Table of Contents

Advertisement

®

Installation, Operation and Maintenance Manual

Please read and save these instructions for future reference. Read carefully before attempting to assemble,

install, operate or maintain the product described. Protect yourself and others by observing all safety

information. Failure to comply with these instructions will result in voiding of the product warranty and may

result in personal injury and/or property damage.

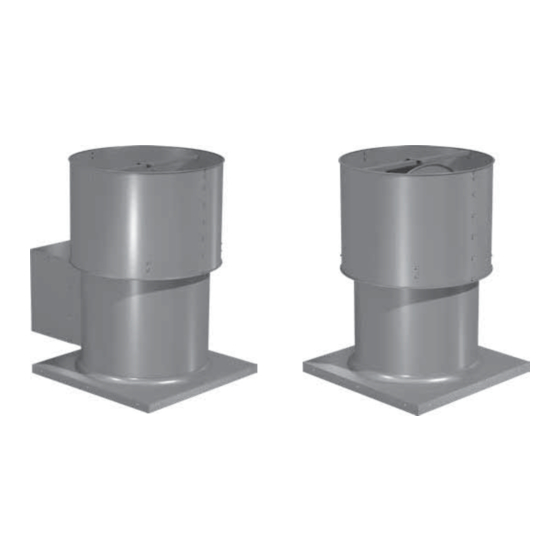

TAUB

General Safety Information

Only qualified personnel should install this fan.

Personnel should have a clear understanding of these

instructions and should be aware of general safety

precautions. Improper installation can result in electric

shock, possible injury due to coming in contact with

moving parts, as well as other potential hazards.

Other considerations may be required if seismic

activity is present. If more information is needed,

contact a licensed professional engineer before

moving forward.

1. Follow all local electrical and safety codes, as

well as the National Electrical Code (NEC) and the

National Fire Protection Agency (NFPA), where

applicable. Follow the Canadian Electric Code

(CEC) in Canada.

2. The rotation of the propeller is critical. It must

be free to rotate without striking or rubbing any

stationary objects.

3. Motor must be securely and adequately grounded.

4. Do not spin fan propeller faster than max

cataloged fan RPM. Adjustments to fan speed

with a Variable Frequency Drive (VFD) may affect

motor load. If the fan RPM is changed, the motor

current should be checked to make sure it is not

exceeding the motor nameplate amps.

5. Do not allow the power cable to kink or come in

contact with oil, grease, hot surfaces or chemicals.

Replace cord immediately if damaged.

6. Verify that the power source is compatible with the

equipment.

®

TAUD

7. Never open access doors to a duct while the fan is

running.

Always disconnect, lock and tag power source

before installing or servicing. Failure to disconnect

power source can result in fire, shock or serious

injury.

When servicing the fan, motor may be hot enough

to cause pain or injury. Allow motor to cool before

servicing.

Precaution should be taken in explosive

atmospheres.

Pour écarter les risques d'incendie, de choc

électrique ou de blessure grave, veiller à toujours

débrancher, verrouiller et étiqueter la source de

courant avant l'installation ou l'entretien.

Lors de toute intervention sur la soufflante, le moteur

peut être suffisamment chaud pour provoquer

une douleur voire une blessure. Laisser le moteur

refroidir avant toute maintenance.

Faire preuve de précaution dans les atmosphères

explosives.

Document 453905

Models TAUD, TAUB-CA and TAUB

Tube Axial Upblast Fans

DANGER

CAUTION

CAUTION

DANGER

ATTENTION

ATTENTION

Tube Axial Upblast Fans

1

Advertisement

Table of Contents

Summarization of Contents

General Safety Information

Power Disconnection Safety

Always disconnect, lock, and tag power source before installing or servicing to prevent fire, shock, or serious injury.

Motor Cooling Caution

Allow motor to cool before servicing as it may be hot enough to cause pain or injury.

Explosive Atmosphere Precaution

Take precautions when working in explosive atmospheres.

Receiving, Unpacking, Handling, and Storage

Receiving Procedure

Inspect all items upon receipt for completeness and shipping damage before accepting delivery.

Unpacking Verification

Verify all required parts and correct quantities; report any missing items to the local representative.

Handling and Rigging

Rig and move fans using provided brackets or skid, handle carefully to avoid finish damage.

Storage Guidelines

Store fans indoors in a low humidity environment, above grade, and at stable temperatures.

Storage Inspection and Maintenance

Inspect fans monthly, rotate propeller, energize motor, and check for moisture or dirt accumulation.

