Table of Contents

Advertisement

DAEDONG Corporation wishes to thank you for purchasing your new DAEDONG diesel engine. Your new engine is

the result of many years of research and development and high quality manufacturing; and we are confident that

your new engine will provide many years of safe, reliable and economical operation. This Operator's Manual is

intended to help you get the maximum return on your investment and to ensure your safety.

We recommend that you thoroughly read and under-

stand this Operator's Manual before handling, storing,

installing, operating or servicing the engine.

It is the policy of DAEDONG to incorporate new technol-

ogy and product improvements on an ongoing basis. In

order to provide the latest technology and the best en-

gine available, there may be some minor differences

between this manual and your engine. Consult your

dealer if you have any questions.

Should your engine require parts or service, please con-

tact your local DAEDONG dealer. Your dealer will need

the following information in order to assist you.

1. Engine make, model number and serial number.

2. Names and code numbers of parts to be ordered.

3. Make and model number of the machine in which

the engine is installed.

FOREWORD

(1) Engine model name and serial number

1

379O001A

Advertisement

Table of Contents

Summary of Contents for Daedong 4A200

- Page 1 FOREWORD DAEDONG Corporation wishes to thank you for purchasing your new DAEDONG diesel engine. Your new engine is the result of many years of research and development and high quality manufacturing; and we are confident that your new engine will provide many years of safe, reliable and economical operation. This Operator’s Manual is intended to help you get the maximum return on your investment and to ensure your safety.

- Page 2 SAFETY FIRST The “SAFETY ALERT SYMBOL” is used throughout this manual and on the engine decals to warn of potential injury. Always read and follow these instructions carefully. Signs Description Hazards or unsafe practices which COULD result in severe WARNING injury or death.

-

Page 3: Table Of Contents

TABLE OF CONTENTS SAFETY INSTRUCTIONS ......... 5 NAME OF PARTS ............9 OPERATING THE ENGINE ........11 PRE-START ENGINE CHECKS ......12 STARTING AND STOPPING THE ENGINE ..12 CHECKS DURING OPERATION ......14 BREAK-IN AND CHECKS ........17 DAILY CHECKS ..........18 BREAKE-IN ............ -

Page 5: Safety Instructions

1. SAFETY INSTRUCTIONS... - Page 6 379O102A 4. An engine should never be operated in the presence of combustible vapors since an explosion may result. DAEDONG bears no responsibility when an engine is oper- 379O101A ated improperly or in a hazardous environment. 1. Engine exhaust fumes are extremely dangerous. Never 5.

- Page 7 SAFETY INSTRUCTIONS 7 379O103A 379O104A 7. The oil, fuel and cooling systems all operate under pressure. 9. Dispose of all fluids and hazardous materials in accor- Always check for and relieve the pressure before discon- dance with local environmental regulations and common necting or removing any part of these systems.

- Page 8 8 DIESEL ENGINE 379O105A 11. Thoroughly read and understand this manual before oper- ating the engine. Contact your DAEDONG dealer if you have any questions. 12. It is the owner’s responsibility to train other operators be- fore they use this engine. All operators should read and...

-

Page 9: Name Of Parts

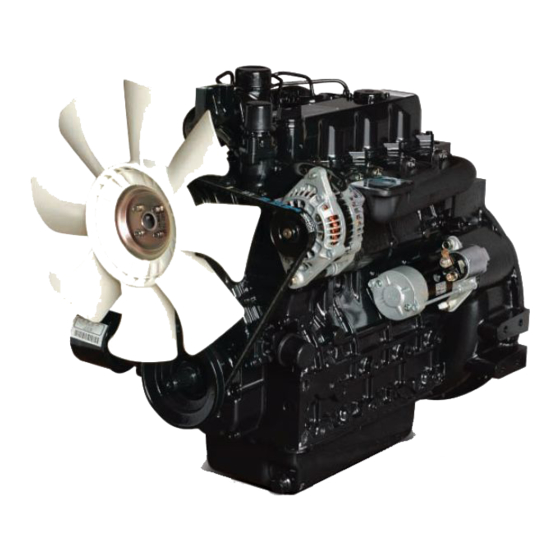

2. NAMES OF PARTS... - Page 10 10 DIESEL ENGINE NAMES OF PARTS 379O201A (1) Intake manifold (10) Oil fill cap (2) Speed control lever (11) Exhaust manifold (3) Engine stop lever (12) Alternator (4) Fuel injection pump (13) Starter (5) Fuel feed pump (14) Oil level dipstick (6) Cooling fan (15) Oil pressure switch (7) Front crankshaft pulley...

