Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summarization of Contents

Chapter 1 Introduction & Safety

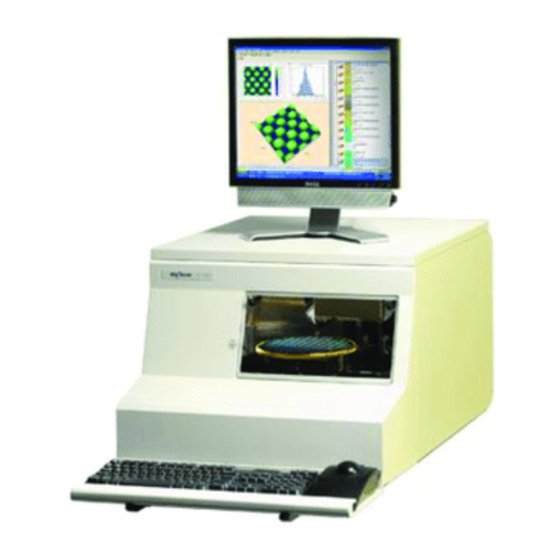

INSTRUMENT OVERVIEW

Provides a summary of the P-16+/P-6 Profiler system's capabilities and head configurations.

SAFETY

Outlines critical safety information, including warnings, cautions, and lockout/tagout procedures.

Chapter 2 Basic Skills

OVERVIEW

Introduces fundamental skills for operating the P-16+/P-6 Profiler, including system startup and application usage.

ERGONOMIC CONSIDERATIONS

Details best practices for ergonomic setup and keyboard usage to ensure user safety and comfort.

POWERING UP THE PROFILER

Explains the step-by-step procedure for turning on the computer and launching the Profiler software.

LOGGING INTO PROFILER SECURITY

Guides users through the process of logging into the Profiler system security using valid credentials.

STARTING THE PROFILER APPLICATION

Describes how to launch the Profiler application, which serves as the interface for scan operations.

Chapter 3 Scan Recipes

INTRODUCTION

Explains the role of recipes in setting scan parameters and enabling high-resolution 2D and 3D scans.

ACCESSING THE SCAN RECIPE CATALOG SCREEN

Details how to navigate and access the primary screen for managing scan recipes.

CREATING AND EDITING A SCAN RECIPE

Provides instructions on accessing the Recipe Editor for creating and modifying scan recipes.

Chapter 4 XY VIEW SCREEN

INTRODUCTION

Introduces the XY View screen, its purpose for sample viewing, positioning, and scan setup.

STARTING THE XY VIEW APPLICATION

Guides users on how to launch the XY View application from the Catalog screen.

SETTING THE MAGNIFICATION

Explains how to adjust the optical zoom function for feature identification and scan placement.

POSITIONING THE SCAN SITE

Covers moving the stage in X, Y, and theta directions for accurate scan positioning.

USING DIE GRID NAVIGATION (OPTIONAL FEATURE, P-16+ ONLY)

Describes how to use die grid navigation for teaching scan and sequence sites by die location.

Chapter 5 View Scan Window

2D SCREEN FUNCTION

Explains the View Scan Window's role in observing scan progress and adjusting parameters for 2D scans.

3D SCREEN FUNCTION

Details the 3D View Scan screen's functionality for 3D analysis and operator monitoring.

Chapter 6 Sequence Recipe and Data

INTRODUCTION

Introduces the Sequence Recipe and Data applications, their capabilities, and components.

STARTING THE SEQUENCE EDITOR APPLICATION

Guides users on how to access and open the Sequence Editor.

CREATING A SEQUENCE RECIPE

Provides a step-by-step procedure for creating a sequence recipe, including die grid navigation.

Chapter 7 Analyzing 3D Scan Data

INTRODUCTION

Explains that 3D scan data analysis displays the 3D scan image and trace information after a scan.

STARTING THE 3D ANALYSIS APPLICATION

Guides users on how to open the Catalog window and select 3D scan data for analysis.

3D ANALYSIS SCREEN FEATURES

Describes the features of the 3D Analysis screen, including image orientation and toolbars.

CUSTOMIZING THE SCAN IMAGE

Explains how to adjust image proportions, shading mode, and scan height colors for better visualization.

CUSTOMIZING THE VIEW

Details how to change image colors, scan height colors, and remove banding using line leveling.

USING IMAGE ARITHMETIC TO COMPARE DATA

Explains how to compare two 3D scans using image arithmetic to evaluate noise and roughness.

SAVING SCAN DATA

Provides instructions on how to save scan data for later review and reanalysis with different parameters.

Creating and Saving 2D Slice Data from a 3D Scan

Guides users on how to create and save 2D slice data from a 3D scan using the Analysis screen tools.

Chapter 8 APEX 2D/3D - GETTING STARTED

INTRODUCTION

Provides information about configuring Apex 2D/3D software to work with the Profiler system.

LICENCE AGREEMENT

Outlines the copyright laws, intellectual property rights, and licensing terms for the software product.

OVERVIEW OF APEX 2D/3D

Introduces the Apex 2D/3D software, its capabilities, and how to start the application.

Starting the Software

Explains how to start the Apex 2D/3D software by clicking the desktop shortcut or Start Menu.

Chapter 9 STRESS (OPTIONAL FEATURE)

Introduction

Explains how stress is generated in films and wafers, and the importance of monitoring film stress data.

THEORY

Discusses the theoretical basis of stress measurement, including the Stoney Equation.

Stoney Equation

Presents the Stoney equation for stress calculation in thin-film layers deposited on a substrate.

Polynomial Fit

Explains the Polynomial Fit method for fitting data to local irregularities and calculating stress.

Least Square Fit

Details the Least Square Fit method for fitting local sections of data to circular arcs for curvature calculation.

