Advertisement

Quick Links

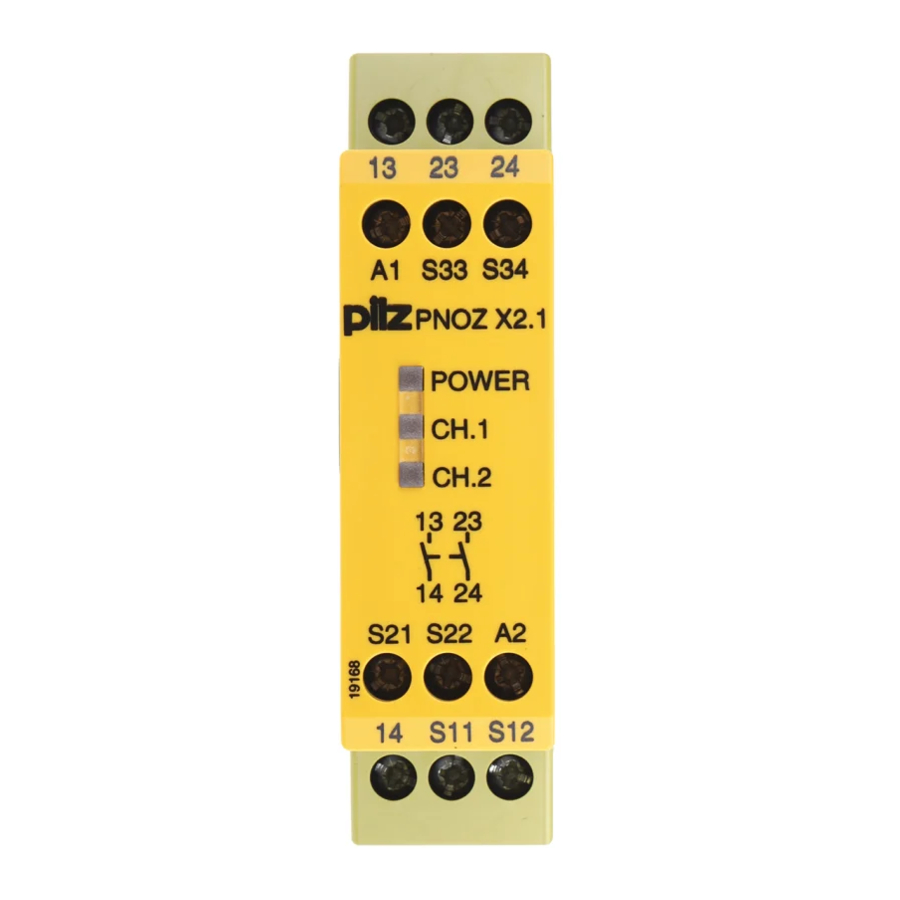

19238-6NL-04

PNOZ X2, PNOZ X2.1, PNOZ X2.2

Sicherheitsbestimmungen

• Das Gerät darf nur von Personen

installiert und in Betrieb genommen

werden, die mit dieser Betriebsanleitung

und den geltenden Vorschriften über

Arbeitssicherheit und Unfallverhütung

vertraut sind. Beachten Sie die VDE-

sowie die örtlichen Vorschriften, insbe-

sondere hinsichtlich Schutzmaßnahmen.

• Beim Transport, der Lagerung und im

Betrieb die Bedingungen nach EN 60068-

2-6 einhalten (s. technische Daten).

• Durch Öffnen des Gehäuses oder eigen-

mächtige Umbauten erlischt jegliche Ge-

währleistung.

• Montieren Sie das Gerät in einen

Schaltschrank; Staub und Feuchtigkeit

können sonst zu Beeinträchtigungen der

Funktionen führen.

• Sorgen Sie an allen Ausgangskontakten

bei kapazitiven und induktiven Lasten für

eine ausreichende Schutzbeschaltung.

Bestimmungsgemäße Verwen-

dung

Das Sicherheitsschaltgerät dient dem

sicherheitsgerichteten Unterbrechen eines

Sicherheitsstromkreises.

Das Sicherheitsschaltgerät erfüllt Forderun-

gen der EN 60947-5-1, EN 60204-1 und

VDE 0113-1 und darf eingesetzt werden in

Anwendungen mit

• Not-Halt-Tastern

• Schutztüren

Das Gerät ist nicht für die Absicherung von

berührungslosen Verdeckungen geeignet, da

kein dynamischer Start möglich ist.

