Table of Contents

Advertisement

Published 03/07

This Operator's Manual is an integral part of the safe operation of this machine and must

be maintained with the unit at all times. READ, UNDERSTAND, and FOLLOW the Safety

and Operation Instructions contained in this manual before operating the equipment. C01-

Cover

®

RHINO

1020 S. Sangamon Ave.

Gibson City, IL 60936

800-446-5158

Email: parts@servis-rhino.com

Effective Serial No. TW84-17675 through Current

OPERATOR'S MANUAL

©2007 Alamo Group Inc.

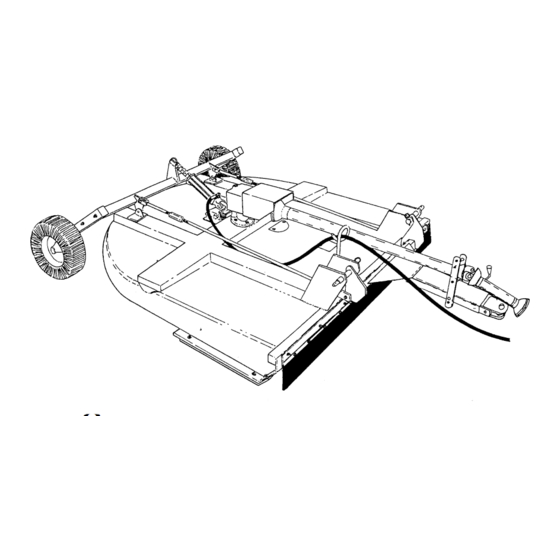

TW84

ROTARY CUTTER

Part NO. 00760962C

$0.00

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for RHINO TW84

- Page 1 Operation Instructions contained in this manual before operating the equipment. C01- Cover ® RHINO 1020 S. Sangamon Ave. Gibson City, IL 60936 800-446-5158 Email: parts@servis-rhino.com Effective Serial No. TW84-17675 through Current ©2007 Alamo Group Inc. TW84 ROTARY CUTTER Part NO. 00760962C $0.00...

-

Page 2: Warranty Information

To the Owner/Operator/Dealer All implements with moving parts are potentially hazardous. There is no substitute for a cautious, safe-minded operator who recognizes the potential hazards and follows reasonable safety practices. The manufacturer has designed this implement to be used with all its safety equipment properly attached to minimize the chance of acci- dents. - Page 3 Your Authorized Alamo Ag Dealer may have shown this video and presented you a DVD Video when you purchased your mower. If you or any mower operator have not seen this video, Watch the Video, Read this Operator’s Manual, and Complete the Video Guidebook before operating your new mower.

- Page 4 Alamo Group Ag. Division is willing to provide one (1) AEM Mower Safety Practices Video Please Send Me: VHS Format – AEM/FEMA Mower Operator Safety Video DVD Format – AEM/FEMA Mower Operator Safety Video Mower Operator’s Manual AEM Mower Operator’s Safety Manual...

-

Page 5: Table Of Contents

TABLE OF CONTENTS SAFETY SECTION ... 1-1 General Safety Instructions and Practices ... 1-2 Operator Safety Instructions and Practices ... 1-3 Equipment Operation Safety Instructions and Practices... 1-5 Connecting or Disconnecting Implement Safety Instructions and Practices ... 1-11 Transporting Safety Instructions and Practices ... 1-11 Maintenance and Service Safety Instructions and Practices ... - Page 6 Boarding the Tractor ... 4-9 Dismounting the Tractor... 4-9 STARTING THE TRACTOR ... 4-10 CONNECTING THE MOWER TO THE TRACTOR ... 4-10 Connecting the Mower-Lift Type ... 4-11 Connecting the Mower-Pull Type ... 4-12 Safety Chains... 4-13 SETTING THE MOWER ... 4-13 Setting Mowing Height-Pull Type ...

