Table of Contents

Advertisement

Quick Links

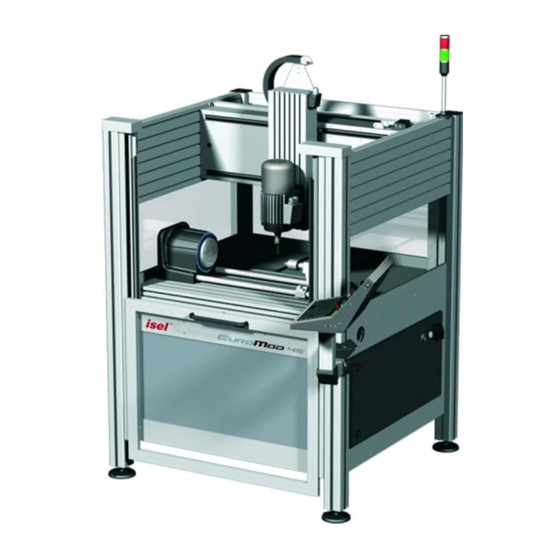

CNC Machine EuroMod 45 with tooling spindle and 4th Axis (Rotational axis)

Assembly Instruction for CNC base machinery

(partly completed machinery)

Operating Instruction for CNC machinery

(complete machinery)

Type: EuroMod ®

Models: EuroMod 30, 45, 65

isel Germany AG

Bürgermeister-Ebert-Straße 40 D-36124 Eichenzell Tel.: (06659) 981-0 Fax: -776

Advertisement

Table of Contents

Summary of Contents for Isel EuroMod 45

- Page 1 CNC Machine EuroMod 45 with tooling spindle and 4th Axis (Rotational axis) Assembly Instruction for CNC base machinery (partly completed machinery) Operating Instruction for CNC machinery (complete machinery) Type: EuroMod ® Models: EuroMod 30, 45, 65 isel Germany AG Bürgermeister-Ebert-Straße 40 D-36124 Eichenzell Tel.: (06659) 981-0 Fax: -776...

- Page 2 This Operating instruction has to be found near the CNC machine, so it has to be guaranteed that the user has always access to the information inside it. Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 1...

- Page 3 For suggestions and information on errors, we are grateful. CE mark for (complete) CNC machinery: isel CNC machinery are CE compliant and marked accordingly. For these machinery the CE declaration of conformity is valid. No CE mark for partly completed CNC machinery: Partly completed machinery (definition from EC machinery directive 2006/42/EC) has no CE mark.

-

Page 4: Table Of Contents

CNC operating panel – right side: button for PC boot / shut down 6.4.1 CNC operating panel – front side: operating elements 6.4.2 CNC operating panel – left side: USB connectors (female) 6.4.3 CNC control software: Installation and starting........... 31 Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 3... - Page 5 Exploded views / spare parts lists ..............47 EuroMod 30 ....................47 14.1 14.2 EuroMod 45 ....................49 14.3 EuroMod 65 ....................51 Bibliography ...................... 53 Index ........................54 Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 4...

-

Page 6: Introduction

For every delivered CNC base machine / CNC machine a check protocol is archived under the special order number at the manufacturer isel Germany AG. The customer can request this protocol. All CNC base machinery / CNC machinery are surveyed with circle form tester QC10 from Renishaw®... - Page 7 CNC machine is delivered with CE mark for this CNC machine the Declaration of Conformity is valid Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 6...

-

Page 8: Intended Use And Reasonably Foreseeable Misuse

usage for water jet cutting tool = water jet nozzle The manufacturer isel Germany AG is able to effect a legal prescribed risk assessment for the CNC-machines. CNC-machines will be delivered with a machinery enclosure. isel CNC base machine: In the new, at 29.12.2009 legally binding machine directive 2006/42/EC, is the term “partly... - Page 9 There must be no manipulations on the locking of the safety door. Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 8...

-

Page 10: Safety Information

If the sound pressure level near the machine should be higher then 70 dB(A) the operator has to wear an applicative ear protection. Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 9... - Page 11 (refer to the chapter accessory) may be used. This cooling equipment has to generate water fog or an air flow for cooling effect. No drops of cooling medium may appear or flow under the clamping plate. Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 10...

-

Page 12: Scope Of Delivery / Distribution State (Qa)

The user is responsible for archiving all his application programs (ISO, PAL, CNC or NCP format) on USB memory stick. The current scope of delivery of your CNC machine is defined in the packaging note. Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 11... -

Page 13: Delivery Status From The Factory (Quality Management)

The delivery of any CNC machine to the customer follows only when all parameters are within the prescribed limit. The results of the measurements are stored and archived according the current machine resp. order. picture: circular form measure with Renishaw QC10 Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 12... - Page 14 The position measurement is the most commonly performed measurement on a machine. The laser measuring system measures the positioning accuracy and repeatability by comparing the displayed position of the machine with the laser measurement system measured the current position. Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 13...

