Table of Contents

Advertisement

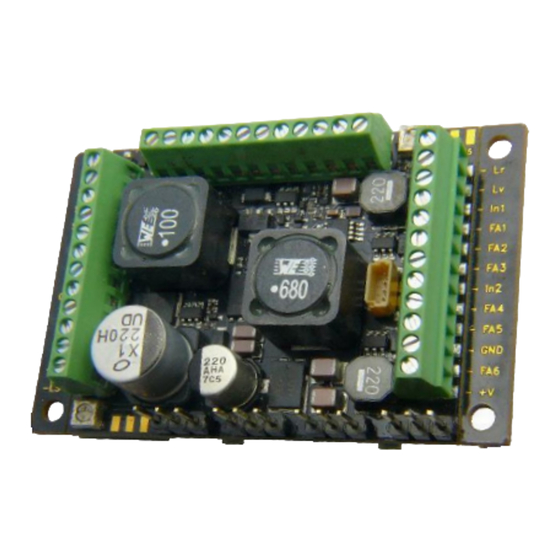

Large-scale Decoder & Sound Decoder MX695, MX696, MX697, MX699

Instruction Manual

LARGE-SCALE DECODER WITH & W/O SOUND

and NON-SOUND LARGE-SCALE DECODER

and: Combinations of loco boards and decoder

and NON-SOUND LARGE-SCALE DECODER

MX695KV, -KS, -LV, LS

MX695KN

MX696V, -S

MX696KS, MX696KV

MX696KN

MX697V, -S

MX699KV, -KS, -LV, -LM

SW-Version 31 --- 2012 08 15

Including the new MX696 decoder --- 2012 11 30

SW-Version 33.0 --- 2013 04 30

with chapter about loco boards --- 2013 05 20

1

Product - Overview .................................................................................................. 2

2

Technical Information ............................................................................................... 4

3

Installation and Wiring ............................................................................................. 5

4

Loco Adapter Boards for Large-Scale Decoder ...................................................... 12

5

Configuration ........................................................................................................ 18

Programming in "Service mode" (on the progr. track) ............................................................. 18

5.1

Programming in "Operations mode" (on-the-main) .................................................................. 18

5.2

5.3

Decoder-ID, Load-Code, Decoder-Type and SW-Version ...................................................... 19

5.4

Engine address(es) in DCC mode ........................................................................................... 19

5.5

Analog operation ...................................................................................................................... 20

5.6

Motor control and regulation .................................................................................................... 21

5.7

Acceleration and Deceleration: ................................................................................................ 24

5.8

The ZIMO "signal controlled speed influence" (HLU) .............................................................. 26

5.9

"Asymmetrical DCC-Signal" stops (Lenz ABC)........................................................................ 26

5.10

5.11

DC Brake Sections (Märklin brake mode) ............................................................................... 27

5.12

Distance Controlled Stopping - Constant Stopping Distance ................................................. 27

5.13

Shunting, Half-Speed and MAN Functions .............................................................................. 28

5.14

The NMRA-DCC function mapping .......................................................................................... 29

5.15

The extended ZIMO Function mapping ................................................................................... 30

"Unilateral Light Suppression" .................................................................................................. 31

5.16

The "Swiss Mapping" (from SW version 32) ............................................................................ 32

5.17

The ZIMO "Input-Mapping" SW versions 34 and up, also for outputs via SUSI ...................... 34

5.18

5.19

Dimming, Low beam and Direction Bits ................................................................................... 34

5.20

Flasher Effect ........................................................................................................................... 35

5.21

F1-Pulse Chains (Only for old LGB products) ......................................................................... 35

5.22

Special Effects (US and other light effects, smoke generator, uncouplers etc.) ..................... 36

5.23

Configuration of smoke generators .......................................................................................... 37

5.24

Configuration of Electric Uncouplers........................................................................................ 38

5.25

Servo Configuration ................................................................................................................. 40

Feedback - Bidirectional communication ............................................................... 41

6

ZIMO SOUND - Selection and Programming ......................................................... 42

7

7.1

7.2

The test run for determining the motor's basic load ................................................................ 46

7.3

7.4

Basic settings independent of powertrain ................................................................................ 47

Steam engine Basic sound settings .................................................................................... 49

7.5

Steam engine Load and acceleration dependency ............................................................. 51

7.6

7.7

Diesel and Electric engines ..................................................................................................... 53

7.8

Random and Switch input sounds ........................................................................................... 56

CV - Summery List ................................................................................................ 57

8

9

Service Insructions................................................................................................. 60

ZIMO decoders contain a microprocessor with appropriate software. The software version can be read out from CV #7 and #65.

The current version may not yet capable of all the functions mentioned in this manual. As with other computer programs, it is also

not possible for the manufacturer to thoroughly test this software with all the possible applications. Installing new software ver-

sions later can add new functions or correct recognized errors. SW updates can be done by the end user for all ZIMO decoders

since production date October 2004, see chapter "Software Update"! Software updates are available at no charge if performed by

the end user (except for the purchase of a programming module); Updates and/or upgrades performed by ZIMO are not consid-

ered a warranty issue and are at the expense of the customer. The warranty covers hardware damage exclusively, provided such

damage is not caused by the user or other equipment connected to the decoder. For update versions, see www.zimo.at.

Page 1

EDITION

2015 06 01

2011 05 01

2015 07 07

2011 08 15

2015 09 23

2018 04 20

2019 05 16

2014 10 12

Advertisement

Table of Contents

Summarization of Contents

Product Overview

MX695K Series with Screw Terminals

Details MX695K versions with screw terminals, full and reduced.

MX695KN Non-Sound Decoder with Screw Terminals

Details MX695KN non-sound decoder with screw terminals.

MX695L Series with Pin Connectors

Details MX695L versions with pin connectors, full and reduced.

MX696 Series: Narrow Body Decoders

Details MX696V and MX696S narrow body decoders, full and reduced.

MX696N Non-Sound Decoder with Screw Terminals

Details MX696N non-sound decoder with screw terminals.

MX696K Series: Narrow Large-Scale Sound Decoder

MX696KV Full Version

Full version of narrow large-scale sound decoder with screw terminals.

MX696KS Reduced Version

Reduced version of narrow large-scale sound decoder with screw terminals.

MX699K Series: Large-Scale Sound Decoder with Screw Terminals

MX699KV Full Version

Full version of large-scale sound decoder with screw terminals.

MX699KS Reduced Version

Reduced version of large-scale sound decoder with screw terminals.

MX697 Series: Large-Scale Sound Decoder for US Interfaces

MX697V Full Version

Full version of large-scale sound decoder for US interfaces.

MX697S Reduced Version

Reduced version of large-scale sound decoder for US interfaces.

MX699L Series: Large-Scale Sound Decoder with Pin Connectors

MX699LV, -LM Full Version

Full version of large-scale sound decoder with pin connectors.