-

Page 7: Safety Section

SAFETY SECTION Safety Section 1-1 © 2007 Alamo Group Inc. -

Page 8: General Safety Instructions And Practices

Safety Messages. Always use good common sense to avoid hazards. Si no lee ingles, pida ayuda a alguien que si lo lea para que le traduzca las medidas de seguridad. TW84 03/07 © 2007 Alamo Group Inc. SAFETY (SG-2) (SG-3) -

Page 9: Operator Safety Instructions And Practices

NOTE: Hearing loss from loud noise [from tractors, chain saws, radios, and other such sources close to the ear] is cumulative over a lifetime without hope of natural recovery. (SG-I7) TW84 03/07 © 2007 Alamo Group Inc. SAFETY “Wait a minute...Save a life!” Never allow inexperienced or EXPOSURE... - Page 10 Use gloves and eye protection when servicing hot components. Contact with a hot surface or fluid can cause serious injury from burns or scalding. TW84 03/07 © 2007 Alamo Group Inc. SAFETY (SG-24) Children can cause the Implement to shift or fall (SG-25) Drugs and alcohol will affect an operator’s...

-

Page 11: Equipment Operation Safety Instructions And Practices

Such an impact could cause the Implement and Tractor to pivot violently resulting in loss of steering control, serious injury, or even death. contact obstacles. (S3PT-12) TW84 03/07 © 2007 Alamo Group Inc. SAFETY (SG-38) (SGM-9) (SSP-3) - Page 12 Implement, and are physically large enough to reach and operate the controls easily. Do not mount the Tractor while the tractor is moving. Mount the Tractor only when the Tractor and all moving parts are completely stopped. TW84 03/07 © 2007 Alamo Group Inc. SAFETY (SBH-6) Shut down PTO and the Tractor...

- Page 13 Attacking insects can cause you to lose control of the tractor, which can result in serious injury or death to you or bystanders. Never dismount a moving tractor. TW84 03/07 © 2007 Alamo Group Inc. SAFETY (SG-13) (SG-23)

- Page 14 Normal ground speed range is from 2 to 5 mph. Use slow mowing speeds when operating on or near steep slopes, ditches, drop-offs, overhead obstructions, power lines, or when debris and foreign objects are to be avoided. (SGM-7) TW84 03/07 © 2007 Alamo Group Inc. SAFETY (SGM-4) Inspect the area before (SGM-6)

- Page 15 Mower exposes the Cutting Blades which creates a potentially serious hazard and can cause serious injury by objects thrown from the Blades or by contact with the Blades. TW84 03/07 © 2007 Alamo Group Inc. SAFETY Check to make sure there are no...

- Page 16 Raising the Mower deck exposes the Cutting Blades which creates a potentially serious hazard and could cause serious injury or even death from objects thrown from the Blades. TW84 03/07 © 2007 Alamo Group Inc. SAFETY (SRM-1) (SRM-4)

-

Page 17: Connecting Or Disconnecting Implement Safety Instructions And Practices

Dropping implement in transport can cause serious damage to the tractor and/or Implement and possibly cause the operator or others to be injured or killed. TW84 03/07 © 2007 Alamo Group Inc. SAFETY (S3PT-16) Safety Section 1-11... - Page 18 Make certain that at least 20% of the tractor’s weight is on the front wheels to maintain safe steerage. Slow down on rough or uneven surfaces. (STI-1) TW84 03/07 © 2007 Alamo Group Inc. SAFETY (SG-19) Safety Section 1-12 (S3PT-20)

-

Page 19: Maintenance And Service Safety Instructions And Practices

(SG-5) Do not modify or alter this Implement. Implement, any of its components or any Implement function. TW84 03/07 © 2007 Alamo Group Inc. SAFETY Never tow the Implement at speeds over 20 (STI-10) (S3PT-8) - Page 20 Missing, broken, or worn items must be replaced at once to reduce the possibility of injury or death from thrown objects, entanglement, or blade contact. TW84 03/07 © 2007 Alamo Group Inc. SAFETY (SG-14) Make sure the tractor engine is off, the...

-

Page 21: Storage And Parking Safety Instructions And Practices

Safety Messages and operation instruction in each of the appropriate sections of the Tractor and Equipment Manuals. Pay close attention to the Safety Signs affixed to the Tractor and Equipment. TW84 03/07 © 2007 Alamo Group Inc. SAFETY PARTS INFORMATION... -

Page 22: Decal Location

(Some shipping and handling charges may apply). Contact your Rhino dealer to order replacement TW84 03/07 © 2007 Alamo Group Inc. SAFETY Safety Section 1-16... - Page 23 02959924 ( ) Quantities for Pull Type Only ** 540 or 1000 RPM units only. Select correct one. * Furnished by tractor manufacturer *** Supplied on Driveline TW84 03/07 © 2007 Alamo Group Inc. SAFETY TYPE PELIGRO DANGER 1*** DANGER...

