Trane Symbio 700 Manual

- Troubleshooting manual (210 pages) ,

- Application manual (60 pages) ,

- Integration manual (36 pages)

Advertisement

Overview

Purpose

The purpose of this document is to provide instructions for integrating the Symbio™ 700 controller into building automation systems. This document is targeted to system integrators and controls contractors.

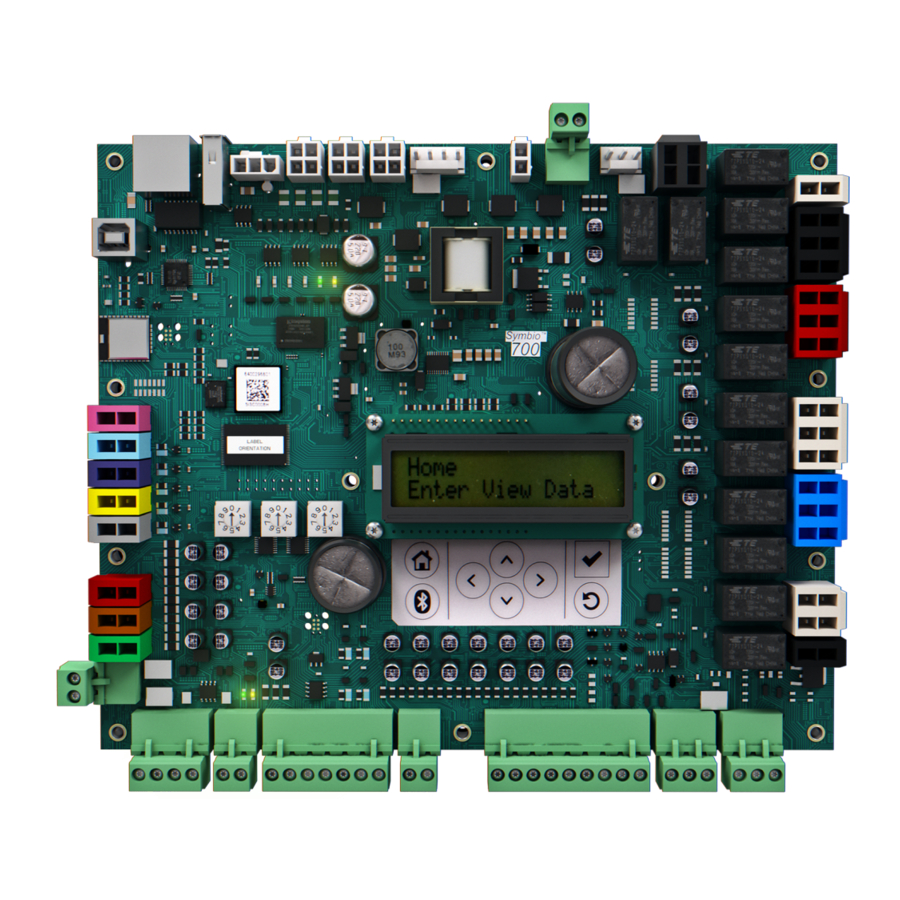

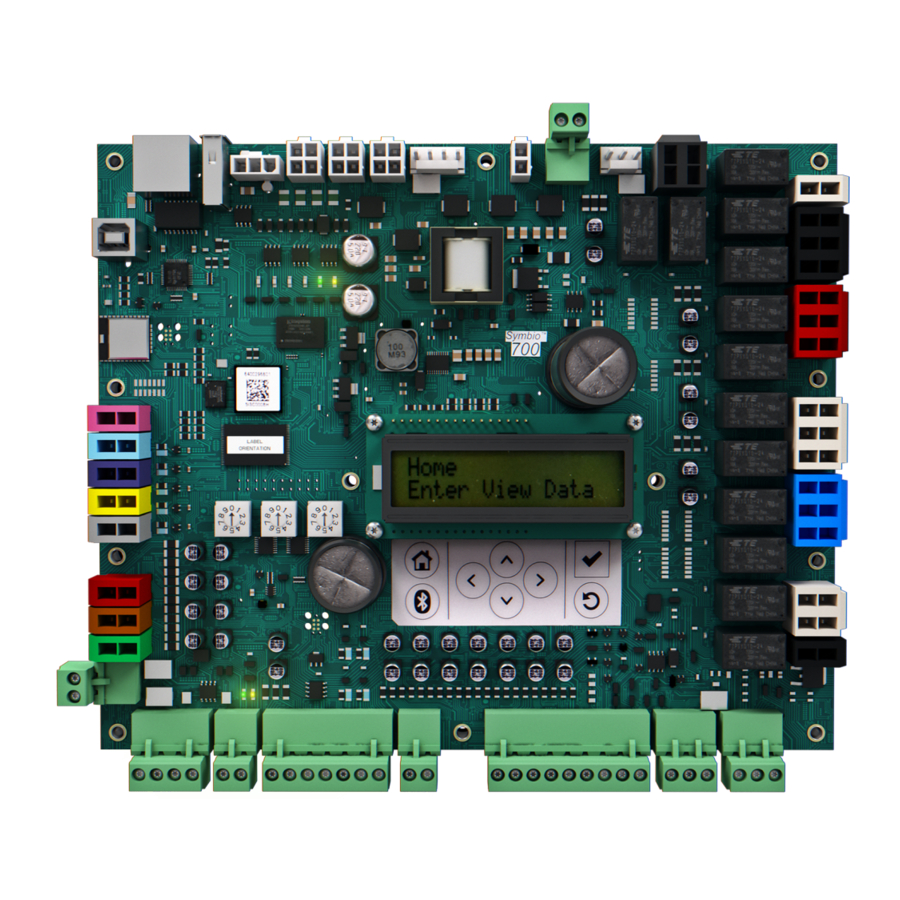

Symbio™ 700 Controller Overview

The Symbio™ 700 controller has been installed, programmed, wired, commissioned, and tested in the factory prior to shipment. While some sensors and end devices are normally wired in the field, nearly all other wiring is factory-provided. Power for the controller is provided and connected from within the control panel.

