Advertisement

Quick Links

Advertisement

Summary of Contents for ESAB Rustler EM 280 PRO

- Page 1 Rustler EM 280 PRO Instruction manual Valid for: HA437YY-XX XXX 0448 534 001 US 20241213...

- Page 2 Cleaning the power source ..............Inspection, cleaning, and replacement .......................... ERROR CODES ....................Error code descriptions ........................ TROUBLESHOOTING ....................... ORDERING SPARE PARTS ..........................WIRING DIAGRAM ......................... ORDERING NUMBERS ............................WEAR PARTS ............................. ACCESSORIES 0448 534 001 - 2 - © ESAB AB 2024...

- Page 3 6. Protect other personnel from arc rays and hot sparks with a suitable non-flammable partition or curtains. 7. Use goggles over safety glasses when chipping slag or grinding. Chipped slag may be hot and can fly far. Bystanders should also wear goggles over safety glasses. 0448 534 001 - 3 - © ESAB AB 2024...

- Page 4 EMF around welding cables and welding machines. Therefore: 1. Welders with pacemakers should consult their physician before welding. EMF may interfere with some pacemakers. 2. Exposure to EMF may have other health effects which are unknown. 0448 534 001 - 4 - © ESAB AB 2024...

- Page 5 2. Have only qualified people remove covers for maintenance and troubleshooting as necessary 3. Keep hands, hair, loose clothing and tools away from moving parts. 4. Reinstall panels or covers and close doors when service is finished and before starting the unit. 0448 534 001 - 5 - © ESAB AB 2024...

- Page 6 6. Use equipment only for its intended purpose. Do not modify it in any manner. User responsibility Users of ESAB equipment have the ultimate responsibility for ensuring that anyone who works on or near the equipment observes all the relevant safety precautions. Safety precautions must meet the requirements that apply to this type of equipment.

- Page 7 Protect your eyes and body. Use the correct welding screen and filter lens and wear protective clothing. • Protect bystanders with suitable screens or curtains. NOISE - Excessive noise can damage hearing Protect your ears. Use earmuffs or other hearing protection. 0448 534 001 - 7 - © ESAB AB 2024...

- Page 8 As the person responsible for the equipment, it is your responsibility to obtain information on approved collection stations. For further information contact the nearest ESAB dealer. California proposition 65 warning WARNING! Welding or cutting equipment produces fumes or gases which contain chemicals known in the State of California to cause birth defects and, in some cases, cancer.

- Page 9 California to cause cancer and birth defects or other reproductive harm. Wash hands after use. For more information, go to www.P65Warnings.ca.gov. ESAB has an assortment of welding accessories and personal protection equipment for purchase. For ordering information contact your local ESAB dealer or visit us on our website. 0448 534 001 - 9 -...

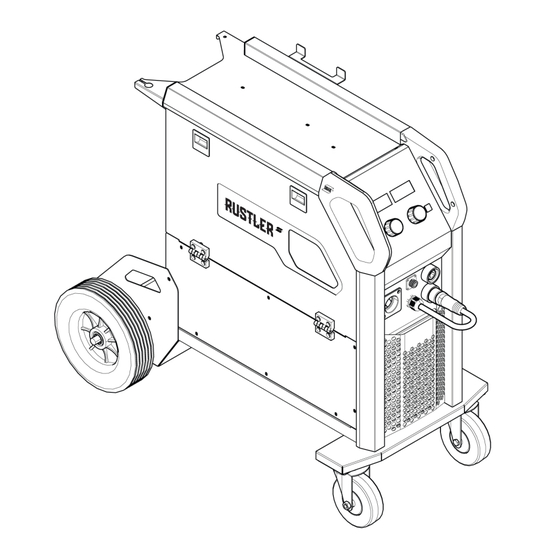

- Page 10 2 INTRODUCTION INTRODUCTION The Rustler EM 280 PRO is a compact welding power source intended for welding with solid wires, flux cored wires (MIG/MAG/GMAW, FCAW). The equipment has built-in wheels and a gas bottle bracket to move easily around the work place and provide a better reach.

- Page 11 The duty cycle is valid for 104 °F (40 °C), or below. Enclosure class The IP code indicates the enclosure class, i.e. the degree of protection against penetration by solid objects or water. Equipment marked IP21 is intended for indoor use. 0448 534 001 - 11 - © ESAB AB 2024...

