Advertisement

Quick Links

KNF 325089 11/22

ATEX

DIAPHRAGM PUMP

Notice!

Before operating the pump and accessories, read and observe the operating and installation instructions as

well as the safety information!

N630.12 EX

TRANSLATION OF ORIGINAL OPERATION AND

INSTALLATION INSTRUCTION

ENGLISH

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for KNF N630.12 EX

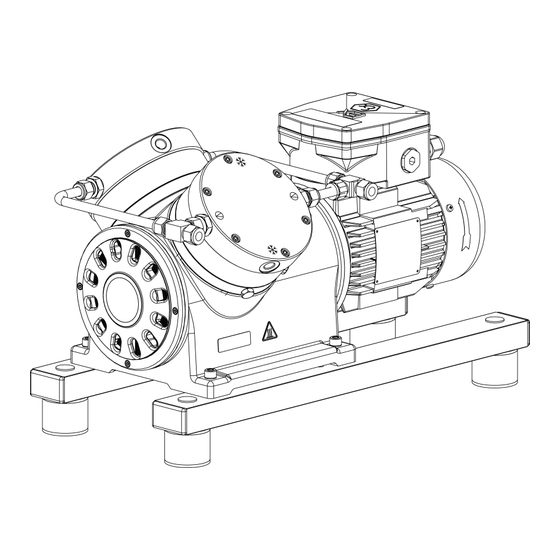

- Page 1 KNF 325089 11/22 N630.12 EX ATEX TRANSLATION OF ORIGINAL OPERATION AND INSTALLATION INSTRUCTION ENGLISH DIAPHRAGM PUMP Notice! Before operating the pump and accessories, read and observe the operating and installation instructions as well as the safety information!

- Page 2 Index KNF Neuberger GmbH Alter Weg 3 1 About this document ............ 3 79112 Freiburg 1.1 Using the operating and installation instructions.. 3 Germany 1.2 Exclusion of liability........... 3 Tel. +49 (0)7664/5909-0 1.3 Symbols and markings.......... 4 Fax. +49 (0)7664/5909-99 2 Use.................. 6 2.1 Proper use .............. 6 2.2 Improper use............. 7...

- Page 3 à In the event of uncertainties with regard to the content of the operating and installation instructions, please contact the manufacturer (contact data: see www.knf.com). Please have the type and serial number of the pump ready. à Read the operating and installation instructions before you commission the pump.

- Page 4 An activity to be carried out is specified here (a step). 1. The first step of an activity to be carried out is specified here. Follow other sequentially numbered steps. This symbol indicates important information. Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 5 Symbol for separate tracking of electrical and elec- tronic devices. The use of this symbol means that this product must be disposed of with normal household waste. Tab.2 Explanations of pictograms Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 6 Variable frequency drive Pumps with three-phase motor are designed for operation with a variable frequency drive in the speed range 500 – 1500 rpm (50 Hz) or 600 – 1800 rpm (60 Hz) (see also Chapter Electrical connection). Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 7 An ignition hazard assessment in accordance with standards DIN EN ISO 80079-36 and DIN EN ISO 80079-37 was performed for the pumps. The protective goals were reached by applying ignition protection type con- structional safety "c". Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 8 Tab.4 Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 9 (or below) (see designation on the type plate) or which is not explosive and not combustible. Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 10 An ignition hazard evaluation according to the standards DIN EN ISO 80079-36 and DIN EN ISO 80079-37 was carried out for the devices.The protective goals were reached by applying ignition protection type con- structional safety "c". Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 11 The devices must not be installed outdoors.Commissioning may only be performed with suitable weather- and corrosion-protection paneling. § The devices must be installed in a way that ensures they are not ex- posed to UV radiation. Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 12 According to DIN EN ISO 80079-36, the maximum surface temperature is the highest temperature that is achieved during operation under the most unfavorable conditions (but within the accepted tolerances) of a part or on a surface of the pump. Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 13 The end user is responsible for disposing of old devices ac- cording to the national and international regulations. Alternatively, KNF products (old devices) may also be returned to KNF for a fee (see chapter 12 Returns). EU/EC directives/standards See EC/EU Declaration of Conformity Customer service and repairs The pumps are maintenance-free.

