Advertisement

Service Literature

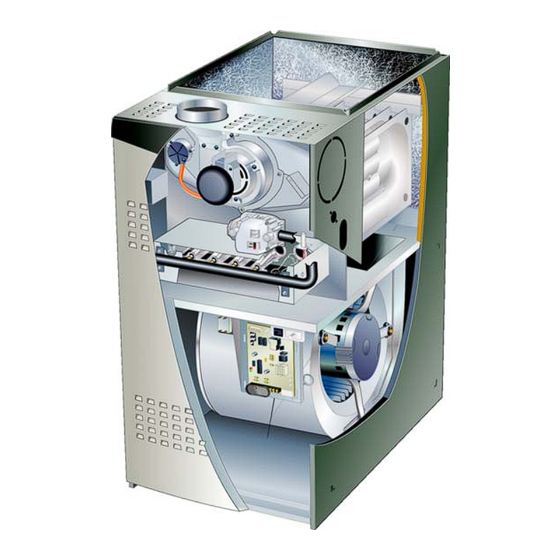

EL180UHE(X) series units are mid-efficiency gas furnaces

used for upflow or horizontal applications only, manufac

tured with Lennox Duralokt heat exchangers formed of

aluminized steel. EL180UHE(X) units are available in heat

ing capacities of 44,000 to 132,000 Btuh and cooling ap

plications 2 to 5 tons. Refer to Engineering Handbook for

proper sizing.

Units are factory equipped for use with natural gas. Kits are

available for conversion to LP/Propane operation.

EL180UHE(X) model units are equipped with a hot surface

ignition system. The EL180UHE(X) unit meets the Califor

nia Nitrogen Oxides (NO

) Standards and California Sea

x

sonal Efficiency requirements. All units use a redundant

gas valve to assure safety shut-off as required by C.S.A.

All specifications in this manual are subject to change. Pro

cedures outlined in this manual are presented as a recom

mendation only and do not supersede or replace local or

state codes. In the absence of local or state codes, the

guidelines and procedures outlined in this manual (except

where noted) are recommended only and do not constitute

code.

TABLE OF CONTENTS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

II Installation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

Corp. 1302-L1

Revised 06-2013

Page 2

Page 4

Page 6

Page 7

Page 20

Page 20

. . . . . . . . .

Page 20

. . . . . . . . .

Page 25

Page 25

. . . . . .

Page 28

Page 1

EL180UHE(X)

WARNING

Improper installation, adjustment, alteration, service

or maintenance can cause property damage, person

al injury or loss of life. Installation and service must

be performed by a licensed professional HVAC in

staller (or equivalent), service agency or the gas sup

plier.

WARNING

Electric shock hazard. Can cause injury

or death. Before attempting to perform

any service or maintenance, turn the

electrical power to unit OFF at discon

nect switch(es). Unit may have multiple

power supplies.

WARNING

Sharp edges.

Be careful when servicing unit to avoid sharp edges

which may result in personal injury.

© 2013 Lennox Industries Inc.

Advertisement

Table of Contents

Summarization of Contents

SPECIFICATIONS

Gas Heating and Installation Data

Covers AFUE, input/output, temp rise, clearances, and pipe sizes for different models.

Electrical, Shipping, and Blower Data

Details electrical specs, shipping weight, and blower performance parameters.

Optional Accessories and High Altitude Adjustments

Cabinet, Filter, and Gas Heat Accessories

Lists optional kits, filter sizes, and gas heat accessories for various models.

High Altitude Derating Guidelines

Explains derating for altitudes above 2000 ft and provides related pressure data.

Blower Performance Data

EL180UH045E36A and EL180UH070E36B Performance

Blower performance (cfm/watts) at various static pressures and speeds for two models.

EL180UH090E48B Performance

Blower performance (cfm/watts) at various static pressures and speeds for a specific model.

Blower Performance Data

EL180UH090E60C and EL180UH110E60C Performance

Blower performance (cfm/watts) for specific models at various static pressures and speeds.

EL180UH135E60D Performance

Blower performance (cfm/watts) for a specific model at various static pressures and speeds.

Unit Component Descriptions

Control Transformer, Interlock, and Breaker

Explains the function of the transformer, door interlock switch, and circuit breaker.

Integrated Control and Electronic Ignition

Details the integrated control, its features, and the electronic ignition sequence.

Fan Operation and Timing Controls

Heating Fan Timing Adjustments

Information on adjustable and non-adjustable heating fan on/off times.

Cooling Fan Timing Specifications

Details non-adjustable cooling fan on/off times and their factory settings.