Gerätebeschreibung

Das Sicherheitsschaltgerät PNOZ X2/X2.1/

X2.2 ist in einem S-95-Gehäuse unterge-

bracht. Es kann mit 24 V Wechselspannung

oder mit 24 V Gleichspannung betrieben

werden.

Merkmale:

• Relaisausgänge: 2 Sicherheitskontakte

(Schließer), zwangsgeführt

• Anschlussmöglichkeit für Not-Halt-

Taster, Schutztürgrenztaster und

Starttaster

• PNOZ X2: überwachter Starttaster

• PNOZ X2.1: automatischer Start möglich

• PNOZ X2.2: wie PNOZ X2, zusätzlich

können mehrere Geräte parallel mit einem

Starttaster gestartet werden

• Statusanzeige

• Überwachung externer Schütze möglich

• keine galvanische Trennung

Das Schaltgerät erfüllt folgende Sicherheits-

anforderungen:

• Schaltung ist redundant mit Selbst-

überwachung aufgebaut

Safety Regulations

• The unit may only be installed and

operated by personnel who are familiar

with both these instructions and the

current regulations for safety at work and

accident prevention. Follow VDE and

local regulations especially as regards

preventative measures.

• Transport, storage and operating

conditions should all conform to

EN 60068-2-6.

• Any guarantee is void following opening of

the housing or unauthorised

modifications.

• The unit should be panel mounted,

otherwise dampness or dust could lead to

function impairment.

• Adequate protection must be provided on

all output contacts especially with

capacitive and inductive loads.

Authorised Applications

The safety relay provides a safety-related

interruption of a safety circuit.

The safety relay meets the requirements of

EN 60947-5-1, EN 60204-1 and VDE 0113-

1 and may be used in applications with

• E-STOP pushbuttons

• Safety gates

The device is not suitable for non-contact

barriers (e.g. light curtains) because a

dynamic start is not possible.

Description

The Safety Relay PNOZ X2/X2.1/X2.2 is

enclosed in a S-95 housing. Every unit can

be operated with 24 V AC or 24 V DC.

Features:

• Relay outputs: 2 safety contacts (N/O),

positive-guided.

• Connections for Emergency Stop Button,

Safety Gate Limit Switch and Reset

button.

• PNOZ X2: monitored manual reset

• PNOZ X2.1: automatic reset possible

• PNOZ X2.2: As PNOZ X2. In addition,

several units may be started in parallel

using one start button.

• Status Indicators.

• Feedback Control Loop for monitoring of

external contactors/relays possible

• no galvanic seperation

The relay complies with the following safety

requirements:

• The circuit is redundant with built-in self-

monitoring

- 1 -

Conseils préliminaires

• La mise en oeuvre de l'appareil doit être

effectuée par une personne spécialisée

en installations électriques, en tenant

compte des prescriptions des différentes

normes applicables (NF, EN, VDE...)

notamment au niveau des risques

encourus en cas de défaillance de

l'équipement électrique.

• Respecter les exigences de la norme

EN 60068-2-6 lors du transport, du

stockage et de l'utilisation de l'appareil.

• L'ouverture de l'appareil ou sa modifi-

cation annule automatiquement la

garantie.

• L'appareil doit être monté dans une ar-

moire; l'humidité et la poussière pouvant

entraîner des aléas de fonctionnement.

• Vérifiez que le pouvoir de coupure des

contacts de sortie est suffisant en cas de

circuits capacitifs ou inductifs.

Domaines d'utilisation

Le bloc logique de sécurité sert à

interrompre en toute sécurité un circuit de

sécurité.

Le bloc logique de sécurité satisfait aux

exigences des normes EN 60947-5-1,

EN 60204-1 et VDE 0113-1 et peut être

utilisé dans des applications avec des

• poussoirs d'arrêt d'urgence

• protecteurs mobiles

L'appareil n'est pas adapté à la surveillance

de barrières immatérielles car une validation

dynamique n'est pas possible (surveillance

du circuit de réarmement).

Description de l'appareil

Inséré dans un boîtier S 95, le bloc logique

de sécurité PNOZ X2/X2.1/X2.2 peut être

alimenté en 24 V AC ou en 24 V DC.