The unit and associated controller can be applied as standalone or as part of a building automation system.

Note: For communicating applications to third-party control systems, network communication wiring must be provided by others.

Communication Options

The Symbio™ 700 controller supports the following communication protocol options for integration to either Trane or Non-Trane control systems:

- BACnet® MS/TP

- BACnet IP

- BACnet Zigbee® (Air-Fi)®

- Modbus® RTU

- Modbus TCP

- LonTalk®

For information pertaining to the integration of the Symbio 700 controller using LonTalk communication, refer to the integration guides specific to those applications.

Units of Measure

The communicated data of the Symbio™ 700 controller can be changed from inch-pound (IP) to the international system (SI) if desired. This can be done by using the Symbio™ Service and Installation app or the Onboard Display.

Regardless of the communicated (system) units of measure, the user may change the displayed units of measure the mobile app or Onboard Display. These user preference units of measure are independent of the communicated units.

Communication Setup and Configuration

Depending on the protocol and associated settings ordered from the factory, some changes may be required during equipment start-up. These can be made using the mobile app or onboard display protocol settings and/or IP settings in the Symbio™ controller.

Mobile App

The Trane Symbio™ Service and Installation mobile app is required to setup, edit, and confirm the communication protocol and associated settings.

The free download of Trane Symbio Service and Installation mobile app is available on the App Store® for iOS, and on Google Play® for Android™.

Figure 1. Trane Symbio service and installation mobile app

Bluetooth Pairing

Quick Connection Instructions

Follow these instructions to quickly connect the mobile app to the Symbio™ 700 controller:

- Turn on Bluetooth®[1].

- Tap

![]() .

. - Start the app. TapView Available Devices.

- Select the controller.

- TapOK to pair.

- Tap

![]() .

.

Connecting to the Symbio™ 700 controller

- Enable Bluetooth®1 on your smart device.

- Access the Symbio 700 controller in the low voltage portion of the equipment.

Figure 2. Symbio 700 controller

![Trane - Symbio 700 - Connecting - Step 1 Connecting - Step 1]()

- Tap

![]() on Symbio 700 keyboard/display to turn on Bluetooth.

on Symbio 700 keyboard/display to turn on Bluetooth. - Confirm the status of Bluetooth communications. A solid blue LED indicates a successful pairing.

Table 1. Bluetooth communication status

Figure 3. Symbio 700 bluetooth status![]()

Blue LED Display Description Tap for On/Off Off NOT CONNECTED Bluetooth Off Blinking WAITING... Bluetooth On — Not Paired On Solid CONNECTED Bluetooth On — Connected/ Paired

![Trane - Symbio 700 - Connecting - Step 2 Connecting - Step 2]()

- Start the mobile app on your smart device.

Figure 4. Login screen

![]()

- On the login screen, tapView Available Devices in the lower section of the screen. Or Trane personnel can login using their Trane Connect username and password.

- On the Unit List page, select the Symbio 700 controller to which you want to pair. If the controller is not listed, tap the refresh arrow in the upper right-hand corner of the screen.

Note: If a Symbio 700 is not the original Symbio controller as shipped with the equipment, the Bluetooth equipment list will list the controller serial number, instead of the equipment serial number. - When prompted, pair the app to the Symbio 700 controller. A popup message displays a 6-digit random number. The same number is shown on the display of the Symbio™ 700 controller until the pairing is complete, allowing the user to confirm connection to the intended controller.

Figure 5. Bluetooth pairing

![Trane - Symbio 700 - Connecting - Step 3 Connecting - Step 3]()

- Tap

![]() on the Symbio 700 on-board keyboard/display to complete the connection.

on the Symbio 700 on-board keyboard/display to complete the connection.

When the LED light is a solid blue and the display reads Bluetooth Connected, the Bluetooth pairing and connection is complete.

To keep the list of previously-connected devices manageable, the Bluetooth smart devices list is limited to 10 devices. When 10 or more Bluetooth devices are defined on the smart device, connection to the Symbio 700 controller is not allowed.

- iOS devices - delete any unused devices until there are less than 10 items.

- Android devices - the devices list is automatically limited to 10 items.

The Symbio Installation and Service tool is required to view, manage, and configure the following:

- Building Automation System configuration (Advanced Controller Configuration)

- BACnet® over Zigbee® (Air-Fi® Wireless)

- BACnet IP (Internet Protocol)

- BACnet MS/TP

- LonTalk®

- Modbus RTU

- Modbus TCP

- Historical Alarms

- Firmware Update (includes both the Symbio 700 Module and the Options Modules)

- Backing up and Restoring the database

- Transfer Settings from one controller to another

- Return the Symbio 700 to its Factory Default configuration by using the Factory Default Database (if available)

- Update the license file

For more detailed information on the Symbio Service and Installation Mobile Application, refer to Quick Start Guide, Symbio Service and Installation App (BAS-SVN043*-EN).

Backing Up and Restoring the Database

Best practice is to backup the database after the unit is fully commissioned and set up. The database can be backed up to a technician-provided USB memory stick by using the Symbio Service and Installation Tool. The Symbio™ 700 controller has a USB port for this purpose. A backup file can be quickly restored into a service board in the event of board replacement. The backup file contains all Symbio 700 installation information, including configuration, setpoints and settings, communications setup, XM Module setup, TGP2 programs, and the Factory Default File.

Note: Restoring a Backup file is best practice when making a service replacement of a Symbio 700 board.