MX699LS Reduced Version

Reduced version of large-scale sound decoder with pin connectors.

Technical Information

Track Voltage Specifications

Specifies track voltage range for DCC and analog operation.

Motor Output and Peak Current

Details maximum continuous motor output and peak current.

Function Output Current and Outputs

Lists function output current and number of outputs per model.

Sound Sample Capacity and Playback

Capacity for sound samples and playback frequencies.

Sound Amplifier and Loudspeaker Impedance

Sound amplifier output power and loudspeaker requirements.

External Energy Storage Options

Options for external energy storage connection and charge current.

Analog Mode Operation

Information on analog mode operation and threshold voltages.

Operating Temperature and Dimensions

Operating temperature range and physical dimensions of decoders.

Overload and Thermal Protection

Details overload protection mechanisms and thermal protection.

Software Update Information

Information on user-completable software updates for decoders.

Installation and Wiring of MX695 - MX699

Function Output Voltage Options

Describes full track, +10V, +5V, and variable low-voltage for outputs.

External Energy Source Connections

Options for external energy sources like capacitors or batteries.

Special Fan Connection

Connection point for the special fan output.

Rail and Motor Connections

Connections for left/right rails and motor terminals.

Switch Input and Volume Control

Input for switch signals and volume control potentiometer.

Speaker and Cam Sensor Connections

Speaker connection options and cam sensor input.

Servo and SUSI Interface Connections

Connections for up to four servos and SUSI interface.

MX696 Series Wiring Diagram

Function Outputs

Function outputs for various elements on the MX696.

Headlight Connections

Connection points for rear and front headlights.

Rail and Motor Connections

Connections for rails and motor terminals.

Cable and Plug Connections

Connections via ribbon cable and specific plugs for MX696S/V.

SUSI Interface

SUSI interface connection details.

Smoke Fan and Capacitor Connections

Connections for smoke fan motor and external capacitor.

Low-Voltage Settings and Servo Connections

Setting low voltage for servos and servo connections.

MX697 Series Wiring Diagram

Additional Input Switches

Connections for additional input switches.

Headlight and Rail Connections

Front/rear headlight and rail connections.

Motor and Ground Connections

Motor and ground connection points.

Loudspeaker and Capacitor Connections

Loudspeaker and external capacitor connections.

Switch Input and Low-Voltage Regulator

Switch input connections and low-voltage regulator.

Low Voltage Outputs

Low voltage outputs for functions (10V, variable, 5V).

Function Outputs

Function outputs for various elements.

Smoke Fan and Volume Control

Smoke fan motor connection and volume control.

Servo Connections

Connections for up to four servos.

MX699 Series Wiring Diagram

Function Output Voltage Options

Full track, +10V, +5V, and adjustable low-voltage for outputs.

External Capacitor Options

Options for external capacitors.

Fan and Smoke Fan Connections

Fan connections and smoke fan motor connection.

Rail and Motor Connections

Connections for rails and motor terminals.

Switch Input and Speaker Volume

Switch input connection and speaker volume control.

Speaker and Cam Sensor Connections

Speaker connection options and cam sensor input.

Servo and SUSI Interface Connections

Servo and SUSI interface connections.

Additional Switch Connections

Additional switch connections.

Tracks and Motor Connections

Decoder Installation Space Requirement

Requirement for adequate space inside the locomotive for decoder installation.

Insulation of Wiring

Ensuring insulation of wiring for accessories and motor.

Connecting Tracks and Motor to Terminals

Connecting tracks and motor to the corresponding decoder terminals.

DC Motor Compatibility

Compatibility with all DC motors used in model railways.

Parallel Connection for Multiple Motors

Connecting multiple motors in parallel for automatic alignment.

Reference to Motor Regulation CVs

Reference to CVs for motor regulation configuration.

Dual Connection Pins for Tracks and Motor

Availability of dual connection pins for tracks and motor.

Speaker, Cam Sensor, and Volume Regulation

Speaker Compatibility and Impedance

Compatibility of 4 Ohm or 8 Ohm speakers and impedance limits.

Sound Amplifier Power

Sound amplifier power specification for MX699.

Connecting Tweeters

Connecting tweeters in parallel with a frequency crossover.

Volume Adjustment for Low-Specification Speakers

Adjusting volume for speakers with lower specifications.

Virtual Cam Sensor Functionality

Explanation of the sufficiency of the virtual cam sensor.

Connecting Real Cam Sensors

Connecting real cam sensors, mechanical or photo-transistor types.

External Volume Control Options

Alternative volume control via external regulator.

MX695 Specific Volume Regulator Settings

MX695 specific volume regulator settings, logarithmic potentiometer.

Volume Regulator Note for MX696/697/699

Note on volume regulators for MX696, MX697, and MX699 decoders.

Consumers and Low Voltage Outputs

Definition of Consumers

Equipment connected to function outputs (lights, LEDs, motors, etc.).

Using Full Track Voltage as Positive Pole

Using full track voltage as the positive pole for consumers.

Using 10V Low Voltage Output

Using 10V low voltage for sound, with warnings about consumption.

Using 5V Low Voltage Output

Using 5V low voltage for servos and consumers.

Variable Low Voltage Adjustment

Adjusting variable low-voltage via coding switch.

Warning: Avoid Software Dimming for Voltage Reduction

Avoid software dimming for voltage reduction to prevent damage.

Reference to Decoder Configuration CVs

Reference to CV chapters for function mapping and effects.

Special Connections for Smoke Fans

Smoke Generator Fan Control

Using outputs to control fan motors of clocked smoke generators.

Motor Braking Feature for Smoke Fans

Feature allowing motor braking for smoke fans.

Servo Configuration

MX699 Servo Connections

MX699 provides 4 connections for common servos.

Servo Wire Color and Order Differences

Attention to different wire orders and colors for servos.

5V Servo Supply Availability

5V servo supply is only available in V-types.

Servo Control Wires and External Power

Control wires usability and external 5V power source.

Switch Inputs

Additional Switch Inputs

Three further inputs (IN 1, IN 2, IN 4) for triggering sounds etc.

Reference to CVs for Sound Configuration

Reference to CV chapters for sound configuration.

External Stay-Alive Capacitor

Types of Stay-Alive Capacitors

Electrolytic capacitor, Goldcap, or battery types.

Benefits of Stay-Alive Capacitors

Improves driving, reduces flickering lights, prevents stalling.

GOLMRUND Goldcap Module Example

Example of a Goldcap module (GOLMRUND).

MX699 Internal Stay-Alive Capacitor

MX699 Internal Stay-Alive Capacitor Details

MX699 has an internal stay-alive capacitor for passing sections.

Using External Stay-Alive Capacitors with MX699

Benefit of connecting external stay-alive capacitors to MX699.

