Summarization of Contents

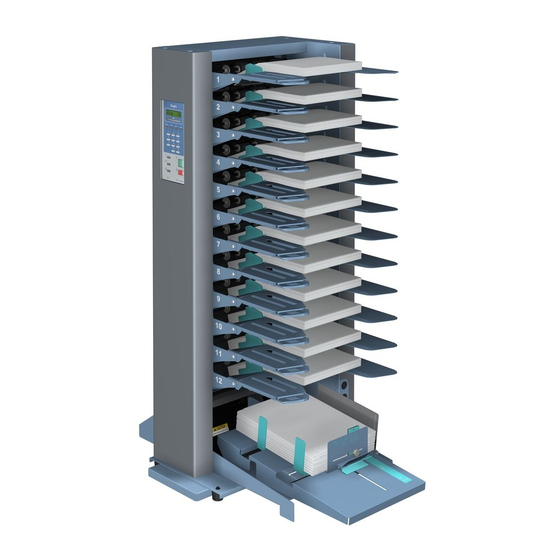

Collation Operations Guide

Power Switch Operation

Controls the unit's power supply via ON/OFF buttons.

Paper Feed Pressure Adjustment

Adjusts feed pressure based on paper size for optimal separation.

Paper Separation Pressure Adjustment

Adjusts separation pressure based on paper thickness for consistent feeding.

Paper Loading Procedure

Guides the process of placing paper into the machine's bins.

Paper Receiving Stopper 1 Adjustment

Positions the stopper for correct paper stacking based on size.

Paper Receiving Stopper 2 Adjustment

Positions the second stopper for proper paper alignment.

Side Guide F Adjustment

Aligns the side guide according to paper size for correct paper path.

Side Guide B Adjustment for Output Mode

Adjusts the side guide B based on the chosen output mode: STRAIGHT or OFFSET.

Control Panel Settings for Collation

Configures collation mode, paper output, and counting methods via the control panel.

Preset Key Operation for Setup

Initiates setup by sending paper to memorize size and thickness.

Starting and Stopping Operations

Initiates or halts the collation process using Start and Stop keys.

Powering Off the Unit

Safely shuts down the machine after operation is complete.

Paper Loading by Collation Mode

Normal Mode Paper Loading

Details how to load paper for standard collation where sets are stacked sequentially.

Interleaving Mode Paper Loading

Explains loading paper for interleaving, inserting separators between sets.

Alternative Mode Paper Loading

Describes loading paper for alternative mode, dividing sheets into odd/even bins.

Block Mode Paper Loading

Guides paper loading for block collation, dividing bins into two groups.

Paper Loading with Downstream Unit

Instructions for loading paper when connected to optional downstream units.

Paper Loading by Size and Direction

Details paper loading orientation based on paper size and downstream unit connection.

Using the Control Panel Features

LCD Window Information Display

Explains the various displays shown on the unit's LCD screen.

Collation Mode Selection

Guides users through selecting operating modes like Normal, Interleaving, Block, and Alternative.

Interleaf Quantity Setting

Configures the number of interleaves to be inserted in the interleaving mode.

Count Display Method Setup

Selects between count-up or count-down display for processed sets.

Paper Receiving Method Configuration

Sets how collated paper is received: OFFSET, OPTION, or STRAIGHT mode.

Adjusting Other Operational Settings

Covers adjustments for overlap, speed, and repeat settings for enhanced performance.

Connecting Downstream Units

Connecting DBM-120/120T Units

Details how to connect DBM-120 and DBM-120T for stapling, folding, and trimming.

Connecting DC-S and DC-S4 Units

Explains the connection of DC-S and DC-S4 units for stapling and punching.

Interpreting Bin Error Lamp Indicators

Green Bin Error Lamp: No Paper

Indicates no paper in a bin; requires replenishment and restart.

Red Bin Error Lamp: Paper Jam

Signals a paper jam within a bin; requires clearing the jam and restarting.

Blinking Green Bin Error Lamp: Empty Feed

Indicates no paper fed from bin; requires re-stacking and potential pressure adjustment.

Blinking Red Bin Error Lamp: Double Feed

Signals a double-fed paper; requires proper alignment and potential pressure adjustment.

Troubleshooting Error Messages

LCD Message: No Paper

Alerts that a bin is empty, requiring paper replenishment to continue.

LCD Message: Tray Full

Indicates the paper receiving table is full; requires clearing the table.

LCD Message: Feed Error

Reports paper jamming in the feed path or gate; requires jam removal.

LCD Message: Preset Error

Occurs if Start is pressed without prior Preset key activation.

LCD Message: Mis-Feed

Indicates no paper was fed from a bin; requires checking and restarting.

LCD Message: Double Detect

Signals that paper has been double-fed; requires checking and restarting.

LCD Message: Paper Jam

Reports jamming in the conveyance route or ejection gate; requires jam removal.

LCD Message: Stacker Jam

Indicates jamming at the ejection gate or receiving table; requires jam removal.

LCD Message: Feed Cover Open

Alerts that the vertical conveyance cover is not properly closed.

LCD Message: Interleave Setup Error

Indicates missing interleave quantity or empty interleave bin.

LCD Message: On-line Error

Reports an error occurring in the connected downstream unit.

Need help?

Do you have a question about the DFC-10 and is the answer not in the manual?

Questions and answers