Protocol Configuration

After completing Bluetooth pairing, the mobile app main screen displays. From here, configure the Symbio™ 700 protocols.

- On the bottom of the home screen, tap Tools.

Figure 6. Tools

![]()

- Tap Protocol Configuration to select the appropriate protocol.

Figure 7. Protocol Configuration

![]()

- Tap Edit.

Figure 8. Edit

![]()

- Edit according to the connectivity requirement of the building automation system.

BACnet MS/TP Protocol Setup

The Symbio™ 700 controller rotary address sets the BACnet® MS/TP MAC address. Each BACnet® MS/TP device on the same MS/TP link must have a unique MAC address. The valid range of BACnet® MS/TP MAC addresses for the Symbio™ 700 is 001–127.

Changing the rotary address will immediately take effect and does NOT require a power cycle to the Symbio™ 700 controller.

The rotary address also sets the BACnet® Device ID which gives a range of 1-127. All BACnet® devices must have a unique BACnet® Device ID. The Device ID can be edited using the mobile app or Onboard Display.

To configure the Symbio™ 700 controller for BACnet® MS/TP Protocol:

- Set theProtocol selection to BACnet® MS/TP.

- Verify theBaud Rate (default is 76,800 bps). All BACnet® MS/TP devices on an MS/TP link must communicate at the same baud rate.

- Verify theCurrent Device ID. To change the device ID, tap Use Software Device ID and enter the desired device ID (See Figure 9).

Note: The valid Device ID range using a software Device ID is 1 – 4194302 as defined by the BACnet standard.

Figure 9. Edit Protocol Configuration

![]()

- Tap Apply to save your changes.

BACnet IP Protocol Setup

The Symbio™ 700 controller can communicate BACnet/IP using a standard Ethernet cable. Connect the Ethernet cable (RJ-45 connectors) between the Ethernet port on the Symbio™ 700 controller and the BACnet network.

Set up the IP address of the Symbio™ 700 controller before changing other BACnet/IP configuration parameters:

- From the Tools page, tap IP Configuration.

Figure 10. IP Configuration

![]()

- Tap Edit.

- Configure IP Address to either obtain the IP address automatically using DHCP or define a Static IP Address. If Static IP Address has been selected, manually enter the applicable IPAddress, Subnet Mask, and Default Gateway.

- Setup the DNS section if using a Domain Name System server to identify the Symbio™ 700 controller by host name.

Figure 11. Host Name

![]()

- Tap Save.

To configure the Symbio™ 700 controller for BACnet IP Protocol:

- Set the Protocol select to BACnet IP.

- Verify the current Device ID. To change the Device ID, click Use Software Device ID and enter the desired Device ID. Most installations will not require you to manually change the BACnet Device ID.

Note: The valid Device ID range using a software Device ID is 1 – 4194302 as defined by the BACnet standard. - Tap Apply to save your changes.

- Set the UDP Port to match the port number used by the BACnet IP network.

- Select BBMD only if the Symbio™ 700 controller is the only BACnet IP device on the IP subnet.

Figure 12. Edit Protocol Configuration

![]()

- Tap Apply.

Air-Fi® Wireless

Air-Fi Wireless – Conforms to ANSI/ASHRAE Standard 135-2016 (BACnet®/ZigBee®1). Air-Fi Wireless provides reliable and secure, and location-flexible communication between equipment controls, sensors, and service tools to the system controller.

Air-Fi networks will be setup by a Trane technician. Integration to a Symbio™ 700 controller setup for Air-Fi communications uses BACnet over Zigbee communications through a Tracer SC+ system controller. Contact your local Trane office for additional information if the Symbio™ 700 controller is setup for Air-Fi Wireless.

Communication Wiring

BACnet® MS/TP or Modbus RTU

The BACnet MS/TP or Modbus RTU communication wire is connected to the J17 Connector. Observe wire polarity when connecting to the + and – terminals. The + terminals and the – terminals are internally connected. The second set of + and – terminals on the J17 Connector are used to make it easier to wire the next device in the communication daisy chain.

BACnet® IP or Modbus TCP

If using BACnet/IP or Modbus TCP using a standard Ethernet cable, connect the Ethernet cable with RJ-45 connectors to the Ethernet port.

Refer to the BACnet standard or BACnet® MS/TP Wiring and Link Performance Best Practices and Troubleshooting guide (BAS-SVX51*–EN) for detailed information on MS/TP wiring.

Figure 13. Communication wiring

BACnet Points List

Object Naming Conventions

The communicated points for the Symbio™ controllers are generally named according to their function. While many of the points are read-only, others include both read and write capability. The established naming convention helps to identify the capabilities of each point. For most points, the suffix identifies the capability according to the following definition.

While there are some exceptions, the majority of the points have been defined according to these guidelines.

| Suffix | Description |

| Status | Points with the Status suffix are defined as read-only. The status point reports the value being used by the controller. |

| Local | Points with the Local suffix are defined as read-only. The local point reports values associated with controller sensors, both wired and wireless. The local value may or may not be actively used by the controller, depending on the presence or absence of a communicated value (BAS). When both a local and communicated value exist, the communicated value is used. |

| Active | Points with the Active suffix are defined as read-only. Points designated as active are normally the result of the arbitration between a communicated value. The active point reports the value being input to the controller. |

| Setpoint | Points with the Setpoint suffix are defined as either read-only or read/write. For BACnet®, the binary input, analog input and multi-state input points are all read-only. These setpoints report the value currently in use by the controller. The analog value, binary value and multi-state value points are all read/write. These points are provided for use by the building automation system (BAS). When used, these points are written internally to arbitration logic. This defines the interaction with hardwired points, editable software configuration points and the relinquish default value/state. Refer to the Appendix for additional information. |