SUSI Interface

SUSI Interface Purpose and Module Connections

SUSI interface for additional modules like sound or couplers.

SUSI for Digital Couplers and Pantographs

SUSI interface used for digital couplers and pantographs.

SUSI for Sound Project Loading

SUSI interface for loading sound projects and updates.

Loco Adapter Boards Overview

Purpose of Loco Adapter Boards

Adapter boards as intermediate parts for decoder installation.

Note on Synchronous Rectifier Absence

Adapter boards for ZIMO decoders lack additional synchronous rectifiers.

LOKPL95BS/BV Boards for MX695LS/LV

LOKPL95BS/BV boards designed for MX695LS/LV decoders.

LOKPL96 Series Loco Boards

Loco boards designed for MX696S/V decoders.

LOKPL95BS and LOKPL95BV Board Details

LOKPL95BS: Circuit Board with Solder Pads

LOKPL95BS circuit board with solder pads for connections.

LOKPL95BV: Board with Additional Variable Low Voltage

LOKPL95BV features additional variable low voltage output.

Servo Connections on MX695 Decoder

Note: Servo connections are not accessible on the loco board.

Special Loco Board Layouts

Special board layouts may include servo connectors.

LOKPL96 Series Board Variations

LOKPL96KS: Screw Terminals and 5V Low Voltage

LOKPL96KS features screw terminals and 5V low voltage.

LOKPL96KV: Screw Terminals, 5V Low Voltage, Servo Connections

LOKPL96KV features 5V low voltage, servo connections, and screw terminals.

LOKPL96LS: 10-Pin Plugs

LOKPL96LS features 10-pin plugs.

LOKPL96LV: 10-Pin Plugs and 5V Low Voltage

LOKPL96LV features 10-pin plugs and 5V low voltage.

LOKPL96LS/LV Connection Method

Connecting 10-pin plugs using cable and crimp sockets.

Loco Board and Decoder Combinations

MX696KS Combination (LOKPL96KS + MX696S)

MX696KS combination, similar to MX695KS but narrower.

MX696KV Combination (LOKPL96KV + MX696V)

MX696KV combination, similar to MX695KV but narrower.

Loco Board and Sound Decoder Combinations

Combinations with 8 Function Outputs

Various combinations featuring 8 function outputs.

Combinations with 8 Outputs, 5V Low Voltage, and Servos

Combinations with 8 outputs, 5V low voltage, and servo connections.

Combinations with 14 Function Outputs

Various combinations featuring 14 function outputs.

Combinations with 14 Outputs, 5V Low Voltage, and Servos

Combinations with 14 outputs, 5V low voltage, and servo connections.

Combinations with Variable Low Voltage

Combinations featuring variable low-voltage (1.5V to 18V).

Decoder and Loco Board Combinations: Plug-in Sockets

Plug-in Sockets for Ribbon Cable (Narrow Design)

MX696S/V with LOKPL96LS/LV using plug-in sockets.

Double Row Sockets for Ribbon Cable (Narrow Design)

MX696S/V with LOKPL96LV using double row sockets.

Decoder and Loco Board Combinations: Wide Design

MX695KS Decoder without Loco Board

MX695KS decoder without a loco board (wide design).

MX695KV Decoder without Loco Board

MX695KV decoder without a loco board (wide design).

Decoder and Loco Board Combinations: Screw Terminals

MX696S with LOKPL96KS

MX696S with LOKPL96KS using screw terminals.

MX696V with LOKPL96KS

MX696V with LOKPL96KS using screw terminals.

MX696S with LOKPL96KV

MX696S with LOKPL96KV using screw terminals.

MX696V with LOKPL96KV

MX696V with LOKPL96KV using screw terminals.

Attention: 5V Servo Supply

5V Servo Supply Availability Note

Attention: 5V for servos is only available at the variable low-voltage output.

Special Loco Board LOKPLSHMAL

LOKPLSHMAL for MX696S or MX696V

Special board for MX696S or MX696V, for HSB Mallet 995901.

Loco Conversion Notes (HSB Mallet Example)

Notes on loco conversion using the HSB Mallet example.

ZIMO Board Connection for Energy Storage

ZIMO board offers connection for energy storage device.

Additional Connections for Uncouplers

Additional connections for uncouplers (servos or Massoth).

Analog Version Loco Conversion

Procedure for converting analog version locomotives.

HSB Mallet Decoder Sound Project Details

Details of the HSB Mallet decoder's high-quality sound project.

Connection Diagram for LOKPLSHMAL

Connection diagram for the LOKPLSHMAL loco board.

LOKPL99 Loco Board with Solder Pads

LOKPL99 for MX699LS and MX699LV

LOKPL99 board with solder pads for MX699LS and MX699LV.

Installation of LOKPL99 Boards

Instructions for installing LOKPL99 boards with wires soldered.

Connection Diagram for LOKPL99

Connection diagram for the LOKPL99 loco board.

Servo Connection Note for MX695

Note: Servos connect directly to the MX695 decoder.

Configuring the MX695 - MX699

Programming Modes: Service vs. Operations

Explains programming in Service Mode and Operations Mode (PoM).

Note on Default CV Values for Sound Decoders

CV values in sound decoders may differ from defaults.

Common CV Adjustments in Sound Projects

Highlights common CV adjustments in sound projects (e.g., CV #29).

Service Mode Programming

Unlocking Service Mode with CV #144

Unlocking Service Mode programming using CV #144.

Acknowledgement Methods in Service Mode

Methods for acknowledging successful programming steps.

Alternative Acknowledgement Method (CV #112)

Using CV #112 for alternative acknowledgement signals.

Operations Mode Programming

Explanation of Operations Mode (PoM)

Explanation of Operations Mode programming (Programming-on-the-main).

DCC Standards for Operations Mode

DCC standards for programming and reading CVs on the main track.

ZIMO Decoders and RailCom for PoM

ZIMO decoders use RailCom for PoM operations.

RailCom Activation Settings

Settings required to activate RailCom for PoM.

Decoder Identification and Version Information

Decoder ID and Type (CV #250)

Decoder ID and type information stored in CV #250.

Load-Code for Coded Sound Projects

Load-code for installing coded sound projects.

Manufacturer ID and Reset Functions (CV #8)

Manufacturer ID and Reset functions via CV #8.

Software Version Number (CV #7)

Decoder SW version number indicated by CV #7.

Sub-Version Number (CV #65)

Sub-version number indicated by CV #65.

Engine Addressing in DCC Mode

Default Engine Address and Recommendations

Default address (CV #1) and recommendations for changing it.

DCC Address Space and Long Addresses

DCC address space exceeding single CV, long addresses.

Automatic Address Calculation by Digital Systems

How digital systems calculate addresses automatically.

Decoder-Controlled Consisting

Consisting via DCC System

Organizing consisting using the DCC system without CV changes.

