Summarization of Contents

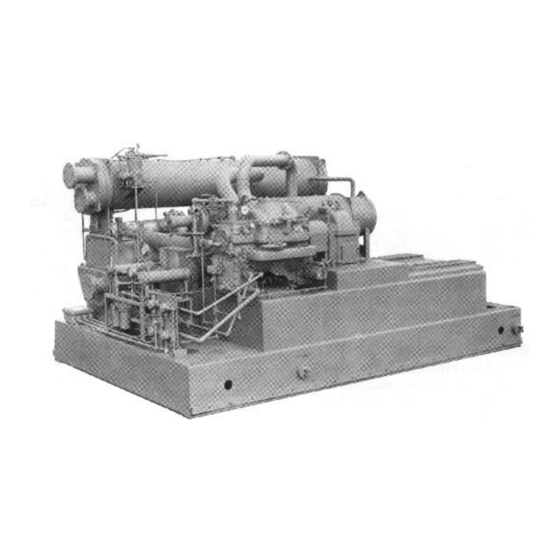

Open Drive Centrifugal Liquid Chillers Safety Guide

General Safety Guidelines

Comprehensive safety advice for operating centrifugal chillers.

Danger Warnings and Precautions

Specific hazards and critical precautions to prevent severe injury or damage.

Warning Statements

Important safety notices regarding equipment operation and potential risks.

Operational Safety Cautions

Cautionary Notes for Safe Operation

Additional safety advice for operating the machinery.

Introduction and Job Data Requirements

Document Overview and Purpose

General introduction, scope, and purpose of the manual.

Required Job Data

Essential information and specifications needed before starting work.

Initial Machine Preparations and Checks

General Preparations and Tightness Verification

Basic setup, cleaning, and leak checks before operation.

Safety Devices, Lubrication, and Piping Inspection

Checks for safety devices, component lubrication, and piping integrity.

Pre-Start System Checks and Control Setup

Turbine Operation and Water Charging Procedures

Checking turbine operation and filling water systems.

Level Controller Configuration and Settings

Setting up and verifying liquid level controllers.

Refrigerant Charging and Alignment Verification

Refrigerant Charging and Alignment Verification

Adding refrigerant and checking coupling alignment.

Safety Control Settings and Grouting Procedures

Verifying safety controls and applying grout.

Control System Calibration and Safety Adjustments

Oil Pressure Switch Settings

Adjusting low oil pressure cutouts for safety.

Load Limiting Control Assembly Calibration

Calibrating systems that limit motor load.

Demand Limit Controller Calibration

Demand Limit Controller Calibration

Steps to calibrate the demand limit controller for load management.

Component Calibration and Adjustment Procedures

Electro-Pneumatic Transducer Calibration

Calibrating the transducer for suction damper control.

Automatic Suction Damper Adjustment

Adjusting the suction damper position for optimal operation.

Compressor Oil Preparation and Start-Up Procedures

Compressor Oil Handling Procedures

Heating, quenching oil, and suction damper adjustments.

Labyrinth Pressurization Steps

Procedures for pressurizing labyrinths to prevent oil issues.

Pre-Start Machine Checklist

Final checks before starting the machine.

Purge Operation and Running System Checks

Automatic Thermal Purge Operation

Operation of the automatic purge system for system cleaning.

Motor-Driven Purge Operation

Using the motor-driven purge for system maintenance.

Running System Monitoring and Checks

Monitoring temperatures, pressures, and levels during operation.

Machine Shutdown and Alignment Procedures

Stopping the Machine Safely

Procedures for safely stopping the compressor.

Refrigerant Charge Adjustment

Fine-tuning refrigerant levels for optimal performance.

Hot Alignment and Doweling Procedures

Post-operation alignment and securing components.

Pumpout Procedures: Overview and Controls

Pumpout Unit General Information

Purpose, adjustments, and control description of the unit.

Pumpout Control Settings

Setting pressure switches for pumpout operations.

Pumpout Unit Operations (5F Model)

Machine Evacuation (5F Units)

Evacuating machines using the pumpout unit.

Refrigerant Transfer (5F Units)

Moving refrigerant between storage tank and machine.

Distilling Refrigerant Charge

Removing Impurities from Refrigerant

Procedures for removing water and impurities from refrigerant.

Pressurization and Refrigerant Handling

Pressurizing the Machine System

Adding pressure to the system for testing or evacuation.

Charging Refrigerant into Machine

Adding refrigerant to the machine for operation.

6D Pumpout Procedures and Operator Guidance

6D Pumpout Evacuation and Transfer

Evacuating and transferring refrigerant with the 6D unit.

Operator Instruction Topics

Key components and knowledge for operators.

Need help?

Do you have a question about the 17M and is the answer not in the manual?

Questions and answers