Table of Contents

Advertisement

Quick Links

Read this manual carefully before you use this machine and keep it handy for future reference. For safe and correct use, be sure to read the

Safety Information before using the machine.

1

Operation

Optional Functions

2

Replenishing Supplies

3

Troubleshooting

4

5

Remarks

Specifications

6

Operating Instructions

Advertisement

Table of Contents

Summary of Contents for Ricoh JP735

- Page 1 Operating Instructions Operation Optional Functions Replenishing Supplies Troubleshooting Remarks Specifications Read this manual carefully before you use this machine and keep it handy for future reference. For safe and correct use, be sure to read the Safety Information before using the machine.

- Page 2 Introduction This manual contains detailed instructions and notes on the operation and use of this machine. For your safety and benefit, read this manual carefully before using the machine. Keep this manual in a handy place for quick reference. Important Contents of this manual are subject to change without prior notice.

-

Page 3: Table Of Contents

TABLE OF CONTENTS Safety Information ....................1 Safety During Operation.....................1 How to Read this Manual ..................3 What You Can Do with this Machine..............4 Machine Exterior ....................6 Machine Interior ..................... 7 Control Panel......................8 Keys ...........................8 Indicators........................9 1. Operation Printing Paper ......................11 Originals .......................12 Printing Preparations ..................13... - Page 4 3. Replenishing Supplies Loading Paper into the Paper Feed Tray ............37 Replenishing Paper....................37 Changing the Paper Size ..................38 When the Add Ink Indicator (j) Lights ............. 39 Master Roll Replacement ..................42 4. Troubleshooting If Your Machine does not Operate as You Want ..........45 x Clearing Misfeeds ...................

-

Page 5: Safety Information

Safety Information When using this machine, the following safety precautions should always be fol- lowed. Safety During Operation In this manual, the following important symbols are used: R WARNING: Indicates a potentially hazardous situation which, if instructions are not followed, could result in death or serious injury. R CAUTION: Indicates a potentially hazardous situation which, if instructions are not followed, may result in minor or moderate injury or damage to property. - Page 6 R CAUTION: • After you move the machine, use the caster fixture to fix it in place. Other- wise the machine might move or come down to cause an injury. • If you use the machine in a confined space, make sure there is a continuous air turnover.

-

Page 7: How To Read This Manual

How to Read this Manual Symbols In this manual, the following symbols are used: R WARNING: This symbol indicates a potentially hazardous situation that might result in death or serious injury when you misuse the machine without following the in- structions under this symbol. -

Page 8: What You Can Do With This Machine

What You Can Do with this Machine Below is a quick summary of this machine's features and where to look in this manual for more information. ❖ Standard Printing See p.15 “Standard Printing”. ❖ Adjusting the Print Image Position See p.18 “Adjusting the Print Image Position”. ❖... - Page 9 ❖ Combining Originals onto One Print See p.29 “Combine—Combining Two Originals onto One Print”. ZCTX040E ❖ Making Color Prints See p.33 “Making Color Prints”. ❖ Printing in Two Colors See p.35 “Printing in Two Colors”.

-

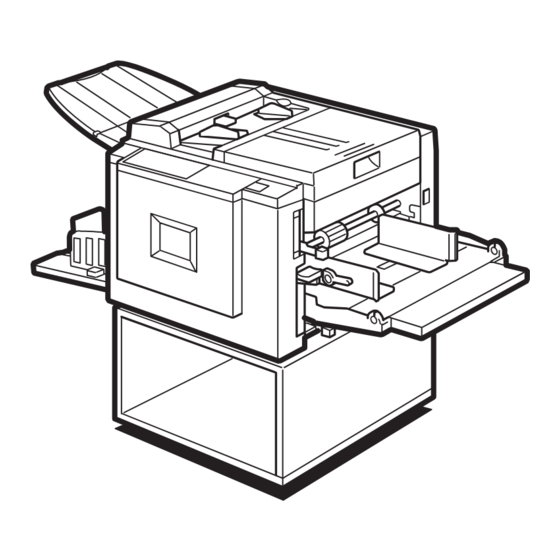

Page 10: Machine Exterior

Machine Exterior Front door Feed roller pressure lever Open for access to the inside of the ma- Use to adjust the contact pressure of the chine. paper feed roller according to the paper thickness. Original delivery tray Paper feed tray The scanned original is delivered here. -