- Page 14 **Liters in standard state (1013 hPa, 20 °C) Pneumatic connections Pump type Value N630.12, N630.3.12 Thread size G 1/4* N630.1.2.12 For hose Ø 10 Tab.11 *Acc. to ISO 228 Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 15 See operating instructions for drive ations Relative air humidity 80% for temperatures to 31 °C, de- creasing linearly to 50% at 40 °C (non-condensing). Max. installation altitude See operating instructions for drive Tab.14 Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 16 Approx. 41 N630.1.2.12 Approx. 49 N630.3.12 Approx. 49 Tab.15 Start-up against pressure/ Please contact KNF Customer Service. vacuum Coupling Parameter Value EX-designation II 2G h IIC T6…T4 Gb Size Tab.16 Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 17 7 Electrical terminal box 8 Screw plug of the hole for pressure monitoring of the diaphragm in- nerspace (1x per head) 9 Pneumatic pump outlet Fig.2 Design N630.3.12 EX Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 18 7 Electrical terminal box 8 Screw plug of the hole for pressure monitoring of the diaphragm in- nerspace (1x per head) 9 Pneumatic pump outlet Fig.3 Design N630.1.2.12 EX Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 19 The closed innerspace (5) between the two diaphragms can be monitored for pressure change with the help of the hole(s) (6) provided for this purpose. Damage to the working diaphragm and safety diaphragm can thereby be de- tected immediately. Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 20 Inspect the pump for transport damage after receiving it. à Document any transport damage in writing. à Remove any transport locking devices on the pump prior to commis- sioning. Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 21 (4 Techni- cal data). NOTICE Transport with carrying strap Fig.5 Position of carrying strap (example) 1. Pull the carrying strap under the pump (see Fig. 5). Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 22 5. Lower the pump carefully at the installation location. Transporting with lifting eyebolt 1. Loosen the M12 screw (1). 1 M12 screw Fig.7 Loosen the M12 screw (pump illustrated as an example) Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 23 3. Lift the pump out of the packaging with the aid of lifting gear. 4. Lower the pump carefully at the installation location. 5. Remove the transport eyebolt (2). 6. Screw the M12 screw (1) back into the thread. Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 24 Store the pump at the installation site prior to installation to bring it up to the ambient temperature. à Mounting dimensions For mounting dimensions, see following figures: Fig.9 Mounting dimensions N630.12 EX Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 25 Diaphragm pump N630.12 EX Installation and connection Fig.10 Mounting dimensions N630.3.12 EX Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 26 Make sure that the installation location is dry and that the pump is pro- tected from rain, spray water, splash water, dripping water and other contaminants. à Make sure that the installation location is accessible for service. Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 27 When connecting to a power source, carefully read and observe the motor operating instructions (including the notice on insulation resis- tance measurement). à When connecting to a power source, observe the applicable regula- tions, directives, and technical standards. Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 28 (see Chapter 4 Technical data). à Pressure relief device Protect the compressors by means of a pressure relief device between the pressure-side connections of the compressor and the first shut-off valve. Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 29 2. Connect the suction line and the pressure line (for mounting dimen- sions, see Chapter 4 Technical data). 3. Lay the suction line and the pressure line at a downward angle to pre- vent condensate from running into the pump. Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 30 1. Connect the water cooling system to the provided hose connections. à Safely drain the water discharge. The flow direction is allowed in both directions. Mounting dimensions For mounting dimensions, see the following dimensional drawings: Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 31 Diaphragm pump N630.12 EX Installation and connection Fig.13 Mounting dimensions N630.12 EX Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 32 Installation and connection Diaphragm pump N630.12 EX Fig.14 Mounting dimensions N630.3.12 EX Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 33 Diaphragm pump N630.12 EX Installation and connection Fig.15 Mounting dimensions N630.1.2.12 EX Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 34 Before pumping gas mixtures of this kind, check the surface temperature before running the pump. à When pumping gas mixtures of this kind, run the pump with water cooling connected. Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 35 Ensure that the pump outlet is not closed or restricted. Risk of explosion from elevated ambient tempera- ture à Monitor the ambient temperature (compres- sion heat, motor heat). WARNING à Ensure sufficient cooling air supply. Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 36 Recommissioning Before recommissioning, observe the applicable standards, guidelines, regulations and technical standards at the electrical connection. à Inspecting the pump Inspect the pump periodically for external damage or leakage. Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 37 The validity of the CE conformity is rendered void if genuine spare parts are not used. à Use only genuine spare parts from KNF when performing servicing work. Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 38 It is the operator's responsibility to assess these factors. Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 39 Clean the pump and free the pump of hazardous materials. à Remove the hoses/pipes from the pneumatic pump inlet and outlet. à Remove the transport eyebolt from the pump if necessary. Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 40 With multi-headed pumps, the parts of the various pump heads could get mixed up. à Change the parts of the individual pump heads that are to be replaced one after the next. Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 41 Felt-tip pen 19 mm open end wrench (for two-headed pumps only) PZ2 Phillips-head screwdriver (for fan cover) Open-end wrench 8 mm Tab.21 *According to accessories list, Chapter 11.2 Accessories Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 42 à WARNING Perform the work steps carefully and without the use of force. 5. For two-headed pumps: Perform steps 3 and 4 for the second pump head. Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 43 Tighten the retainer plate screw (13) (tightening torque: 11 Nm). 24. For two-headed pumps: Perform steps 1 to 23 for the second pump head. Changing valves 1. Remove the two O-rings (2) from the intermediate plate (18). Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 44 – Electrically connect the pump. – Test the functionality of the pump. To ensure the required gas tightness of the pump following servic- ing, a leak test is to be performed. Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 45 Tool and material Quantity Tool/material Feeler gage 3 mm Test adapter for coupling (see Chapter 11.2 Accessories) Open-end wrench 8 mm Size 13 open-end wrench with torque indicator Tab.22 Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 46 6 Pump-side coupling half 7 Compressor housing 8 Stud bolts 9 Motor fan cover 10 Fastening screw for mo- tor fan cover Fig.19 Replacing sprocket (depicted pump as an example) Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 47 Make certain that the inner diameter of the ribbed disk (2) lies against the nut (1) and the outer diameter lies against the motor flange (3) (see Fig. 20). Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 48 – Disconnect the pump electrically and pneumatically again. 7. Pump integrated in application – Connect the suction and pressure sides to the pump. – Electrically connect the pump. – Test the functionality of the pump. Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 49 (see Chapter 9 Servicing). à Triggering device for PTC thermis- Determine the cause. tor sensor tripped. à See operating instructions for motor. Tab.24 Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 50 Determine the cause. à Contact KNF Customer Service. Drive worn or defective. à See operating instructions for the drive. à Coupling worn or defective. See operating instructions for coupling. Tab.26 Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 51 2. Clean the pump (see Chapter 9.2.2 Cleaning the pump). 3. Send the pump together with completed Health and Safety Clearance and Decontamination Form to KNF, stating the nature of the trans- ferred medium. Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 52 Order number Transport eyebolt 311535 Suction filter G1/4 316661 Wrench for retainer plate 321664 Test adapter for coupling 322184 Water cooling connection: N630.12 310064 N630.3.12 310444 N630.1.2.12 310444 Tab.30 Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 53 Returns KNF shall undertake to repair the pump only under the condition that the customer presents a certificate regarding the medium that is pumped and the cleaning of the pump. In this case too, old devices can be returned.

- Page 54 Diaphragm pump N630.12 EX 13 Appendix à 13.1 Declaration of Conformity à 13.2 Motor à 13.3 Coupling 13.1 Declaration of Conformity For further information, see also § Konformitätserklärung N630.12EX.pdf Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 59 Diaphragm pump N630.12 EX Appendix 13.2 Motor For further information, see also § Betriebsanleitung Motor.pdf § Konformitätserklärung Motor.pdf Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 60 Table of contents 2021-05-31 Operating manual Electric motors Size 63 - 225 ATEX / IECEx Doc-ID: 6316 Read the operating manual before starting all work.

