Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summarization of Contents

Sound Decoders: First Time Use

Get the HM7000 APP

Instructions for downloading and installing the Hornby HM7000 control APP.

Setup APP and Link Decoder

Steps for setting up the APP and linking the HM7000 decoder via Bluetooth.

Download Sound Profile

How to select and install locomotive sound profiles via the APP.

About This Reference Manual

Function & Hardware Naming Conventions

Explains naming conventions for decoder function outputs (HFOs) and controller functions.

HM7000 Series Decoders Overview

Modes of Operation: DCC, Bluetooth, DC Analogue

Overview of control methods: DCC, Bluetooth via APP, and limited DC operation.

Bluetooth Advantages & DC Operation Warning

Advantages of BLE control and reasons to avoid DC operation.

DC Power Supply Considerations

Suitable Hornby Power Supplies

Lists Hornby power supplies compatible with HM7000 decoders for BLE operation.

DC Power: Analogue Train Controllers

DC Controllers Not Recommended

Lists specific DC controllers not recommended for HM7000 decoders.

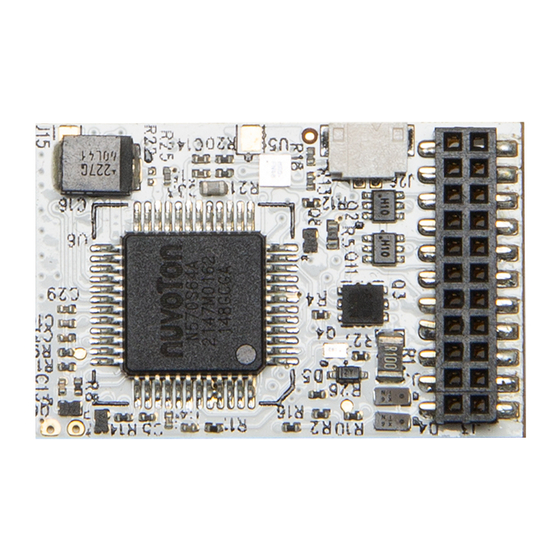

HM7000 Decoder Family Introduction

Decoder Connections Overview

General overview of HM7000 decoder connections for power, motor, and function outputs.

Non-Sound Decoders: Types & Limitations

Operational Limitations Notes

Outlines operational limitations and differences for non-sound decoders compared to sound decoders.

Decoder Functionality Explained

Sound vs. Non-Sound Decoder Functions

Details function ranges for sound and non-sound decoders.

Firmware, Updates, and Sound Profiles

OTA Updates Process

Explains Over-The-Air (OTA) updates via the HM7000 APP for bug fixes and feature enhancements.

Sound Locomotive Updates

Details on updating sound profiles, including factory preloads and repurposing decoders.

Decoder Firmware Structure Overview

Internal Firmware Components (LDROM, APROM, SPIROM)

Explains the roles of LDROM (Boot code), APROM (Control Code), and SPIROM (Sound Code).

Common CVs: Introduction and Primary Address

CV1: Primary Address Configuration

Details the primary address setting (1-127) for decoders and controller limitations.

Speed Control CVs: Acceleration, Deceleration, Vhigh

CV3: Acceleration Rate

Determines the decoder's acceleration rate.

CV4: Deceleration Rate

Determines the decoder's deceleration/braking rate.

Advanced CV Settings: BEMF and Control Mode

CV10: BEMF Cut-out Speed Step

Sets the point where BEMF compensation ceases based on speed step.

CV12: Decoder Control Mode Select

Configures control mode (DCC, DC, Radio/BLE) for sound decoders.

Address Storage: Long Addresses and Consists

CV17 & CV18: Storing Long Addresses

CVs used to store long addresses (above 127).

CV19: Consist Setup

Configures secondary address for consist or double-heading operations.

CV29: Decoder Configuration Explained

CV29: Bit Functions and Values

Examines each bit within CV29 for decoder feature configuration.

CV51-58: Lighting Configuration Details

Hi-Level Outputs for Lighting

Details connections for HFO1-HFO4 used for lighting control via F0, F1, F2.

Special Decoder Functions Overview

F25: Shunting Mode (CV120)

Facilitates manual speed control for low-speed operations, configurable via CV120.

F28: Auto Function Control (AFC) Sound Play

AFC Sound Selection: Running vs. Stationary

Selects sounds to play during locomotive running based on speed step.

Programming Explanations & Sound Selection Help

Sound Selection Help for AFC

Guides on selecting sounds for AFC operation using bit representations in CVs.

Sound Decoders: Adjusting Sound Volumes

CV158: Global Sound Volume

Sets all sound volumes to a common level, with individual adjustments recommended.

Locomotive Type Volume Settings

Details volume settings for Steam, Diesel, and Electric locomotives.

CV159-161: Specific Volume Settings

CV160: ELECTRIC Motor Volume

Adjusts volume for electric locomotive motors.

CV161: Steam/Diesel Engine Volume

Adjusts volume for steam/diesel locomotive engines.

Horn & Whistle Selection (F2/F3)

CV205/207: Sound Selection

Configures which horns/whistles are available for F2 and F3.

CV206/208: Play Mode (Sequential/Random)

Sets whether F2/F3 horns/whistles play sequentially or randomly.

DIESEL Sound Playback: 3 & 4 Notch Systems

3 Notch Diesel Configuration

Configures the 3-notch diesel engine sound system using CVs 210-215.