-

Page 24: Decal Description

DANGER! Guard Missing, Do Not Operate. If you see this decal, Do Not Operate the mower until the shield has been replaced. P/N 00756004 DANGER! Rotating Driveline Keep Away, Contact can cause death. P/N 00756005 TW84 03/07 © 2007 Alamo Group Inc. SAFETY Safety Section 1-18... - Page 25 P/N 00769737 DANGER! Make certain that drivelines are correct length and are securely attached. P/N 00756494 TW84 03/07 © 2007 Alamo Group Inc. SAFETY Safety Section 1-19...

- Page 26 Slow Moving Vehicle Decal. Keep SMV reflector clean and visible. DO NOT transport or operate without the SMV. P/N 03200347 IMPORTANT! - Required for Equal-Angle Driveline Unit. P/N 00764848 TW84 03/07 © 2007 Alamo Group Inc. SAFETY Safety Section 1-20...

- Page 27 P/N D114 WARNING! Avoid Bodily Injury, Use 540RPM PTO Speed Only. P/N D103 Operator's Manual (with repair parts) and warranty was attached to this implement during final inspection. P/N 00763977 TW84 03/07 © 2007 Alamo Group Inc. SAFETY Safety Section 1-21...

- Page 28 P/N D302 WARNING! DO NOT transport at speeds higher than 20 mph. Only transport behind a sized and equipped tractor. P/N 00777394 Logo Product Name: Rhino P/N D303 TW84 03/07 © 2007 Alamo Group Inc. SAFETY properly Safety Section 1-22...

- Page 29 Name Decal - TW84 00760604 WARNING! Never Exceed Maximum Towing Speed 25 MPH P/N 1458383 TW84 03/07 © 2007 Alamo Group Inc. SAFETY Safety Section 1-23...

-

Page 30: Federal Laws And Regulations

(Refer to U.S. Dept. of Labor, Employment Standard Administration, Wage & Home Division, Child Labor Bulletin #102.) TW84 03/07 © 2007 Alamo Group Inc. SAFETY This section is not intended as a legal... -

Page 75: Introduction Section

INTRODUCTION SECTION Introduction Section 2-1 © 2007 Alamo Group Inc. - Page 76 Indicates an imminently hazardous situation that, if not avoided, MAY result in MINOR INJURY. Identifies special instructions or procedures that, if not strictly observed, could result in damage to, or destruction of the machine, attachments or the environment. TW84 03/07 © 2007 Alamo Group Inc. INTRODUCTION Introduction Section 2-2...

- Page 77 Slow down on hills, rough terrain, and curves. The front, rear, left, and right are determined by the normal direction of travel, the same as driving an automobile. TW84 03/07 © 2007 Alamo Group Inc. INTRODUCTION Introduction Section 2-3 The Mower manufacturer strongly...

-

Page 78: Attention Owner/Operator

NOTE: Warranties are honored only if completed “Owner Registration and Warranty” forms are received by Alamo Group within thirty days of delivery of the implement. 3. Record the Blade Model and Serial Numbers on the Warranty page at the front of the Operator’s Manual. -

Page 79: Assembly Section

ASSEMBLY SECTION Assembly Section 3-1 © 2007 Alamo Group Inc. -

Page 80: Standard A-Frame Assembly

5/8 x 1-1/2 bolts (7) and locknuts (8). Tighten all bolts securely Attach the Cat. II Hitch pins (10) to the top front holes in the lift lugs and retain with pins (11). TW84 03/07 Assembly Section 3-2 © 2007 Alamo Group Inc. -

Page 81: Optional A-Frame Assembly

3/4 x 1-1/2 (17) and locknut (13). 5. Install Brace supports (4) to the rear lugs on the Main Frame with bolts 3/4 x 2 (10), flatwashers (14), bushings (6) and locknuts (13). TW84 03/07 © 2007 Alamo Group Inc. ASSEMBLY Assembly Section 3-3... -