| Input | Points with the Input suffix are defined as read-only. These points normally reflect the status of a sensor input, either hardwired or communicating wirelessly (Air-Fi®). However, the input point reflects the arbitrated result of the controller sensor input and a communicated value, if present. When both a controller sensor and communicated value exist, the controller will use and report the communicated value. |

| Arbitrator | Points with the "Arbitrator" suffix are to be used as read-only. The arbitrator prioritizes inputs from communicating points, hardwired points and stored defaults points. The priority array of the arbitration point displays each of the values provided, including the active status, indicating which of the input sources is being used. Refer to the Appendix for additional information. |

| BAS | Points with the BAS suffix are defined as read/write. These points are provided for use by the building automation system (BAS). When used, these points are written to arbitration logic. This defines the interaction with hardwired points, editable software configuration points and the relinquished default value/state. Refer to the Appendix for additional information. |

| Command | Points with the Command suffix are defined as read/write. These points are written to change the default behavior of the controller. Once written, these point values may be persisted. |

| Request | Points with the Request suffix are defined as read/write. These points are written to request a change the operating behavior of the controller. |

BACnet Points List

Download

Equipment-specific BACnet® points lists are available on trane.com product page.

Arbitrations

Standalone Control vs Enable External/BAS Control

The Symbio™ 700 controller allows for two types of control: standalone control and external/BAS control.

Standalone Control

- The Arbitration Method Request point must be set toStandalone Control.

- In Standalone Control, the Symbio™ 700 controller will ignore all BAS input and the only way to control the equipment is through the onboard display or local inputs.

- Standalone Control should only be used in very specific situations as there is limited flexibility on control of the equipment.

Enable External/BAS Control

- The Arbitration Method Request point must be set toEnable External/BAS Control.

- In Enable External/BAS Control, the Symbio™ 700 controller will look at all available sources (wired, Air-Fi, BAS, etc) and will determine which option to use based on validity of source. In general if BAS input is not valid, the Symbio™ 700 controller will revert back to Air-Fi or wired inputs for the source.

- Enable External/BAS Control is the default setting for the equipment and is the preferred setup for most situations because of the flexibility it offers.

Space Temperature Setpoint Single Setpoint Method

The Space Temperature Single Setpoint Arbitration Method is used to determine the correct space temperature setpoint value when you have a single setpoint from various local inputs, wired or wireless, and the potential for a Building Automation System to communicate a value.

There are two methods to determine the Space Temperature Setpoint Active when using a single setpoint. The Symbio™ 700 controller will use the Arbitration Method Request point to determine the method, below is the breakdown of each step.

Standalone Control

- The Arbitration Method Request point must be set to Standalone Control.

- The Symbio™ 700 controller will then look at available inputs and determine which one to use.

- If the Symbio™ 700 controller only has a valid wired sensor input it will use it to determine the active setpoint.

- If the Symbio™ 700 controller only has a valid Air-Fi sensor input it will use it to determine the active setpoint.

- If the Symbio™ 700 controller has both a valid wired and a valid Air-Fi sensor input it will first use the Air-Fi sensor input to determine the active setpoint. If the Air-Fi sensor fails or loses communication the Symbio™ 700 controller will use the wired sensor to determine the active setpoint. If both the wired and Air-Fi sensors fail then the Symbio™ 700 controller will use the default setpoint to determine the active setpoint.

- The Space Temperature Setpoint BAS point is ignored during Standalone Control.

- After determining the correct setpoint input to use the Symbio™ 700 controller will write its decision to the Space Temperature Setpoint Input Active point.

- The Symbio™ 700 controller will then look at the Occupancy Status point and the Demand Shed Input point to determine which offsets to use.

- If the Occupancy Status point is Occupied or Occupied Bypass then the Symbio™ 700 will add and subtract the Occupied Offset point amount. If active, the Symbio™ 700 will also add and subtract the Demand Shed Offset Setpoint point amount.

- If the Occupancy Status point is Occupied Standby then the Symbio™ 700 will add and subtract the Occupied Standby Offset point amount. If active, the Symbio™ 700 will also add and subtract the Demand Shed Offset Setpoint point amount.

- The Symbio™ 700 controller will apply the Space Heating/Cooling Limits to the setpoints.

- If the Occupancy Status Point is Unoccupied then the Symbio™ 700 will use the Unoccupied Cooling Setpoint and the Unoccupied Heating Setpoints.

- After determining the correct Occupancy Status and applying the limits the Symbio™ 700 controller will write the new heating and cooling setpoints to Space Temp Cooling Setpoint Status point and Space Temp Heating Setpoint Status point.

- The Symbio™ 700 controller will then look at the Heat Cool Mode Status point to determine the correct active setpoint.

- If the Heat Cool Mode Status is Heat then the Symbio™ 700 controller will use the Space Temp Heating Setpoint Status.

- If the Heat Cool Mode Status is Cool then the Symbio™ 700 controller will use the Space Temp Cooling Setpoint Status.

- After determining the correct Heat Cool Mode Status the Symbio™ 700 controller will write the correct setpoint to Space Temperature Setpoint Active.

Enable External/BAS Control

- The Arbitration Method Request point must be set to Enable External/BAS Control.

- The Symbio™ 700 controller will then look at the Space Temperature Setpoint BAS point to determine requested setpoint.

- The Space Temperature Setpoint BAS is a BACnet commandable point.

- If the Symbio™ 700 controller has a wired setpoint it will show as a priority 15 writing to the Space Temperature Setpoint BAS point. If the Symbio™ 700 controller has an Air-Fi setpoint it will show as a priority 14 writing to the Space Temperature Setpoint BAS point.

- In order for the Symbio™ 700 controller to use a communicated setpoint from a Building Automation System, a valid setpoint must be written to the Space Temperature Setpoint BAS point at a higher priority than 14. Writing at a lower priority than 14 will cause the communicated value to be ignored by the Symbio™ 700 controller.

