Summary of Contents for Sterlitech CF016SS-FO Cell

- Page 1 CF016SS-FO Cell Assembly & Operation Manual www.sterlitech.com info@sterlitech.com 1-877-544-4420 Copyright © 2024...

- Page 2 Contents Table of Contents ....................Introduction ............... CF016SS-FO Cell Components ................CF016SS-FO Cell Assembly ............CF016SS-FO Cell Connections and Parts ..................Operation of the Cell ............Supplementary Operating Information ..........Accessory and Spare Part Ordering Information ................ Return Material Authorization ....................

- Page 3 Introduction Introduction The CF016SS-FO Cell is a laboratory-scale filtration unit that is designed to evaluate a variety of engineered osmosis processes, including Forward Osmosis (FO), and Pressure Retarded Osmosis (PRO). It simulates the flow dynamics of larger, commercially available membrane elements such as industrial spiral wound membrane elements. Users can vary the operating conditions and fluid dynamics over broad ranges.

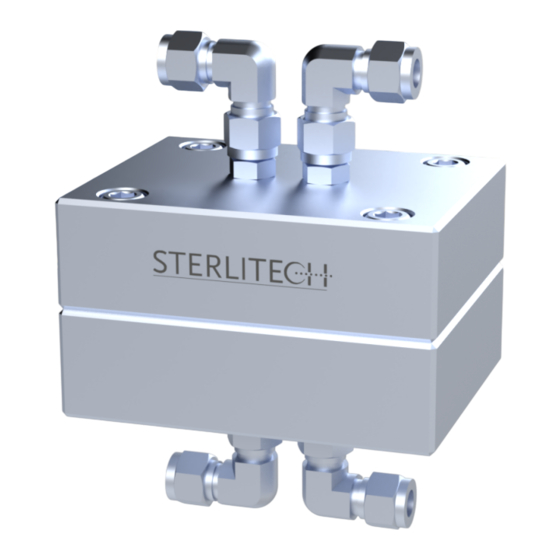

- Page 4 Cell Components CF016SS-FO Cell Components Figure 1 illustrates a typical assembly of the CF016SS-FO Cell. The cell is also packaged with a membrane cutting template. Figure 1: CF016SS Forward Osmosis Cell Body Assembly NUMBER DESCRIPTION MATERIAL WETTED? Screw & Washer Set...

- Page 5 0.09”. Note: Shims and Spacers are not included with a CF016SS-FO Cell purchase. Place a piece of pre-cut membrane onto the cell bottom using the two alignment pins to hold the membrane in position. The membrane should be installed with the shiny side (active side) down, toward the cavity in the cell bottom.

- Page 6 System Assembly CF016SS-FO Cell Connections and Parts Figure 2: Cross Flow System Diagram for CF016SS-FO Cell 8 10 8 11 Legend Feed Tank Concentrate Pressure Gauge Draw Solution Pressure Gauge Feed Pump Draw Solution Tank Concentrate Flow Meter Draw Solution Pump...

- Page 7 Operation of the Cell Operation of the CF016SS-FO Cell To operate the CF016SS-FO Cell: Open all the valves in the system to relieve any pressure build-up before turning on the feed pump. Turn the system ON and set the feed pump to desired flow rate.

- Page 8 Experimentation with the CF016SS-FO Cell can help predict the best operating parameters. Cell and Membrane Cleaning The CF016SS-FO Cell can be cleaned with or without the membrane installed. Leave the membrane installed to simulate the cleaning conditions of Clean-In-Place (CIP), a common practice in larger systems with spiral-wound or tubular membranes.

- Page 9 This information is not intended as a license to operate under, or a recommendation to infringe upon, any patent of Sterlitech or others covering any material or use.The foregoing may not be altered except by a written agreement signed by officers of the manufacturer.

- Page 10 Sterlitech’s benchtop cross flow membrane test system provides the versatility required to innovate. Sterlitech’s comprehensive line of products is supported by the expertise of its technical specialists who can assist with application-specific product selection, and provide customized solutions where necessary. Unique problem-solving approaches, flexibility, and consistent quality have made Sterlitech Corporation a renowned global provider of filtration products and equipment.

Need help?

Do you have a question about the CF016SS-FO Cell and is the answer not in the manual?

Questions and answers