Page 82: Single Tail Wheel Assembly - Lift Type

Install bolts 11) & nuts (12) on top and bottom of tailwheel beam. Insert through pair of holes which will give approximate desired cutting height. Tighten all bolts per Torque Chart. TW84 03/07 Assembly Section 3-4 © 2007 Alamo Group Inc. -

Page 83: Dual Tail Wheel Assembly - Lift Type

Install bolts (10) & nuts (11 - not shown) on top and bottom of tailwheel beam. Insert through pair of holes which will give approximate desired cutting height. Tighten all bolts.. TW84 03/07 Assembly Section 3-5 © 2007 Alamo Group Inc. -

Page 84: Pull-Type

Attach the two level-lift control rods to the lower lugs on tongue and to lugs on the rear axle tube using pins, washers and cotter pins. Note: The adjusting nuts on control rods should be to rear of machine. Asm-R- 0037. TW84 03/07 © 2007 Alamo Group Inc. ASSEMBLY Assembly Section 3-6... -

Page 85: Hydraulic Or Manual Lift

Install the Wheels on the Wheel Hubs. Note: If Laminated Tires are used, place the flat side of the Lug Nut against the Wheel Asm-R-0127. Note direction of travel and curvature of rubber segments in tire and install as shown in Asm-R-0127. TW84 03/07 Assembly Section 3-7 © 2007 Alamo Group Inc. -

Page 86: Front And Rear Deflectors (Standard Equipment) And Chainguards (Optional Equipment At Extra Cost)

2" x 1-1/2" Bolts (3), Flatwashers (4) and Locknuts (5). Then attach Deflectors (6) and Bar Strap (7) to Mounting Plates with 1/2" x 1-1/2" bolts(8) Flatwashers(9) and Locknuts (10). Fasten Side Rear Chain TW84 03/07 © 2007 Alamo Group Inc. ASSEMBLY Assembly Section 3-8... -

Page 87: Chain Guard (Extra Equipment)

Guards attach with 1/2" x 3" bolts (10), Flatwashers (11), Spacers (12) and Locknuts (13). Fasten Side Rear Chain Guard (14) to Chain Guard Mounting Plates (1&2) with 1/2" x 1-1/4" bolts (15) Flatwashers (16) and Locknuts (17). TW84 03/07 © 2007 Alamo Group Inc. ASSEMBLY Assembly Section 3-9... - Page 88 ASSEMBLY TW84 03/07 Assembly Section 3-10 © 2007 Alamo Group Inc.

-

Page 89: Driveline Attachment

Remove top two bolts in front cover plate in gearbox. Attach shield assembly using 2 longer bolts (5) and washers (6) supplied. Spacers (4) must be installed between gearbox and shield bracket. Install bolts with lockwashers and tighten. Install wing nut (2) to retain shield. TW84 03/07 © 2007 Alamo Group Inc. ASSEMBLY Assembly Section 3-11... -

Page 90: Check Chains (Extra Equipment) For Lift Models

For additional safety in transport, raise mower as high as possible without having driveline hit deck and shorten check chains as much as possible to prevent inadvertent falling in transport. TW84 03/07 © 2007 Alamo Group Inc. ASSEMBLY Assembly Section 3-12... -

Page 91: Jackshaft Bearing Support Assembly (Figure -Pull Type)

Jackshaft through bearing (4) slide spacer (7) on Jackshaft (NOTE: Spacer goes between bearing and Quick Disconnect Yoke.) See parts pages for Jackshaft Bearing Support prior to Serial # 10705 NOTE: ALL Yokes must be set as shown for proper phasing. TW84 03/07 Assembly Section 3-13 © 2007 Alamo Group Inc. -

Page 93: Operation Section

OPERATION SECTION Operation Section 4-1 © 2007 Alamo Group Inc. - Page 94 Proper operation of the TW84 mower, as detailed in this manual, will help ensure years of safe and satisfactory use of the mower.