-

Page 15: Installation And Connection Of The Cnc Machine

The sliding door of the machine hood opens downward so you need no additional space above the machine Operating position Space requirement EuroMod 30 Operating position Space requirement EuroMod 45 Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 14... - Page 16 CNC Base machinery / CNC machinery: Type EuroMod Operating position Space requirement EuroMod 65 Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 15...

-

Page 17: Transport Of The Cnc Machine

Take care during transport that the machine is not suspended to heavy vibrations. Keep the triangular key for manual unlock of the door outside the machine. 5.3 Put up the CNC machine Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 16... - Page 18 CNC base machine / CNC machine measuring / calibration with laser interferometer at the customer / end-user site (article number: 991300 0001). Picture: Laser measurement of an isel base machine in plant Dermbach in Thuringia Assembly instruction / Operating instruction for EuroMod 30, 45, 65...

-

Page 19: Enclosure

As the operator of the CNC base machine, you are responsible for taking appropriate protective measures based on your risk assessment to comply the requirements for the machine according to Machinery Directive 2006/42/EC. Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 18... -

Page 20: Cabling And Compressed Air Connection

3 - 6 bar impulse milling spindle with automatic tool change > 7.5 bar impulse on the milling spindle mounted swivel unit for 2 bar impulse exhaust (specially for woodworking) Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 19... -

Page 21: Initial Operation

If you need to change the arrangement of the coordinates, please read the manuals for the motor power amplifiers IMD10 /1.1/, IMD20 or IMD40 /1.2/ or contact our technical support. Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 20... -

Page 22: Assignment Of The Motion Axes

/ motor. because of the feature of supervising standstill of axis in the motor power amplifiers. Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 21... -

Page 23: Work Piece Mounting Resp. Clamping

Axis direction always is to be seen according the tool tip, so the coordinate system has to be a XYZ orthogonal system (remember the right hand rule). Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 22... -

Page 24: Operation Modes

The key switch = mode selection switch may be used only by authorized and knowledgeable staff, because there is no protection against moving machinery axes when the door / cover is opened in TEST mode. Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 23... -

Page 25: Cover Lock, Cover Unlock, Cover Interlock

(X, Y, Z) of the CNC machine and all optional rotation axes (A, B, C). Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 24... - Page 26 The servo motors of the machine are not powered. Turn the triangular key back to the right. In the state safety interlock manually unlocked you must not operate the machine. Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 25...

-

Page 27: Cnc Operating Panel

The operation of the CNC machine takes place using the buttons on the external hand control unit or optionally via the buttons on the CNC operating panel /4/, the keyboard, the mouse/trackball or via touchscreen. external hand control unit CNC operating panel Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 26... - Page 28 If you press the stop button the currently started application program (ISO, PAL, CNC or NCP format) and therewith any motion of the machinery axes is stopped. The current line in the application program keeps marked /6/ /7/. Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 27...

- Page 29 Operation mode TEST = TEST = Setup mode Any switch on resp. turning on to target speed the working spindle is generally impossible. Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 28...

- Page 30 The key switch = mode selection switch may be used only by authorized and knowledgeable staff, because there is no protection against moving machinery axes when the door / cover is opened in TEST mode. Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 29...

-

Page 31: Cnc Operating Panel - Left Side: Usb Connectors (Female)

ProNC /6/ a so called WIBU-USB-dongle has to be plugged to one of the two USB connectors. For the execution of ISO or NCP programs with Remote /7/ no WIBU-USB-dongle is needed. Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 30... -

Page 32: Cnc Control Software: Installation And Starting

Further informations about the CNC-Software can be found in the corresponding manuals resp. ReadMe files on the installations CD. Alternatively you can start the installation assistant. This assistant will guide you through the setup process. Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 31... -

Page 33: Accessories

500, 750, 900 working spindle UFM 500, UFM 1050 vacuum clamping system isel-Vakufit pneumatics accessories cold air cooling isel-CoolMin: cooling unit with cold air nozzle (up to -20°C) exhaust unit industrial vacuum cleaner engraving spindle diamond engraving head... -

Page 34: Dust Extraction (Optionally)

ProNC / Remote. Those manuals are stored in PDF format on the installations CD resp. the delivered USB memory stick. Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 33... -

Page 35: Technical Support And Sale

Here our customers have the chance to see practical demonstrations. Furthermore we present our product palette at the important fairs worldwide (please consult out homepage to find more informations). Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 34... -

Page 36: Cleaning, Lubrication And Maintenance

The EC-Safety data sheet according directive 93/112/EU and ISO 11014-1 can be sent to you on demand. 9.2.2 Later lubrication For the lubrication of linear bearings with waves is only the isel special grease used. Under the following article numbers the grease can be ordered: 299032 0002 grease cartridge... -

Page 37: Lubrication Of The X Axis

Put the grease gun over the viewable and accessable grease nipples and press the grease gun. When finished push the stoppers back into EuroMod 30/45/65: Grease nipples at the X their original position. axis Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 36... -

Page 38: Lubrication Of The Y Axis

Put the grease gun over the viewable and accessable grease nipple and press the grease gun. When finished push the stoppers back into their original position. Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 37... -

Page 39: Lubrication Of The Z Axis

Put the grease gun over the viewable and accessable grease nipple and press the grease gun. When finished push the stopper back into its EuroMod 30/45/65: Grease nipple at the Z original position. axis Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 38... -

Page 40: Faults

- clean the filter in the ventilator device inside the control cabinet motor power amplifier defect change motor power amplifier Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 39... - Page 41 Check parameters in the frequency converter is converter frequency converter blinking Overcurrent / low voltage Check parameters in the frequency converter according AC motor data (note motor data identification plate) Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 40...

