Advertisement

Quick Links

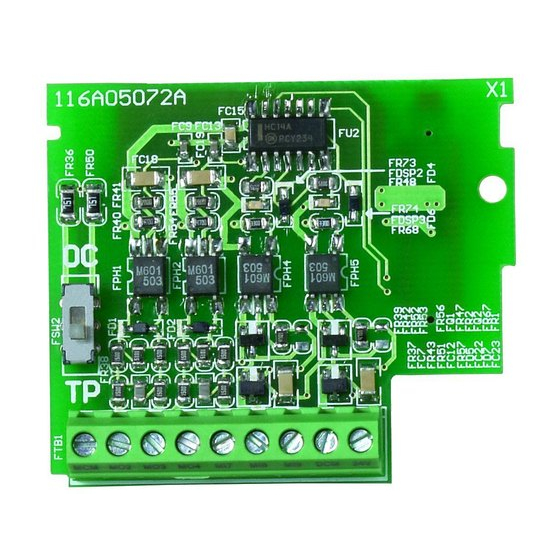

EME-PG01

Please thoroughly read this instruction sheet before installing option cards and putting them into use.

The content of this instruction sheet may be revised without prior notice. Please consult our distributors or download the

most updated version at http://www.delta.com.tw/industrialautomation.

Layout

PG Card (EME-PG01)

Pul se Fe ed ba ck

Installation

Make sure that the AC Motor Drive is powered off before operation.

DO NOT insert or remove the card when the AC Motor Drive is

powered on.

Please mount the extension card as shown and fix it with the screw

packed with the card.

Terminals Screw Torque: Maximum 2kgf-cm

Wire Length

Types of Encoder Output

Maximum Length

Voltage

Open Collector

Line Driver

Complementary

NOTE

EME-PG01 needs additional power source DC 5 ~ 24V, as to

details please refer to table of terminals descriptions.

Only when the extension card is correctly installed on the AC

Motor Drive, the extension card will be automatically detected.

The parameters can be set in Group 13. If extension card is not

installed, only parameters Group 0 ~ Group 10 can be set.

Refer to Chapter 5: Parameters in the user manual for further

details.

Notes

Please use a shielded cable to prevent interference. Do not run

control wires parallel to any high voltage AC power line (200 V and

above).

The wire length and signal frequency are in inverse proportion.

Always use this product in a clean indoor location free from dust,

corrosive gas and liquid.

When the relays are used to switch inductive loads (relays,

contactors, motors, etc), connect an RC network or Varistor parallel

to the load to suppress voltage spikes.

For safety, it is recommended to use fuses for the circuitry that is

switched by the relays. The fuse specification must be within the

specified contact limits.

The ends of wires must be tinned or crimped.

To avoid interference, route the extension card wires separately and

as far away (at least 15cm) as possible from other control wires,

motor wires and power wires, etc. Where these wires must cross

each other, please make sure they are at a 90

Always use and operate this product within the limit of its

specifications.

Pulse Generator Card for VFD-E Series Instruction Sheet

P ul se O utp ut

Screw torque:

Maximum 2kgf-cm

Wire Gauge

50m

50m

14 ~ 24 AWG

2

(2.1 ~ 0.2 mm

)

300m

70m

o

angle.

Specification

Environmental

Operating Temperature

Storage Temperature

Ambient Humidity

Installation Altitude

Vibration

Terminals Descriptions

Terminal Symbols

Input Voltage: DC 5 ~ 24V

Vcc

When the encoder output type is voltage output,

input voltage is DC 12 ~ 24V

0V

Power source and input signal common

Input signal from the encoder. Input type is selected

A ,

A

by SW2. It can be 1-phase or 2-phase input.

B ,

B

Maximum 300KP/sec

Output signal from the encoder.

A/O, B/O

Open collector: max. output DC24V 50mA

Grounding

Types of Encoder Output

Types of Encoder

SW2

Output

OC

VCC

Voltage

O/P

TP

0V

OC

Q

Line driver

TP

Q

OC

VCC

Complementary

O/P

TP

0V

OC

VCC

O/P

TP

Open

0V

collector

Note: Based on the design, the input signal terminals from

the encoder should be connected to the terminals

A

of

and

A and B, so as to avoid damage to the encoder.

2007-07-09

5011659701-TPG 1

o

o

-10

C to 50

C (non-condensing and not frozen)

o

o

-20

C to + 60

C

Less than 90%RH (non-condensing)

Below 1000m

Below 20 Hz: Maximum 9.81 m/s

2

20 ~ 50Hz: Maximum 5.88 m/s

Descriptions

Wiring Diagram

VFD-E

NFB

U(T1)

R(L1)

R

V(T2)

S

S(L2)

W(T3)

T

T(L3)

EME-PG01

A

A

B

B

OC

Vcc

0V

A/O

TP

B/O

0V

*The power source of RPM meter

is supplied by the customers.

VFD-E

NFB

U(T1)

R(L1)

R

V(T2)

S

S(L2)

W(T3)

T

T(L3)

EME-PG01

A

A

B

B

OC

Vcc

0V

A/O

TP

B/O

0V

*The power source of RPM meter

is supplied by the customers.

B

on EME-PG01 card, not the terminals of

2

(1G);

(0.6G)

Motor

3~

A

A

Vin

PG

B

GND

B

+

DC

5~24V

-

RPM Meter

Motor

3~

A

Vin

PG

GND

B

+

DC

5~24V

-

RPM Meter

Advertisement

Summary of Contents for Delta Electronics Pulse Generator Card EME-PG01

- Page 1 EME-PG01 Pulse Generator Card for VFD-E Series Instruction Sheet Please thoroughly read this instruction sheet before installing option cards and putting them into use. The content of this instruction sheet may be revised without prior notice. Please consult our distributors or download the most updated version at http://www.delta.com.tw/industrialautomation.

- Page 2 EME-PG01 請詳細閱讀下列說明後才使用本產品,以確保使用安全。 由於產品精益求精 , 當內容規格有所修正時 , 請洽詢代理商或至台達網站(http://www.delta.com.tw/industrialautomation/)下載最新版本 。 外觀 PG 卡 (EME-PG01) 脈波回授 安裝方式 安裝前請確認驅動器在斷電狀態下。 請以下圖方式安裝擴充卡並使用包裝內的螺絲固定以避免擴充卡鬆 脫。 端子螺絲扭力︰Maximum 2kgf-cm 線徑線長 編碼器輸出型式 最大長度 電壓輸出型 Voltage 開集極型 Open Collector 差動型 Line Driver 300m 互補型 Complementary NOTE EME-PG01 需外加電源 DC 5 ~ 24V,詳細規格請參考端子規格表。 若擴充卡正確安裝至變頻器上,變頻器將會自動偵測擴充卡且可使用...

Need help?

Do you have a question about the Pulse Generator Card EME-PG01 and is the answer not in the manual?

Questions and answers