-

Page 95: Standard Equipment And Specifications

Mower with the wrong size Tractor can cause Mower component damage and equipment failure resulting in possible serious injury or death. TW84 03/07 © 2007 Alamo Group Inc. OPERATION TW84 30 HP Min. (Pull) 60 HP (Lift) 2”... -

Page 96: Operator Requirements

Serious injury or death to the operator or others could result if the operator is under the influence of drugs or alcohol. TW84 03/07 © 2007 Alamo Group Inc. OPERATION Drugs and alcohol will affect an operator’s... -

Page 97: Tractor Requirements

(ROPS). Always wear seat belts. Serious injury or even death could result from falling off the tractor--particularly during a turnover when the operator could be pinned under the ROPS. TW84 03/07 © 2007 Alamo Group Inc. OPERATION (SG-7) Operation Section 4-5... -

Page 98: Tractor Safety Devices

The power required to operate a mower is determined by the tractor PTO horsepower. For most mowing conditions, the TW84 mower requires a tractor with at least 60 HP for a lift unit and 30 HP for a pull type. -

Page 99: Drawbar-Pull Type Mower

Lift arm stabilizers must be used with this type of drawbar to prevent the mower from swaying from side to side. OPS-R- 0061 TW84 03/07 © 2007 Alamo Group Inc. OPERATION Operation Section 4-7... -

Page 100: Front End Weight

OPS-U- 0007 Do not mount the Tractor while the tractor is moving. Mount the Tractor only when the Tractor and all moving parts are completely stopped. TW84 03/07 © 2007 Alamo Group Inc. OPERATION (S3PT-16) Operation Section 4-8... -

Page 101: Boarding The Tractor

Use all handrails and steps for support and never rush or jump off the tractor. OPS-U- 0009 TW84 03/07 © 2007 Alamo Group Inc. OPERATION (SG-10) Operation Section 4-9... -

Page 102: Starting The Tractor

Use extreme caution when connecting the mower to the tractor. The mower should be securely resting at ground level or setting on blocks. Keep hands and feet from under the mower deck and clear of pinch points between the tractor hitch arms and mower pins. OPS-R-0001 TW84 03/07 © 2007 Alamo Group Inc. OPERATION (SG-23) (SG-13) -

Page 103: Connecting The Mower-Lift Type

Adjust any lower link check chains, guide blocks, or sway blocks to prevent the mower from swaying side to side and possible con- tact with tractor rear tires. TW84 03/07 © 2007 Alamo Group Inc. OPERATION Operation Section 4-11... -

Page 104: Connecting The Mower-Pull Type

Lower the jack until the tongue is completely supported by the drawbar. Remove jack from the tongue and place on storage bracket of mower main frame. TW84 03/07 © 2007 Alamo Group Inc. OPERATION Operation Section 4-12... -

Page 105: Safety Chains

Shut down the tractor and remove the key. Level the mower deck front to rear by extending or retracting the 3-point top link. TW84 03/07 © 2007 Alamo Group Inc. OPERATION (SG-14) Operation Section 4-13... - Page 106 3-Point lift maintaining a set height or when a constant preadjusted cut height is required. See Check Chains in the Assembly Section for this accessory. TW84 03/07 © 2007 Alamo Group Inc. OPERATION Align Operation Section 4-14...

-

Page 107: Setting Mowing Height-Pull Type

In addition, a more even distribution of the clippings from the rear of the mower will be achieved with this angle TW84 03/07 © 2007 Alamo Group Inc. OPERATION . OPS-R-0002_D... -

Page 108: Driveline Attachment

At its shortest length, there must be at least a 1” clearance between each profile end and opposite profile universal joint. At its farthest operating extension, a minimum profile engagement of 12” must be maintained. TW84 03/07 © 2007 Alamo Group Inc. OPERATION Operation Section 4-16 (S3PT-17) - Page 109 NOTE: When raising the mower, at least 1” clearnace must be maintained between the driveline and the mower deck. If necessary, place an upper lift stop on the 3-point hitch control lever to limit the height the mower can be raised. OPS-R-0005_C TW84 03/07 © 2007 Alamo Group Inc. OPERATION Operation Section 4-17...