-

Page 11: Operating The Engine

3. OPERATING THE ENGINE PRE-START ENGINE CHECKS ....... 12 STARTING AND STOPPING THE ENGINE .... 12 CHECK DURING OPERATION ........ 14... -

Page 12: Pre-Start Engine Checks

12 DIESEL ENGINE PRE-START ENGINE CHECKS STARTING AND STOPPING THE ENGINE STARTING Always check the engine and make sure it is ready for safe 1. Set the fuel cock to the “ON” or “OPEN” position. operation before starting – See page 18 for details. 2. - Page 13 ! ! ! ! ! Check for faulty wiring. If the light still remains on, do not use the engine and consult your DAEDONG dealer. 379O301A To avoid personal injury : Keep children or non-essential bystanders (1) SPEED CONTROL LEVER away from the engine while it is running.

-

Page 14: Checks During Operation

If the warning persists, do not use the engine. Consult your 4. Check and adjust the fan belt tension. DAEDONG dealer for service. 5. Ensure that the system is filled to the correct coolant level with the proper mix of anti-freeze and water. - Page 15 OPERATING THE ENGINE 15 STOP THE ENGINE IMMEDIATELY: 1. If the engine speed suddenly changes. 2. If there is an unusual noise. 3. If the engine exhausts suddenly darkens. 4. If the oil pressure or temperature light come on. REVERSED ENGINE ROTATION AND REMEDIES While not common, it is possible for a diesel engine to run backwards.

-

Page 17: Break-In And Checks

4. BREAK-IN AND CHECKS DAILY CHECKS ............18 BREAK-IN ..............18 PERIODIC CHECKS ..........19... -

Page 18: Daily Checks

18 DIESEL ENGINE DAILY CHECKS BREAK-IN Regular maintenance is an important factor in preventing down- During the engine break-in period, the following actions are time and accidents. Always make the following checks before critical to engine performance and life. operating the engine. 1. -

Page 19: Periodic Checks

BREAK-IN AND CHECKS 19 PERIODIC CHECKS Interval I t e m Ref.Pgae 50 hours Check fuel lines and air intake connections Change engine oil Clean air cleaner element 100 hours Clean fuel filter Check battery electrolyte level Check and adjust fan belt tension Check cooling system hoses &... -

Page 21: Maintenance

5. MAINTENANCE FUEL ................. 22 ENGINE OIL ............. 24 RADIATOR (optional) ..........26 AIR CLEANER (optional) ........31 BATTERY (optional) ..........32 FAN BELT ..............34 LONG-TERM STORAGE ......... 34... -

Page 22: Fuel

22 DIESEL ENGINE FUEL FUEL LEVEL CHECK AND REFUELING BLEEDING THE FUEL SYSTEM To avoid fire and serious injury, DO NOT bleed 1. Always refuel before the fuel level reaches “EMPTY”. the fuel system while the engine is hot. 2. Use diesel fuel only. Other fuels and fuel mixtures will degrade performance and may damage the engine. - Page 23 MAINTENANCE 23 CHECKING THE FUEL LINES 4. When the engine starts or when air is expelled from the injection pump, close the air vent knob by turning it clockwise. 5. If the engine still does not start, loosen the fuel line con- nection at the injection nozzle.