Furnace Component Details

Rollout, Primary Limit, and Flame Sensor

Explains the function and safety aspects of rollout switches, primary limit control, and flame sensor.

Measuring Flame Signal

Flame Signal Microamp Readings

Provides a table of normal, low, and dropout microamp readings for flame signal.

Furnace Component Functions

Gas Valve and Combustion Air Inducer Operation

Details the gas valve, its redundancy, and the function of the combustion air inducer.

Ignitor Checks and Specifications

Outlines ignitor material, resistance, voltage, and basic troubleshooting checks.

Ignitor Troubleshooting Procedures

Ignitor Resistance and Voltage Testing

Detailed steps for testing ignitor resistance and voltage supply.

Combustion Air Inducer Pressure Switch

Pressure Switch Function and Testing

Explains the pressure switch role in safety and provides troubleshooting guidance.

Furnace Venting and Installation Notes

Multiple Venting Positions and Requirements

Describes furnace venting configurations and installation considerations.

Blower Motor Service and Replacement

Blower Wheel Alignment and Motor Testing

Instructions for blower wheel centering, motor set screw alignment, and initial motor tests.

Motor Control Module Installation

Guidelines for installing a replacement motor control module, including torque and drip loop.

Blower Motor Electrical Troubleshooting

Power, Fan Speed, and Control Voltage Tests

Detailed tests for blower motor power, fan speed signals, and control voltages.

Motor Module Replacement and Testing

Harness Disconnection and Motor Resistance Tests

Steps for unplugging harnesses, testing motor resistance, and checking continuity.

Motor Control Module Installation and Drip Loop

Guidelines for installing a new motor control module, including torque and drip loop formation.

Installation, Start-Up, and Safety Procedures

Unit Installation, Heating Start-Up, and Shutdown

Covers unit installation, heating start-up, safety, and shutdown protocols.

Heating System Service Checks and Gas Piping

Details CSA certification, gas piping requirements, and leak testing procedures.

Gas Pressure, Flow, and Combustion Analysis

Gas Pressure Adjustment and Supply Measurement

Procedures for adjusting gas pressure, measuring supply pressure, and checking flow.

Proper Combustion and High Altitude Settings

Guidelines for checking combustion efficiency, CO levels, and high altitude adjustments.

Ground and Voltage Verification Procedures

Line Voltage Checks for Grounding

Procedures to measure AC voltage for proper grounding and voltage levels.

Typical Operating Characteristics

Blower Operation, Speed, and Static Pressure

Covers blower operation, speed tap adjustment, and external static pressure measurement.

Temperature Rise and Fan Timing

Explains temperature rise dependence and fan timing controls.

Maintenance and Cleaning Procedures

Preliminary Checks and Filter Maintenance

Covers initial checks, electrical inspection, and filter upkeep.

Heat Exchanger and Burner Cleaning

Detailed steps for cleaning the heat exchanger and burners.

Component Removal and Reassembly

Burner, Inducer, and Heat Exchanger Service

Instructions for removing and reinstalling the burner assembly, inducer, and heat exchanger.

System Checks and Maintenance

Supply Air Blower and Flue System Inspection

Covers blower wheel cleaning and inspection of the flue and chimney system.

Electrical System and Amp Draw Checks

Procedures for checking electrical wiring, voltage, and motor amp draw.

Wiring and Sequence of Operation

EL180UHE Schematic and Heating Sequence

Provides the wiring diagram and a detailed sequence of operation for heating.

Heating Sequence Troubleshooting Guide

Initial System Checks and Fault Codes

Verifies control self-check, polarity, ground, voltage, and component states for troubleshooting.

Burner, Limit, and Pressure Switch Verification

Checks burner operation, flame presence, primary limit, and pressure switch status for faults.

Continued Heating Sequence Troubleshooting

Ignitor, Flame Sensing, and Limit Checks

Monitors ignitor performance, flame signal, and limit/pressure switch operations.

Rollout, Pressure Switch Faults, and Watchguard

Analyzes fault codes for rollout, pressure switches, and watchguard conditions.

Cooling Sequence Troubleshooting Flow

Cooling Control, Ground, Polarity, and Voltage Checks

Verifies control operation, ground, polarity, and voltage in cooling mode.

Rollout Switch and Cooling Call Monitoring

Monitors rollout switch status and response to thermostat calls for cooling.

Continuous Fan Sequence Troubleshooting

Fan Operation During Heat and Cool Calls

Describes fan behavior during manual selection and heating/cooling demands.

Need help?

Do you have a question about the EL180UH070E36B and is the answer not in the manual?

Questions and answers