Summary of Contents for Daikin FFA60A2VEB

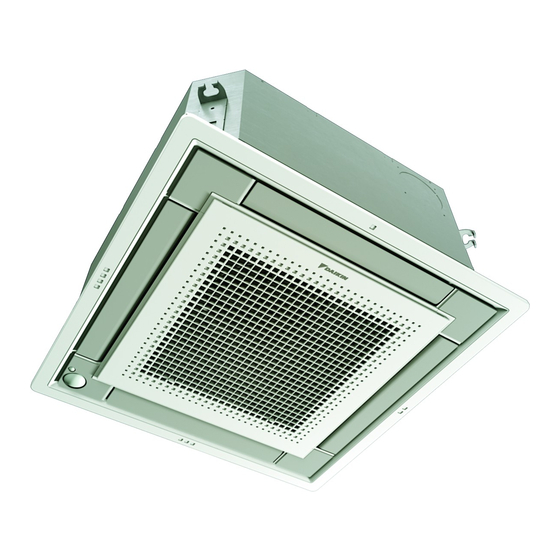

- Page 1 Installation and operation manual Split system air conditioners FFA25A2VEB FFA35A2VEB Installation and operation manual FFA50A2VEB English Split system air conditioners FFA60A2VEB ...

- Page 2 3P480520-1A...

-

Page 3: Table Of Contents

Table of contents 12.2.3 About the heating operation......... 16 Table of contents 12.2.4 To operate the system ..........16 12.3 Using the dry program..............16 12.3.1 About the dry program ..........16 12.3.2 To use the dry program..........16 1 About the documentation 12.4 Adjusting the air flow direction............ -

Page 4: For The Installer

▪ Format: Paper (in the box of the indoor unit) Daikin website (publicly accessible). ▪ Installer and user reference guide: ▪ The full set of latest technical data is available on the Daikin extranet (authentication required). ▪ Preparation of the installation, good practices, reference data,…... -

Page 5: System Layout

4 Preparation Outdoor units Cooling Heating Preparation RXM25~60 Outdoor –10~46°C DB –15~24°C DB temperature –16~18°C WB Preparing installation site Indoor 18~32°C DB 10~30°C DB temperature 4.1.1 Installation site requirements of the 2MXM50 Outdoor –10~46°C DB –15~24°C DB indoor unit temperature 3MXM40~68 –16~18°C WB INFORMATION Indoor 18~32°C DB 10~30°C DB 4MXM68~80 temperature The sound pressure level is less than 70 dBA. -

Page 6: Guidelines When Installing The Drain Piping

5 Installation ▪ Decoration panel. Install the decoration panel always after installing the unit. ▪ Ceiling strength. Check whether the ceiling is strong enough to support the weight of the unit. If there is a risk, reinforce the ceiling before installing the unit. ▪... - Page 7 5 Installation ▪ Checking for water leaks To connect the drain piping to the indoor unit General guidelines NOTICE ▪ Pipe length. Keep drain piping as short as possible. Incorrect connection of the drain hose might cause leaks, and damage the installation space and surroundings. ▪...

-

Page 8: Connecting The Refrigerant Piping

5 Installation Connecting the refrigerant piping DANGER: RISK OF BURNING 5.2.1 About connecting the refrigerant piping Before connecting the refrigerant piping Make sure the outdoor and indoor unit are mounted. Typical workflow Connecting the refrigerant piping involves: ▪ Connecting the refrigerant piping to the outdoor unit ▪... -

Page 9: Pipe Bending Guidelines

5 Installation Piping size Tightening Flare Flare shape (mm) torque (N•m) dimensions (A) (mm) (mm) 90° ±2 Ø6.4 15~17 8.7~9.1 Ø9.5 33~39 12.8~13.2 Refrigerant piping Ø12.7 50~60 16.2~16.6 R=0.4~0.8 Part to be brazed Taping Manual valve Pressure-reducing valve 5.2.4 Pipe bending guidelines Nitrogen ▪... -