Consisting via Individual CV Programming

Organizing consisting by programming decoder CVs individually.

Focus on Decoder-Controlled Consisting

This chapter covers only decoder-controlled consisting.

Analog Operation

Analog Operation Capabilities (DC/AC)

All ZIMO decoders operate in DC or AC analog modes.

Enabling Analog Operation via CV #29

Enabling analog operation by setting CV #29, Bit 2 = 1.

Analog Operation Design for Large-Scale Decoders

Large-scale decoders designed for analog operation.

Controller Influence on Analog Behavior

Influence of locomotive controller on analog operation.

Motor Control and Regulation

Note on Default CV Values vs. Sound Projects

Note that decoder settings may differ from defaults due to sound projects.

Speed Curve Programming

Information on programming the speed curve.

Three-Step Speed Curve Programming

Programming three-step speed curves using CVs #2, #5, #6.

28-Step Speed Curve Programming

Free programmable speed curve using CVs #67 - #94.

CV #57: Motor Control Reference Voltage

CV #57 specifies the reference voltage for motor regulation.

Fine-Tuning Motor Regulation

Tips for Optimizing CV #56 Settings

Steps for finding optimal CV #56 settings for motor regulation.

CV #9: Motor Control Frequency and EMF Sampling

CV #9 for adjusting motor control frequency and EMF sampling rate.

CV #56: PID Regulation Parameters

CV #56 for tailoring motor regulation with PID values.

Motor Control Frequency and EMF Sampling Rate (CV #9)

Motor Control via Pulse Width Modulation

Motor control using pulse width modulation at different frequencies.

Low Frequency Motor Control

Use of low frequency motor control (30-159Hz) for older motors.

High Frequency Motor Control

Use of high frequency motor control (20kHz) for quiet operation.

Periodic Motor Power Interruption

Periodic interruption for EMF measurement and load compensation.

Adjusting Sampling Frequency with CV #9

Adjusting sampling frequency and time using CV #9.

PID Regulation (CV #56)

Tailoring Motor Regulation with PID Values

Tailoring motor regulation to type, weight using PID values.

Setting PID Values with CV #56

Setting proportional and integral values using CV #56.

Fine-Tuning Suggestions for Default Settings

CV #9 and CV #56 Remarks for Fine-Tuning

Remarks on CVs #9 and #56 for fine-tuning motor regulation.

Procedure for Optimal CV #56 Settings

Steps for finding optimal CV #56 settings.

Load Compensation, Curve, and Experimental CVs

Goal of Load Compensation

Objective of load compensation: maintaining constant speed.

Using 100% Load Compensation

Usefulness of 100% load compensation for preventing stalls.

Warning: Load Compensation in Consists

Warning against 100% load compensation in consists.

Defining Load Compensation Intensity (CV #58)

Defining load compensation intensity using CV #58.

Advanced Load Compensation (CVs #10, #113)

Using CVs #10 and #113 for precise load compensation.

Experimental CVs for Test Purposes

Experimental CVs for testing effects on motor regulation.

CV #58: BEMF Intensity

CV #58 for adjusting BEMF intensity.

CV #10: EMF Feedback Cutoff

CV #10 for controlling EMF feedback cutoff.

CV #113: BEMF Reduction

CV #113 for reducing BEMF intensity.

The Motor Brake

Purpose of the Motor Brake

Usefulness of the motor brake for preventing roll-away on inclines.

CV #151: Motor Brake Control

CV #151 for controlling the motor brake.

Acceleration and Deceleration Settings

Basic Acceleration and Deceleration Times (CVs #3, #4)

Setting basic acceleration and deceleration times with CVs #3 and #4.

NMRA Standard for Acceleration/Deceleration

NMRA standard requires a linear progression for acceleration/deceleration.

Recommended Values for Smooth Driving

Recommended values for smooth drivability and slow starts/stops.

Sound Project Default Values for CVs #3, #4

Sound projects may have different default values for CVs #3 and #4.

Improving Acceleration/Deceleration with CVs #121, #122, #123

Enhancing acceleration/deceleration using exponential and adaptive features.

CV #146: Eliminating Start-Up Jolts

CV #146 for eliminating start-up jolts caused by gear backlash.

Special Operating Mode: km/h Speed Regulation

Introduction to km/h Speed Regulation

Alternative method for driving with prototypical speeds using km/h.

Calibration Run Requirement

Calibration run must be performed for each engine.

Calibration Step 1: Engine Setup

Initial engine setup for the calibration run.

Calibration Step 2: Starting Calibration Mode (CV #135)

Starting calibration mode by programming CV #135.

Calibration Step 3: Setting Speed Regulator

Setting the speed regulator to a medium speed position.

Calibration Step 4: Function Activation

Activating function F0 (headlights) at the start marker.

Calibration Step 5: Reading CV #136

Reading CV #136 for calibration results.

CV #135: Normal vs. km/h Operation Control

CV #135 controls selection between normal or km/h operation.

Signal Controlled Speed Influence (HLU)

Introduction to ZIMO Signal Controlled Speed Influence (HLU)

HLU offers a second level of communication for track section data.

HLU Application: Train Stopping and Speed Limits

HLU used for stopping trains and applying speed limits in stages.

HLU Acceleration/Deceleration Time Note

Note on HLU acceleration/deceleration times (CVs #49, #50).

Importance of Track Layout for HLU

Proper track layout is crucial for functioning HLU train control.

Importance of Stop/Pre-Braking Sections for HLU

Correct stop/pre-braking sections are vital for HLU train control.

CV #49: HLU Acceleration

CV #49 for configuring HLU acceleration.

CV #50: HLU Deceleration

CV #50 for configuring HLU deceleration.

HLU Method with MX9 or Successor

HLU method using MX9 track section modules or successors.

Defining HLU Speed Limits

Defining internal speed steps for HLU speed limits.

CVs #51-55: HLU Speed Limits

CVs #51 through #55 for setting HLU speed limits.

CV #59: HLU Reaction Time

CV #59 for configuring HLU reaction time.

Asymmetrical DCC Signal Stops (Lenz ABC Method)

Activating Asymmetrical DCC Signal Stop Mode (CV #27)

Activating the asymmetrical DCC signal stop mode using CV #27.

Note on ABC Slow Speed Step Support

Note: ZIMO decoders do not support standard ABC slow speed steps.

Position Dependent Stops with ABC Method

Position dependent stops using the Lenz ABC method.

Asymmetrical Threshold Adjustment for ABC Stops

Adjusting the asymmetrical threshold for ABC stops.

CV #142: High-Speed Correction for ABC Stops

CV #142 for high-speed correction in ABC asymmetrical stops.

DC Brake Sections (Märklin Brake Mode)

Classic Automated Control Methods

Classic methods for automated layout control or stopping at signals.

Settings for Track-Polarity Dependent DC Brake Sections

Settings for track-polarity dependent DC brake sections.

