Table of Contents

Advertisement

Quick Links

®

Bendix

ATR-1

®

™

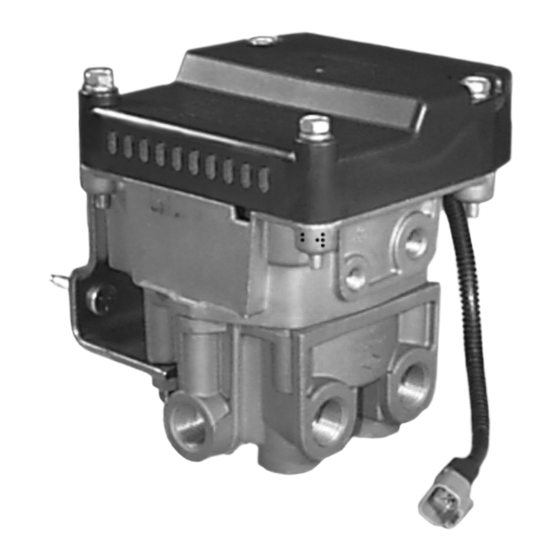

MOUNTING

BRACKET

BODY

SUPPLY

PORT

COVER PLATE FOR

REMOTE MOUNT

FIGURE 1 - ATR-1

ANTILOCK TRACTION RELAY VALVE

™

DESCRIPTION

The ATR-1

antilock traction relay is a specialized air brake

™

valve developed for use on Bendix antilock/traction equipped

vehicles.

It is essentially three separate valves working in combination

in a single housing. An R-14

valve and is fitted with a modified cover containing a double

check valve and a traction control solenoid. The ATR-1

contains both air and electric components to provide the

service braking and traction control (differential braking)

functions. A Bendix antilock traction controller can be

mounted to the ATR-1

™

valve or a cover plate can be installed

and the antilock controller mounted elsewhere on the vehicle.

When an ATR-1

valve is combined with an antilock traction

™

controller the resulting assembly is referred to as an antilock

traction assembly.

The ATR-1

valve replaces the standard relay valve used to

™

control the rear axle service brakes and performs the standard

relay function. Like the standard relay valve it replaces, the

ATR-1

valve (sometimes with attached antilock controller)

™

AntiLock Traction Relay Valve

CONTROLLER

MOUNTING HOLES (4)

SERVICE

REMOTE MOUNT ATR-1

style service relay is the base

™

TRACTION CONTROL

SOLENOID

UNDRILLED

"CON" PORT

PORT

RELAY VALVE

™

is normally mounted near the service brakes it serves. A

mounting bracket, furnished with the valve, permits either

frame or cross member mounting. All air connections on

the ATR-1

™

valve are identified for ease of installation. The

letter identification and air line connections are shown below

for reference.

ATR-1

VALVE AIR CONNECTION

™

valve

™

Supply (to reservoir)

Delivery (to brake Chamber)

Service (to brake valve rear delivery)

Control (not drilled or threaded on ATR-1

The ATR-1

™

which includes the R-12

The internal components of the relay portion of all of these

valves are interchangeable with the R-12

the same basic components are used to service all of them.

The ATR-1

™

to accommodate specific applications, however the standard

is 4 psi.

DELIVERY

PORT (4)

2 PIN SOLENOID

CONNECTOR

valve is part of the R-12

™

™

, R-14

™

, BP-R1

valve is available with various crack pressures

SUPPLY

PORT

EMBOSSED

IDENT.

SUP

DEL

SER

™

valve) CON

family of relay valves

™

, AR-1

™

.

valve and therefore

™

1

Advertisement

Table of Contents

Summary of Contents for BENDIX ATR-1 ANTILOCK TRACTION RELAY

- Page 1 The ATR-1 antilock traction relay is a specialized air brake ™ frame or cross member mounting. All air connections on valve developed for use on Bendix antilock/traction equipped the ATR-1 ™ valve are identified for ease of installation. The vehicles.

-

Page 2: Operation

antilock components and their operation. For a description of antilock operation, refer to the appropriate Service Data Sheet covering the electronic controller used with the CONTROLLER ATR-1 valve. ™ SERVICE BRAKES APPLYING (FIGURE 4) Reservoir air pressure is present at the supply port and flows through internal body and cover passages to the supply of the normally closed (NC) traction control solenoid. - Page 3 CONTROLLER BRAKE VALVE TRACTION SOLENOID CHECK VALVE RELAY PISTON INLET EXHAUST MODULATOR REAR AXLE RESERVOIR SPRING BRAKE FIGURE 4 - SERVICE BRAKE APPLICATION SERVICE BRAKES HOLDING (FIGURE 5) its seat. The exhaust valve remains closed. With both the inlet and exhaust valves closed, air pressure in the brake The air pressure being delivered to the brake chambers is chambers is held stable and neither increases nor decreases.

- Page 4 CONTROLLER BRAKE TRACTION VALVE SOLENOID CHECK VALVE RELAY PISTON INLET EXHAUST MODULATOR REAR AXLE RESERVOIR SPRING BRAKE EXHAUST FIGURE 6 - SERVICE BRAKES RELEASING TRACTION CONTROL SERVICE APPLICATION SERVICE BRAKES RELEASING (FIGURE 6) (FIGURE 7) When the brake application is released, air from above the GENERAL relay piston flows back through the blend back and service pistons to the foot brake valve and is exhausted.

- Page 5 FIGURE 8 - PARTIAL ANTILOCK TRACTION SYSTEM SCHEMATIC...

-

Page 6: Preventive Maintenance

Never remove a component or plug unless you are certain all replaced with a new or genuine Bendix remanufactured unit, system pressure has been depleted. available at any authorized parts outlet. -

Page 7: Vehicle Preparation

Always check the vehicle brake or genuine Bendix remanufactured unit or repaired using system for proper operation after performing brake work and a genuine Bendix maintenance kit piece number 109368, before returning the vehicle to service. - Page 8 PRIOR INTERNAL COMPONENT CONFIGURATION Assembly of items 29-35 Key Description Key Description ECU Control 19 Relay Piston Bolts (4) 20 Piston Spring (if used) Cover 21 O-Ring Base 22 Retaining Ring Retaining Ring 23 Check Valve* Exhaust Cover 24 O-Ring O-Ring 25 Inlet Seat* O-Ring...

-

Page 9: Cleaning And Inspection

DISASSEMBLY Then, depending on the internal configuration: 12a. Remove check valve seat(23), with o-rings(27 & 28). PREPARATION FOR DISASSEMBLY Remove o-rings(27 & 28) from the check valve seat. 1. Remove all air fittings and plugs from the valve. Then Remove the check valve(24), guide(25), and 2. - Page 10 ASSEMBLY 1. Prior to assembly, lubricate all o-rings, seals, and pistons, 4b. Install the o-ring(34) onto the plug(35). Install into the cover(3) bore and while holding it in place install the as well as body and cover bores, using silicone lubricant. retaining ring(22).

- Page 11 NOTES...

- Page 12 BW1794 © 2004 Bendix Commercial Vehicle Systems LLC 10/2004 Printed in U.S.A. All rights reserved.

Need help?

Do you have a question about the ATR-1 ANTILOCK TRACTION RELAY and is the answer not in the manual?

Questions and answers