Page 11: Machine Interior

Machine Interior Document feeder Paper delivery tray Place the original in the document feeder Completed prints are delivered here. one sheet at a time. Drum unit Main switch The master is wrapped around this unit. Use to turn the power on or off. Ink holder lock lever Master eject box Release this lever in order to pull out the... -

Page 12: Control Panel

Control Panel Keys {Image Density} key {Combine} key Press to make prints darker or lighter. See p.20 Press to combine originals onto one print. “Adjusting the Print Image Density”. See p.29 “Combine—Combining Two Originals onto One Print”. {Type of Original} key {Image Position} keys Press to select Letter, Photo or Let- ter/Photo mode. -

Page 13: Indicators

Indicators M: Open Cover/Unit indicator Magnification indicators See p.58 “When the Open Cover/Unit In- Show the preset magnification ratio se- dicator (M) Lights”. lected. See p.23 “Preset Reduce/En- large—Reducing and Enlarging Using x: Misfeed indicator Preset Ratios”. See p.47 “x Clearing Misfeeds”. B: Load Paper indicator Machine indicators Show the jammed area with the x indi-... -

Page 15: Operation

1. Operation Printing Paper The following types of print paper are not recommended for this machine. • Paper smaller than 90 mm × 140 mm, 3.6" × 5.6" • Paper larger than 275 mm × 395 mm, 10.8" ×15.6" • Paper heavier than 127.9 g/m , 34.0 lb •... -

Page 16: Originals

Operation Originals Note ❒ Originals that can be set in the document feeder are as follows: • Maximum size: 275 × 395 mm, 10.8" × 15.6" • Minimum size: 90 × 140 mm, 3.6" × 5.6" • Maximum weight: 127.9 g/m , 34.0 lb •... -

Page 17: Printing Preparations

Printing Preparations Printing Preparations Note Loading Paper ❒ Correct the paper curl before setting the paper. If you cannot Lower the paper feed tray adjust- do so, stack the paper with the ment lever. curl face down as shown. Release the paper feed side plate lock levers and adjust the side plates to match the paper size. -

Page 18: Preparing The Paper Delivery Tray

Operation Preparing the Paper Delivery Tray Adjust the paper delivery side plates to match the paper size. Adjust the paper delivery end plate to match the paper size. Turn on the main switch. -

Page 19: Standard Printing

Standard Printing Standard Printing Press the {Master Making} key. -Printing In this manual, the word, “printing” is used as opposed to “copying” in or- der to distinguish between the pro- cess that your machine uses to make prints, and the process used by a stan- dard copier machine. - Page 20 Operation Enter the number of prints re- quired with the number keys. Note ❒ Up to 9999 prints can be entered at a time. ❒ To change the number entered, press the {Clear/Stop} key and enter the new number. Press the {Print Start} key. Note ❒...

-

Page 21: After Printing

After Printing After Printing Lower the paper feed tray adjust- ment lever and remove the paper from the paper feed tray. Remove the prints from the paper delivery tray. Turn off the main switch. -

Page 22: Adjusting The Print Image Position

Operation Adjusting the Print Image Position After master making, you can adjust Note the print image position to suit your ❒ When you shift the image for- needs. There are two ways to do this: wards, leave a margin (more than 5 mm, 0.2") at the leading ❖... -

Page 23: Shifting The Print Image Position To The Right Or Left

Adjusting the Print Image Position Note Shifting the Print Image ❒ The image position can be shift- Position to the Right or Left ed up to about 10 mm, 0.4" each way. Lock the paper delivery side plates and shift the tray adjustment le- ver back to the paper feeding po- sition. -

Page 24: Adjusting The Print Image Density

Operation Adjusting the Print Image Density You can adjust the print image densi- After Making a Master ty to suit your needs. There are two ways to do this: Press the {Speed} key to decrease ❖ Before Making a Master the printing speed. -