-

Page 110: Pre-Operation Inspection And Service

Make sure all pins have cotter pins and washers. Serious injury may occur from not maintaining this machine in good working order. TW84 03/07 © 2007 Alamo Group Inc. OPERATION (SG-14) (SG-21) -

Page 111: Tractor Pre-Operation Inspection/Service

Ensure the manual canister is secured to the equipment with the operator’s manual inside. • Ensure all decals are in place and legible. Replace missing, damaged, and illegible decals. OPS-U- 0011 TW84 03/07 © 2007 Alamo Group Inc. OPERATION The following Maintain these Operation Section 4-19... - Page 112 Missing, broken, or worn items must be replaced at once to reduce the possibility of injury or death from thrown objects, entanglement, or blade contact. TW84 03/07 © 2007 Alamo Group Inc. OPERATION All safety devices should be inspected (SGM-3)

- Page 113 • Ensure the gearbox vent is in place and free from clogs. OPS-R-0040 TW84 03/07 © 2007 Alamo Group Inc. OPERATION Operation Section 4-21...

-

Page 114: Cutting Component Inspection

• Ensure carrier hub nut is tightened with the cotter pin inserted and spread. OPS-R-0041_A 9.3 Cutting Component Inspection Inspect blade pan and blade assembly for the following: OPS-U-0031 TW84 03/07 © 2007 Alamo Group Inc. OPERATION Operation Section 4-22... - Page 115 Failure to replace abnormally worn blades may lead to catastrophic failure of the blades and ejection of the broken part with tremendous force which may cause serious bodily injury or death. OPS-U-0032 TW84 03/07 © 2007 Alamo Group Inc. OPERATION Operation Section 4-23...

- Page 116 Blade bolts are tight Wheel lug nuts are tight Transport locks are in good condition Operator’s Signature: DO NOT OPERATE an UNSAFE TRACTOR or MOWER TW84 03/07 © 2007 Alamo Group Inc. OPERATION Make ____________________ ________________ Shift Condition at Start of Shift...

- Page 117 The engine coolant fluid level is full The radiator is free of debris The air filter is in good condition Operator’s Signature: DO NOT OPERATE an UNSAFE TRACTOR or MOWER TW84 03/07 © 2007 Alamo Group Inc. OPERATION Make ____________________ ________________ Shift Condition at...

-

Page 118: Driving The Tractor And Implement

When operating in traffic always use the Tractor’s flashing warning lights and reduce your speed. Be aware of traffic around you and watch out for the other guy. TW84 03/07 © 2007 Alamo Group Inc. OPERATION (SG-23) (SG-19) -

Page 119: Starting The Tractor

When operating in traffic, always use the Tractor’s flashing warning lights and reduce your speed. Be aware of traffic around you and watch out for the other guy. TW84 03/07 © 2007 Alamo Group Inc. OPERATION Operation Section 4-27... -

Page 120: Raising The Mower

Use extreme caution when operating on steep slopes. Keep the tractor in a low gear when going downhill. DO NOT coast or free-wheel downhill. OPS-R-0019 TW84 03/07 © 2007 Alamo Group Inc. OPERATION When OPS-R-0042 Determine the Operation Section 4-28... -

Page 121: Crossing Ditches And Steep Inclines

When confronted with an incline or ditch, do not approach from an angle which is perpendicular or straight on as damage to or over-collapse of the driveline may occur. OPS-R-0021_A TW84 03/07 © 2007 Alamo Group Inc. OPERATION Operation Section 4-29... -

Page 122: Operating The Tractor And Implement

Stop mowing immediately if blades strike a foreign object. Repair all damage and make certain rotor or blade carrier is balanced before resuming mowing. (SGM-5) TW84 03/07 © 2007 Alamo Group Inc. OPERATION Inspect the area before Operation Section 4-30... -

Page 123: Foreign Debris Hazards

If a bystander comes within 300 feet of the tractor while the mower is being operated, stop the tractor at once, idle the engine and disengage the PTO. Do not engage the PTO again until all bystanders are well past the 300 foot distance. OPS-R-0024 TW84 03/07 © 2007 Alamo Group Inc. OPERATION (SGM-6) Remove all... -

Page 124: Engaging The Power Take Off (Pto)