Particularités :

• Sorties disponibles : 2 contacts à

fermeture de sécurité

• Bornes de raccordement pour poussoirs

AU, détecteurs de position et poussoir de

validation

• PNOZ X2: surveillance du circuit de

validation

• PNOZ X2.1: réarmement automatique

possible

• PNOZ X2.2: comme PNOZ X2, mais

permet le réarmement de plusieurs

appareils en parallèle avec un seul

poussoir de réarmement.

• LEDs de visualisation

• Auto-contrôle des contacteurs externes

possible

• pas d'isolation galvanique

Le relais PNOZ X2/X2.1/X2.2 répond aux

exigences suivantes :

• conception redondante avec auto-

surveillance

Advertisement

Summarization of Contents

Safety Regulations

General Safety Provisions

Essential rules for installation, operation, and handling of the safety relay.

Transport, Storage, and Operating Conditions

Compliance with EN 60068-2-6 for transport, storage, and operation.

Installation and Modification

Warning against opening housing or unauthorized modifications voids warranty.

Authorised Applications

Safety Circuit Interruption

The safety relay provides safety-related interruption of a safety circuit.

Suitable Applications

Use in applications with E-STOP pushbuttons and safety gates.

Unsuitable Applications

Not suitable for non-contact barriers due to dynamic start requirement.

Device Description

Housing and Power Options

The safety relay is housed in an S-95 unit and operates on 24 V AC or 24 V DC.

Product Features

Includes relay outputs, connection options for E-STOP/gate switches, status indicators.

Safety Compliance

Relay complies with safety requirements for redundancy and self-monitoring.

Function Description

Initialisation and Ready State

Unit is ready when POWER LED is illuminated and reset circuit is closed.

Input Circuit Closed

Relays energise, status indicators illuminate, safety contacts close.

Input Circuit Opened

Relays de-energise, status indicators extinguish, safety contacts open.

Operating Modes

Single-channel Operation

Input wiring without redundancy, earth faults detected in reset circuit.

Two-channel Operation

Redundant input circuit detects earth faults and shorts across buttons.

Automatic Reset

Unit becomes active as soon as the input circuit is closed.

Manual Reset

Unit is active only after a reset button is pressed or reset contact is closed.

Monitored Manual Reset

Voltage must be applied before start/reset contacts close for safety.

Installation

Mounting Requirements

Unit must be panel mounted with minimum IP54 protection.

DIN-Rail Attachment

Unit can be attached to a DIN-rail using its rear notch.

Operation

Contact Protection

Fuse recommended for output contacts to prevent welding.

Max. Cable Length Calculation

Formula and details for calculating maximum input circuit cable length.

Short-Circuit Detection Test

Procedure to test the short-circuit detection function after installation.

Wiring Guidelines

Recommendations for wiring material and proximity switches.

Application Examples

Input Circuit Wiring

Examples for single-channel and two-channel input circuits.

Safety Gate Control

Example for dual-channel safety gate control wiring.

External Contactor Wiring

Example for expanding contacts using external contactors.

Troubleshooting

Earth Faults

Behavior and recovery procedure for earth faults.

Contact Failure

Issues with welded contacts and reactivation troubleshooting.

Power LED Issues

Reasons for the Power LED not illuminating (short-circuit, no power).

Technical Data

Electrical Data

Supply voltage, power consumption, frequency range, residual ripple.

Safety Contact Ratings

Details on instantaneous safety contacts and utilization category.

Cable and Fuse Specifications

Contact material, fuse characteristics, and max. cable resistance.

Timing Specifications

Switch-on Delay

Delay before the unit becomes active.

Reset Times

Delay times for de-energisation and monitored start.

Environmental Conditions

EMC Compliance

Electromagnetic compatibility according to standards.

Vibration and Climate

Suitability for vibration and climatic conditions.

Mechanical Specifications

Housing and Terminals

Details on housing material and terminal area.

Cable Cross-Section and Torque

Specification for conductor cross-section and connection terminal torque.

Order Information

Product Variants and Part Numbers

Table listing product types, features, terminals, and order numbers.

Output Relay Service Life

Service Life Graph

Graph showing service life based on switching cycles and current.

Declaration of Conformity

Machinery Directive Compliance

Product compliance with the Machinery Directive 2006/42/EC.

Need help?

Do you have a question about the 774 303 and is the answer not in the manual?

Questions and answers