Page 25: Changing The Printing Speed

Changing the Printing Speed Changing the Printing Speed Use the {Speed} key to adjust the speed of the machine to suit the im- age density and paper type. Press the {Speed} key to select the printing speed. Note ❒ The following speeds are avail- able: •... -

Page 26: Stopping The Machine During The Multi-Print Run

Operation Stopping the Machine during the Multi- print Run When You Want to Stop the When You Want to Change the Machine during the Multi-print Number of Prints Entered or Run and Print the Next Check the Completed Prints Original Press the {Clear/Stop} key. -

Page 27: Preset Reduce/Enlarge-Reducing And Enlarging Using Preset Ratios

Preset Reduce/Enlarge—Reducing and Enlarging Using Preset Ratios Preset Reduce/Enlarge—Reducing and Enlarging Using Preset Ratios ❒ You can select a ratio regardless of You can select a preset ratio for print- ing. the size of an original or printing paper. With some ratios, parts of the image might not be printed or margins will appear on prints. - Page 28 Operation ❖ Enlargement (Metric version) Make sure that the original and the print paper are of the correct Indica- Original Print size. Size Size large- ment Place the original in the document Ratio feeder and specify the number of B5VB4 B5 JIS B4 JIS 141%...

-

Page 29: Printing On Different Types Of Paper Thickness

Printing on Different Types of Paper Thickness Printing on Different Types of Paper Thickness Depending on the thickness of the pa- Make sure that the paper feed per that you are printing on, you need side plates touch the paper light- to perform the following steps. -

Page 30: Separation Pressure Lever

Operation Separation Pressure Lever To prevent double-feed, adjust the paper separation pressure us- ing the separation pressure lever. Note ❒ Paper separation pressure can be adjusted according to the pa- per weights as shown in the fol- lowing table. Posi- Metric version Inch version tion Use this position if the lead-... -

Page 31: Selecting Original Type

Selecting Original Type Selecting Original Type Select one of the following two types Press the {Image Density} key to ad- to suit your originals: just the image density. ❖ Photo mode Delicate tones of photographs and pictures can be reproduced with this mode. -

Page 32: Auto Cycle-Processing A Master And Making Prints In One Step

Operation Auto Cycle—Processing a Master and Making Prints in One Step Use the {Auto Cycle} key to process masters and make prints in one step. Place the original in the document feeder. Press the {Auto Cycle} key. Enter the number of prints re- quired with the number keys. -

Page 33: Combine-Combining Two Originals Onto One Print

Combine—Combining Two Originals onto One Print Combine—Combining Two Originals onto One Print You can print two separate originals For an enlargement ratio of 115%, use the {Enlarge/Reduce} key to se- on a single sheet of paper. The follow- lect “B5VA4”. ing diagrams show the available pa- For an enlargement ratio of 122%, per lists and orientations. - Page 34 Operation Press the {Combine} key. The beeper sounds after the first original has been stored. Place the second original face down in the document feeder. Note ❒ If you wish to select a different reproduction ratio for the sec- ond original, you need to enter the new settings before the beeping stops.

- Page 35 Combine—Combining Two Originals onto One Print Enter the number of prints with the number keys. Press the {Print Start} key to make your prints.

- Page 36 Operation...

-

Page 37: Optional Functions

2. Optional Functions Color Printing Using the Optional Color Drum In addition to the standard black Check the image position on the drum, color drum units (red, blue, trial or proof print. green, brown, yellow, purple, navy, maroon, orange, and teal) are also Note available as options. - Page 38 Optional Functions Lift the drum handle to unlock the Remove the drum unit from the drum. machine while holding the upper drum stay. Slowly pull the drum out. Note ❒ Be careful not to let the drum unit fall. Set the color drum unit on the guide rail.

-

Page 39: Printing In Two Colors

Color Printing Using the Optional Color Drum Lower the drum unit lock lever. Prepare two originals. Place the first original in the document feeder. GRCOLO0E Close the front door. Press the {Master Making} key. Note ❒ Make sure that the Cover Open indicator (M) turns off. - Page 40 Optional Functions Enter the number of prints with Change the drum unit. See p.33 the number keys. “Changing the Color Drum Unit”. Press the {Print Start} key. Place the second original and press the {Master Making} key. Remove the prints from the paper delivery tray and re-load them Check the image position.

