Advertisement

Table of Contents

- 1 Table of Contents

- 2 How It Works

- 3 Technical Data

- 4 Fundamental Safety Advice

- 5 Machine Installation

- 6 Description of the Machine Parts

- 7 Handling and Operation

- 8 Shingling Axle

- 9 Setting up the Machine

- 10 Optimisation Menu

- 11 Quick Set-Up

- 12 Quick Check

- 13 Sensors, Pneumatics, Motors

- Download this manual

Advertisement

Table of Contents

Summarization of Contents

Introduction and Overview

Declaration of Conformity

Details the manufacturer's declaration for compliance with EC directives.

Preface

Provides an introduction to the product and its benefits.

How It Works - Principles and Features

Explains operational principles, application area, and standard equipment.

Technical Specifications

Formats and Dimensions

Details the dimensions and formats supported by different delta models.

Connections and Requirements

Details electrical and compressed air connection requirements for the machine.

Safety Guidelines and Warnings

Warning Symbols and Permitted Use

Explains safety symbols, their meanings, and defines the machine's permitted uses.

Safety at Work Practices

Provides essential safety rules and practices for operating the machine.

Installation and Setup Procedures

Transport and Unpacking

Covers machine transport, lifting, fork requirements, and unpacking procedures.

Cleaning, Positioning, and Electrical Connection

Instructions for cleaning, positioning, electrical connection, and securing the machine.

Pre-Commissioning Checks

Essential checks before first use, including control box and safety hoods.

Machine Components

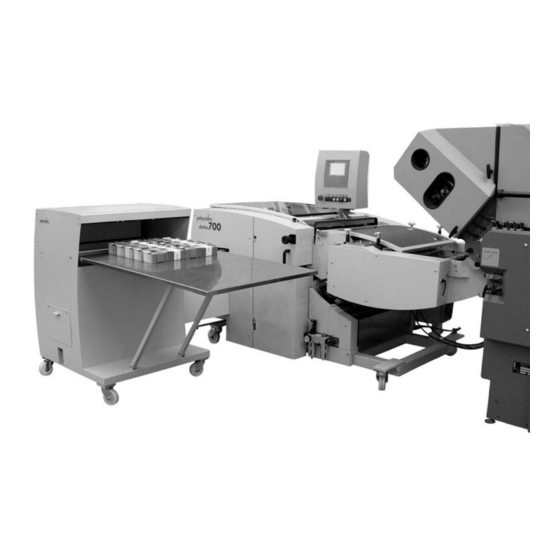

Machine Group Designation

Identifies and labels the main components and groups of the machine.

Sensors Overview and Functions

Details the types of sensors and their operating principles.

Cylinder Overview

Overview of various cylinders used in the machine.

Motors Overview

Overview of the motors used in the delta machine.

Operation, Setup, and Optimisation

Handling and Operating Controls

Describes the functions and layout of the machine's operating controls.

Group 1 Controls Description

Detailed explanation of the function of each control in Group 1.

Group 2 Controls Description

Details the functions of the menu items in Group 2.

Group 3 & 4 Controls Descriptions

Explains screen information and Group 4 numeric/function keys.

Delivery System Plan

Illustrates the layout and product flow of the delta automatic delivery system.

Installing the Automatic Delivery

Step-by-step guide for physically installing the automatic delivery unit.

Infeed Round Belt Adjustment

Instructions for adjusting the round belts for product infeed.

Upper Round Belt Adjustment (Shaft 1)

Detailed steps for adjusting the upper round belts on shaft 1.

Lower Round Belt Adjustment (Shafts 2 & 4)

Steps for positioning lower round belts correctly for product alignment.

Photocell, Press Drive, and Format Adjustments

Guides for photocell placement, press drive speed, and large format handling.

Pressing Unit Adjustment

Step-by-step guide for adjusting the pressing unit with pre and main rollers.

Sheet Calibration and Auto Setup

Functions for product measurement comparison and automatic shingling axle adjustment.

Shingling Device Adjustment

Adjusting the shingling axle for shingle formation and infeed angle.

Shaft Infeed and Belt Force Reduction

Adjusting upper belts for feeding and reducing belt pressing force.

Support Finger Adjustment

Stabilizing the product by raising the support finger.

Pressure Axle and Roller Adjustments

Adjusting pressure axle and contact rollers for product contact.

Shaft and Jogging Plate Adjustments

Adjusting lateral jogging plates, adjusting frame, and rear jogging plate angle.

Delivery Unit Adjustment

Adjusting the side loader to the required delivery side.

Operator Controls for Parameter Settings

How to change values and settings for batch, compensation, and sheet thickness via controls.

Parameter Settings

Configuring batch counter, stacking level compensation, and sheet thickness.

Operation Modes and Jogging Function

Configuring jogging function, single sheet, and shingled stream operation modes.

Optimisation Menu

Adjustments deviating from default values for performance tuning.

Quick Procedures

Quick Set-up Guide

Provides a concise guide for mechanical and control adjustments.

Delivery Height and Belt Checks

Verifying delivery height, brochure angle, and belt parallelism.

Roller, Speed, and Finger Checks

Verifying roller thickness adjustment, speed difference, and finger adjustment.

Need help?

Do you have a question about the delta 502 and is the answer not in the manual?

Questions and answers