4 Notch Diesel Configuration

Configures the 4-notch diesel engine sound system using CVs 210-217.

ELECTRIC LOCOMOTIVES: Engine Running Sound Playback

Explanation & Configuration (CV218-222)

Details configuration of electric engine sounds and their playback.

ELECTRO-DIESEL LOCOMOTIVES: Engine Running Sound Playback

The DIESEL Part Explanation

Refers to diesel setup section for electro-diesel engine configuration.

The ELECTRIC Part Explanation

Refers to electric setup section for electro-diesel engine configuration.

Appendix 1: Understanding CVs & Binary

Bytes and Bits Explained

Explains the basic structure of data in decoders as bytes and bits.

Appendix 2: Decoder Addressing Works

Definitions: Short & Long Addresses

Defines short (1-127) and long (above 128) address types.

General Description: CVs & Addresses

Explains CVs as bytes and how short/long addresses are stored.

Address Selection: Long or Short?

How Short Addresses Are Stored

Details storage of short addresses using the first 7 bits of CV1.

How Long Addresses Are Stored

Details storage of long addresses using CV17 and CV18.

Controller Address Programming Methods

Older Controllers: Manual Programming

Explains manual programming for long addresses with older controllers.

More Recent Controllers: Automatic Type Detection

Describes how modern controllers automatically detect and program addresses.

Appendix 3: Using AUX Outputs (HFOs)

Introduction to HFOs

Explains HFOs as Hardware Function Outputs for connecting devices like LEDs.

HFO Naming Conventions

Relates HFO numbers to AUX numbers and controller functions (F0, F1, etc.).

HFO Electrical Information

Decoder Current Limits

Details current handling capabilities of HFOs and the decoder's total current rating.

Load Type: LEDs

Connecting LEDs to 8/21/Next18 Decoders

Explains LED connection for common positive bus decoders.

Connecting LEDs to 6 Pin Decoders

LED Wiring: 6 Pin Decoder Variant

Details LED wiring for 6-pin decoders using Halfwave and Fullwave methods.

LED Current Draw & Resistor Calculation

Calculating Resistor Values for LEDs

Provides formula and guidance for calculating series resistors for LEDs.

LED Voltage Ratings & Preferred Resistors

Lists typical forward voltages and preferred resistor values for different LED colors.

Load Type: Filament Bulbs/Incandescent Lamps

Resistors and Power Dissipation (IMPORTANT)

Discusses heat dissipation considerations for resistors used with LEDs and lamps.

Load Type: Relays

Non-Latching Relays Explained

Details operation of non-latching relays and their connection to HFOs.

Appendix 4: Setting up Asymmetrical DCC Control (ADCC)

ADCC Explanation

Explains ADCC as a system for automatic locomotive actions triggered by track signal asymmetry.

CV27: ADCC Rail Select Configuration

CV125-127: Configuring Automatic Actions

Sets automatic actions (stop, hold, shuttle) upon ADCC detection.

Appendix 6: Motor Control & Tuning (Speed Curves, PIDs)

Introduction to Motor Control

Explains factors affecting motor control and the importance of speed curves and algorithms.

About Speed Curves

Defines speed curves as relationships between speed step and motor voltage.

Explanation of Speed Step Curve Graphs

Describes how speed steps translate to voltage levels and define throttle response.

Tuning Motor Control Algorithms

What is a Motor Control Algorithm?

Defines motor control algorithms as mathematical formulae for optimal motor control.

Motor Control Algorithm Tuning Methods

3 Methods of Algorithm Tuning

Outlines three stages for adjusting motor control algorithms: Auto-Calibration, PA factors, PID.

Stage 1: Auto-Calibration Procedure

Running the Auto-Calibration Process

Step-by-step guide for performing the auto-calibration process.

Stage 2: Adding PA Control Factors

PA Motor Control Algorithm Adjustment

Details CVs for further adjustment using PA factors after auto-calibration.

Stage 3: PID Control Algorithm (Manual Tuning)

PID Motor Control Algorithm CVs

Lists CVs (153-155) for manual adjustment of PID parameters (Proportional, Integral, Derivative).

Appendix 7: Power Bank & Stay Alive Connection

Smart Charging Explained

Describes the smart charging feature for the R7377 Power Bank.

Special Decoder Functions

ABC Configuration CVs

Lists CVs related to Asymmetrical DCC Control (ABC) configuration.

Motor Control Algorithm CVs (Auto-Calibration)

Lists CVs affected by the Auto-Calibration procedure for motor control.

Sound Volume & Motor Control CVs

Sound Volume Configuration CVs

Lists CVs for adjusting global and specific sound volumes.

Motor Control CVs for PA & PID Adjustment

Lists CVs for PA adjustment (CV150-152) and PID adjustment (CV153-155).

Diesel Sound Playback Configuration

3 & 4 Notch Diesel Systems

Details configuration for 3-notch and 4-notch diesel engine sound playback.

Diesel Start Delay After Brake Release

Configures delay before movement after brake release for diesel locomotives.

Appendix 9: Decoder Specifications

Sound Decoders Specification Summary

Summarizes operational, electrical, and physical specs for HM7000 sound decoders.

Need help?

Do you have a question about the HM7000-8TXS and is the answer not in the manual?

Questions and answers