings, and check menu functions.

REMOTE CONTROLLER MODEL-SPECIFIC FUNCTIONS

PAR-SL97A-E CONTROLLER INTERFACE AND BUTTONS

Explanation of PAR-SL97A-E controller interface and button functions.

PAR-SL100A-E CONTROLLER INTERFACE AND BUTTONS

Explanation of PAR-SL100A-E controller interface and button functions.

ERROR INFORMATION

VIEWING AND RESETTING ERROR INFORMATION

How to check and reset error information on the remote controller.

CHECKING ERROR INFORMATION VIA MAINTENANCE MENU

How to view error information through the maintenance menu.

SERVICE MENU ACCESS AND NAVIGATION

ACCESSING THE SERVICE MENU AND PASSWORD ENTRY

Steps to access the service menu, including password entry.

SERVICE MENU CONTENT AND NAVIGATION

Explanation of the service menu content and screen navigation.

TEST RUN PROCEDURES

TEST RUN FOR PAR-41MAA AND OPERATION STEPS

Procedure for performing a test run on PAR-41MAA models.

TEST RUN FOR PAR-SL97A-E AND PAR-SL100A-E

Test run procedures for PAR-SL97A-E and PAR-SL100A-E models.

FUNCTION SETTING PROCEDURES

FUNCTION SETTING FOR PAR-41MAA MODEL

Steps for setting functions on PAR-41MAA models.

SETTING INDOOR UNIT ADDRESSES AND MODES

Setting indoor unit addresses, modes, and sending data.

REMOTE CONTROLLER FUNCTION SETTING METHODS

FUNCTION SELECTION PROCEDURE FOR PAR-SL97A-E

Procedure for selecting functions using the PAR-SL97A-E remote controller.

OPERATING INSTRUCTIONS FOR PAR-SL97A-E

Step-by-step operating instructions for the PAR-SL97A-E remote controller.

REMOTE CONTROLLER FUNCTION SETTING METHODS

FUNCTION SETTING PROCEDURE FOR PAR-SL100A-E

Procedure for setting functions using the PAR-SL100A-E remote controller.

ERROR HISTORY MANAGEMENT

ACCESSING AND VIEWING ERROR HISTORY

Steps to access and view the error history records.

DELETING THE ERROR HISTORY

Procedure for deleting error history records.

PRELIMINARY ERROR HISTORY AND DELETION

Managing preliminary error history records.

SELF-DIAGNOSIS

SELF-DIAGNOSIS FOR PAR-41MAA MODEL

Performing self-diagnosis on PAR-41MAA models.

INTERPRETING SELF-DIAGNOSIS RESULTS AND RESETTING ERRORS

Interpreting self-diagnosis results and resetting error history.

MALFUNCTION DIAGNOSIS METHODS

SELF-DIAGNOSIS FOR PAR-SL97A-E MODEL

Malfunction diagnosis method for PAR-SL97A-E models.

SELF-DIAGNOSIS FOR PAR-SL100A-E MODEL

Malfunction diagnosis method for PAR-SL100A-E models.

REMOTE CONTROLLER CHECK

ACCESSING AND PERFORMING REMOTE CONTROLLER CHECK

Steps to access and perform the remote controller check.

INTERPRETING REMOTE CONTROLLER CHECK RESULTS

Interpreting results of the remote controller check.

SMOOTH MAINTENANCE FUNCTION

ACCESSING AND SETTING SMOOTH MAINTENANCE

Steps to access and set the smooth maintenance function.

VIEWING OPERATION DATA FOR SMOOTH MAINTENANCE

Viewing operation data within the smooth maintenance function.

REQUEST CODE FOR OPERATION DATA

ACCESSING REQUEST CODES VIA SERVICE MENU

Steps to access request codes through the service menu.

SETTING REFRIGERANT ADDRESS AND REQUEST CODE

Setting refrigerant addresses and request codes for data retrieval.

Need help?

Do you have a question about the Mr.Slim PUZ-M140YKA2 and is the answer not in the manual?

Questions and answers