- Page 61 © Herforder Elektromotoren-Werke GmbH & Co. KG Goebenstr. 106 D-32051 Herford Tel.: +49 (0) 5221 5904-0 Fax: +49 (0) 5221 5904-34 E-Mail: info@hew-hf.de Internet: www.hew-hf.de Release: Created by: Kothes! Technische Kommunikation GmbH & Co. KG www.kothes.de This issue replaces all previous issues. All previous issues are invalid.

- Page 62 Electric motors Size 63 - 225 ATEX / IECEx Table of contents General information ............... 5 Information on this operating manual ......5 Explanation of symbols ..........6 Limitation of liability ............7 Copyright ................ 8 Spare parts ..............8 Warranty conditions ............

- Page 63 Electric motors Size 63 - 225 ATEX / IECEx Table of contents Installation and commissioning .........32 Safety ................32 Installation ..............34 6.2.1 Ventilation at the location for use ....34 6.2.2 Types of construction as per EN 60034-7 ..34 6.2.3 Erecting the machine ........37 6.2.4 Installation .............37 Connecting to the energy supply .........38...

- Page 64 Electric motors Size 63 - 225 ATEX / IECEx General information Pos : 1.1 /KN2006- SM/Allgemei nes /100 1 Allgemeines _Titel @ 8\mod_1142088318714_1.doc @ 75727 1 General information Pos : 1.2 /KN2006- SM/Allgemei nes /110 1.1 Informati onen z ur Anl eitung (Maschi ne) @ 40\mod_1182336499793_1.doc @ 495957 1.1 Information on this operating manual This operating manual makes it possible to handle the machine safely and efficiently.

- Page 65 Electric motors Size 63 - 225 ATEX / IECEx General information Pos : 1.5 /KN2006- SM/Allgemei nes /120 1.1 Symboler kl ärung @ 8\mod_1142089345047_1.doc @ 75774 1.2 Explanation of symbols Safety instructions The safety instructions in this manual are indicated by symbols. The safety instructions are introduced by signal words which express the extent of the risk.

- Page 66 Electric motors Size 63 - 225 ATEX / IECEx General information Pos : 1.7 /KN2006- SM/Allgemei nes /121 1.1.1 Bes ondere Sic her heitshi nweis e_Titel @ 8\mod_1142090242324_1.doc @ 75783 Special safety instructions The following symbols are used in safety instructions in order to point out particular hazards.

- Page 67 Electric motors Size 63 - 225 ATEX / IECEx General information Pos : 1.15 /KN 2006-SM /Allgemeines/140 1.1 Ur heberschutz @ 8\mod_1142092015791_1.doc @ 75819 1.4 Copyright This operating manual is protected by copyright and for internal use only. The manual must not be made available to third parties, reproduced in any way (including excerpts), its content must not be utilised and/or communicated without the written approval of the manufacturer, except for internal purposes.

- Page 68 Electric motors Size 63 - 225 ATEX / IECEx Safety Pos : 2.1 /F I/..Seitenumbr uch ..@ 0\mod272_1.doc @ 1522 Pos : 2.2 /KN2006- SM/Sic herheit/001 1 Sic her hei t_Titel @ 8\mod_1142425976781_1.doc @ 77461 2 Safety Pos : 2.3 /KN2006- SM/Sic herheit/001 1.0 Einführung @ 8\mod_1142427208593_1.doc @ 77470 This section provides you with an overview of all important aspects of safety required for providing staff with optimum protection as well as safe, fault-free operation.

- Page 69 Electric motors Size 63 - 225 ATEX / IECEx Safety and the safety of employees who may be at risk from a potentially explosive atmosphere. This includes adherence to further organisational measures, such as: ⚫ marking potentially explosive areas. ⚫ drawing up an explosion protection document for each zone.

- Page 70 Electric motors Size 63 - 225 ATEX / IECEx Safety ◼ Trained person has been informed of the tasks with which he has been entrusted and the possible risks in case of incorrect behaviour in training measures provided by the user. ◼...

- Page 71 Electric motors Size 63 - 225 ATEX / IECEx Safety Pos : 2.17 /KN 2006-SM /Sic her hei t/004 Pers onal/004 1.1.1 U nbefugte @ 13\mod_1152892272765_1.doc @ 148636 2.2.2 Unauthorised parties WARNING! Danger for unauthorised parties. Unauthorised persons who do not meet with the requirements described here, are not familiar with the hazards in the working area.

- Page 72 Electric motors Size 63 - 225 ATEX / IECEx Safety WARNING! Danger from improper use. Improper use of the machine can cause dangerous situations. Take particular care not to use the machine as follows: – Operation beyond the original designated application.

- Page 73 Electric motors Size 63 - 225 ATEX / IECEx Safety Pos : 2.28 /KN 2006-SM /Sic her hei t/006 Pers önliche Schutz ausstattung/006 1.1.0_2 Bei bes onderen Ar beiten z u tragen_Titel @ 8\mod_1143361122656_1.doc @ 80999 To be worn for special tasks When carrying out special tasks, special safety equipment and clothing is required.

- Page 74 Electric motors Size 63 - 225 ATEX / IECEx Safety Pos : 2.35 /KN 2006-SM /Sic her hei t/007 Besondere Gefahr en/El ektrisc her Strom_Gefahr! @ 8\mod_1143366795746_1.doc @ 81188 Electrical current DANGER! Danger to life from electrical current. There is an immediate risk of fatal injury in case of contact with live parts.

- Page 75 Electric motors Size 63 - 225 ATEX / IECEx Safety Pos : 2.39 /KN 2006-SM /Sic her hei t/007 Besondere Gefahr en/Heiß e Oberfl äc hen_Vorsicht! @ 8\mod_1143375956657_1.doc @ 81347 Hot surfaces CAUTION! Risk of burns from hot surfaces. Contact with hot parts can cause burns. Therefore: –...