Chapter 10 3D STRESS (OPTIONAL FEATURE, P-16+ ONLY)

Introduction

Explains 3D stress analysis capabilities for full wafer stress measurements using Apex software.

Definitions

Defines common terms referenced in the 3D Stress chapter, providing clarity on terminology.

The 3D Stress Application Window

Describes the 3D Stress Catalog window and its navigation buttons for accessing recipes and data.

Creating a 3D Stress Recipe

Guides users on creating new 3D stress recipes using the Stress Catalog window and editor.

Chapter 11 SYSTEM SECURITY

INTRODUCTION

Explains the Profiler system security design for user membership and access control.

KLA-Tencor Operating System Security

Details how the Profiler software integrates with Windows XP security for user and feature control.

LOGIN AND LOGOUT PROCEDURE

Describes how to change access levels by logging off and logging back into the Profiler software.

CONFIGURING KLA-TENCOR SECURITY

Explains how to define security settings using the Security Configuration Editor for access control.

PROCEDURE TO MODIFY SECURITY SETTINGS

Provides steps to navigate and modify security settings within the Security Configuration Editor.

ACCESS POLICY SETTINGS

Details how Access Policy Settings control user access to Windows XP functions and features.

APPLICATION LIFECYCLE

Allows users to define programs that automatically start with Windows XP logon for system convenience.

GLOBAL SETTINGS

Explains how to enable or disable automatic logon into Windows XP for system security and ease of use.

SECURITY GROUPS

Describes the default Windows XP and Profiler software security groups for user access control.

COMPUTER MANAGEMENT/USER ACCOUNTS

Explains the Windows XP security interface for managing user accounts and creating new ones.

Chapter 12 CALIBRATIONS

STANDARD CALIBRATION MATRIX

Outlines the interconnected calibrations and their prerequisites for system accuracy.

APPLIED FORCE CALIBRATION

Details the procedure for calibrating the force applied by the stylus tip to the sample surface.

VIDEO CALIBRATION

Ensures stage position correlates to the video image, calculating video pixels per micron.

SCAN POSITION OFFSET CALIBRATION

Calculates X-, Y-axis offsets for accurate positioning of the sample stage relative to optics and stylus.

STEP HEIGHT CALIBRATION

Describes the automated procedure for calibrating step height for each range using standards.

P-16 SERIES LEVEL CALIBRATIONS

Explains the Tilt and Level calibrations required for parallel stage motion and accurate scans.

Level Calibration Procedure

Provides the automated procedure for performing the Level calibration to ensure stage surface flatness.

WAFER CENTER CALIBRATION

Calibrates the wafer center as the (0,0) reference point for accurate sequence transportability.

Chapter 13 STYLUS CHANGE PROCEDURE

INTRODUCTION

Introduces stylus types, handling requirements, and color-coding for radius identification.

STYLUS REMOVAL AND REPLACEMENT

Contains procedures for changing the stylus in the sensor assembly, emphasizing safe handling.

Stylus Removal

Details the steps for safely removing the current stylus from the sensor assembly.

Stylus Replacement

Guides users on how to properly install a new stylus, including seating and tightening procedures.

Scan Position Offset Calibration

Explains the procedure to calculate X-, Y-axis offsets for accurate sample stage positioning.

Chapter 14 CONFIGURATION

OPERATING ENVIRONMENT

Describes the system's operating environment requirements, including vibration isolation and air space.

SYSTEM GEOMETRY

Displays handler and manual load positions, emphasizing the importance of correct setup.

STAGE CONFIGURATION

Details editable items within the Stage Configuration area, noting which require specific procedures.

LICENSE OPTIONS

Provides the interface for importing and exporting license files based on the tool's MAC address.

RECIPE TRANSPORT OPTIONS

Sets default paths for exporting scan and sequence recipes and data, including path configuration.

SEQUENCE EXECUTION OPTIONS

Automatically saves sequence data under lot ID and/or operator ID, with prompts before each sequence.

PROXIMITY SENSOR CONFIGURATION (P-16+ ONLY)

Explains configurable parameters for the proximity sensor that signals near proximity to the sample surface.

PRECISION LOCATORS (P-16+ ONLY)

Describes fixtures for exact sample positioning, including wafer, disk, and stress precision locators.

Chapter 15 Preventive Maintenance

INTRODUCTION

Introduces the chapter on preventive maintenance (PM) procedures for reliable system operation.

PERIODIC PREVENTIVE MAINTENANCE

Details maintenance procedures divided into categories: weekly, monthly, and semi-annual PMs.

Weekly PM Procedures

Outlines essential weekly tasks including calibration, disk capacity check, and backup.

Chapter 16 BACKUP AND RESTORE

Introduction

Explains the purpose of Backup and Restore procedures for preventing data loss and system settings.

Profiler Backup Procedure

Provides step-by-step instructions for performing a backup of the Profiler software and its data.

Profiler Restore Procedure

Guides administrators on restoring configuration, calibrations, recipes, and data from backup files.

Appendix A HAZARDOUS MATERIALS

INTRODUCTION

Identifies environmentally hazardous materials within the product according to WEEE and RoHS directives.

HAZARDOUS MATERIAL CONTENT

Lists common hazardous materials found in electronic components, cables, and casings.

HAZARDOUS MATERIALS LIST

Provides a detailed list of materials and their corresponding used components for proper disposal.

Appendix B P SERIES PROFILER - PREPARING FOR SHIPMENT

INTRODUCTION

Provides guidelines and steps for the proper and safe shipment of P series Profiler tools.

Required tools

Lists the minimum parts required for preparing the Profiler for shipment.

PROCEDURE

Details the step-by-step procedure for preparing the Profiler for shipment, covering hardware and software.

Need help?

Do you have a question about the P-6 and is the answer not in the manual?

Questions and answers