-

Page 41: Replenishing Supplies

3. Replenishing Supplies Loading Paper into the Paper Feed Tray The Load Paper indicator (B) and the Load paper into the paper feed machine indicator “A” lights when tray. the paper feed tray runs out of paper. Replenishing Paper Press the {Clear/Stop} key. Note ❒... -

Page 42: Changing The Paper Size

Replenishing Supplies Load paper into the paper feed Changing the Paper Size tray. Lower the paper feed tray adjust- ment lever. Remove the paper from the paper feed tray. Note ❒ Correct any paper curl before setting the paper. ❒ Make sure that the side plates Release the paper feed side plate touch the paper lightly. -

Page 43: When The Add Ink Indicator (J) Lights

When the Add Ink Indicator (j) Lights When the Add Ink Indicator (j) Lights The Add Ink indicator (j) lights up when it is time to supply ink. R CAUTION: • Keep the ink or ink container out of reach of children. R CAUTION: •... - Page 44 Replenishing Supplies Release the ink holder lock lever and pull out the ink holder. Remove the used ink cartridge. Remove the cap of the new ink cartridge. TSLT012E Insert the new cartridge into the ink holder.

- Page 45 When the Add Ink Indicator (j) Lights Note ❒ Always supply ink of the same color. ❒ Make sure that the part indicated by the arrow mark is firmly inserted into the guide. TSLT011E Slide the ink holder back in until it clicks into place. Close the front door.

-

Page 46: Master Roll Replacement

Replenishing Supplies Master Roll Replacement The Master End indicator (C) lights Note up when it is time to replace the mas- ❒ When the Master End indicator ter roll. lights up, it is necessary to re- place the master roll even if Open the right side cover. - Page 47 Master Roll Replacement Close the plotter cover using both hands until it clicks into place. TSLH023E Close the right side cover.

- Page 48 Replenishing Supplies...

-

Page 49: Troubleshooting

4. Troubleshooting If Your Machine does not Operate as You Want If a malfunction or a misfeed occurs within the machine, the following indicators will light. ❖ When the misfeed indicator (x) lights with the machine indicators Indicator Page x and “P” p.48 “When “x”... - Page 50 Troubleshooting ❖ When the open cover/unit indicator (M) lights up Indicator Meaning Page Close the front door or the right side p.58 “When the Open Cover/Unit Indica- cover. tor (M) Lights” M and “M” Set the drum. M and “D” Close the plotter cover. M and “E”...

-

Page 51: Clearing Misfeeds

x Clearing Misfeeds x Clearing Misfeeds The machine indicator shows the area where jams occur. Important ❒ When clearing misfeeds, do not turn off the main switch. If you do, your print settings are cleared. -After clearing misfeeds Press the {Clear Modes/Recovery} key to reset the error indicators. -

Page 52: When "X" And "P" Light Up

Troubleshooting When “x” and “P” light up An original misfeed occurs in the document feeder. Open the cover of the document feeder. Pull out the original gently. Close the cover of the document feeder. - Page 53 x Clearing Misfeeds -To prevent original misfeeds: Use the exposure glass for the following kinds of originals. • Originals heavier than 127.9 g/m , 34.0 lb • Originals lighter than 40 g/m , 10.8 lb • Carbon coated originals • Damaged originals •...

-

Page 54: When "X", "B" And "A" Light Up

Troubleshooting When “x”, “B” and “A” light up A paper misfeed occurs in the paper feed section. R CAUTION: • Be careful not to cut yourself on any sharp edges when you reach inside the machine to remove misfed sheets of paper or masters. Lower the paper feed tray adjustment lever. - Page 55 x Clearing Misfeeds Re-insert the drum unit until the drum unit locks into position and put the lever back in place. Close the front door. -To prevent paper misfeeds: If the paper is curled or the originals leading edge margin is too narrow, the fol- lowing action is necessary.