Settings for Polarity Independent DC Brake Sections

Settings for polarity independent DC brake sections (Märklin).

Distance Controlled Stopping

Selecting Constant Stopping Method (CV #140)

Selecting constant stopping method using CV #140.

Suitability for Red Signals and HLU/ABC

Method suitability for red signals and HLU/ABC influences.

Distance Controlled Stopping for Manual Driving

Distance controlled stopping activation for manual driving.

CV #141: Setting Constant Stopping Distance

CV #141 for setting the constant stopping distance.

CV #142: High-Speed Compensation for HLU

CV #142 for high-speed compensation with HLU.

Shunting, Half-Speed, and MAN Functions

Prototypical Acceleration/Deceleration (CVs #3, #4, #121-123)

Prototypical acceleration/deceleration using various CVs.

Temporarily Reducing Momentum with Function Keys

Temporarily reducing or eliminating momentum with function keys.

CV #124: Shunting Key Functions Summary

CV #124 summarizes shunting key functions.

Preferred CVs for Shunting/MAN Functions

CVs #155, #156, #157 are preferred for shunting/MAN functions.

Shunting Key Functions: Low Gear and Momentum

Shunting key functions for low gear activation and momentum.

NMRA-DCC Function Mapping

Function Outputs (FO) Overview

ZIMO decoders have 8 or 14 function outputs (FO).

Controlling Loads via Function Keys

Controlling loads (lights, smoke generators) using function keys.

Limitations of NMRA Function Mapping

Limitations include 8-Bit register and directional headlights.

CVs #33 to #46 for NMRA Function Mapping

CVs #33 to #46 for specifying NMRA function mapping.

Modified NMRA Function Mapping

Example of Function Mapping Modification

Example showing modification of function mapping.

CV #61 for Alternative Function Mapping

CV #61 offers alternative function mapping without left shifts.

Direction Dependent Taillights with Special Effect CVs

Using special effect CVs for direction dependent taillights.

Example 1: Red Taillights Switched with F1

Example 1: Red taillights switched with F1, changing direction.

Example 2: Headlights and Taillights Switched with F0/F1

Example 2: Headlights and taillights switched together with F0/F1.

Unilateral Light Suppression

Feature for Switching Off Lighting on One Side

Feature to switch off lighting on one side of a locomotive with a function key.

CV #107: Light Suppression (Front)

CV #107 for light suppression on cab side 1 (front).

CV #108: Light Suppression (Rear)

CV #108 for light suppression on cab side 2 (rear).

CV #109, #110: Additional FU-output Suppression

CVs #109 and #110 for suppressing additional function outputs.

The "Swiss Mapping"

Purpose of Swiss Mapping

Swiss mapping allows operation of locomotive lighting for Swiss locomotives.

Swiss Mapping for Various Lighting States

Switching lighting states for single loco, cars coupled, shunting etc.

Requirements for Swiss Mapping

Requires many independently connected lights and decoder function outputs.

CV Groups for Swiss Mapping

Lighting states defined by 13 CV groups, each with 6 CVs.

CV #430: Swiss Mapping Group 1 "F-Key"

CV #430 defines F-Key for Swiss Mapping Group 1.

CV #431: Swiss Mapping Group 1 "M-Key"

CV #431 defines M-Key for Swiss Mapping Group 1.

CV #432: Swiss Mapping Group 1 "A1" Forward

CV #432 defines A1 forward function output for Swiss Mapping.

CV #433: Swiss Mapping Group 1 "A1" Forward (Additional)

CV #433 defines additional A1 forward function output.

CV #434: Swiss Mapping Group 1 "A2" Reverse

CV #434 defines A2 reverse function output for Swiss Mapping.

CV #435: Swiss Mapping Group 1 "A2" Reverse (Additional)

CV #435 defines additional A2 reverse function output.

CV #399: Speed Dependent Headlights

CV #399 for speed dependent headlights (Rule 17).

Swiss Mapping CV Configuration Example

Application of Swiss Mapping Shown with SBB Re422 Example

Application of Swiss mapping shown with an SBB Re422 example.

Function Outputs and Keys in Swiss Mapping

Function outputs and keys used in Swiss Mapping.

CV Configuration Example for Swiss Mapping

Example CV configurations for Swiss Mapping.

ZIMO "Input-Mapping"

Overcoming NMRA Function Mapping Limitations

Overcoming NMRA mapping limitations with ZIMO input mapping.

Adapting Function Keys and Sound Functions

Adapting function keys to operator wishes without changing sound projects.

CVs #400, #401, #428: Input Mapping

CVs #400, #401, #428 for input mapping.

Dimming Functionality (CV #60)

CV #60 for PWM dimming of function outputs.

Dim Mask 1 (CV #114)

CV #114 to exclude outputs from dimming.

Dimming, Low Beam, and Direction Bits

Connecting Devices Requiring Reduced Voltage

Connecting devices needing reduced voltage (e.g., 18V bulbs).

PWM Voltage Reduction with CV #60

Using PWM duty cycle for voltage reduction via CV #60.

Dim Mask 2 (CV #152)

CV #152 for excluding specific outputs from dimming.

Low/High Beam with Low Beam Mask

Defining Function Keys for Low Beam

Using F6 (CV #119) or F7 (CV #120) as low beam key.

CV #119: Low Beam Mask for F6

CV #119 for assigning function outputs for low/high beam.

CV #120: Low Beam Mask for F7

CV #120 for assigning function outputs for low/high beam.

Alternative Low Voltage Supply with Uncoupler CV

Using CV #115 for alternative low voltage supply.

Flasher Effect

Flasher Functions and CV Assignment

Flasher functions assigned using CV #118.

CV #117: Flasher Functions

CV #117 defines duty cycle for flasher function.

CV #118: Flashing Mask

CV #118 defines which outputs operate as flashers.

F1-Pulse Chains (Only for old LGB products)

CV #112: Special ZIMO Configuration Bits

CV #112 for special ZIMO configuration bits, including pulse chains.

Special Effects for Function Outputs

Assigning Special Effects to Function Outputs

Assigning special effects to 10 function outputs using CVs.

6-Bit Effects Code and 2-Bit Direction Code

Understanding the 6-bit effects code and 2-bit direction code.

No Effect and Directional Effects Codes

Codes for no effect, and directional effects.

Special Effects Examples (Mars Light, Random Flicker)

Examples of special effects like Mars light and random flicker.

CV #125: Special Effects (Front Headlight)

CV #125 for special effects on front headlight.

CV #126: Special Effects (Rear Headlight)

CV #126 for special effects on rear headlight.

CVs #127-132: Special Effects for FO1-FO6

CVs #127-132 for special effects on function outputs FO1-FO6.

CVs #159, #160: Special Effects for FO7, FO8

CVs #159, #160 for special effects on function outputs FO7, FO8.