-

Page 24: Engine Oil

24 DIESEL ENGINE ENGINE OIL REPLACING THE FUEL FILTER & BLEEDING 379O502A 379O503A (1) Fuel filter cartridge (1) Oil level dipstick Oil filter plug (2) Air vent Pipe [Lower end of oil level gage] (3) Pipe joint A : Engine oil level within this range is proper. (4) Filter Bracket To prevent injury, always stop the engine be- fore checking the oil or performing any other... - Page 25 4. Change the oil after every 100 hours of operation thereafter. 5. For best results, it is recommended that the oil level be kept at the upper mark. 6. Engine oil quantity. Model Quantity ( ) Model Quantity ( ) 3C093 3C093G 3A165 TD1300 4A200 TD1400 4A220 TD1700...

-

Page 26: Radiator (Optional)

26 DIESEL ENGINE RADIATOR (OPTIONAL) REPLACING THE OIL FILTER Radiators must be handled and installed properly to avoid cool- ant leaks. It should be a daily routine to check the engine coolant level. Check it before each use while the engine is cold. To avoid injury, always stop the engine and al- low it to cool before changing the coolant or performing any other cooling system service. - Page 27 MAINTENANCE 27 CHECKING LEVEL,ADDING AND CHANGING COOLANT 379O505A 379O506A (1) Pressure cap (1) Coolant reserve tank (A) FULL (B) LOW 1. Without a reserve tank, remove the radiator cap while the ! ! ! ! ! Do not use dirty water or seawater for engine is cold.

- Page 28 3. Close the drains securely and add the proper amount of coolant. Typical capacities are shown below for standard radiators. Model Quantity ( ) Model Quantity ( ) 3C093 3C093G 3A165 TD1300 4A200 TD1400 379O507A 4A220 TD1700...

- Page 29 MAINTENANCE 29 IF COOLANT OVERFLOW PERSISTS: IF ENGINE OVERHEATING OCCURS: 1. Clean dirt and debris from the radiator guard, if equipped, 1. Never disregard an engine warning light or other alarm. and the radiator core (fins and tubes) to ensure that cool- 2.

- Page 30 30 DIESEL ENGINE CLEANING THE RADIATOR REPAIRING RADIATOR LEAKS Cooling system leaks should be repaired promptly to prevent equipment damage or possible injury. The use of “stop-leak” type additives is not recommended. ANTI-FREEZE Freezing temperatures can quickly and severely damage the engine if the cooling system is unprotected.

-

Page 31: Air Cleaner (Optional)

MAINTENANCE 31 AIR CLEANER (OPTIONAL) The coolant mixture should not exceed 50% anti-freeze by volume. Freezing Point Boiling Point Anti-freeze IMPORTANT Vol% °C °F °C °F 379O509A (1) Aircleaner body (3) Wing-head bolt NOTE : (2) Element (4) Evacuator valve 1. -

Page 32: Battery (Optional)

32 DIESEL ENGINE BATTERY (OPTIONAL) Ensure that the wing nut for the filter element To avoid personal injury : is tight. A loose element or loose cover will Avoid contact with battery electrolyte. Sul- allow dust ingestion that can severely damage furic acid will burn the skin and destroy the engine. - Page 33 MAINTENANCE 33 LONG-TERM STORAGE (BATTERY) 379O510A 379O511A (1) Larger Red cable (4) Hightest level (7) Plug (2) Ground cable (5) Lowevst level (8) Hightest level (3) Battery case (6) Lowevst level Always observe the correct polarity. Attach- 1. Before long-term engine storage: ing cables to the wrong terminals will cause ! ! ! ! ! Remove the battery.

-

Page 34: Fan Belt

34 DIESEL ENGINE FAN BELT LONG-TERM ENGINE STORAGE 1. Drain the engine oil and replace with clean oil. Run the engine for 5 minutes. 2. Open the drain cocks and remove the radiator cap to drain all of the coolant from the engine and radiator. Leave the drain cocks open. -

Page 35: Troubleshooting

6. TROUBLESHOOTING... - Page 36 If the engine does not start or run properly, refer to the following charts to determine the cause and identify corrective actions. If the cause cannot be determined, contact your DAEDONG dealer for assistance. PROBLEM: ENGINE WILL NOT START OR IS DIFFICULT TO START...