- If the Air-Fi sensor fails or loses communication the Symbio™ 700 controller will use the wired sensor to determine the active setpoint. If both the wired and Air-Fi sensors fail then the Symbio™ 700 controller will use the default setpoint to determine the active setpoint.

- When using the Symbio™ 700 Display or Mobile Service Tool to change setpoints, these tools write to the relinquish default values and will not show up in the priority array. The relinquish default value will only be used if no other valid sensor input is available.

- After determining the correct sensor input to use the Symbio™ 700 controller will write its decision to the Space Temperature Setpoint Input Active point.

- The Symbio™ 700 controller will then look at the Occupancy Status point and the Demand Shed Input point to determine which offsets to use.

- If the Occupancy Status point is Occupied or Occupied Bypass then the Symbio™ 700 will add and subtract the Occupied Offset point amount. If active, the Symbio™ 700 will also add and subtract the Demand Shed Offset Setpoint point amount.

- If the Occupancy Status point is Occupied Standby then the Symbio™ 700 will add and subtract the Occupied Standby Offset point amount. If active, the Symbio™ 700 will also add and subtract the Demand Shed Offset Setpoint point amount.

- The Symbio™ 700 controller will apply the Space Heating/Cooling Limits to the setpoints.

- If the Occupancy Status Point is Unoccupied then the Symbio™ 700 will use the Unoccupied Cooling Setpoint and the Unoccupied Heating Setpoints.

- After determining the correct Occupancy Status and applying the limits the Symbio™ 700 controller will write the new heating and cooling setpoints to Space Temp Cooling Setpoint Status point and Space Temp Heating Setpoint Status point.

- The Symbio™ 700 controller will then look at the Heat Cool Mode Status point to determine the correct active setpoint.

- If the Heat Cool Mode Status is Heat then the Symbio™ 700 controller will use the Space Temp Heating Setpoint Status.

- If the Heat Cool Mode Status is Cool then the Symbio™ 700 controller will use the Space Temp Cooling Setpoint Status.

- If the Heat Cool Mode Status is Heat then the Symbio™ 700 controller will use the Space Temp Heating Setpoint Status.

Space Temperature Setpoint Dual Setpoint Method

The Space Temperature Dual Setpoint Arbitration Method is used to determine the correct space temperature setpoint value when you have a two setpoints from various local inputs, wired or wireless, and the potential for a Building Automation System to communicate two values.

There are two methods to determine the Space Temperature Setpoint Active when using dual setpoints. The Symbio™ 700 controller will use the Arbitration Method Request point to determine the method, below is the breakdown of each step.

Standalone Control

- The Arbitration Method Request point must be set to Standalone Control.

- The Symbio™ 700 controller will then look at available inputs and determine which one to use.

- If the Symbio™ 700 controller only has a valid wired sensor input it will use it to determine the active setpoints.

- If the Symbio™ 700 controller only has a valid Air-Fi sensor input it will use it to determine the active setpoints.

- If the Symbio™ 700 controller has both a valid wired and a valid Air-Fi sensor input it will first use the Air-Fi sensor input to determine the active setpoints. If the Air-Fi sensor fails or loses communication the Symbio™ 700 controller will use the wired sensor to determine the active setpoint. If both the wired and Air-Fi sensors fail then the Symbio™ 700 controller will use the default setpoint to determine the active setpoint.

- The Occupied Cooling/Heating Setpoint BAS points are ignored during Standalone Control.

- After determining the correct sensor input to use the Symbio™ 700 controller will write its decision to the Space Temperature Cooling/Heating Setpoint Input Active points.

- The Symbio™ 700 controller will then look at the Occupancy Status point and the Demand Shed Input point to determine which setpoints to use.

- If the Occupancy Status point is Occupied or Occupied Bypass then the Symbio™ 700 will use the standard Heating/Cooling Setpoints. If active, the Symbio™ 700 will add and subtract the Demand Shed Offset Setpoint point amount.

- If the Occupancy Status point is Occupied Standby then the Symbio™ 700 will use the Occupied Standby Heating/Cooling Setpoints. If active, the Symbio™ 700 will add and subtract the Demand Shed Offset Setpoint point amount.

- The Symbio™ 700 controller will apply the Space Heating/Cooling Limits to the setpoints.

- If the Occupancy Status Point is Unoccupied then the Symbio™ 700 will use the Unoccupied Cooling Setpoint and the Unoccupied Heating Setpoints.

- After determining the correct Occupancy Status and applying the limits the Symbio™ 700 controller will write the new heating and cooling setpoints to Space Temp Cooling Setpoint Status point and Space Temp Heating Setpoint Status point.

- The Symbio™ 700 controller will then look at the Heat Cool Mode Status point to determine the correct active setpoint.

- If the Heat Cool Mode Status is Heat then the Symbio™ 700 controller will use the Space Temp Heating Setpoint Status.

- If the Heat Cool Mode Status is Cool then the Symbio™ 700 controller will use the Space Temp Cooling Setpoint Status.

- After determining the correct Heat Cool Mode Status the Symbio™ 700 controller will write the correct setpoint to Space Temperature Setpoint Active.

Enable External/BAS Control

- The Arbitration Method Request point must be set to Enable External/BAS Control.

- The Symbio™ 700 controller will then look at the Occupied Cooling/Heating Setpoint BAS points to determine requested setpoint.

- The Occupied Cooling/Heating Setpoint BAS points are BACnet® commandable point.

- If the Symbio™ 700 controller has a wired sensor it will show as a priority 15 writing to the Occupied Cooling/Heating Setpoint BAS points. If the Symbio™ 700 controller has an Air-Fi sensor it will show as a priority 14 writing to the Occupied Cooling/Heating Setpoint BAS points.