Page 10: About Connecting The Electrical Wiring

5 Installation 5.3.5 To connect the electrical wiring on the WARNING indoor unit ALWAYS use multicore cable for power supply cables. NOTICE WARNING ▪ Follow the wiring diagram (delivered with the unit, If the supply cord is damaged, it must be replaced by the located at the inside of the service cover). -

Page 11: Configuration

6 Configuration If you want Then Configuration Outdoor unit General 2MX+3MX Field settings +4MX+5MX During cooling Make the following field settings so that they correspond with the operation (22) actual installation setup and with the needs of the user: Setup volume During heating Monitoring 1 ▪... -

Page 12: Checklist Before Commissioning

7 Commissioning NOTICE The stop valves (gas and liquid) on the outdoor unit are fully open. Before starting up the system, the unit MUST be energised for at least 6 hours. The crankcase heater needs to heat up the compressor oil to avoid oil shortage and To perform a test run compressor breakdown during startup. -

Page 13: Error Codes When Performing A Test Run

Action Result Daikin website (publicly accessible). Press at least 4 seconds. The Service Settings menu ▪ The full set of latest technical data is available on the Daikin is displayed. extranet (authentication required). Piping diagram: Indoor unit Select Test Operation. Service Settings... -

Page 14: Wiring Diagram

9 Technical data Wiring diagram Unified Wiring Diagram Legend For applied parts and numbering refer to the wiring diagram sticker supplied on the unit. Part numbering is realized by Arabic numbers in ascending order for each part and is represented in the overview below by symbol “*” in the part code. CIRCUIT BREAKER PROTECTIVE EARTH CONNECTION... -

Page 15: For The User

10 About the system For the user For more information about the user interface, see the operation About the system manual of the installed user interface. The indoor unit of this split system air conditioner can be used for heating/cooling applications. Operation NOTICE Do not use the system for other purposes. -

Page 16: Operating The System

12 Operation Heating operation Outdoor units Cooling Heating 2MXM50 Outdoor –10~46°C DB –15~24°C DB Fan only operation temperature 3MXM40~68 –16~18°C WB 2 Press the ON/OFF button on the user interface. Indoor 18~32°C DB 10~30°C DB 4MXM68~80 Result: The operation lamp lights up and the system starts temperature operating. -

Page 17: 13 Maintenance And Service

13 Maintenance and service ▪ Depending on the settings, the user interface can display the WARNING TIME TO CLEAN AIR FILTER notification. Clean the air filter Never touch the air outlet or the horizontal blades while the when the notification is displayed. swing flap is in operation. -

Page 18: To Clean The Air Outlet And Outside Panels

13 Maintenance and service NOTICE ▪ Do NOT use gasoline, benzene, thinner polishing powder or liquid insecticide. Possible consequence: Discoloration and deformation. ▪ Do NOT use water or air of 50°C or higher. Possible consequence: Discoloration and deformation. ▪ Do NOT scrub firmly when washing the blade with water. -

Page 19: After-Sales Service And Warranty

13 Maintenance and service 13.5.3 Recommended maintenance and WARNING inspection cycles ▪ Do NOT pierce or burn refrigerant cycle parts. ▪ Do NOT use cleaning materials or means to accelerate Be aware that the mentioned maintenance and replacement cycles the defrosting process other than those recommended do not relate to the warranty period of the components. -

Page 20: 14 Troubleshooting

14 Troubleshooting NOTICE Malfunction Measure The system operates ▪ Check if air inlet or outlet of outdoor or ▪ The table indicates main components. Refer to your but cooling or heating indoor unit is not blocked by obstacles. maintenance and inspection contract for more details. is insufficient. -

Page 21: Symptom: White Mist Comes Out Of A Unit (Indoor Unit)

15 Relocation 14.1.4 Symptom: White mist comes out of a unit 14.1.12 Symptom: The outdoor unit fan does not (Indoor unit) spin ▪ When humidity is high during cooling operation. If the interior of an During operation. The speed of the fan is controlled in order to indoor unit is extremely contaminated, the temperature distribution optimise product operation. - Page 24 4P456960-1 2017.03...

Need help?

Do you have a question about the FFA60A2VEB and is the answer not in the manual?

Questions and answers