- Page 12 Electric shock! Do not touch the workpiece or the welding head during operation! WARNING! Secure the equipment - particularly if the ground is uneven or sloping. NOTE! When moving the equipment use intended handle. Never pull the cables. 0448 534 001 - 12 - © ESAB AB 2024...

- Page 13 Correctly earthed (electrically) in accordance with local regulations. • Connected to the correct size power point and fuse as indicated in table below 1. Rating plate with supply connection data. 0448 534 001 - 13 - © ESAB AB 2024...

- Page 14 Generators with Automatic Voltage Regulation (AVR) or with equivalent or better type of regulation, with rated power 9.8 KW, are recommended. 0448 534 001 - 14 - © ESAB AB 2024...

- Page 15 2. MIG / MAG / GMAW torch and spool gun 6. Gas inlet connection 3. Polarity changeover cable 7. Mains supply switch, ON/OFF 4. Electrode negative terminal (-) 8. Mains supply cable 0448 534 001 - 15 - © ESAB AB 2024...

- Page 16 For MIG/MAG/GMAW welding, the welding cable can be connected to the positive welding terminal (+) or negative welding terminal (-), depending on the type of electrode used. The connection polarity is stated on the electrode packaging. 0448 534 001 - 16 - © ESAB AB 2024...

- Page 17 Do not overload the spool hub brake! A high brake force may overload the motor and reduce motor life and result in poor weld quality. 0448 534 001 - 17 - © ESAB AB 2024...

- Page 18 4) Secure the spool of wire on the spool hub, by tightening the brake hub nut. 5) Straighten out the new welding wire 4–8 in. (10–20 cm) and thread the wire through the wire feeder mechanism. 0448 534 001 - 18 - © ESAB AB 2024...

- Page 19 Too long a torch liner risks damage to the wire-feed assembly if forced to fit when attempting to connect the torch to the power unit. Refer to the torch manual for instructions for torch liner replacement. 0448 534 001 - 19 - © ESAB AB 2024...

- Page 20 10)Set and verify the wire feed tension for correct wire feed pressure, see "Setting wire feed pressure" chapter. After completion, close the wire spool side cover of the power source. 0448 534 001 - 20 - © ESAB AB 2024...

- Page 21 5) Manually rewind the wire spool. Pay attention to not release the end of the wire and unwind the spool. 6) Secure the end of the wire to the wire spool basket or plastic spool. 7) Remove wire retention nut. 8) Remove wire spool. 0448 534 001 - 21 - © ESAB AB 2024...

- Page 22 When changing to a different type of wire, the wire guides may need to be changed to match the new type of wire. For information about the correct wire guides depending on wire diameter and type, see the "WEAR PARTS" appendix. 0448 534 001 - 22 - © ESAB AB 2024...

- Page 23 2) Remove the lower front feed roll. 3) Remove the middle wire guide. 4) Unlock the wire outlet guide quick lock (A) by folding it out. 5) Remove the wire outlet guide (B). 0448 534 001 - 23 - © ESAB AB 2024...

- Page 24 Always check the feed roll pressure setting on a case-by-case basis by feeding out the wire against an insulated object as described above. 0448 534 001 - 24 - © ESAB AB 2024...

- Page 25 Example: If the power source operates at a 40% duty cycle, it will provide the rated amperage for a maximum of 4 minutes out of every 10-minute period. For the remaining time, 6 minutes, the power source must be allowed to cool down. 0448 534 001 - 25 - © ESAB AB 2024...

- Page 26 5 OPERATION 0448 534 001 - 26 - © ESAB AB 2024...

- Page 27 In the menu, there are a number of weld variables to be accessed. To access the weld variables, press the parameter selection button until the menu icon is illuminated. Press this button again to 0448 534 001 - 27 - © ESAB AB 2024...

- Page 28 The welding process continues until the switch is pressed in again, the wire feed and arc then stops and when the switch is released the gas post-flow starts. 0448 534 001 - 28 - © ESAB AB 2024...

- Page 29 The remote function enables settings to be adjusted via the remote unit by disabling the external control panel. Spool gun This indicator lights up when the spool gun is connected. 0448 534 001 - 29 - © ESAB AB 2024...

