Advertisement

Document Title:

Description

Profile:

WLO, L110E [GB]

Description

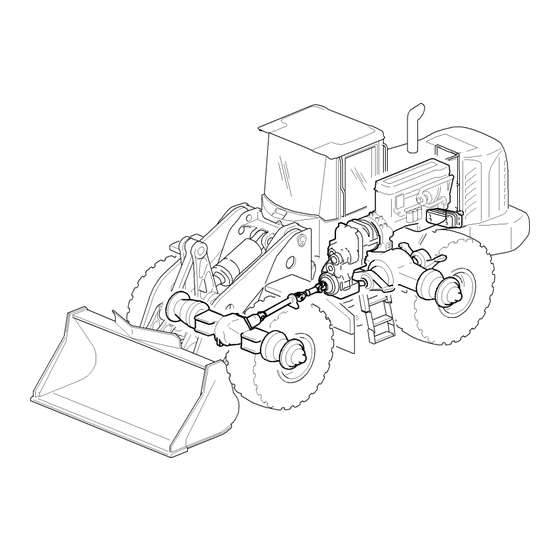

Wheel loaders L110E and L120E are articulated four-wheel drive machines.

The engine is a six-cylinder, four-stroke, direct-injection, turbocharged diesel engine of the D7D type.

The transmission is hydro-mechanical where all gears are in constant mesh and the designation is HTE204 for L110E and

HTE205 for L120E.

There is a single-stage hydraulic torque converter between engine and transmission.

Front and rear axles have fully floating axle shafts with planetary gears in the hubs. The front axle is equipped with a

differential lock.

The service and parking brakes on the machine are wet type disc brakes.

The service brakes are integrated in the respective wheel hubs and the parking brake is located on the output shaft in the

transmission.

The steering system is hydrostatic with a variable load-sensing axial piston pump and two hydraulic cylinders (steering

cylinders).

Figure 1

Function Group:

000

Information Type:

Service Information

Service Information

Date:

2014/5/9 0

Advertisement

Table of Contents

Summary of Contents for Volvo L110E

- Page 1 Wheel loaders L110E and L120E are articulated four-wheel drive machines. The engine is a six-cylinder, four-stroke, direct-injection, turbocharged diesel engine of the D7D type. The transmission is hydro-mechanical where all gears are in constant mesh and the designation is HTE204 for L110E and HTE205 for L120E.

- Page 2 Document Title: Function Group: Information Type: Date: E 1234, Nipple Service Information 2014/5/9 0 Profile: WLO, L110E [GB] E 1234, Nipple Figure 1 E1234 9993522 Standard pipe bushing, R1/4" – R1/8" Testing nipple, part No. 930032 Standard T-pipe, R 1/4"...

- Page 3 Document Title: Function Group: Information Type: Date: E 1281 Nipple Service Information 2014/5/9 0 Profile: WLO, L110E [GB] E 1281 Nipple Figure 1 E1281 Sealing washer Accumulator with internal threads, M16 x 1.5 Nipple part No. 957030 Sleeve, standard R 1/4"...

- Page 4 Service Information Document Title: Function Group: Information Type: Date: E 1708, Checking point Service Information 2014/5/9 0 Profile: WLO, L110E [GB] E 1708, Checking point Figure 1...

- Page 5 The Operator's Manual must always be kept in the cab for easy reference. Volvo designs and manufactures machines with a high level of safety as well as effectiveness. All this work may be wasted if anyone who is about to perform service on any of our machines does not read the safety instructions, or does not follow them, e.g., does not replace guards, climbs on slippery machine parts instead of using a ladder, grabs a hold of hoses...

- Page 6 As proof that the requirements are met, an EU Declaration of Conformity, issued by Volvo CE, is supplied with each separate machine. This EU declaration also covers attachments and equipment manufactured by Volvo CE. The documentation is a valuable document, which should be kept safe and retained for at least 10 years.

- Page 7 If anyone in your company discovers that a certain machine has been modified in a non-approved manner, your company must notify the customer and manufacturer in writing regarding the applicable machine and how it was modified.

-

Page 8: Service Information

no safety seals have been opened by an unauthorized person. all modifications and repairs have been performed in the manner prescribed by Volvo. only genuine Volvo parts/accessories, or attachments that fulfil Volvo's requirements have been used. WARNING Machine operators must have sufficient skills and knowledge of the content in the Operator's Manual before operating the machine. - Page 9 Figure 1 Entering/leaving the machine Always wear a hard hat, protective goggles, gloves, work shoes and other safety items that your work requires. Avoid standing in front of or behind the machine when the engine is running. Always use a rubber window scraper or brush with a long handle when cleaning the outside of the windows in order to avoid unnecessary climbing on the machine.

- Page 10 Figure 3 Use the seat belt during all operation If the seatbelt needs washing: Use a mild soap solution when washing and let the belt dry while it's fully pulled out before it's rolled up. Make sure that the belt is installed correctly. ...

- Page 11 Safety rules when servicing 191 Service Information 2014/5/8 0 Profile: WLO, L110E [GB] Safety rules when servicing This section covers general safety rules when checking and servicing. Other rules, information and warning texts are given in the Operator's manual. CE marking This machine is CE-marked.