- In order for the Symbio™ 700 controller to use a communicated setpoint from a Building Automation System, a valid setpoint must be written to the Occupied Cooling/Heating Setpoint BAS points at a higher priority than 14. Writing at a lower priority than 14 will cause the communicated value to be ignored by the Symbio™ 700 controller.

- If the Air-Fi sensor fails or loses communication the Symbio™ 700 controller will use the wired sensor to determine the active setpoint. If both the wired and Air-Fi sensors fail then the Symbio™ 700 controller will use the default setpoint to determine the active setpoint.

- When using the Symbio™ 700 Display or Mobile Service Tool to change setpoints, these tools write to the relinquish default values and will not show up in the priority array. The relinquish default value will only be used if no other valid sensor input is available.

- After determining the correct sensor input to use the Symbio™ 700 controller will write its decision to the Space Temperature Cooling/Heating Setpoint Input Active points.

- The Symbio™ 700 controller will then look at the Occupancy Status point and the Demand Shed Input point to determine which offsets to use.

- If the Occupancy Status point is Occupied or Occupied Bypass then the Symbio™ 700 will use the standard Heating/Cooling Setpoints. If active, the Symbio™ 700 will add and subtract the Demand Shed Offset Setpoint point amount.

- If the Occupancy Status point is Occupied Standby then the Symbio™ 700 will use the Occupied Standby Heating/Cooling Setpoints. If active, the Symbio™ 700 will add and subtract the Demand Shed Offset Setpoint point amount.

- The Symbio™ 700 controller will apply the Space Heating/Cooling Limits to the setpoints.

- If the Occupancy Status Point is Unoccupied then the Symbio™ 700 will use the Unoccupied Cooling Setpoint and the Unoccupied Heating Setpoints.

- After determining the correct Occupancy Status and applying the limits the Symbio™ 700 controller will write the new heating and cooling setpoints to Space Temp Cooling Setpoint Status point and Space Temp Heating Setpoint Status point.

- The Symbio™ 700 controller will then look at the Heat Cool Mode Status point to determine the correct active setpoint.

- If the Heat Cool Mode Status is Heat then the Symbio™ 700 controller will use the Space Temp Heating Setpoint Status.

- If the Heat Cool Mode Status is Cool then the Symbio™ 700 controller will use the Space Temp Cooling Setpoint Status.

- After determining the correct Heat Cool Mode Status the Symbio™ 700 controller will write the correct setpoint to Space Temperature Setpoint Active.

Occupancy Method

Table 2. Occupancy arbitration

| Occupancy Request Active | Occupancy Input Active | Timed Override Timer Is Active | Occupancy Status |

| Occupied | Occupied | N/A | Occupied |

| Occupied | Unoccupied | Inactive | Occupied Standby |

| Occupied | Unoccupied | Active | Occupied Bypass |

| Unoccupied | N/A | Inactive | Unoccupied |

| Unoccupied | N/A | Active | Occupied Bypass |

| Occupied Bypass | Occupied | N/A | Occupied |

| Occupied Bypass | Unoccupied | Inactive | Occupied Standby |

| Occupied Bypass | Unoccupied | Active | Occupied Bypass |

| Occupied Standby | N/A | Inactive | Occupied Standby |

| Occupied Standby | N/A | Active | Occupied Bypass |

| Auto | Occupied | N/A | Occupied |

| Auto | Unoccupied | Inactive | Unoccupied |

| Auto | Unoccupied | Active | Occupied Bypass |

The Occupancy Arbitration Method is used to determine the correct Occupancy Status value when you have local inputs, wired or wireless, and the potential for a Building Automation System to communicate a value.

There are two methods to determine the Occupancy Status. The Symbio™ 700 controller will use the Arbitration Method Request point to determine the method, below is the breakdown of each step.

Standalone Control

- The Arbitration Method Request point must be set to Standalone Control.

- The Symbio™ 700 controller will then look at available inputs and determine which one to use.

- The Symbio™ 700 controller will use the wired occupancy input on the Symbio™ 700 controller to determine occupancy if no Air-Fi sensor is configured.

- If the Symbio™ 700 controller has both a wired and an Air-Fi sensor input it will first use the AirFi sensor input to determine the active occupancy. If the Air-Fi sensor fails or loses communication the Symbio™ 700 controller will use the wired sensor to determine the active occupancy.

- The Occupancy Input BAS and the Occupancy Input Arbitrator points are ignored during Standalone Control.

- After determining the correct sensor input to use the Symbio™ 700 controller will write its decision to the Occupancy Input Active point.

- The Symbio™ 700 controller will then look at available inputs and determine if a time override is active.

- The Symbio™ 700 controller will use the wired TOV input on the Symbio™ 700 controller to determine TOV if no Air-Fi sensor is configured.

- If the Symbio™ 700 controller has both a wired and an Air-Fi sensor input it will first use the Air-Fi sensor input to determine the TOV. If the Air-Fi sensor fails or loses communication the Symbio™ 700 controller will use the wired sensor to determine the TOV.

- The Timed Override Request and Timed Override Status Arbitrator points are ignored during Standalone Control.

- After determining the TOV input and applying Occupied Bypass Time the Symbio™ 700 controller will write the TOV status to Timed Override Status Active and Timed Override Timer Is Active points.

- The Symbio™ 700 controller will then use the three inputs shown in Table 1 along with the Unoccupied Heating/Cooling setpoints to determine the Occupancy Status.

Enable External/BAS Control

- The Arbitration Method Request point must be set to Enable External/BAS Control.

- The Symbio™ 700 controller will then look at available inputs and determine which one to use.

- In Enable External/BAS Control the Symbio™ 700 controller will use the Occupancy Input Arbitrator point to determine the active input.