- Page 30 6 CONTROL PANEL 2-stroke mode (welding without ending arc) 4-stroke mode (welding without ending arc) 0448 534 001 - 30 - © ESAB AB 2024...

- Page 31 ARC ON ON/OFF Material Fe /AL/SS/Cu/FCW MAG, CO2, Ar, NOG, Diameter 0.035 0.030/0.035/ 0.040/0.045 Display value during WFS/AMP welding Unit (metric or imperial) IPM MPM/IPM Default settings No/Yes Version no 0448 534 001 - 31 - © ESAB AB 2024...

- Page 32 Area to maintain Every 3 months Clean or replace Clean weld terminals. Check or replace weld unreadable labels. cables. Every 6 months Clean inside equipment. Use dry compressed air with reduced pressure. 0448 534 001 - 32 - © ESAB AB 2024...

- Page 33 During cleaning, always wear recommended personal safety equipment, such as ear plugs, safety glasses, masks, gloves, and safety shoes. CAUTION! Repair, cleaning, and electrical work should be performed by an authorized ESAB service technician. Use only ESAB original spare and wear parts. 1) Disconnect the power source from the power supply.

- Page 34 The wear parts of the welding torch should be cleaned and replaced at regular intervals in order to achieve trouble-free wire feed. Regularly blow the wire guide clean and clean the contact tip. 0448 534 001 - 34 - © ESAB AB 2024...

- Page 35 "Err" followed by the error code number shown in the display. Screens Error code descriptions Error codes that the user can handle are listed below. If any other error code appears, contact an authorized ESAB service technician. Error code Description Err 002...

- Page 36 Clean the liners and other mechanical parts of the wire feed mechanism through the wire feed using pressurized air. mechanism Clean and adjust the roller pressure as per the table on the decal on the left side door. 0448 534 001 - 36 - © ESAB AB 2024...

- Page 37 Spare parts and wear parts can be ordered through your nearest ESAB dealer, see esab.com. When ordering, please state product type, serial number, designation and spare part number in accordance with the spare parts list.

- Page 38 APPENDIX APPENDIX WIRING DIAGRAM Rustler EM 280 PRO 0448 534 001 - 38 - © ESAB AB 2024...

- Page 39 APPENDIX ORDERING NUMBERS Ordering number Denomination Notes 0700 401 201 Rustler EM 280 PRO 208 V / 230 V ±15%, 1Φ50/60 Hz, NAM 0448 534 * Instruction manual 0448 533 001 Quick start guide The three last digits in the document number of the manual show the version of the manual. Therefore they are replaced with * here.

- Page 40 0.035 (0.9) 0.045 (1.2) 0445850005 0.045 (1.2) 0.045 (1.2) 0445850006 0.052 (1.4) 0.062 (1.6) V-K-knurled Part no. Size in. (mm) 0445850030 0.035 (0.9) 0.045 (1.2) 0445850032 0.045 (1.2) 0.052 (1.4) 0448 534 001 - 40 - © ESAB AB 2024...

- Page 41 Fe/SS/C 0.024 (0.6) 0.062 (1.6) 0446080881 0.030 (0.8) 0.062 (1.6) Wire outlet guide Part no. Wire Size in. (mm) 0445830881 Fe/SS/C 0.024 (0.6) 0.062 (1.6) 0445830885 0.030 (0.8) 0.062 (1.6) 0448 534 001 - 41 - © ESAB AB 2024...

- Page 42 OKC 50 cable connector, female (2 ea.) 0700400858 Gas hose 5/8 in 18 RH fittings, 13.1 ft. (4.0 m) 0781-9411 Victor GF-250-50-580 flow gauge regulator for Ar/CO2 0781-2703 Victor GRF400-320 flow gauge regulator for CO2 0448 534 001 - 42 - © ESAB AB 2024...

- Page 43 APPENDIX 0448 534 001 - 43 - © ESAB AB 2024...

- Page 44 For contact information visit http://esab.com ESAB Corporation, 2800 Airport Road Denton, TX 76207, USA, Phone +1 800 378 8123 manuals.esab.com...

Need help?

Do you have a question about the Rustler EM 280 PRO and is the answer not in the manual?

Questions and answers