- Page 12 Engine off and ignition key removed. (Does not apply for special checks). Pressurized lines and pressure tanks shall be depressurized carefully so that the high pressure is released without 191 Safety when working on hydraulic systems risk. [ 1] Yellow-black warning flag should be attached to the steering wheel (USA - a red flag may be used instead) Frame joint lock connected.

- Page 13 Never wear loose fitting clothing, for example, a scarf or jewellery, that can get caught and cause injury when working on the machine. Always use a hard hat, safety glasses, gloves, protective work shoes and other protective items as required by the work situation.

- Page 14 Service Information 2014/5/8 0 boom Profile: WLO, L110E [GB] Working under raised boom Always secure the loader linkage with Support 999 3831 (2 pcs. L330, L350) before starting to work. Position the support on an even and firm ground surface.

- Page 15 Figure 2 Securing the boom 999 3831 Support...

-

Page 16: Fire Prevention Measures

Fire prevention measures Service Information 2014/5/8 0 Profile: WLO, L110E [GB] Fire prevention measures General There is always a risk of fire. Find out which type of fire extinguisher to use, where it is located and how to use it. - Page 17 NOTICE If a high-pressure washer is used when cleaning, work carefully since damage may be caused to electrical components and insulation of the electrical cabling even at relatively moderate water pressure and temperature. Protect electrical cabling in a suitable manner. ...

- Page 18 Service Information 2014/5/8 0 regarding tyre handling Profile: WLO, L110E [GB] Some simple rules regarding tyre handling WARNING Tires installed on a split rim may explode and cause very severe injuries. Inflating Never stand to the side of the tyre while inflating which is fitted on a split rim. Use a self-locking outlet with a hose long enough to allow you to stand outside of the hazard zone during inflation, see the illustration.

- Page 19 2014/5/8 0 supporting complete machine Profile: WLO, L110E [GB] Safety when lifting and supporting complete machine 191 Safety rules when servicing Place the machine in service position, see Always use jacks and support equipment with sufficient capacity. It is important to support the front and/or rear axle in a safe way before doing other work.

- Page 20 Figure 2 E-models 11668007 Stand jack Support point Recommended method for rear axle Prevent the rear axle from oscillating by locking it with jacks or wooden blocks between the frame and axle on both sides. NOTE! Do not forget to remove the oscillation lock before lowering the machine. The machine must be secured with axle stands or stand jacks with sufficient capacity, 5–15 tons.

- Page 21 Figure 4 V1031966 On smaller machines (L50–L120), use a garage jack under the differential carrier assembly. Do not forget to lock the axle to prevent oscillation. Place the axle stands under the frame's rear edge. Figure 5 Support points Do not use a jack with a small lifting surface under the differential carrier assembly. Use a wheel trolley for safe handling of the wheels.

- Page 22 Date: Safety when working with Service Information 2014/5/8 0 batteries Profile: WLO, L110E [GB] Safety when working with batteries Figure 1 Battery charging WARNING Risk of serious corrosive injuries! Batteries contain sulphuric acid which is very corrosive to the human body and parts of the machine. In addition, batteries give off hydrogen gas when they are loaded (supplying electricity) or being charged.

- Page 23 Always cover the top of the battery with a rag or other non-conducting material when you work close to the batteries. Always refit the terminal caps on the batteries. Batteries contain substances hazardous to health and the environment. Therefore, discarded batteries be handled 191 Environmentally safe handling according to governing local/national regulations.

-

Page 24: Starting With Booster Batteries

Service Information 2014/5/8 0 batteries Profile: WLO, L110E [GB] Starting with booster batteries When starting with booster batteries, the following must be observed: Check that the booster batteries or other power source have the same voltageas the standard batteries. WARNING The batteries could explode due to the current surge if a fully charged battery is connected to a completely discharged battery. - Page 25 Service Information 2014/5/8 0 and fuel Profile: WLO, L110E [GB] Safety when handling oils and fuel When changing oil in engine, hydraulic system or transmission: Keep in mind that the oil may be hot and can cause scalding or burn injuries.

- Page 26 Safety when working with Service Information 2014/5/8 0 air conditioning refrigerant Profile: WLO, L110E [GB] Safety when working with air conditioning refrigerant General Special competence is required for service work and more involved work which requires opening of the air conditioning system.

- Page 27 remove the filler plug on the compressor. If you suspect a leak, certified and trained personnel at a licensed workshop should be contacted for troubleshooting and repair. The refrigerant gas is heavier than air and will sink to the floor. Therefore, make sure that any escaped gas is ventilated before work is started in any low-lying areas.

- Page 28 2014/5/8 0 accumulators Profile: WLO, L60E, L120E, L90E, L180E HL, L330E, L50E, L220E, L110E, L180E, L70E, L150E [GB] Safety when handling accumulators WARNING If the pressure is not released before opening the system, oil under high pressure will jet out, resulting in serious personal injuries.

-

Page 29: Safety When Working On Hydraulic Systems

2014/5/8 0 hydraulic systems Profile: WLO, L110E [GB] Safety when working on hydraulic systems The hydraulic systems in our loaders operate at very high pressures, up to approx. 42 MPa (6090 psi). To avoid serious personal injuries it is very important that the systems are maintained in the right way, and that all persons who come into contact with the machines are very careful in their work and are very attentive to any defects. - Page 30 Download the full PDF manual instantly. Our customer service e-mail: aservicemanualpdf@yahoo.com...

Need help?

Do you have a question about the L110E and is the answer not in the manual?

Questions and answers