-

Page 56: When "X" And "C" Light Up

Troubleshooting • When the leading edge margin of the original is less than 5 mm, 0.2" or there is a solid image on the leading edge, insert the original with the widest mar- gin first or make a leading edge margin by making a copy. GRLEAD0E When “x”... - Page 57 x Clearing Misfeeds If the paper is completely wrapped around the drum, pull out the drum unit and remove the misfed paper from the drum. TSLH02BE Re-install the drum unit locks in position and put the lever back in place. Note ❒...

- Page 58 Troubleshooting • If you cannot correct the paper curl, stack the paper with the curl face down as shown. • When the leading edge margin of the original is less than 5 mm, 0.2" or there is a solid image on the leading edge, insert the original with the widest mar- gin first or make a leading edge margin by making a copy.

-

Page 59: When "X" And "D" Light Up

x Clearing Misfeeds When “x” and “D” light up Open the right side cover. Open the plotter cover, and then remove the misfed master. TSLH02EE If you could not remove the misfed master in steps B and C, take out the drum and remove the misfed master from the inside. -

Page 60: When "X" And "E" Light Up

Troubleshooting When “x” and “E” light up Check where the misfed master is. Remove the misfed master as follows: When a master misfeed occurs in the master eject section A Pull out the master eject box. B Remove the misfed master. Note ❒... - Page 61 x Clearing Misfeeds When a master misfeed occurs on the drum A Lift the lever to unlock the drum unit and pull out the unit. Reference For how to remove the drum unit, see p.33 “Changing the Color Drum Unit”. B Remove the master from the drum.

-

Page 62: When The Open Cover/Unit Indicator (M) Lights

Troubleshooting When the Open Cover/Unit Indicator (M) Lights MMake sure that the following door/units are closed. The machine indicator shows the place where the door/units are not closed. ❖ Right Side Cover Close the right side cover firmly until it locks into position. ❖... - Page 63 When the Open Cover/Unit Indicator (M) Lights ❖ Drum Unit Set the drum unit completely until it locks in position.

-

Page 64: When The Master Eject Indicator (K) Lights

Troubleshooting When the Master Eject Indicator (k) Lights The Master Eject indicator (k) lights when it is time to empty master eject box or when you need to set the master eject box. Take out the master eject box and remove the used masters. Note ❒... -

Page 65: Poor Printing

Poor Printing Poor Printing Dirt on the Back Side of Paper GRDIRT0E Note ❒ When you use paper smaller than the original, select the proper reduction ra- tio. Otherwise, you might get dirty background prints. ❒ When you use postcards and the like, the background might be dirty because postcards do not absorb ink well. - Page 66 Troubleshooting Reference See p.33 “Changing the Color Drum Unit”for the details. Clean the pressure roller with a clean cloth. With a clean cloth, remove any ink that has accumulated on the trailing edge of the drum unit. TSLH02CE Insert the drum unit until it locks in position, then lower the drum unit lock lever.

-

Page 67: Dirt On The Front Side Of Paper (Black Line/Stain)

Poor Printing Turn on the main switch. Dirt on the Front Side of Paper (Black Line/Stain) GRBLAC1E Note ❒ When black lines or stains still appear on prints even if you clean the above, contact your service representative. ❒ If there is no margin or if there is a solid image area near the leading edge of the original, make a margin of at least 5 mm, 0.2"... -

Page 68: White Prints Or Incomplete Prints

Troubleshooting White Prints or Incomplete Prints GRWHIT0E • Make sure that the paper feed side plates touch the paper lightly. Put back the lock levers. When you get white or incomplete prints even when you have checked the above, perform the following procedure. Pull out the drum unit. - Page 69 Poor Printing Remove the master from the drum. TSLH031E Remove paper that is stuck to the drum. TSLH02BE Insert the drum unit until it locks in position, then lower the drum unit lock lever.

- Page 70 Troubleshooting Close the front door.

-

Page 71: Remarks

5. Remarks Operation Notes General Cautions • While printing, do not turn off the main switch. • While printing, do not open the door or covers. • While printing, do not unplug the power cord. • While printing, do not move the machine. •... - Page 72 Remarks • The outer portion of the image might not be printed under low temperature. In this case, either select the slower printing speed, or increase the room tem- perature. • The paper exit pawl might come in contact with the printing paper and cause black lines on the prints.

