Advertisement

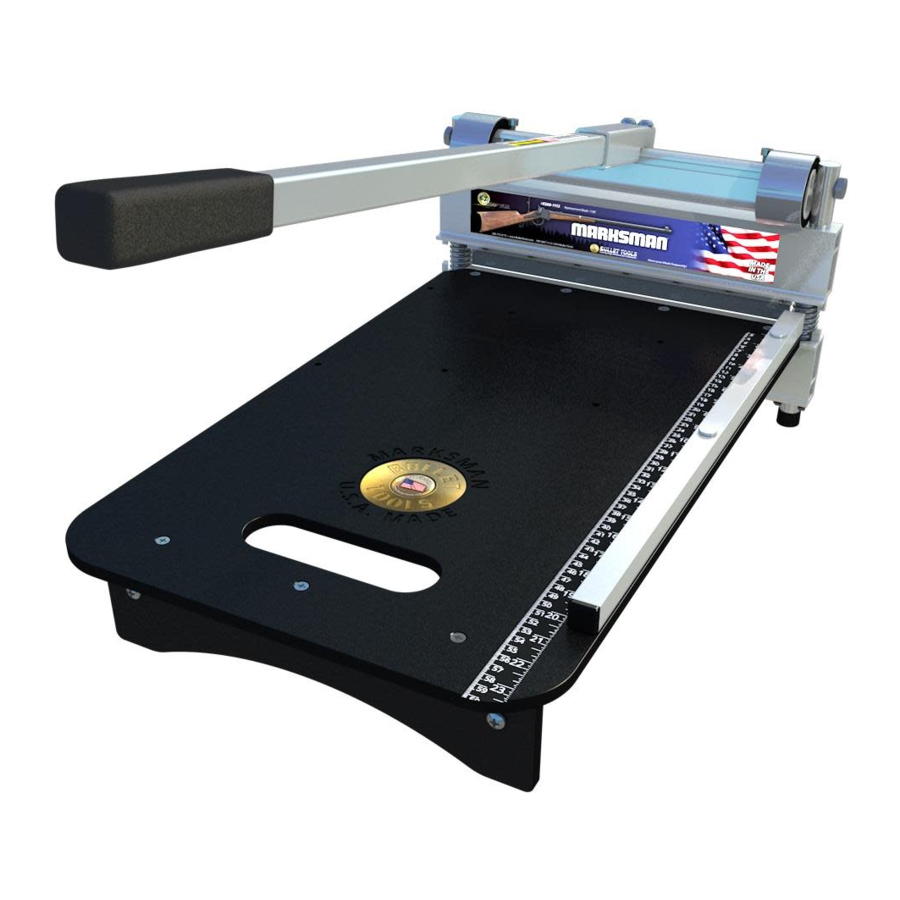

Features include

- Ability to cut inside without dust

- Built in ruler for accurate cuts

- Full table with high-density polymer wear surface

- Metal-jacketed polymer bearings

- Aircraft grade aluminum frame

And can cuts material 5/8" (16 mm) thick and 13" (330 mm) wide, including:

- Engineered Hardwood Flooring (up to 1⁄2" / 12 mm thick and 1250 Janka—ONLY cut by flipping material over with the back facing up)

- Laminate Flooring

- LVT, LVP, VCT

- PVC & Rubber Tile

- Cove Base

- WPC/SPC/MLF

- Rigid Core

This owner's manual provides the information needed to operate and maintain this Marksman. Carefully read and follow all safety and operating instructions in this manual. Ensure every operator of this flooring cutter reads this manual before operating the unit. The replacement of any part on this flooring cutter with a component other than a manufacturer authorized replacement part may adversely affect the performance, durability, or safety of the product.

Be sure safety precautions are observed. Read and follow all safety and operating instructions in this operator's manual. The manufacturer reserves the right to make changes on or add improvements to its product at any time without prior notice or obligation. The manufacturer reserves the right to decide, upon its sole discretion and at any time, to discontinue this product or replacement parts thereof.

