Lennox EL180UHE Series Manual

Hide thumbs

Also See for EL180UHE Series:

- Installation instructions manual (32 pages) ,

- Installation instructions manual (34 pages)

Advertisement

Service Literature

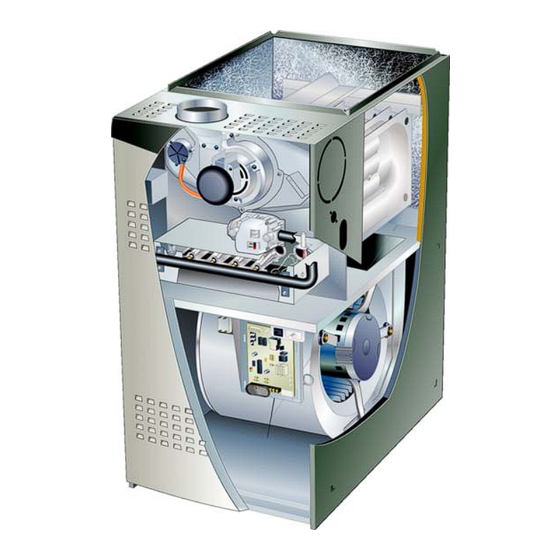

EL180UHE(X) series units are mid-efficiency gas furnaces

used for upflow or horizontal applications only, manufac

tured with Lennox Duralokt heat exchangers formed of

aluminized steel. EL180UHE(X) units are available in heat

ing capacities of 44,000 to 132,000 Btuh and cooling ap

plications 2 to 5 tons. Refer to Engineering Handbook for

proper sizing.

Units are factory equipped for use with natural gas. Kits are

available for conversion to LP/Propane operation.

EL180UHE(X) model units are equipped with a hot surface

ignition system. The EL180UHE(X) unit meets the Califor

nia Nitrogen Oxides (NO

) Standards and California Sea

x

sonal Efficiency requirements. All units use a redundant

gas valve to assure safety shut-off as required by C.S.A.

All specifications in this manual are subject to change. Pro

cedures outlined in this manual are presented as a recom

mendation only and do not supersede or replace local or

state codes. In the absence of local or state codes, the

guidelines and procedures outlined in this manual (except

where noted) are recommended only and do not constitute

code.

TABLE OF CONTENTS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

II Installation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

Corp. 1302-L1

Revised 06-2013

Page 2

Page 4

Page 6

Page 7

Page 20

Page 20

. . . . . . . . .

Page 20

. . . . . . . . .

Page 25

Page 25

. . . . . .

Page 28

Page 1

EL180UHE(X)

WARNING

Improper installation, adjustment, alteration, service

or maintenance can cause property damage, person

al injury or loss of life. Installation and service must

be performed by a licensed professional HVAC in

staller (or equivalent), service agency or the gas sup

plier.

WARNING

Electric shock hazard. Can cause injury

or death. Before attempting to perform

any service or maintenance, turn the

electrical power to unit OFF at discon

nect switch(es). Unit may have multiple

power supplies.

WARNING

Sharp edges.

Be careful when servicing unit to avoid sharp edges

which may result in personal injury.

© 2013 Lennox Industries Inc.

Advertisement

Table of Contents

Need help?

Do you have a question about the EL180UHE Series and is the answer not in the manual?

Questions and answers