- If the Symbio™ 700 controller has a wired sensor it will show as a priority 15 writing to the Occupancy Input Arbitrator point. If the Symbio™ 700 controller has an Air-Fi sensor it will show as a priority 14 writing to the Occupancy Input Arbitrator point.

- There are two ways the Symbio™ 700 controller can use a communicated occupancy command from a Building Automation System.

- To write a binary occupancy command to the Symbio™ 700 controller the Building Automation System must write a valid command to the Occupancy Input BAS point. The Occupancy Input BAS has a heartbeat and must be written to once every 15 minutes or the point will fail, and the value will be ignored. Once the Occupancy Input BAS point has been written to the value will show up on the Occupancy Input Arbitrator point as a priority 12.

- To write a multistate occupancy command to the Symbio™ 700 controller the Building Automation System must write a valid command to the Occupancy Request point. The Occupancy Request point is a commandable point and does not have a heartbeat.

- The Building Automation System only needs to write to either the binary point OR the multistate point, not both.

- After determining the correct input to use the Symbio™ 700 controller will write its decision to the Occupancy Input Active point.

- The Symbio™ 700 controller will then look at available inputs and determine if a time override is active.

- In Enable External/BAS Control the Symbio™ 700 controller will use the Timed Override Status Arbitrator point to determine the active input.

- If the Symbio™ 700 controller has a wired sensor it will show as a priority 15 writing to the Timed Override Status Arbitrator point. If the Symbio™ 700 controller has an Air-Fi sensor it will show as a priority 14 writing to the Timed Override Status Arbitrator point.

- In order to use communicated value from a Building Automation System, a valid value must be written to the Time Override Request point. Once the Time Override Request point has been written to the value will show up on the Timed Override Status Arbitrator point as a priority 12.

- After determining the TOV input and applying Occupied Bypass Time the Symbio™ 700 controller will write the TOV status to Timed Override Status Active and Timed Override Timer Is Active points.

- The Symbio™ 700 controller will then use the three inputs shown in Table 1 along with the Unoccupied Heating/Cooling setpoints to determine the Occupancy Status.

Sensor Complex Method

The Sensor Complex Arbitration Method is used to determine the correct sensor value when you have local inputs, wired or wireless, and the potential for a Building Automation System to communicate a value. This arbitration method uses a heartbeat on the BAS point to help determine the validity of the communicated value.

Space CO2

Space Temperature

Space Humidity

Outdoor Air Temperature

Standalone Control

- The Arbitration Method Request point must be set to Standalone Control.

- The Symbio™ 700 controller will then look at available inputs and determine which one to use.

- The Symbio™ 700 controller will use the wired input on the Symbio™ 700 controller to determine the active value if no Air-Fi sensor is configured.

- If the Symbio™ 700 controller has both a wired and an Air-Fi sensor input it will first use the AirFi sensor input to determine the active value. If the Air-Fi sensor fails or loses communication the Symbio™ 700 controller will use the wired sensor to determine the active value.

- The sensor BAS and the sensor Arbitrator points are ignored during Standalone Control.

- After determining the correct sensor input to use the Symbio™ 700 controller will write its decision to the sensor Active point.

Enable External/BAS Control

- The Arbitration Method Request point must be set to Enable External/BAS Control.

- The Symbio™ 700 controller will then look at available inputs and determine which one to use.

- In Enable External/BAS Control the Symbio™ 700 controller will use the sensor Arbitrator point to determine the active input.

- If the Symbio™ 700 controller has a wired sensor it will show as a priority 15 writing to the Arbitrator point. If the Symbio™ 700 controller has an Air-Fi sensor it will show as a priority 14 writing to the Arbitrator point.

- In order for the Symbio™ 700 controller to use a communicated sensor value from a Building Automation System a valid sensor value must be written to the sensor BAS point. When a valid communicated sensor value is received it will show as a priority 12 writing to the Arbitrator point.

- The BAS point must have a valid value communicated at least once every 15 minutes or the point will fail. If the BAS point fails the priority 12 value will be removed from the Arbitrator point, and it will revert back to the next highest priority available.

- After determining the correct input to use the Symbio™ 700 controller will write its decision to the sensor Active point.

Setpoint Simple Method

The Setpoint Simple Arbitration Method is used to determine the correct setpoint value when you only have the potential for a Building Automation System to communicate a value.

Occupied Standby Cooling Setpoint Occupied Standby Heating Setpoint

Standalone Control

- The Arbitration Method Request point must be set to Standalone Control.

- The Symbio™ 700 controller will then use the relinquish default set for the BAS point as the active value.

- The relinquish default is set from the factory and can be changed by using the display on the Symbio™ 700 controller.

- The Symbio™ 700 will write the relinquish default value to setpoint Active point.

Enable External/BAS Control

- The Arbitration Method Request point must be set to Enable External/BAS Control.

- The Symbio™ 700 controller will then look at available inputs and determine which one to use.

- In Enable External/BAS Control the Symbio™ 700 controller will use the setpoint Arbitrator point to determine the active input.

- If the Symbio™ 700 controller has a wired setpoint it will show as a priority 15 writing to the Arbitrator point. If the Symbio™ 700 controller has an Air-Fi setpoint it will show as a priority 14 writing to the Arbitrator point.

- In order for the Symbio™ 700 controller to use a communicated setpoint value from a Building Automation System a valid setpoint value must be written to the setpoint sensor BAS point. When a valid communicated setpoint value is received it will show as a priority 12 writing to the Arbitrator point.

- The BAS point must have a valid value communicated at least once every 15 minutes or the point will fail. If the BAS point fails the priority 12 value will be removed from the Arbitrator point, and it will revert back to the next highest priority available.

- After determining the correct input to use the Symbio™ 700 controller will write its decision to the setpoint Active point.