- Page 76 Electric motors Size 63 - 225 ATEX / IECEx Safety Pos : 2.45 /KN 2006-Pr ojekte/Herforder Elektromotoren-Wer ke/Sic herheit/008 1.1 Sic her heitsei nrichtungen_Titel @ 59\mod_1203337625484_1.doc @ 1037161 2.6 Safety devices Pos : 2.46 /KN 2006-SM /Sic her hei t/008 Sicherheits einric htungen/Kein eigener Not-Aus (M asc hine) @ 41\mod_1183384960738_1.doc @ 503378 Integration into an emergency stop The machine is for use within a plant.

- Page 77 Electric motors Size 63 - 225 ATEX / IECEx Safety Switch secured with a padlock Securing the machine to prevent it from being switched back on: …….. at ..h. Switch off the energy supply. DO NOT SWITCH ON If possible, secure the switch with a padlock and attach a The padlock must only be removed clearly visible sign according to Fig.

- Page 78 Electric motors Size 63 - 225 ATEX / IECEx Safety Pos : 2.52 /KN 2006-SM /Sic her hei t/011 U mweltsc hutz/011 U mwelts chutz Titel und Einführung @ 9\mod_1143987199086_1.doc @ 84175 2.9 Environmental protection CAUTION! Risk of environmental damage in case of incorrect handling.

- Page 79 Electric motors Size 63 - 225 ATEX / IECEx Technical data Pos : 3.2 /KN2006- SM/T echnisc he D aten/001 1 Tec hnisc he Daten_Ti tel @ 8\mod_1143124628960_1.doc @ 80561 3 Technical data Pos : 3.3 /KN2006- Proj ekte/H erfor der El ektromotoren- Wer ke/T ec hnis che D aten/HIN WEIS - Die notwendigen tec hnischen D aten @ 59\mod_1203077215350_1.doc @ 1034411 NOTE! The necessary technical data can be found on the respective type plates.

- Page 80 Electric motors Size 63 - 225 ATEX / IECEx Technical data Pos : 3.10 /KN 2006-SM /nL---------- Abschnitts ende ---------- @ 8\mod_1141997892953_0.doc @ 75471 s: 3.11 /KN 2006-Pr ojekte/H erforder Elektr omotor en- Wer ke/Technisc he Daten/ATEX/009 1.1 Ex-Kennz eic hnung @ 60\mod_1203497200012_1.doc @ 1039729 3.3 Explosion protection marking EXPLOSION PROTECTION! acc.

- Page 81 Electric motors Size 63 - 225 ATEX / IECEx Technical data Section Designation Significance Explosion protection symbol Marking for protection from explosions Device group Device group II. The motor can be used in potentially explosive areas except in mining. Category For application in Zone 1 and Zone 21 …...

- Page 82 Electric motors Size 63 - 225 ATEX / IECEx Construction and function Pos : 4.2 /KN2006- SM/Aufbau und F unktion/001 1 Aufbau und F unkti on_Titel @ 8\mod_1143713625726_1.doc @ 83161 4 Construction and function Pos : 4.3 /KN2006- Proj ekte/H erfor der El ektromotoren- Wer ke/Aufbau und F unktion/AT EX/002 1.1.0 Übersicht @ 68\mod_1209358678629_1.doc @ 1157152 4.1 Overview of sizes 63 to 132 15 16 Fig.

- Page 83 Electric motors Size 63 - 225 ATEX / IECEx Construction and function 4.2 Overview of sizes 160 to 225 17 18 Fig. 6: Overview of sizes 160 to 225 Flange rings 12 Terminal box cover seal Sealing rings DS* 13 Terminal box cover Cover plate DS* 14 Screwed cable glands Rolling bearings DS*...

- Page 84 Electric motors Size 63 - 225 ATEX / IECEx Construction and function Pos : 4.5 /KN2006- SM/Aufbau und F unktion/005 1.1 Anschl üss e_Titel @ 9\mod_1144394868217_1.doc @ 86353 4.3 Connection, motor protection Pos : 4.6 /KN2006- Proj ekte/H erfor der El ektromotoren- Wer ke/Aufbau und F unktion/005 1.1.0 Ansc hlüss e @ 54\mod_1196341904624_1.doc @ 832892 Before connecting the explosion protected motor, check the following: do the ratings on the type plate match the mains voltage and frequency? does the explosion protection match the environment in which the motor is operated...

- Page 85 Electric motors Size 63 - 225 ATEX / IECEx Construction and function 4.5 Operation on the frequency converter The motors of EX versions “pressure-proof encapsulation” Ex d(e) and “protection by housing” Ex t are approved for inverter operation. For approved versions, the possible frequency range must be obtained from the EU prototype test certificate.

- Page 86 Electric motors Size 63 - 225 ATEX / IECEx Transportation, packaging and storage Pos: 5.2 /KN2006-SM/Transport, Verpackung und Lagerung/001 1 Transport, Verpackung und Lagerung_Titel @ 9\mod_1144048567385_1.doc @ 84502 5 Transportation, packaging and storage Pos : 5.3 /KN2006- SM/Trans por t, Ver pac kung und Lag erung/002 1.1.0 War nung! Lebensgefahr durch sc hwebende Las ten @ 9\mod_1144048709603_1.doc @ 84516 Suspended loads WARNING! Risk of fatal injury from suspended loads.

- Page 87 Electric motors Size 63 - 225 ATEX / IECEx Transportation, packaging and storage Pos : 5.7 /KN2006- SM/Trans por t, Ver pac kung und Lag erung/002 1.1.0 Vorsic ht Tr ansportsc häden bei unsac hgemäß em Trans por t_Vorsic ht!Sac hsc haden @ 9\mod_1144051344560_1.doc @ 84538 Improper transportation CAUTION! Risk of damage in case of improper...

- Page 88 Electric motors Size 63 - 225 ATEX / IECEx Transportation, packaging and storage Pos : 5.14 /KN 2006-SM /Transport, Verpac kung und Lager ung/006 1.1 Transport_Titel @ 9\mod_1145448098995_1.doc @ 90988 5.2 Transportation Pos : 5.15 /KN 2006-Pr ojekte/Herforder Elektromotoren-Wer ke/Trans port/005 1.1.0 Ansc hl agpunkte @ 54\mod_1196342213558_1.doc @ 832949 ◼...