-

Page 42: Remote Diagnosis

Now the participant can enter this session number into the edit field, click on the button “Connect” and the Remote diagnosis can start. Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 41... -

Page 43: Technical Data Of Cnc Machine / Cnc Base Machine

Germany AG is responsible for this safety. So EuroMod machine is always delivered with CE mark. For this CNC machine the Declaration of Conformity is valid. Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 42... -

Page 44: Mechanical Values / Electrical Values

Contact termination: not fixed installation according to EN 60204-1, section 5.1 „Net input connectors“ 12.3 Sound pressure level The sound pressure level varies by application and toolkit. Sound pressure level without working spindle: < 75 dB (A) Technical changes reserved! Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 43... -

Page 45: Declaration Of Conformity Or Declaration Of Incorporation

For each isel CNC machine delivered with a tool (e.g. milling or engraving spindle, metering device, measuring device like CCD camera or triangulation laser, water jet nozzle, plasma burner) the Declaration of Conformity in this manual is valid. -

Page 46: Declaration Of Conformity For Machinery

Representative for composition of technical documentation is: Helmut Danz Place, Date: Dermbach, 4.01.2010 _____________________________ Werner Kister, Managing Board Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 45... -

Page 47: Declaration Of Incorporation For Partly Completed Machinery

The partly completed machinery must not be put into service until the final machinery into which it is to be incorporated has been declared in conformity with the provisions of Machinery Directive 2006/42/EU. Place, Date: Dermbach, 4.01.2010 _____________________________ Werner Kister, Managing Board Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 46... -

Page 48: Exploded Views / Spare Parts Lists

CNC Base machinery / CNC machinery: Type EuroMod 14 Exploded views / spare parts lists 14.1 EuroMod 30 Figure: Exploded view CNC Base machine EuroMod 30 (without tool) EuroMod - MP30 POS-NR. Artikelnummer MENGE BENENNUNG Zeich.- Nr. Teileart Oberfläche DZ3703 Untergestell EuroMod - MP30... - Page 49 392810 0500 Encoderleitung - Achsanschluß 392740 0200 Encoderleitung - Achsanschluß 392740 0300 Encoderleitung - Achsanschluß 392740 0500 Table: Spare part list CNC Base machine EuroMod 30 (without tool) Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 48...

-

Page 50: Euromod 45

DZ 3304-3 LES22 - Y-Axis EuroMod 45 L=996 DZ3304 Baugruppe 675012 1052 DZ3729 LES21 - Z-Axis L=596 DZ3729 Baugruppe 675012 3311 DZ 3311-3 Abdeckung 1 LES22 EuroMod DZ3311 Blechteil eloxiert Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 49... - Page 51 Motorleitung - Achsanschluß 392740 0200 Encoderleitung - Achsanschluß 392740 0300 Encoderleitung - Achsanschluß 392740 0500 Encoderleitung - Achsanschluß Table: Spare part list CNC Base machine EuroMod 45 (without tool) Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 50...

-

Page 52: Euromod 65

DZ 3312-3 Abdeckung 2 LES22 EuroMod Blechteil eloxiert DZ3313 675012 33131 DZ 3313-3 Abdeckung 3 LES22 EuroMod Blechteil eloxiert DZ3314 675012 33141 DZ 3314-3 Abdeckung 4 LES22 EuroMod Blechteil eloxiert Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 51... - Page 53 Motorleitung - Achsanschluß 392740 0200 Encoderleitung - Achsanschluß 392740 0300 Encoderleitung - Achsanschluß 392740 0500 Encoderleitung - Achsanschluß Table: Spare part list CNC Base machine EuroMod 65 (without tool) Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 52...

-

Page 54: Bibliography

Remote: Operating instruction for outputting ISO-, NCP- and CNC-files: Manual for Control software Remote; isel-automation 06/2005 /8.1/ EC machinery directive 98/37/EU (till 28.12.2009 useable) /8.2/ EC machinery directive 2006/42/EU (from 29.12.2009 legally binding) Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 53... -

Page 55: Index

Weight ................43 NetViewer................. 41 WIBU-USB-dongle ............. 30 Newsletter ................ 34 Windows operating system ..........26 wiring diagrams ..............19 work piece zero ..............20 Operating mode alternation ..........29 Assembly instruction / Operating instruction for EuroMod 30, 45, 65 page 54...

Need help?

Do you have a question about the EuroMod 45 and is the answer not in the manual?

Questions and answers