Do not put hands or feet under mower decks. Blade Contact can result in serious injury or even death. Stay away until all motion has stopped and the decks are securely blocked up. TW84 03/07 © 2007 Alamo Group Inc. OPERATION (SRM-1) (SRM-7) -

Page 125: Pto Rpm And Ground Speed

When mowing in reverse, operate the tractor and mower at a much reduced ground speed to ensure control is maintained of the tractor and cutter. TW84 03/07 © 2007 Alamo Group Inc. OPERATION OPS-R-0026_H Operation Section 4-33... - Page 126 12” from ground level, disengage the tractor PTO and wait for all mower rotation to come to a complete stop before proceeding to raise the mower. OPS-R-0027_B TW84 03/07 © 2007 Alamo Group Inc. OPERATION Never raise the Operation Section 4-34 (SGM-1)

- Page 127 90 degree angle to the first pass to reduce streaking for a more uniform cut. OPS-R-0044 TW84 03/07 © 2007 Alamo Group Inc. OPERATION (SRM-7) If possible, Operation Section 4-35...

-

Page 128: Shutting Down The Implement

Use extreme care to keep feet and hands from under the mower and clear of any pinch points caused by the tractor hitch arms and mower pins. OPS-R-0030_A TW84 03/07 Operation Section 4-36 © 2007 Alamo Group Inc. - Page 129 Do not let the driveline fall into mud or dirt, which can contaminate the bearing and shorten the life of the driveline. OPS-R-0031_A TW84 03/07 © 2007 Alamo Group Inc. OPERATION Lower the Operation Section 4-37...

-

Page 130: Mower Storage

By using good judgement and following safe transport procedures, the possibility of accidents while moving between locations can be substantially minimized. OPS-U- 0017 TW84 03/07 © 2007 Alamo Group Inc. OPERATION (SG-10) Operation Section 4-38... -

Page 131: Transporting On Public Roadways

Make certain that the “Slow Moving Vehicle” (SMV) sign is installed in such a way as to be clearly visible and legible. When transporting the Equipment use the Tractor flashing warning lights and follow all local traffic regulations. TW84 03/07 © 2007 Alamo Group Inc. OPERATION NOTE: When... - Page 132 Use caution and reduce speed if other vehicles or pedestrians are in the area. OPS- U- 0022 TW84 03/07 © 2007 Alamo Group Inc. OPERATION emblem roads, have Operation Section 4-40...

-

Page 133: Hauling The Tractor And Implement

OPS-U- 0025 TW84 03/07 © 2007 Alamo Group Inc. OPERATION Operation Section 4-41... -

Page 134: Troubleshooting Guide

Blade rotation incorrect. Using Straight Blades. Carrier RPM too low. Mower not level. Tractor tires mashing down grass. Ground speed too fast. TW84 03/07 © 2007 Alamo Group Inc. OPERATION against Remedy Loosen locked Blade. Replace Driveline. Replace Blades in sets. - Page 135 BREAKING BLADE BOLTS Operating with loose Blade Bolts. Worn Blade Bolt. CUTTING TOO HIGH Blades bent up. Blade Carrier bent. TW84 03/07 © 2007 Alamo Group Inc. OPERATION Free blades. Replace blade bolts. Replace Blades. Increase cutting height. Replace Blades; with hardened, high-quality, Rhino Blades from the manufacturer.

- Page 136 DRIVELINE INTEGRAL Integral Shields deformed. SHIELDS RATTLING OR NOT TURNING FREELY Nylon Bearing worn. TW84 03/07 © 2007 Alamo Group Inc. OPERATION Turn Blades right side up and tighten. Raise mower and reduce ground speed. Use protective device with joint.