CV #62: Effects Modifications

CV #62 for effects modifications.

CV #63: Light Effects Modification

CV #63 for light effects modification.

CV #64: Effects Modifications

CV #64 for effects modifications.

CV #393: ZIMO Config. 5

CV #393 for ZIMO configuration.

Smoke Generators Without Fan

Intensity Control for Smoke Generators

Intensity can be programmed for standstill, cruising, acceleration.

Connecting Smoke Generators to Function Outputs

Connecting generators to FO1-FO8 and programming effect CVs.

CVs #137, #138, #139: Smoke Generator Characteristics

CVs #137-139 define smoke generator characteristics.

CV #351: Exhaust Fan Speed at Cruising Speed (Diesel)

CV #351 defines exhaust fan speed at cruising for diesel engines.

CV #352: Exhaust Fan Speed at Acceleration (Diesel)

CV #352 defines exhaust fan speed during acceleration for diesel engines.

CV #353: Automatic Smoke Generator Shutdown

CV #353 for automatic smoke generator shutdown.

CV #355: Exhaust Fan Speed at Standstill

CV #355 defines exhaust fan speed at standstill.

Configuration of Electric Uncouplers

System KROIS and System ROCO

Uncoupler control defined by CVs #115 and #116.

Notes on Automated Uncoupling ("Coupler Waltz")

Automated train disengagement and coupler unloading.

CV #115: Uncoupler Control (Pull-in Time)

CV #115 controls uncoupler pull-in time and hold voltage.

CV #116: Automatic Disengagement during Uncoupling

CV #116 controls automatic disengagement during uncoupling.

Massoth Coupler

Massoth Coupler Connection

Connection details for the Massoth coupler.

Massoth Coupler Operation and CV Usage

Massoth coupler operation and required CV programming.

Reasons for Using "Uncoupler" Function Effect

Reasons to use the 'uncoupler' function effect anyway.

Servo Configuration

Servo Output Protocol and SUSI Use

Servo protocol settings and alternative SUSI use.

CV #161: Servo Protocol Settings

CV #161 for servo protocol and alternative SUSI use.

Servo Stop Position Settings (CV #162-169)

CVs #162-169 for setting servo stop positions and speed.

Servo Action Assignment (CV #181-184)

CVs #181-184 for assigning servo actions.

Special Assignment for Live Steam Engines (CV #185)

CV #185 for special servo assignments in live steam engines.

Feedback – Bidirectional Communication

ZIMO Decoder Feedback Features

ZIMO decoders feature feedback since DCC formation.

ZIMO Loco Number Identification

ZIMO loco number identification capability.

Bidirectional Communication (RailCom)

All ZIMO decoders are ready for bidirectional RailCom communication.

RailCom Configuration CVs

Relevant CVs for RailCom configuration.

CV #28: RailCom Configuration

CV #28 for RailCom configuration settings.

CV #29: Base Configuration Data

CV #29 for base configuration data.

CV #136: Feedback Speed Setting

CV #136 for setting feedback speed via RailCom display factor.

CV #158: Special Bits + RailCom Variants

CV #158 for special bits and RailCom variants.

RailCom Activation Requirements

RailCom activated with CV #29, Bit 3=1 and CV #28=3.

ZIMO SOUND – Selection and Programming

Sound Projects: Types and Customization

Types of sound projects: Ready to use, Full featured, Sound Collections.

ZIMO Sound Database Projects

Projects available from ZIMO sound database: Free D'load, Coded, Preloaded.

Selecting Loco Type with CV #265

CV #265 for selecting loco type in sound collection.

Operating Sound Decoder with "Euro Steam/Diesel" Collection

Operating sound decoder with Euro steam/diesel collection.

Function Key Allocations for Sound

Allocating sounds to function keys (F2-F11).

Stationary Sounds for Random Generator

Stationary sounds allocated to the random sound generator.

Sound Project Components

Main Engine or Driving Sound

The central sound component, like chuff or cooling fan.

Other Scheduled Sounds

Sounds like boiling, draining, brake squeals activated by driving situation.

Function Sounds

Sounds activated by function keys (whistles, horns, bells).

Switch Input and Random Sounds

Sounds triggered by switch inputs or random generators.

CV #300 Procedures

Introduction to CV #300 Procedures

Modifying loaded sound projects during operation using CV #300.

Procedure for Sound Sample Selection

Procedure for selecting sound samples, using function keys.

Function Key Meanings during Selection Procedure

Special meanings of function keys during sound selection.

Acoustic Signals for Selection Procedure Support

Acoustic signals (cuckoo jingle) supporting the selection procedure.

Sound Sample Allocation to Function Keys

Initiating Sound Sample Allocation (CV #300)

Allocating sound samples to function keys F1-F19 using CV #300.

Sound Sample Allocation Procedure

Procedure for allocating sound samples to function keys.

Function Key Meanings during Allocation

Special meanings of function keys during sound allocation.

Sound Sample Allocation to Random Generators

Random Generator Sound Sample Allocation (CV #300)

Allocating sound samples to random generators Z1-Z8 using CV #300.

Switch Input Sound Sample Allocation

Allocating sound samples to switch inputs S1, S2, S3.

Incremental Programming of Sound CVs

Introduction to Incremental Programming

Incremental programming for optimizing sound effects.

Using Function Keys for Incremental Programming

Function keys temporarily assigned for incremental programming.

CV #301: Grouped Incremental Programming

CV #301 for incremental programming of CVs #266, #267, #268.

Function Key Meanings for Incremental Programming

Special meanings of function keys during incremental programming.

Test Run for Determining Motor's Basic Load

Purpose of Motor's Basic Load Test

Test to determine basic load for adjusting driving sound to engine load.

Technical Background of Load Dependency

How EMF measurements are used for load dependency.

Initiating Test Run with Pseudo-Programming

Initiating automated test run using Pseudo-Programming.

Calibration Run Requirements

Requirements for calibration run (track length, no inclines/curves).

CV #302: Test Run Initiation

CV #302 for initiating test runs.

CV #302: Reverse Direction Calibration

CV #302 for calibrating reverse direction.

Storing Measured Results (CVs #777-780)

Storing measured results in CVs #777, #778, #779, #780.

Note on Heavy Trains and Basic Load

Note on how heavy trains affect basic load.

Basic Settings Independent of Powertrain

Note on Default CV Values and HARD RESET

Note on default CV values and effect of HARD RESET.

CV #265: Select Loco Type

CV #265 for selecting loco type in sound collections.

CV #266: Total Volume

CV #266 for setting total volume.

CV #395: Driving Sound Volume (Multiplier)

CV #395 for adjusting driving sound volume.

CV #310: ON/OFF Key for Engine and Random Sound

CV #310 defines ON/OFF key for engine and random sounds.

CV #312: Blow-off Key

CV #312 defines the blow-off key.

