Table of Contents

Advertisement

Quick Links

This is an industrial component. Only a qualified systems integrator should be allowed to

design it into a system. The integrator must determine proper plumbing, mounting, driveline

and guard components.

Improper installation or use could lead to a serious, even fatal, accident. The system

integrator must communicate all safe operation procedures to the end user(s).

Before operation, fully understand and follow the instructions shown in this manual and any

instructions communicated by the system integrator. No one should be allowed to operate or

maintain this pump that has not been fully trained to work safely according to the

configuration of the pump system and in accordance with all applicable government and

industry regulations.

DO NOT paint over nameplates, ID tags or warning tags.

Confidential & Proprietary: This document contains confidential and proprietary information which is the exclusive property

of Roper Pump Company, Commerce, GA. U.S.A. and shall not be reproduced, communicated, disclosed, or disseminated in

any manner to third parties or used for any purpose other than its intended purpose without prior written consent of the

management of Roper Pump Company.

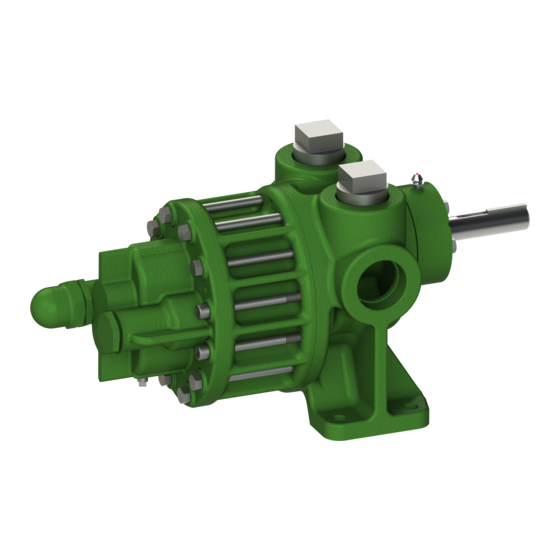

F SERIES TYPE 27

OWNERS MANUAL

SAFETY INSTRUCTIONS

Roper Pump Company

P.O. Box 269

Commerce, GA 30529 USA

Telephone: (706) 335-5551

TeleFAX: (706) 335-5490

Email:

sales@roperpumps.com

www.roperpumps.com

G12-208

06/13/16

1

Advertisement

Table of Contents

Summarization of Contents

Warnings and General Guidelines

System Pressure and Hazardous Fluids

Guidelines for managing system pressure and handling hazardous or toxic fluids safely.

Plumbing Guidelines

Recommendations for proper inlet and discharge plumbing to minimize suction losses and prevent damage.

Mounting Base Requirements

Specifications for mounting bases to ensure rigidity, shock absorption, and proper stress distribution.

Pump and Drive Assembly Safety

Ensuring adequate guards and following safety codes for pump and drive assemblies.

Driveline Alignment Checks

Importance of correct pump-to-driveline alignment to prevent premature failure.

Close Coupled Drive Systems

Information on hydraulic or gearmotor units mounted directly to the pump.

PTO Drive Shaft Guarding

Safety requirements for guarding PTO drive systems to prevent injury.

Nameplate Data Identification

Pump Model Number (Figure)

Explanation of the figure number's components for identifying the pump model.

Pump Specification (SPEC)

Understanding the specification number for special configurations or applications.

Pump Type Designation

Meaning of the TYPE number for in-house identification of pump construction.

Pump Serial Number

Importance of the unique serial number for pump identification and communication.

Direction of Pump Rotation

1 & 2 F1-F100 CW Rotations

Illustrations showing Clockwise (CW) rotation for 1 & 2 F1-F100 pump models.

1 & 2 F1-F100 CCW Rotations

Illustrations showing Counter-Clockwise (CCW) rotation for 1 & 2 F1-F100 pump models.

17 & 18 F10-F100 CW Rotations

Illustrations showing Clockwise (CW) rotation for 17 & 18 F10-F100 pump models.

17 & 18 F10-F100 CCW Rotations

Illustrations showing Counter-Clockwise (CCW) rotation for 17 & 18 F10-F100 pump models.

17 & 18 F1-F5 CW & CCW Rotations

Illustrations showing CW and CCW rotations for 17 & 18 F1-F5 pump models.

1 & 2 F75-F300 CW & CCW Rotations

Illustrations showing CW and CCW rotations for 1 & 2 F75-F300 pump models.

Relief Valve Operation and Adjustment

Adjusting the Relief Valve

Step-by-step guide for setting the relief valve pressure under operating conditions.

Replacing Relief Valve Components

Procedure for replacing spring/piston or changing pump direction via the relief valve.

Parts List and Cross-Sectional Diagrams

1 & 2 F1-F5 SPEC 0 Parts Diagram

Cross-sectional diagram for 1 & 2 F1-F5 Spec 0 pump model.

1 & 2 F1-F5 SPEC 5 Parts Diagram

Cross-sectional diagram for 1 & 2 F1-F5 Spec 5 pump model.

1 & 2 F10-F20 SPEC 0 Parts Diagram

Cross-sectional diagram for 1 & 2 F10-F20 Spec 0 pump model.

1 & 2 F10-F20 SPEC 5 Parts Diagram

Cross-sectional diagram for 1 & 2 F10-F20 Spec 5 pump model.

1 & 2 F35-F50 SPEC 0 Parts Diagram

Cross-sectional diagram for 1 & 2 F35-F50 Spec 0 pump model.

1 & 2 F35-F50 SPEC 5 Parts Diagram

Cross-sectional diagram for 1 & 2 F35-F50 Spec 5 pump model.

1 & 2 F75-F100 SPEC 0 & 17 Parts Diagram

Cross-sectional diagram for 1 & 2 F75-F100 Spec 0 & 17 pump models.

1 & 2 F75-F100 SPEC 5 & 174 Parts Diagram

Cross-sectional diagram for 1 & 2 F75-F100 Spec 5 & 174 pump models.

1 & 2 F150-F300 SPEC 17 Parts Diagram

Cross-sectional diagram for 1 & 2 F150-F300 Spec 17 pump model.

1 & 2 F150-F300 SPEC 174 Parts Diagram

Cross-sectional diagram for 1 & 2 F150-F300 Spec 174 pump model.

17 & 18 F1-F5 SPEC 0 Parts Diagram

Cross-sectional diagram for 17 & 18 F1-F5 Spec 0 pump model.

17 & 18 F10-F20 SPEC 0 Parts Diagram

Cross-sectional diagram for 17 & 18 F10-F20 Spec 0 pump model.

17 & 18 F35-F50 SPEC 0 Parts Diagram

Cross-sectional diagram for 17 & 18 F35-F50 Spec 0 pump model.

17 & 18 F75-F100 SPEC 0 Parts Diagram

Cross-sectional diagram for 17 & 18 F75-F100 Spec 0 pump model.

Need help?

Do you have a question about the F3 and is the answer not in the manual?

Questions and answers