-

Page 137: Maintenance Section

MAINTENANCE SECTION Maintenance Section 5-1 © 2007 Alamo Group Inc. -

Page 138: Maintenance

U-joints, gearbox, and/or driveshaft. Lubrication Fitting Location ITEM DESCRIPTION FREQUENCY U-Joints 8 hours Gearbox Check Daily Tailwheel Pivot 10 Hours Wheel Hubs Weekly Telescoping 8 hours TW84 03/07 © 2007 Alamo Group Inc. MAINTENANCE Maintenance Section 5-2... -

Page 139: Gearbox

Tail Wheel Bearings are packed at the factory with heavy-duty bearing grease. Grease Fittings are provided in the Wheel Hub and Tail Wheel Beam. Grease after 10 hours of use. Mnt-R-0107. TW84 03/07 Maintenance Section 5-3 © 2007 Alamo Group Inc. -

Page 140: Driveline Lubrication

16 hours. Mnt-0024. Make certain that the Driveline Integral Shields are free to telescope and rotate around the Driveline without binding. TW84 03/07 © 2007 Alamo Group Inc. MAINTENANCE FIGURE Mnt-0024. Do not force grease through the Needle Cup... -

Page 141: Blade Servicing

Do not heat or weld on hard surface blades as this can alter material strength causing blades to fail in a hazardous manner that could cause injury. TW84 03/07 © 2007 Alamo Group Inc. MAINTENANCE (SGM-10) Maintenance Section 5-5... -

Page 142: Blade Removal

IMPORTANT: Always recheck gearbox output shaft slotted blade carrier retaining nut torque after a few hours operation. Avoid personal injury. Do not work under cutter without support blocks to keep frame from falling. TW84 03/07 © 2007 Alamo Group Inc. MAINTENANCE Maintenance Section 5-6... -

Page 143: Slip Clutch

Attach machine to tractor, set engine at approximately half throttle and quickly engage PTO. This procedure will break clutch facings loose and allow the proper torque to be maintained. Return nuts and bolts to original position. - See Mnt-R-0109. TW84 03/07 © 2007 Alamo Group Inc. MAINTENANCE Maintenance Section 5-7... -

Page 144: Mower Storage

NOTE: These values apply to fasteners as received from supplier, dry or when lubricated with normal engine oil. They do not apply if special graphited or molydisulphide greases or other extreme pressure lubricants are used. This applies to both UNF fine and UNC coarse threads. TW84 03/07 © 2007 Alamo Group Inc. MAINTENANCE Maintenance Section 5-8... - Page 146 LIMITED WARRANTIES 1.01. Servis-Rhino warrants for one year from the purchase date to the original non-commercial, governmental, or municipal purchaser (“Purchaser”) and warrants for six months to the original commercial or industrial purchaser (“Purchaser”) that the goods purchased are free from defects in material or workmanship. 1.02.

- Page 147 TO THE OWNER/OPERATOR/DEALER In addition to the standard Limited Warranty shown on the facing page, Rhino also provides: 1.) A FIVE-YEAR (60 months) LIMITED WARRANTY* on GEARBOX components provided they have been properly maintained† and have not been subjected to abuse or mis-use except as limited below. * WARRANTY LIMITATIONS - GEARBOX A) Warranty is ONE-YEAR (12 MONTHS) for Seals (After one year, seals are considered to be WEARING PARTS and replacement is the users' responsibility.)

- Page 148 TW84 ROTARY CUTTER TW84-SOM-03/07 P/N 00760962C Printed U.S.A...

- Page 149 DATE DELIVERY SIGNED, WARRANTY WARRANTY THIS IMPORTANT! COPY LAST DROP WARRANTY drop tape, tear), 60936-9907 City, Gibson Ave. Sangamon 1020 SERVIS-RHINO ® WARRANTY WILL ATTENTION: DEALER DAYS OUT, FILLED THIS PLACE SIGN, OWNER FILL PLEASE fold Please Company Group Alamo...

-

Page 150: Warranty Registration Information

Operator’s Manual including safety signs, safety equipment, safe operation, maintenance, and the potential hazards of unauthorized alteration or modification of the product. I have been informed of the warranty provisions and know that the warranty is not in effect until this form is received by Alamo Group. - Page 152 Operator’s Manual including safety signs, safety equipment, safe operation, maintenance, and the potential hazards of unauthorized alteration or modification of the product. I have been informed of the warranty provisions and know that the warranty is not in effect until this form is received by Alamo Group.

- Page 154 Operator’s Manual including safety signs, safety equipment, safe operation, maintenance, and the potential hazards of unauthorized alteration or modification of the product. I have been informed of the warranty provisions and know that the warranty is not in effect until this form is received by Alamo Group.

Need help?

Do you have a question about the TW84 and is the answer not in the manual?

Questions and answers