CV #354: Steam Chuff Frequency at Speed Step 1

CV #354 for steam chuff frequency at speed step 1.

Steam Engine: Basic Sound Settings

Volume Adjustments for Background Sounds

Volume adjustments for background sounds (boiling, brake squeal etc.).

Volume Adjustments for Function Sounds

Volume adjustments for function sounds (whistles, bells etc.).

Volume Adjustments for Switch Input Sounds

Volume adjustments for sounds activated by switch inputs.

Steam Engine: Load and Acceleration Dependency

Load Dependency Basis and Procedure

Sound load dependency based on engine load and accel/decel settings.

Note on ZIMO Decoders' Position and Acceleration Sensor

Decoders' position/acceleration sensor improves load dependency.

Steps for Setting Load Dependent Sound

Steps to set up load dependent sound.

Note on Default CV Values and HARD RESET

Guideline values for CVs; HARD RESET restores project defaults.

CV #275: Chuff Volume at Low Speed

CV #275 for chuff volume at low speed and no-load.

CV #276: Chuff Volume at High Speed

CV #276 for chuff volume at high speed and no-load.

CV #277: Chuff Volume Change According to Load

CV #277 for adjusting chuff volume based on load.

CV #278: Load Change Threshold

CV #278 for load change threshold.

CV #279: Reaction Time to Load Change

CV #279 for reaction time to load changes.

CV #281: Acceleration Threshold for Full Load Sound

CV #281 for acceleration threshold for full load sound.

CV #282: Duration of Acceleration Sound

CV #282 for duration of acceleration sound.

Diesel and Electric Engines: Sound Components

Diesel Motor Sound, Turbocharger, Thyristor, Electric Motor, Switchgear

Description of sound components for diesel and electric engines.

CV #266: Total Volume

CV #266 for setting total volume.

CV #280: Diesel Engine Load Influence

CV #280 determines diesel sound reaction to load.

CV #154: Various Special Bits (DIESEL/ELECTRO)

CV #154 for special bits affecting diesel/electro sounds.

CV #158: Special Bits (Functions, RailCom)

CV #158 for special bits related to functions and RailCom.

CV #345: SHIFT Key for Sound Variations

CV #345 defines SHIFT key for switching sound variations.

CV #346: Prerequisite for Switching Collections

CV #346 for switching sound collections.

CV #347: Key for Solo Driving and Sound Performance

CV #347 defines key for solo driving and sound performance.

CV #348: Switch-over Parameters for Selected Key

CV #348 sets parameters for switch-over key.

CV #387: Influence of Acceleration on Diesel Sound

CV #387 for influence of acceleration on diesel sound steps.

Diesel Engine Sound Adjustments

CV #388: Influence of Deceleration on Diesel Sound

CV #388 for influence of deceleration on diesel sound steps.

CV #389: Acceleration Influence Limitation

CV #389 limits acceleration influence over diesel sound steps.

CV #390: Momentum Reduction for Solo Driving

CV #390 reduces momentum when driving solo.

CV #391: Speed Drop During Upshifts

CV #391 defines speed drop during upshifts for diesel engines.

CV #366: Maximum Turbo Sound Volume

CV #366 sets maximum turbo sound volume for diesel engines.

CV #367: Turbo RPM Dependency on Speed

CV #367 adjusts turbo RPM dependency on speed.

Electric Engine Sound Adjustments

CV #295: Thyristor Control Volume During Deceleration

CV #295 for thyristor volume during deceleration.

CV #357: Thyristor Control Lowering Volume at Higher Speeds

CV #357 for lowering thyristor volume at higher speeds.

CV #358: Thyristor Control Volume Reduction Curve

CV #358 for thyristor volume reduction curve.

CV #362: Thyristor Control Switchover Threshold

CV #362 for thyristor control switchover threshold.

CV #296: Electric Motor Sound Maximum Volume

CV #296 for maximum electric motor sound volume.

CV #297: Electric Motor Sound Audible Threshold

CV #297 for when electric motor sound becomes audible.

CV #298: Electric Motor Sound Volume Dependent on Speed

CV #298 for electric motor sound volume dependent on speed.

CV #299: Electric Motor Sound Pitch Dependent on Speed

CV #299 for electric motor sound pitch dependent on speed.

CV #350: Switchgear Sound Lock-out

CV #350 for switchgear sound lock-out after start-up.

CV #359: Switchgear Sound Playback Duration (Speed Changes)

CV #359 for switchgear sound playback duration during speed changes.

CV #360: Switchgear Sound Playback Duration (Stop)

CV #360 for switchgear sound playback duration after stop.

CV #361: Switchgear Sound Playback Delay

CV #361 for switchgear sound playback delay.

CV #363: Switch Gear Sound Shifting Steps

CV #363 for dividing speed into shift steps for switch gear sound.

CV #380: Manual Electric Brake Key

CV #380 for manual electric brake key control.

CV #381: Electric Brake

CV #381 for electric brake.

Electric Brake Settings

CV #382: Electric Brake Maximum Speed

CV #382 for electric brake maximum speed.

CV #383: Electric Brake Pitch

CV #383 for electric brake pitch.

CV #384: Electric Brake Deceleration Threshold

CV #384 for electric brake deceleration threshold.

CV #385: Electric Brake Downhill

CV #385 for electric brake downhill behavior.

CV #386: Electric Brake Loops

CV #386 for electric brake loops.

Coasting and Notching Functions

Coasting/Notching for Engine Sound Control

Coasting/Notching functions for engine sound not derived from speed/load.

CV #374: Coasting-Key Activation

CV #374 activates Coasting function with a key.

CV #375: Coasting-Step Definition

CV #375 defines sound speed for coasting.

CV #398: Automatic Coasting

CV #398 for automatic coasting effect.

Random and Switch Input Sounds

Random Generator Interval Settings

CV #315 defines the shortest interval for random generator Z1.

CV #315: Minimum Interval for Random Generator Z1

CV #315 for minimum interval of random generator Z1.

CV #316: Maximum Interval for Random Generator Z1

CV #316 for maximum interval of random generator Z1.

CV Summary List

CV #1: Short Address

The short address; active when Bit 5 in CV #29 is 0.

CV #2: Start Voltage

Internal speed step for lowest external speed step.

CV #3: Acceleration Rate

Multiplied by 0.9 equals acceleration time.

CV #4: Deceleration Rate

Multiplied by 0.9 equals deceleration time.

CV #5: Top Speed

Internal speed step for highest external speed step.

CV #6: Medium Speed

Internal speed step for medium external speed step.

CV #7: SW-Version Number

The current SW number; for subversion see CV #65.

CV #8: Manufacturer ID, Reset, Set

Manufacturer ID, Reset functions, given by NMRA; CV #8=8 Hard Reset.

CV #9: Motor Regulation

Sample time (tens digit), sample rate (ones digit).