- Page 89 Electric motors Size 63 - 225 ATEX / IECEx Transportation, packaging and storage Pos : 5.21 /KN 2006-SM /Transport, Verpac kung und Lager ung/006 1.1.0 Transport von Pal etten mit dem Gabels tapl er @ 9\mod_1144392667613_1.doc @ 86319 Transporting pallets by forklift Packages which are fastened to pallets can be transported by forklift under the following conditions: ◼...

- Page 90 Electric motors Size 63 - 225 ATEX / IECEx Transportation, packaging and storage Pos : 5.28 /KN 2006-SM /Transport, Verpac kung und Lager ung/007 1.1 Lagerung_Ti tel @ 38\mod_1179315679426_1.doc @ 471241 5.4 Storage Pos : 5.29 /KN 2006-Pr ojekte/Herforder Elektromotoren-Wer ke/Trans port/007 1.1.0 Lager ung der Pac ks tüc ke @ 59\mod_1203074612840_1.doc @ 1034278 Storing packages Store the packages under the following conditions: ◼...

- Page 91 Electric motors Size 63 - 225 ATEX / IECEx Installation and commissioning Pos : 6.2 /KN2006- SM/Installation & Inbetri ebnahme/001 1 Ins tall ati on und Ers tinbetriebnahme_Titel @ 9\mod_1144393592402_1.doc @ 86332 6 Installation and commissioning Pos : 6.3 /KN2006- Proj ekte/H erfor der El ektromotoren- Wer ke/Ins tall ation & Inbetriebnahme/AT EX/HIN WEIS - Nor men, Ric htlini en Ex- Ber eich @ 60\mod_1203665634793_1.doc @ 1043962 NOTE! When installing and commissioning adhere to the current standards and directive for electrical...

- Page 92 Electric motors Size 63 - 225 ATEX / IECEx Installation and commissioning Pos : 6.12 /KN 2006-SM /Installati on & Inbetriebnahme/003 1.1.0 El ektrisc he Anl age_Gefahr! @ 9\mod_1144397463440_1.doc @ 86395 Electrical equipment DANGER! Danger to life from electrical current. There is a risk of fatal injury from contact with live parts.

- Page 93 Electric motors Size 63 - 225 ATEX / IECEx Installation and commissioning Pos : 6.18 /KN 2006-SM /Installati on & Inbetriebnahme/005 1.1 Installation_Titel @ 9\mod_1144401700720_1.doc @ 86426 6.2 Installation Pos : 6.19 /KN 2006-Pr ojekte/Herforder Elektromotoren-Wer ke/Installation & Inbetri ebnahme/1.1.1 Bel üftung am Einsatzort @ 59\mod_1203072994994_1.doc @ 1034256 6.2.1 Ventilation at the location for use The ventilation for the motor must not be obstructed.

- Page 94 Electric motors Size 63 - 225 ATEX / IECEx Installation and commissioning Type of Symbol Explanation construction ◼ IM B7 2 bearing covers IM 1061 ◼ with feet ◼ Construction type IM B3 ◼ Fastening on the wall ◼ Feet right, viewed from drive side ◼...

- Page 95 Electric motors Size 63 - 225 ATEX / IECEx Installation and commissioning Type of Symbol Explanation construction ◼ IM V18 2 bearing covers IM 3611 ◼ without feet ◼ Shaft end bottom ◼ Securing flange type C ◼ IM V19 2 bearing covers IM 3631 ◼...

- Page 96 Electric motors Size 63 - 225 ATEX / IECEx Installation and commissioning Pos : 6.23 /KN 2006-Pr ojekte/Herforder Elektromotoren-Wer ke/Installation & Inbetri ebnahme/1.1.1 M aschi nenaufstellung @ 59\mod_1203075619986_1.doc @ 1034390 6.2.3 Erecting the machine DANGER! Risk of death due to insufficient protection classes.

- Page 97 Electric motors Size 63 - 225 ATEX / IECEx Installation and commissioning Pos : 6.26 /KN 2006-SM /nL---------- Abschnitts ende ---------- @ 8\mod_1141997892953_0.doc @ 75471 Pos : 6.27 /KN 2006-Pr ojekte/Herforder Elektromotoren-Wer ke/Installation & Inbetri ebnahme/006 1.1 Elektrischer Ans chl uss _Titel @ 59\mod_1203082082094_1.doc @ 1034835 6.3 Connecting to the energy supply Pos : 6.28 /KN 2006-SM /Sic her hei t/007 Besondere Gefahr en/El ektrisc her Strom_Gefahr! @ 8\mod_1143366795746_1.doc @ 81188 Electrical current...

- Page 98 Electric motors Size 63 - 225 ATEX / IECEx Installation and commissioning Ex d motors Connection to the terminal box with these motors is implemented with a standard connection. You must take great care when selecting the cable connection. It is imperative that the version is approved and approved for at least the protection class of the motor.

- Page 99 Electric motors Size 63 - 225 ATEX / IECEx Installation and commissioning Pos : 6.34 /KN 2006-Pr ojekte/Herforder Elektromotoren-Wer ke/Installation & Inbetri ebnahme/1.1.1 Is ol ations wi ders tand pr üfen @ 59\mod_1203315508128_1.doc @ 1036431 6.3.3 Checking the insulation resistance ◼...

- Page 100 Electric motors Size 63 - 225 ATEX / IECEx Installation and commissioning Pos : 6.39 /KN 2006-Pr ojekte/Herforder Elektromotoren-Wer ke/Installation & Inbetri ebnahme/VOR SICHT - Her ausg esc hleuderte Pas sfeder @ 59\mod_1203079038551_1.doc @ 1034432 CAUTION! Risk of personal injury and/or material damage from feather keys ejected at speed.

- Page 101 Electric motors Size 63 - 225 ATEX / IECEx Operations Pos : 7.2 /KN2006- SM/Bedienung/001 1 Bedi enung _Titel @ 9\mod_1144402040153_1.doc @ 86490 7 Operations Pos : 7.3 /KN2006- Proj ekte/H erfor der El ektromotoren- Wer ke/Bedienung/1.1 Allgemei nes @ 59\mod_1203412166172_1.doc @ 1038421 7.1 General information During operation no staff are required in the machine area or in the direct vicinity to operate it.