This manual covers the Marksman. For technical questions or repair parts, please call MARSHALLTOWN customer service at 1-800-888-0127 or visit www.MARSHALLTOWN.com.

PRODUCT OPERATION

When most materials are cut, the 'drop' piece will have a beveled edge, while the 'keep' piece (the piece left on

- Slide the Camlock lever over to unlock cutter.

![]()

- Place product on table. It is recommended that you HOLD MATERIAL IN PLACE until the cut is complete. Bring handle down until blade touches material.

![]()

- Push handle down until the material is cut completely. Some effort may be required depending of hardness of material.

![]()

SAFETY LOCK

The safety lock can be disengaged by sliding the knob over.

TRANSPORT

Always re-engage the Safety Lock pin and secure the extended handle in the down position while storing, carrying, or transporting your cutter.

CUTTING GUIDE

The Marksman is designed to cut a variety of materials. Some of the most common materials are Engineered Hardwood Flooring (up to 1⁄2" / 12 mm thick and 1250 Janka—ONLY cut by flipping material over with the back facing up), laminate flooring, LVT/LVP/VCT, PVC, rubber tile, cover base, WPC/SPC/MLF, and rigid core.

45 DEGREE CUTS

Firmly lift the friction-fit fence to remove it from the table and press back down in the appropriate 45-degree position.

FLOPPY MATERIALS

When cutting floppy materials, flip the anvil: Remove anvil and blade-stop using a 4 mm or 5⁄32" hex key. Reinstall with flat side up instead of bevel. This makes fibrous and floppy materials (examples: cove base, thin vinyl plank) cut more easily.

For Kevlar® fiber reinforced materials (example: rubber belting), put flat side of anvil up above, but also remove plastic blade-stop.

DOUBLE CUTTING

Most materials cutter very well with just one cut. However, some brands of fiber cement siding and other products may require cutting twice to produce a better cut. Simply make your first cut 1⁄8" to 1⁄4" (3 to 6 mm) longer than your mark, then go back and make your second cut on your mark. This is very useful to create a cleaner cut when a trim molding or transition cannot be used to cover your cut end.

MAINTENANCE

Honing the Blade

Push the handle down until the blade 1⁄8" (3 mm) above the tabletop. Place the provided Hone Stone against the flat side of the blade. Slide the honing stone from one end of the blade to the other 3-4 times. This will remove any burrs from your blade.

When you first get your cutter, you should hone after your 5th cut, then hone your blade every 10th cut for the first 100 cuts until your blade is broken in. From there, you only need to hone once per job. Use caution when honing the blade. The blade is sharp and can easily cause injury. Cut-resistant gloves are recommended when honing the blade.

For more information on honing your blade, scan the QR code or visit www.marshalltown.com/honing-your-blade

Sharpening the Blade

The blade can be sharpened to restore a one-sided, 21° – 22° knife edge. It is important to note that the blade must be sharpened only on the beveled side, leaving the flat side flat. We recommend that power grinding only be done professionally, as the blade must be fluid cooled during this process.

Replacing the Blade

Blade is extremely sharp! Use cut-resistant gloves when replacing the blade.

- TURN Cutter UPSIDE DOWN

Tip: put the cutter on the edge of a sturdy table.

- LOOSEN BLADE Using a Phillips screwdriver, remove the screws.

![]()

- REMOVE BLADE Hold blade by each end and carefully lift out of pocket.

- INSTALL BLADE Hold blade by each end and carefully place into the blade pocket in the head, with the flat side of the blade facing the table. Be sure that it is firmly seated, and the pocket is clear of debris.

- TIGHTEN THE BLADE Using a Phillips screwdriver, replace & tighten the screws, starting with the center screw.

![]()

Lubrication

After every 100 cuts, it is recommended that the cutter be lubricated. Use a light oil and grease (wheel bearing grease) and apply according to the image below. Lubricating the cutter will extend the life of the cutter and result in easier cutting.