Setpoint/Mode Complex Method

The Setpoint/Mode Complex Arbitration Method is used to determine the correct setpoint value when you have local inputs, wired or wireless, and the potential for a Building Automation System to communicate a value. Demand Limit

Standalone Control

- The Arbitration Method Request point must be set to Standalone Control.

- The Symbio™ 700 controller will then look at available inputs and determine which one to use.

- The Symbio™ 700 controller will use the wired input on the Symbio™ 700 controller to determine the active value if no Air-Fi setpoint is configured.

- If the Symbio™ 700 controller has both a wired and an Air-Fi setpoint input it will first use the AirFi setpoint input to determine the active value. If the Air-Fi setpoint fails or loses communication the Symbio™ 700 controller will use the wired setpoint to determine the active value.

- The setpoint BAS is ignored during Standalone Control.

- After determining the correct setpoint input to use the Symbio™ 700 controller will write its decision to the setpoint Active point.

Enable External/BAS Control

- The Arbitration Method Request point must be set to Enable External/BAS Control.

- The Symbio™ 700 controller will then look at available inputs and determine which one to use.

- In Enable External/BAS Control the Symbio™ 700 controller will use the setpoint BAS point to determine the active input.

- If the Symbio™ 700 controller has a wired setpoint it will show as a priority 15 writing to the Arbitrator point. If the Symbio™ 700 controller has an Air-Fi setpoint it will show as a priority 14 writing to the Arbitrator point.

- In order for the Symbio™ 700 controller to use a communicated setpoint value from a Building Automation System a valid setpoint value must be written to the setpoint BAS point at a priority higher than 14.

- After determining the correct input to use the Symbio™ 700 controller will write its decision to the setpoint Active point.

Safety Information

Read this manual thoroughly before operating or servicing this unit.

Warnings, Cautions, and Notices

Safety advisories appear throughout this manual as required. Your personal safety and the proper operation of this machine depend upon the strict observance of these precautions.

The three types of advisories are defined as follows:

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in minor or moderate injury. It could also be used to alert against unsafe practices.

Indicates a situation that could result in equipment or property-damage only accidents.

Important Environmental Concerns

Scientific research has shown that certain man-made chemicals can affect the earth's naturally occurring stratospheric ozone layer when released to the atmosphere. In particular, several of the identified chemicals that may affect the ozone layer are refrigerants that contain Chlorine, Fluorine and Carbon (CFCs) and those containing Hydrogen, Chlorine, Fluorine and Carbon (HCFCs). Not all refrigerants containing these compounds have the same potential impact to the environment. Trane advocates the responsible handling of all refrigerants.

Important Responsible Refrigerant Practices

Trane believes that responsible refrigerant practices are important to the environment, our customers, and the air conditioning industry. All technicians who handle refrigerants must be certified according to local rules. For the USA, the Federal Clean Air Act (Section 608) sets forth the requirements for handling, reclaiming, recovering and recycling of certain refrigerants and the equipment that is used in these service procedures. In addition, some states or municipalities may have additional requirements that must also be adhered to for responsible management of refrigerants. Know the applicable laws and follow them.

Proper Field Wiring and Grounding Required!

Failure to follow code could result in death or serious injury. All field wiring MUST be performed by qualified personnel. Improperly installed and grounded field wiring poses FIRE and ELECTROCUTION hazards. To avoid these hazards, you MUST follow requirements for field wiring installation and grounding as described in NEC and your local/state/national electrical codes.

Personal Protective Equipment (PPE) Required!

Failure to wear proper PPE for the job being undertaken could result in death or serious injury. Technicians, in order to protect themselves from potential electrical, mechanical, and chemical hazards, MUST follow precautions in this manual and on the tags, stickers, and labels, as well as the instructions below:

- Before installing/servicing this unit, technicians MUST put on all PPE required for the work being undertaken (Examples; cut resistant gloves/sleeves, butyl gloves, safety glasses, hard hat/bump cap, fall protection, electrical PPE and arc flash clothing). ALWAYS refer to appropriate Safety Data Sheets (SDS) and OSHA guidelines for proper PPE.

- When working with or around hazardous chemicals, ALWAYS refer to the appropriate SDS and OSHA/GHS (Global Harmonized System of Classification and Labelling of Chemicals) guidelines for information on allowable personal exposure levels, proper respiratory protection and handling instructions.

- If there is a risk of energized electrical contact, arc, or flash, technicians MUST put on all PPE in accordance with OSHA, NFPA 70E, or other country-specific requirements for arc flash protection, PRIOR to servicing the unit. NEVER PERFORM ANY SWITCHING, DISCONNECTING, OR VOLTAGE TESTING WITHOUT PROPER ELECTRICAL PPE AND ARC FLASH CLOTHING. ENSURE ELECTRICAL METERS AND EQUIPMENT ARE PROPERLY RATED FOR INTENDED VOLTAGE.

Follow EHS Policies!

Failure to follow instructions below could result in death or serious injury.

- All Trane personnel must follow the company's Environmental, Health and Safety (EHS) policies when performing work such as hot work, electrical, fall protection, lockout/ tagout, refrigerant handling, etc. Where local regulations are more stringent than these policies, those regulations supersede these policies.

- Non-Trane personnel should always follow local regulations.

Only qualified personnel should install and service the equipment. The installation, starting up, and servicing of heating, ventilating, and air-conditioning equipment can be hazardous and requires specific knowledge and training. Improperly installed, adjusted or altered equipment by an unqualified person could result in death or serious injury. When working on the equipment, observe all precautions in the literature and on the tags, stickers, and labels that are attached to the equipment.

Documents / ResourcesDownload manual

Here you can download full pdf version of manual, it may contain additional safety instructions, warranty information, FCC rules, etc.

Advertisement

Need help?

Do you have a question about the Symbio 700 and is the answer not in the manual?

Questions and answers