- Page 102 Electric motors Size 63 - 225 ATEX / IECEx Faults Pos : 8.2 /KN2006- SM/Stör ung en/001 1 Stör ung en_Titel+Text @ 9\mod_1144439647801_1.doc @ 86957 8 Faults The following chapter describes possible causes of faults and the work to eradicate them. In case of faults which occur several times, reduce the maintenance interval accordingly to suit the actual strain.

- Page 103 Electric motors Size 63 - 225 ATEX / IECEx Faults Pos : 8.10 /KN 2006-SM /Störungen/003 1.1.0 Elektrisc he Anlage_Gefahr! @ 9\mod_1144439649994_1.doc @ 86978 Electrical equipment DANGER! Danger to life from electrical current. There is a risk of fatal injury from contact with live parts.

- Page 104 Electric motors Size 63 - 225 ATEX / IECEx Faults Pos : 8.16 /KN 2006-SM /Störungen/003 1.1.0 Verhalten bei Stör ung en (Ger ät) @ 9\mod_1144441786782_1.doc @ 87239 How to act in case of faults The following basic instructions apply: In case of faults which pose an immediate risk to people or objects of material value, activate the emergency stop function immediately.

- Page 105 Electric motors Size 63 - 225 ATEX / IECEx Faults Fault Possible cause Remedy To be remedied by ◼ Bearing noises Scoring on inner bearing Replace bearing, avoid Manufacturer ring, e.g. from motor vibrations when at a starting up with bearing standstill locked ◼...

- Page 106 Electric motors Size 63 - 225 ATEX / IECEx Faults Pos: 8.21 /KN2006-SM/Störungen/007 1.1 Inbetriebnahme nach behobener Störung_Titel @ 9\mod_1144442691882_1.doc @ 87274 8.3 Commissioning after remedied fault Pos : 8.22 /KN 2006-SM /Störungen/007 1.1.0 Inbetriebnahme nac h behobener Störung --> Standard --> ggf. anpass en @ 9\mod_1144442763671_1.doc @ 87281 After remedying the fault carry out the following steps for re- commissioning: Reset the emergency stop devices.

- Page 107 Electric motors Size 63 - 225 ATEX / IECEx Maintenance Pos : 9.2 /KN2006- SM/War tung/001 1 Wartung_Titel @ 9\mod_1144434830143_1.doc @ 86796 9 Maintenance Pos : 9.3 /KN2006- SM/War tung/002 1.1 Sic herheit_Titel @ 9\mod_1144434831619_1.doc @ 86810 9.1 Safety Pos: 9.4 /KN2006-SM/Wartung/003 1.1.0 Personal --> Standard --> ggf. anpassen @ 9\mod_1144434832402_1.doc @ 86817 ◼...

- Page 108 Electric motors Size 63 - 225 ATEX / IECEx Maintenance Pos : 9.10 /KN 2006-SM /Wartung/003 1.1.0 Elektrisc he Anlage @ 9\mod_1144434833265_1.doc @ 86824 Electrical equipment DANGER! Danger to life from electrical current. There is a risk of fatal injury from contact with live parts.

- Page 109 Electric motors Size 63 - 225 ATEX / IECEx Maintenance ◼ At all lubricating points which are supplied with lubricant by hand, remove the expelled, used or excess grease and dispose of it in accordance with the local regulations. Pos : 9.18 /KN 2006-SM /Wartung/004 1.1.0.0 Ents orgung Öl @ 9\mod_1144439240623_1.doc @ 86943 ◼...

- Page 110 Electric motors Size 63 - 225 ATEX / IECEx Maintenance In case you have any questions on maintenance work and intervals, contact the manufacturer, see service address on page 2. Pos : 9.26 /KN 2006-SM /nL---------- Abschnitts ende ---------- @ 8\mod_1141997892953_0.doc @ 75471 Pos : 9.27 /KN 2006-Pr ojekte/Herforder Elektromotoren-Wer ke/Wartung/006 1.1.0 Wartungsplan @ 54\mod_1196342707944_1.doc @ 833101 The standard version motors are fitted with permanently lubricated bearings.

- Page 111 Electric motors Size 63 - 225 ATEX / IECEx Maintenance Pos : 9.29 /KN 2006-Pr ojekte/Herforder Elektromotoren-Wer ke/Wartung/1.1 Sc hraubenanz ugsdr ehmomente @ 67\mod_1208937207889_1.doc @ 1150009 9.4 Tightening torque values for screws Explosion protection EXPLOSION PROTECTION! The introduction of ignition sources such as sparks, open flames and hot surfaces can cause explosions in the potentially explosive area.

- Page 112 Electric motors Size 63 - 225 ATEX / IECEx Maintenance 9.4.2 Screw connections, property class 8.8 and A4-70 NOTE! Only use tightening torque values for screws of property class 8.8 and A4-70 (A4-80) in high- strength parts (e.g. grey cast iron, steel). Thread Tightening torque Thread...

- Page 113 Electric motors Size 63 - 225 ATEX / IECEx Maintenance Pos : 9.31 /KN 2006-SM /Wartung/009 1.1 M aß nahmen nac h erfolgter Wartung_Titel @ 9\mod_1144438930025_1.doc @ 86928 9.5 Measures on completion of maintenance Pos : 9.32 /KN 2006-Pr ojekte/Herforder Elektromotoren-Wer ke/Wartung/AT EX/007 1.1.0 Potential ausgleich und Erdung anbring en EX-SCHUTZ @ 60\mod_1203501310249_1.doc @ 1040296 Explosion protection EXPLOSION PROTECTION! Introducing ignition sources such as sparks in the...