- Page 37 TROUBLESHOOTING 37 PROBLEM: ENGINE SUDDENLY STOPS RUNNING POSSIBLE CAUSE CORRECTIVE ACTIONS ! ! ! ! ! Check fuel level and refill. Lack of fuel ! ! ! ! ! Check the fuel system. Repair leaks and bleed air from the system. ! ! ! ! ! Clean or replace as needed.

- Page 38 38 DIESEL ENGINE PROBLEM: LOW ENGINE POWER OUTPUT POSSIBLE CAUSE CORRECTIVE ACTIONS ! ! ! ! ! Check and clean injection nozzles, being careful not to damage the orifice. Clogged or faulty fuel injector ! ! ! ! ! Replace injection nozzle(s) if not working properly after cleaning. ! ! ! ! ! Check valves for leakage –...

- Page 39 TROUBLESHOOTING 39 PROBLEM: EXHAUST SMOKE OR DARK EMISSIONS POSSIBLE CAUSE CORRECTIVE ACTIONS ! ! ! ! ! Contact dealer for repairs. Fuel governor malfunction ! ! ! ! ! Drain and replace with proper fuel. Poor quality fuel ! ! ! ! ! Clean or replace as required. Faulty fuel injector ! ! ! ! ! Check injection timing, injection pump, valve adjustment and typical causes of Incomplete fuel combustion...

- Page 40 40 DIESEL ENGINE PROBLEM: ENGINE OVERHEATS POSSIBLE CAUSE CORRECTIVE ACTIONS ! ! ! ! ! Check for and repair leaks. Add coolant. Low coolant level ! ! ! ! ! Adjust or replace belt as required. Loose or broken fan belt ! ! ! ! ! Add water or replace coolant to achieve proper mix.

-

Page 41: Wiring Diagrams

7. WIRING DIAGRAMS... - Page 42 42 DIESEL ENGINE 3C093 SERIES 379O701A...

- Page 43 WIRING DIAGRAMS 43 TD1300, TD1400, TD1700, 3A139, 3A165, 4A200T, 4A220, 4A220T 379O702A...

-

Page 45: Specifications

8. SPECIFICATIONS... - Page 47 SPECIFICATIONS 47 Specifications are subject to change without notice. CAUTION MODEL 4A220T 4A200T 4A220 4A200 3A165 3A139 TD1700 TD1400 TD1300 3CO93 3CO93G-2 3CO93G-3 Vertical, water cooled, Type Vertical, water-cooled, 4-cycle diesel 4-cycle disedl turbo Number of cylnders Bore and stroke 87.0 x 92.4 83.0 x 92.4 87.0 x 92.4...

- Page 48 48 DIESEL ENGINE MODEL 4A220T 4A200T 4A220 4A200 3A165 3A139 TD1700 TD1400 TD1300 3CO93 3CO93G-2 3CO93G-3 Lubricant Engine oil SAE 15W-40 817 x 527 x 695 661 x 527 x 695 817 x 488 x 695 817 x 488 x 695 722 x 488 x 730 722 x 488 x 730 739 x 509 x 710...

-

Page 49: Index

9. INDEX... - Page 50 50 DIESEL ENGINE AIR CLEANER (optional) ........31 ENGINE OIL ............. 24 Checking and adding engine oil ......25 Changing engine oil ..........25 Replacing the oil filter .......... 26 BATTERY (optional) ..........32 Long-term storage ..........33 BREAK-IN ..............18 FAN BELT ..............

- Page 51 INDEX 51 RADIATOR (optional) ..........26 TROUBLESHOOTING ..........35 Checking, adding and changing coolant ..... 27 Engine will not start or is difficult to start ... 36 Changing the coolant .......... 28 Engine suddenly stops running ......37 If coolant overflow persists ........29 Low engine power output ........

Need help?

Do you have a question about the 4A200 and is the answer not in the manual?

Questions and answers