CV Summary List (Continued)

CV #10: Compensation-Cutoff

Internal speed step for BEMF intensity per CV#113.

CV #57: Voltage Reference

Value = 1/10 of fixed voltage. "0" = track voltage.

CV #58: BEMF Intensity

Load compensation at low speeds.

CV #59: HLU Reaction Time

Delay for HLU changes, in tenth of a second.

CV #60: Dimming

Reduction of function output voltage through PWM.

CV #61: ZIMO Extended Mapping

Configurations not covered by NMRA mapping.

CV #62: Light Effects Modification

Adjusts minimum dim value.

CV #63: Light Effects Modification

Cycle time (tens digit), Off-time extension (ones digit).

CV #64: Light Effects Modification

Ditch light off-time modification.

CV #65: SW Subversion Number

Completes the version number in CV #7.

CV #66: Forward Trimming

Multiplies speed step by trim value/128.

CVs #67-94: Free Speed Table

Internal speed step for each of the 28 external steps.

CV #95: Reverse Trimming

Multiplies speed step by trim value/128.

CV #96: User Data

Free memory space for user data.

CV #107: Light Suppression (Cab 1 Forward)

Light suppression for cab 1 (forward).

CV #108: Light Suppression (Cab 2 Rear)

Light suppression for cab 2 (rear).

CV #112: Special ZIMO Configuration Bits

Special ZIMO configuration bits.

CV #113: BEMF Reduction

BEMF reduction.

CV #114: Dim Mask 1

Dim Mask 1.

CV #115: Uncoupler Control

Uncoupler control.

CV #116: Automatic Uncoupling

Automatic uncoupling.

CV #117: Flasher

Flasher.

CV #118: Flasher Mask

Flasher mask.

CV #119: F6 Low Beam Mask

F6 low beam mask.

CV #120: F7 Low Beam Mask

F7 low beam mask.

CV Summary List (Continued)

CV #121: Exponential Acceleration

Speed range included (Tens digit), curve (Ones digit).

CV #122: Exponential Deceleration

Speed range included (Tens digit), curve (Ones digit).

CV #123: Adaptive Acceleration/Deceleration

Accel. Convergence (Tens dig.), Decel. Conv. (Ones...).

CV #124: Shunting Keys, Outputs instead of SUSI

Shunting key (for half speed, accel. deactivation), Switch between SUSI.

CV #125: Effects FO Front

Effects FO Front.

CV #126: Effects FO Rear

Effects FO Rear.

CV #127: Effects F1

Effects F1.

CV #128: Effects F2

Effects F2.

CV #129: Effects F3

Effects F3.

CV #130: Effects F4

Effects F4.

CV #131: Effects F5

Effects F5.

CV #132: Effects F6

Effects F6.

CV #134: Asymmetrical Stops (ABC)

Sensitivity (Hundredth), Threshold (Tens, ones digit).

CV #135: km/h Control

Calibration run; Relation km/spd. step.

CV #136: km/h Control / RailCom Contr. value

Calibration value after calibration run; or correct. value for RailCom.

CV #144: Prog./ Update Lock

Bit 6=1: Service mode-Lock, Bit 7=1: Update-Lock.

CV #145: Gear Backlash Compensation

Hundredth of a second at min. speed after dir.-change.

CV #146: Experimental-CVs

Special motor regulation settings.

CV #151: Motor Brake

Force and speed of application.

CV #152: Dim Mask 2

Individual outputs exempted from dimming per CV #60.

CV #153: Continue w/o signal

Tenth of seconds: stop after losing DCC signal.

CV #154: Special OEM-Bits

Special OEM-Bits.

CV #155: Half-speed Key Selection

Function key selection (instead of CV #124).

CV #156: Momentum Deactivation Key Selection

Function key selection (instead of CV #124).

CV #157: MAN Key Selection

Function key selection.

CV #158: Several Sound Bits + RailCom Variants

RailCom speed feedback methods.

CV #159: Effects on F7

Same as CVs #125-132 but for F7 and F8.

CV #160: Effects on F8

Same as CVs #125-132 but for F7 and F8.

CV #161: Servo Protocol

Servo protocol settings.

CV #162: Servo 1 Left Stop

Defines left stop position.

CV #163: Servo 1 Right Stop

Defines right stop position.

CV #164: Servo 1 Center Stop

Defines center position for 3-position control.

CV #165: Servo 1 Speed

Time in tenth of seconds between left and right stop.

CV #166: Servo 2 Left Stop

Defines left stop position.

CV #167: Servo 2 Right Stop

Defines right stop position.

CV #168: Servo 2 Center Stop

Defines center position for 3-position control.

CV #169: Servo 2 Speed

Time in tenth of seconds between left and right stop.

CV #170: Servo 3 Left Stop

Defines left stop position.

CV #171: Servo 3 Right Stop

Defines right stop position.

CV #172: Servo 3 Center Stop

Defines center position for 3-position control.

CV #173: Servo 3 Speed

Time in tenth of seconds between left and right stop.

CV #174: Servo 4 Left Stop

Defines left stop position.

CV #175: Servo 4 Right Stop

Defines right stop position.

CV #176: Servo 4 Center Stop

Defines center position for 3-position control.

CV #177: Servo 4 Speed

Time in tenth of seconds between left and right stop.

CV #181-184: Servo Operation Modes

Operating modes (One key, two keys ...).

CV #185: Special Live Steam Engine Settings

Operating settings for live steam engines.

CV #186-189: Special Pantograph Configurations

Pantograph settings for special projects.

CV #190-191: Dimming Times with Effect 88

Turn-ON/OFF times for effects 88, 89 and 90.

Service Instructions

Troubleshooting Decoder Failures

Common reasons for decoder failures and troubleshooting steps.

Recommended Action Before Sending for Repair

Read out important data before sending decoder for repair.

Required Information for Repair Submission

Required information for submitting a defective decoder for repair.

Additional Information for Defective Decoder Submission

Verify Defect Before Shipment

Verify defect, check for configuration errors or simple remedies.

Warning: Simulated Defects

Warning about simulated defects due to sound project/CV table mismatches.

Contact ZIMO Service for Poor Drivability

Contact ZIMO service for issues related to poor drivability.

Decoder Repair Policy

ZIMO only accepts decoders for repair, not complete engines.

Detailed Defect Description Requirement

Requirement for detailed description of the defect or reason for return.

OEM Decoder Repair Considerations

OEM decoder repair handled by ZIMO service department.

Using Original OEM Sound Project in Replacement Decoder

Using original OEM sound project in replacement decoders.

Preloaded Sound Projects - Direct Supplier Contact

Preloaded sound projects usually require contacting original supplier.

ZIMO Repair Form Download

Download link for the ZIMO repair form.

Need help?

Do you have a question about the MX699 and is the answer not in the manual?

Questions and answers