Advertisement

Table of Contents

- 1 Table of Contents

- 2 How It Works

- 3 Technical Data

- 4 Fundamental Safety Advice

- 5 Machine Installation

- 6 Description of the Machine Parts

- 7 Handling and Operation

- 8 Shingling Axle

- 9 Setting up the Machine

- 10 Optimisation Menu

- 11 Quick Set-Up

- 12 Quick Check

- 13 Sensors, Pneumatics, Motors

- Download this manual

Advertisement

Table of Contents

Summarization of Contents

How it works

Declaration of Conformity

Manufacturer's declaration of compliance with EC directives and standards.

Technical Data

Formats

Details the infeed and product dimensions for different delta models.

Connections

Electrical connection requirements and compressed air consumption specifications.

Fundamental Safety Advice

Warning advice and symbols

Explains safety symbols and their meanings to prevent hazards.

Safety at work

Outlines general safety rules and practices for personnel operating the machine.

Machine installation

Transport

Guidelines for lifting, handling, and transporting the machine safely.

Unpacking

Instructions for removing the machine from its packaging and checking for damage.

Electrical connection

Checks and information regarding the electrical supply and wiring.

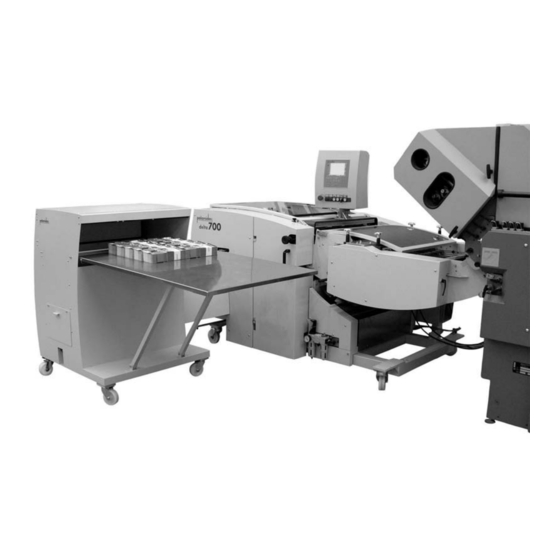

Description of the machine parts

Machine group designation

Identifies and labels the main functional groups and components of the machine.

Handling and Operation

Operating controls

Details the functions and layout of the machine's control panel and buttons.

Group1 description

Explains the function of each button and switch in Group 1 of the operating controls.

Setting up the machine

Infeed and Belt Adjustments

Instructions for adjusting round belts and infeed for proper product handling.

Photocell and Drive Adjustments

Procedures for positioning photocells and adjusting the press drive speed.

Pressing and Shingling Setup

Steps for setting up pressing, calibration, auto setup, and shingling.

Component Adjustments

Guides for adjusting various machine components like belts, fingers, rollers, and plates.

Optimisation menu

Package compression

Adjusting pressure applied to packages during production.

Shingling

Adjusting the overlap between products in the shingled stream.

Quick set-up

Mechanical set-up

Guides through the physical setup and adjustments of the machine.

Controls

Steps for configuring machine settings via the operator controls.

Quick Check

Plan

Questions to verify correct delivery height and product angle.

Sensors, Pneumatics, Motors

Sensor Overview and Function

Details the types of sensors, their principles, and functions.

Cylinder Functions

Provides an overview and function of various cylinders used in the machine.

Motor Functions

Details the types and functions of motors installed in the machine.

Need help?

Do you have a question about the delta 703 and is the answer not in the manual?

Questions and answers