Removing from Storage

Pre-Assembly Checks

Check fasteners, set screws, propeller rotation, and ensure no parts are rubbing before assembly.

General Information

Unit Identification Tags

Locate and use manufacturer's engraved metal nameplate for model and serial number information.

Pre-Installation Requirements

Verify mounting surface can bear fan weight and ensure the fan is operated in a level position.

Electrical Disconnects

Ensure disconnects are located near motors for shut-off and locked-out during maintenance.

Moving Parts Safety

All moving parts must have guards; secure fan propeller before maintenance; check for free rotation.

Guards and Protective Devices

Do not operate fans without protective devices; check local codes for compliance.

Inspection Door Operation

Ensure fan propeller has stopped and is secured before opening inspection door; keep door closed.

Inlet Air Pressure and Suction

Fans create suction at the inlet; exercise caution around fans and ensure inlet area is clear of objects.

Fans Rigging and Lifting

Lifting Procedures

Use all lifting brackets, keep fan level, test-lift, and avoid lifting in windy conditions.

Handling and Finish Protection

Rig using brackets or skid; handle to avoid scratching or chipping the coating to prevent corrosion.

Electrical Connections

General Requirements

Supply compatibility, proper fusing, adherence to local/national codes are essential.

Direct Drive Wiring

Route supply internally via provided hole with optional disconnect switch.

Belt Drive Wiring

Route supply internally or connect to disconnect switch/motor directly.

High Temp/Smoke Exhaust Wiring

Keep supply lines out of airstream; may require isolated power for smoke exhaust.

Fusible Link Damper Lifter Safety

Damper Lifter Precautions

Disconnect power, use caution around lifters, they may release dampers unexpectedly.

High Tension Damper Lifter Pinning

Extra heavy duty lifters on specific models must be pinned to prevent accidental tripping during servicing.

Pinning Procedure Illustration

Figures 2A and 2B illustrate safety pin placement for servicing versus in-service states.

Unit Start-Up Procedures

Pre-Operation Safety

Disconnect and secure all electrical power to the OFF position before any inspection or servicing.

Initial Equipment Verification

Verify equipment matches order and electrical specifications; report discrepancies immediately.

Pre-Start-Up Checklist

Confirm voltage, check piping, rotate propeller, check fasteners, alignment, guarding, and connections.

Initial Start-Up Steps

Check fasteners, propeller rotation, and adjust fan RPM while monitoring motor amperage.

Making Electrical Connections

Ensure supply voltage/phase/amperage compatibility; connect wiring to disconnect switch or motor.

Routine Maintenance and Operation

Pre-Operation Safety

Disconnect and secure all electrical power to the OFF position before any inspection or servicing.

Fan Operation Frequency

Run or 'bump' fans every thirty days to ensure components are up to temperature and grease is redistributed.

Operating Condition Changes

Consult manufacturer before changing operating speed, pressure, or temperature for safe operation.

Motor Maintenance

Limit cleaning to exterior surfaces; lubricate motors with fittings per recommendations; replace grease after 2000 hours.

Fastener Tightness

Periodically inspect and tighten all fasteners and set screws due to normal fan vibration.

Direct Drive Lubrication

Lubricate motors only when fittings are provided; many are permanently lubricated.

Belt Drive Bearings

Inspect bearings, locking collars, and set screws at regular intervals for proper function.

Belt Drive Lubrication

Lubricate bearings semiannually with high-quality grease; use special grease for extreme temperatures.

Belt Drive Belt Checks

Check V-belts for wear, tension, alignment; replace belts in sets; do not pry belts on or off.

V-Belt Replacement and Alignment

V-Belt Replacement Procedure

Procedure for replacing V-belts, including shaft preparation, sheave alignment, and tensioning.

Pulley and Belt Alignment

Check pulley and belt alignment for proper operation, avoiding wear, noise, and power loss.

Field Coating Touch-Up and VFD Operation

Field Coating Touch-Up

Procedure for repairing minor scratches in the coating using primer and topcoat.

Variable Frequency Drive (VFD) Operation

Check motor amps when adjusting VFD frequency; do not exceed maximum class fan RPM.

VFD Resonant Frequency Testing

Perform coast-down tests to identify and remove resonant frequencies from the operating range.

Parts List and Identification

Model Identification

Fans have embossed nameplates with model/serial numbers for service and replacement parts.

Explosion Resistant Motor

A fan with an explosion-resistant motor does not certify the entire unit as explosion-proof.

Component Identification

Diagram showing key components of the fan assembly for reference.

Need help?

Do you have a question about the TAUD and is the answer not in the manual?

Questions and answers