- Page 114 Electric motors Size 63 - 225 ATEX / IECEx Removal Pos : 10.2 /KN 2006-SM /Demontag e/001 1 D emontage_Titel @ 9\mod_1144501489239_1.doc @ 87445 10 Removal Pos : 10.3 /KN 2006-SM /Demontag e/001 1.0 N ac hdem das Gebrauchsende erreic ht ist...(Mas chi ne) @ 41 \mod_1183385607485_1.doc @ 503412 Once the period of use has expired, the machine must be removed and disposed of in an environmentally friendly manner.

- Page 115 Electric motors Size 63 - 225 ATEX / IECEx Removal Pos : 10.12 /KN 2006-SM/D emontage/003 1.1.0 Gr undleg endes @ 9\mod_1144870287285_1.doc @ 89626 Improper removal WARNING! Risk of injury from improper removal. Stored residual energy, sharp parts, points and corners on and in the device or on the required tools can cause injuries.

- Page 116 Electric motors Size 63 - 225 ATEX / IECEx Removal Pos : 10.16 /KN 2006-SM/D emontage/009 1.1 Ents orgung --> Standar d --> ggf. anpas sen! @ 8\mod_1142093514566_1.doc @ 75855 10.3 Disposal If no agreements have been made for return or disposal, have the dismantled components recycled: ◼...

- Page 117 EC / EU – declaration of conformity HERFORDER ELEKTROMOTOREN-WERKE GmbH & Co. KG D – 32051 Herford Goebenstraße 106 Tel.: 05221 59040 info@HEW-HF.de D – 32008 Herford post office box 1852 Electrical operating equipment: Explosion-proof three phase asynchronous motors ( flame-proof encapsulation ) with squirrel cage marking gas marking dust DCEx 63...

- Page 118 Appendix Diaphragm pump N630.12 EX 13.3 Coupling For further information, see also § Rotex-BA.pdf Translation of Original Operation and Installation Instruction, english, KNF 325089 11/22...

- Page 119 KTR-N 40210 EN ® ROTEX Sheet: 1 of 27 Operating/Assembly instructions Edition: ® ROTEX Torsionally flexible jaw couplings type No. 001 - shaft coupling, No. 018 - DKM, with taper clamping sleeve and their combinations according to directive 2014/34/EU Type No. 001 - shaft coupling Type No.

- Page 120 KTR-N 40210 EN ® ROTEX Sheet: 2 of 27 Operating/Assembly instructions Edition: ® ROTEX is a torsionally flexible jaw coupling. It is able to compensate for shaft misalignment, for example caused by manufacturing inaccuracies, thermal expansion, etc. Table of contents Technical data Advice General advice...

- Page 121 KTR-N 40210 EN ® ROTEX Sheet: 3 of 27 Operating/Assembly instructions Edition: Technical data ® Illustration 1: ROTEX (material: powder metal, Al-D and Al-H) Table 1: Material powder metal steel (Sint) Spider (component 2) Dimensions [mm] Com- Size Rated torque [Nm] General Finish bore ponent...

- Page 122 KTR-N 40210 EN ® ROTEX Sheet: 4 of 27 Operating/Assembly instructions Edition: Technical data ® Illustration 2: ROTEX (material: GJL/GJS) Table 4: Material cast iron (GJL)/nodular iron (GJS) Spider (component 2) Dimensions [mm] Rated torque [Nm] Com- General Size Finish bore ponent d (min-max) 92 ShA...

- Page 123 KTR-N 40210 EN ® ROTEX Sheet: 5 of 27 Operating/Assembly instructions Edition: Technical data ® Illustration 3: ROTEX (material: steel) Table 5: Material steel Dimensions [mm] Spider (component 2) Com- Rated torque [Nm] Size Finish bore General ponent 92 ShA 98 ShA 64 ShD d (min-max)

- Page 124 KTR-N 40210 EN ® ROTEX Sheet: 6 of 27 Operating/Assembly instructions Edition: Technical data ® Illustration 4: ROTEX type DKM Table 6: Type DKM Spider (component 2) Dimensions [mm] Size Rated torque [Nm] General Dimensions d, D, D 92 ShA 98 ShA 1280 1920...

- Page 125 KTR-N 40210 EN ® ROTEX Sheet: 7 of 27 Operating/Assembly instructions Edition: Technical data Coupling design: Screwing on cam side Screwing on collar side Different combinations of types TB1 and TB2 are possible. ® Illustration 5: ROTEX type with taper clamping sleeve Table 7: Type with taper clamping sleeve Dimensions [mm] Spider...

- Page 126 KTR-N 40210 EN ® ROTEX Sheet: 8 of 27 Operating/Assembly instructions Edition: Advice 2.2 Safety and advice symbols This symbol indicates notes which may contribute to Warning of potentially explosive preventing bodily injuries or serious bodily injuries that atmospheres may result in death caused by explosion. This symbol indicates notes which may contribute to Warning of personal injury preventing bodily injuries or serious bodily injuries that...

- Page 127 KTR-N 40210 EN ® ROTEX Sheet: 9 of 27 Operating/Assembly instructions Edition: Advice 2.5 Coupling selection For a permanent and failure-free operation of the coupling it must be selected according to the selection instructions (according to DIN 740 part 2) for the particular application (see ®...

- Page 128 KTR-N 40210 EN ® ROTEX Sheet: 10 of 27 Operating/Assembly instructions Edition: Assembly The coupling is generally supplied in individual parts. Before assembly the coupling has to be inspected for completeness. 4.1 Components of the coupling ® Components of ROTEX , shaft coupling type No.

- Page 129 KTR-N 40210 EN ® ROTEX Sheet: 11 of 27 Operating/Assembly instructions Edition: Assembly 4.1 Components of the coupling Features of standard spiders 92 Shore A 98 Shore A 64 Shore D Spider hardness ® ® ® T-PUR T-PUR T-PUR (Shore) (orange) (yellow) (purple)

- Page 130 KTR-N 40210 EN ® ROTEX Sheet: 12 of 27 Operating/Assembly instructions Edition: Assembly 4.2 Advice for finish bore Table 9: Recommended fit pairs acc. to DIN 748-1 Bore [mm] Shaft tolerance Bore tolerance above up to (KTR standard) If a feather keyway is intended to be used in the hub, it should correspond to the tolerance ISO JS9 (KTR standard) with standard operating conditions or ISO P9 with complicated operating conditions (frequently alternating torsional direction, shock loads, etc.).