-

Page 73: Print Paper

Operation Notes Print Paper • When the paper is curled, stack the paper with the curl face down, otherwise the paper might wrap around the drum or stains might appear. • Postcards and the like do not absorb ink well. Offset images might appear on the rear side of subsequent prints. -

Page 74: Where To Put Your Machine

Remarks Where to Put Your Machine Your machine's location should be carefully chosen because environmental con- ditions greatly affect its performance. Environmental Conditions Optimum environmental conditions R CAUTION: • Keep the machine away from humidity and dust. Otherwise a fire or an elec- tric shock might occur. -

Page 75: Power Connection

Where to Put Your Machine Power Connection R WARNING: • Connect the power cord directly into a wall outlet and never use an ex- tension cord. • Only connect the machine to the power source describe in the manual. • Do not damage, break or make any modifications to the power cord. Do not place heavy objects on it. -

Page 76: Maintaining Your Machine

Remarks Maintaining Your Machine To maintain high print quality, clean Paper Feed Roller (paper feed the following parts and units regular- tray) Document Feeder Wipe off the paper dust on the pa- per feed roller with a damp cloth, then wipe it with a dry cloth. Lift the document feeder cover. -

Page 77: Combination Chart

Combination Chart Combination Chart This combination chart shows which modes can be used together. ❍ means that these modes can be used together. × means that these modes cannot be used together. × ❍ ❍ ❍ ❍ Enlarge/Reduce ❍ ❍ ❍... - Page 78 Remarks...

-

Page 79: Specifications

6. Specifications Main Frame ❖ Configuration: Desk top ❖ Printing Process: Full automatic one drum stencil system ❖ Original Type: Sheet ❖ Original Size: Maximum 275 mm × 395 mm, 10.8" × 15.6" ❖ Pixel Density: 300 × 300 dpi ❖... - Page 80 Specifications ❖ Print Paper Size: Maximum 275 mm × 395 mm, 10.8" × 15.6" Minimum 90 mm × 140 mm, 3.6" × 5.6" ❖ Leading Edge Margin: 5 mm ± 3 mm, 0.2" ± 0.12" ❖ Print Paper Weight: 35 g/m to 127.9 g/m , 9.3 lb to 34 lb ❖...

- Page 81 Main Frame ❖ Noise Emission *1: Sound Power Level Printing Speed Noise Emission Stand-by 32 dB(A) During printing 60 cpm 77 dB(A) 90 cpm 80 dB(A) Sound Pressure Level*2 Printing Speed Noise Emission Stand-by 23 dB(A) During printing 60 cpm 64 dB(A) 90 cpm 68 dB(A)

-

Page 82: Consumables

Specifications Consumables Name Size Remarks Master for LG drum Length: 50 m, 164ft/roll 100 masters can be made per roll Width: 240 mm, 9.5" 1 roll/pack Master for B4 drum Length: 50 m, 164ft/roll 100 masters can be made per roll Width: 280 mm, 11.0"... -

Page 83: Index

INDEX {Image Density} key , 8 , 20 Access to machine , 71 {Image Position} key , 18 Adjusting the Print Image Density , 20 {Image Position} keys , 8 Adjusting the Print Image Position , 18 After clearing misfeeds , 47 Indicators , 9 After Printing , 17 Add ink indicator (j) , 39... - Page 84 Paper delivery end plate , 7 Paper delivery side plates , 7 Paper delivery tray , 7 Paper Feed Roller , 72 Paper feed side plate lock levers , 6 Paper feed side plates , 6 Paper feed tray , 6 Paper feed tray adjustment lever , 6 Photo mode , 27 Poor Printing , 61...

- Page 85 MEMO...

- Page 86 MEMO C261-8608...

- Page 87 Note to users in the United States of America Notice: This equipment has been tested and found to comply with the limits for a Class A digital devices, pur- suant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment.

- Page 88 Type for CP6123L+/LDD735/JP735 Printed in China EN USA C261-8608...

Need help?

Do you have a question about the JP735 and is the answer not in the manual?

Questions and answers