Table of Contents

Summarization of Contents

Introduction

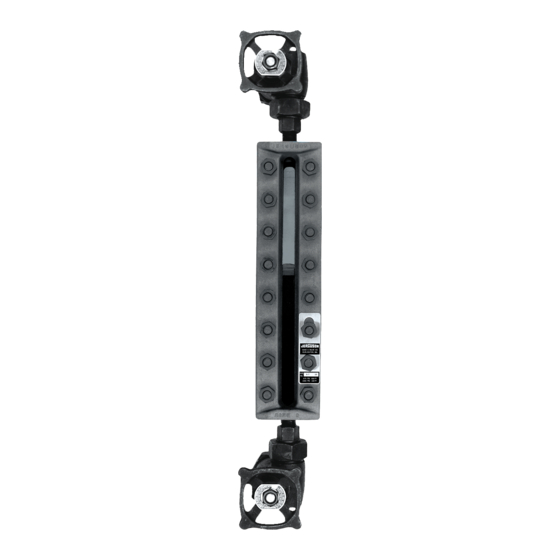

Flat Glass Gages (Armored Gages)

Describes Jerguson Flat Glass Gages as simple, rugged instruments for accurate liquid level readings in diverse applications.

Bringing Gage Into Service

Valve Opening Procedure

Details the step-by-step process for safely opening isolation valves and bringing the gage into service.

Maintenance

Inspecting Glass

Guides on visually checking the gage glass for clouding, scratches, or chemical attack for potential replacement.

Cleaning Glass

Provides instructions on cleaning gage glasses using commercial cleaners or dilute acids without removing the glass.

Receiving / Storing Glass

Advises on inspecting, handling, and storing replacement glass carefully to prevent damage.

Disassembly

Outlines precautions before disassembling the gage, emphasizing depressurization and ambient temperature.

Reassembly

Refers to cutaway diagrams showing the construction of Reflex and Transparent glass gages.

Special Applications

Spring Washers for Temperature Extremes

Explains using Belleville spring washers to maintain gasket loading in extreme temperature applications.

Shields for Protection from Chemical Attack

Details the use of PCTFE or mica shields for transparent gage glasses with corrosive fluids.

Vacuum Service

States that glass gages are suitable for vacuum service if they do not have a PCTFE shield.

High / Low Temperature Service

Recommends uniform insulation for gages in high/low temperature service to prevent thermal stress.

Operation in Low Temperature Service

Advises slow warm-up procedures for gages in low-temperature service to prevent thermal shock.

Need help?

Do you have a question about the 20 Series and is the answer not in the manual?

Questions and answers