- Page 131 KTR-N 40210 EN ® ROTEX Sheet: 13 of 27 Operating/Assembly instructions Edition: Assembly 4.3 Assembly of the hubs Illustration 10: Assembly of the hubs Illustration 11: Assembly of coupling 4.4 Assembly of taper clamping sleeve Assembly of taper clamping sleeve: Clean the contact surfaces of the taper clamping sleeves and of shaft and hub and afterwards apply thin fluid oil lightly (e.

- Page 132 KTR-N 40210 EN ® ROTEX Sheet: 14 of 27 Operating/Assembly instructions Edition: Assembly 4.4 Assembly of taper clamping sleeve Disassembly of taper clamping sleeve: The taper clamping sleeve is released by removing the setscrews. Afterwards one of the setscrews used as forcing screw is screwed in the thread of the sleeve and tightened.

- Page 133 KTR-N 40210 EN ® ROTEX Sheet: 15 of 27 Operating/Assembly instructions Edition: Assembly 4.5 Displacements - alignment of the couplings Examples of the displacement combinations Illustration 15: specified in illustration 15: Combinations of displacement Example 1: K = 30 % K = 70 % Example 2:...

- Page 134 KTR-N 40210 EN ® ROTEX Sheet: 16 of 27 Operating/Assembly instructions Edition: Start-up Before start-up of the coupling, inspect the tightening of setscrews in the hubs, the alignment and the distance dimension E and adjust, if necessary, and also inspect all screw connections for the tightening torques specified. If used in potentially explosive atmospheres the setscrews to fasten the hubs as well as all screw connections must be secured against working loose additionally, e.

- Page 135 KTR-N 40210 EN ® ROTEX Sheet: 17 of 27 Operating/Assembly instructions Edition: Breakdowns, causes and elimination ® The below-mentioned failures can lead to a use of the ROTEX coupling other than intended. In addition to the specifications given in these operating/assembly instructions make sure to avoid such failures. The errors listed can only be clues to search for the failures.

- Page 136 KTR-N 40210 EN ® ROTEX Sheet: 18 of 27 Operating/Assembly instructions Edition: Breakdowns, causes and elimination Hazard notes for Breakdowns Causes potentially explosive Elimination atmospheres 1) Set the unit out of operation Operating parameters 2) Review the operating parameters and select do not meet with the a bigger coupling (consider mounting space) performance of the...

- Page 137 KTR-N 40210 EN ® ROTEX Sheet: 19 of 27 Operating/Assembly instructions Edition: Disposal In respect of environmental protection we would ask you to dispose of the packaging resp. products on termination of their service life in accordance with the legal regulations and standards that apply. •...

- Page 138 KTR-N 40210 EN ® ROTEX Sheet: 20 of 27 Operating/Assembly instructions Edition: Enclosure A Advice and instructions regarding the use in potentially explosive atmospheres Applicable hub designs/types: a) Hubs that may be used in group II, category 2 and 3 : ®...

- Page 139 KTR-N 40210 EN ® ROTEX Sheet: 21 of 27 Operating/Assembly instructions Edition: Enclosure A Advice and instructions regarding the use in potentially explosive atmospheres 10.1 Intended use in potentially explosive atmospheres Conditions of operation in potentially explosive atmospheres ® ROTEX couplings are suitable for the use according to EU directive 2014/34/EU.

- Page 140 KTR-N 40210 EN ® ROTEX Sheet: 22 of 27 Operating/Assembly instructions Edition: Enclosure A Advice and instructions regarding the use in potentially explosive atmospheres 10.2 Inspection intervals for couplings in potentially explosive atmospheres Equipment category Inspection intervals For couplings operated in zone 2 or zone 22 the inspection and maintenance intervals of the usual operating/assembly instructions for standard operation apply.

- Page 141 KTR-N 40210 EN ® ROTEX Sheet: 23 of 27 Operating/Assembly instructions Edition: Enclosure A Advice and instructions regarding the use in potentially explosive atmospheres 10.2 Inspection intervals for couplings in potentially explosive atmospheres ® ROTEX coupling Illustration 17.1: ® ROTEX elements Illustration 17.2: ®...

- Page 142 KTR-N 40210 EN ® ROTEX Sheet: 24 of 27 Operating/Assembly instructions Edition: Enclosure A Advice and instructions regarding the use in potentially explosive atmospheres 10.3 Standard values of wear In case of backlash > X mm, the flexible spider/DZ elements must be replaced. The general condition of the coupling can both be monitored at standstill and during operation.

- Page 143 KTR-N 40210 EN ® ROTEX Sheet: 25 of 27 Operating/Assembly instructions Edition: Enclosure A Advice and instructions regarding the use in potentially explosive atmospheres 10.4 marking of coupling for potentially explosive atmospheres ® The ATEX marking of the ROTEX coupling is applied on the outer sheath or on the front side. The flexible spider resp.

- Page 144 KTR-N 40210 EN ® ROTEX Sheet: 26 of 27 Operating/Assembly instructions Edition: Enclosure A Advice and instructions regarding the use in potentially explosive atmospheres 10.4 marking of coupling for potentially explosive atmospheres Deviating marking applies until 31st October 2019: Short marking: II 2GD c IIC T X/I M2 c X ...

- Page 145 KTR-N 40210 EN ® ROTEX Sheet: 27 of 27 Operating/Assembly instructions Edition: Enclosure A Advice and instructions regarding the use in potentially explosive atmospheres 10.5 EU Certificate of conformity EU Certificate of conformity corresponding to EU directive 2014/34/EU dated 26 February 2014 and to the legal regulations The manufacturer - KTR Systems GmbH, D-48432 Rheine - states that the ®...

- Page 148 KNF worldwide You can find our local KNF partners at: www.knf.com...

Need help?

Do you have a question about the N630.12 EX and is the answer not in the manual?

Questions and answers