Summarization of Contents

Introduction

Disclaimer

Jolywood reserves the right to change the manual without prior notice.

Limitation of Liability

Jolywood is not responsible for injuries or losses from installation errors.

Safety Precautions

Warning

Read all safety rules before installation, wiring, or maintenance.

General Safety

Covers general safety aspects for module installation and handling.

Operation Instruction

Provides instructions to avoid module damage and ensure safe operation.

Unload, Transportation and Storage

Marks on Outer Packaging

Important symbols and warnings on the outer packaging for safe handling.

Unloading Instructions

Guidelines for safely unloading modules from transport vehicles.

Secondary Transportation and Precautions

Procedures and safety measures for transporting modules further or storing them.

Storage

Specifies environmental conditions and placement for module storage.

Unpacking Instruction

Unpacking Safety Instruction

Safety measures to follow during the unpacking process.

Unpacking Steps

Detailed steps on how to properly unpack the modules.

Installation

Installation Safety

Key safety guidelines to ensure safe installation practices.

Installation Method

Overview of installation methods, including mechanical and electrical aspects.

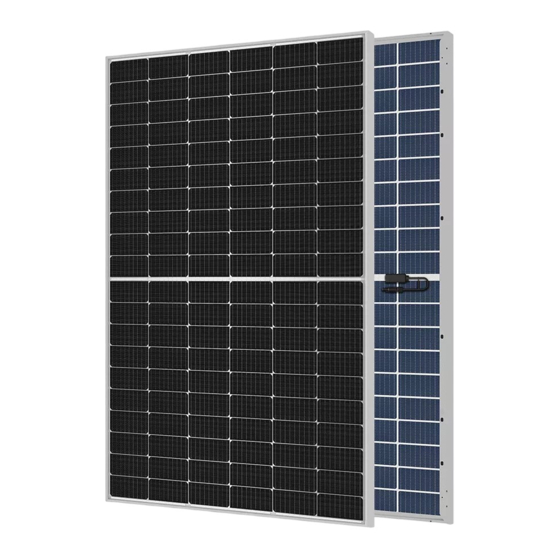

Framed Bifacial Double-Glass Modules (installation with clamps)

Framed Bifacial Double-Glass Modules (installation with bolts)

Details on installing framed modules using bolts, including component specifications.

Grounding

Grounding

All module frames and brackets must be grounded per National Electrical Code.

Grounding

Modules can be grounded with third-party listed equipment per manufacturer instructions.

Grounding Hole Locations

Refer to website for detailed grounding hole locations and dimensions.

Electrical Contact for Grounding

Forming electrical contact by penetrating anodized coating and tightening ground screw.

Maintenance for PV Modules

Module Visual Inspection and Replacement

Regular inspection for damage; replace damaged modules with identical types.

Annual Maintenance

Annual maintenance by trained personnel; wear protective gear.

Hardware Security Check

Check if installed hardware is securely in place.

Array Fuse Check

Check if all array fuses in non-grounded poles are working properly.

Module Replacement Safety

Replace damaged modules with identical types; use safety guards when handling.

Sun Exposure Safety

Cover modules with opaque material when exposed to sun for safety.

Bypass Diodes in Junction Boxes

Module junction boxes have bypass diodes for heating and current loss.

Connector and Cable Inspection

Check cable security; run cables in ducts away from water-prone areas.

Periodic Connection Check

Check electrical, grounding, and mechanical connections every 6 months.

Cleaning Solvents

Do not use WD-40 or organic solvents on junction boxes, wires, or connectors.

Dustproof Plug Handling

Dustproof plug should only be removed during installation.

Cleaning

Water Quality Requirements

Specifies water quality parameters (pH, content, turbidity, hardness) for cleaning.

Module Inspection After Cleaning

Check for clean appearance, no ash, scratches, or cracks on module surface.

Post-Cleaning Checks

Ensure module brackets are not tilted/bent and terminals are connected after cleaning.

Cleaning Record

Complete the PV module cleaning record after cleaning.

Need help?

Do you have a question about the HD144P and is the answer not in the manual?

Questions and answers