PARTS BREAKDOWN

PARTS BREAKDOWN

REPLACEMENT PARTS

| REF # | DESCRIPTION | EDI | PART # |

| 27 | REPLACEMENT 13" EZ SHEAR FLOORING BLADE | 29794 | 113B |

| 25, 27 | MARKSMAN SHEAR MAINTENANCE KIT | 29789 | 1113-SMK |

| 2, 4, 7, 8, 16, 20, 21, 22, 25, 26, 28, 29, 31, 32 | MARKSMAN REPLACEMENT POWER HEAD | 29771 | 1113-RP-PH |

| 25 | BLADE STOP REPLACEMENT, 13" x 1⁄2" FOR MARKSMAN AND MAGNUM EDGE 13" | 29768 | 869-RP-1113 |

| 8 | M10 x 80 HEX AXLE BOLTS REPLACEMENT SET | 29898 | 863-RP-EZ80 |

| 10 | REPLACEMENT HANDLE GRIP, 1" SQ x 5" | 29907 | 868-RP-MAG |

| 26 | ANVIL REPLACEMENT, 13" x 1⁄2" FOR MARKSMAN AND MAGNUM EDGE | 29766 | 854-RP-1113 |

| 19 | REPLACEMENT HANDLE SPRING PIN, 5⁄16" 1 SIDED | 29860 | 847-RP |

| 3,10,19 | 1" SQUARE REPLACEMENT HANDLE UPPER ONLY (SHARPSHOOTER & MARKSMAN) | 29881 | 858-RP-U009 |

| 5,11,17 | FENCE REPLACEMENT FOR SHARPSHOOTER, MARKSMAN, EZ SHEAR | 29870 | 856-RP-100F |

| 16 | FOOT CAP REPLACEMENT FOR SHARPSHOOTER, MARKSMAN, EZ SHEAR | 29855 | 838-RP-EZ |

| 7 | M6-1.0 X 12 MM ALLEN 10.9 ZINC BUTTON SOCKET CAP SCREW | WR1585 | FAS-SCW-5612 |

| 9, 30 | BULLET™ LOWER HANDLE | 33181 | 33181 |

TROUBLESHOOTING

Before troubleshooting double-check the manual:

- Is your cutter properly assembled?

- Is it being operated correctly?

- Is it properly lubricated?

- Has the blade been honed as recommended?

Visually inspect cutter, watching for objects that might obstruct the blade or powerhead travel:

- Foreign material presence between the blade and anvil, in the pin springs or under the cam.

- Check your blade for chips, cracks or burrs.

- Make sure bearings are intact and lubricated. They should not be spinning/moving on the cam during use.

| PROBLEM | CHECK FIRST | CHECK SECOND | CHECK THIRD | CHECK FOURTH |

| Difficulty cutting | Ensure cam lock is OFF. If equipped, engage power lobes (Model 226) | Make sure handle is FULLY extended | Check blade sharpness/ condition | Inspect and lubricate bearings/pins |

| Not cutting completely through material | Inspect pins for oblong/wallowed orifice | Adjust front stroke stop (MAGNUM cutters) | Check bearings for wear/play | Ensure blade is proper nominal height |

| Blade sticking after completing cuts | Check/remove & replace blade stops if damaged | Ensure blade screws are tight | Remove anvil, turn it over, reinstall | Check for marks on anvil (overbite) |

| Rough or crushed cuts | Check veneer thickness (max= 1⁄16") | Check blade condition (chips, burrs, breaks) | Ensure blade is honed and sharp | Review approved materials list |

| Cuts aren't square | Loosen fence screws, align fence, tighten | Check pins for uneven wear | Inspect blade and anvil/blade-stop for contact | |

| Handle not returning to open position | Ensure pins are lubricated | Apply grease to contact area of bearing | Lubricate axle bolts | Check springs for breakage |

| Material won't fit into cut area | Check max thickness of material for your cutter | Reverse back stroke stop | Ensure blade is proper nominal height | If you have two bearings, switch which bearing is engaged |

| Cam lock pin bent/stuck | Do not lift or carry cutter by the handle | Return handle slowly to open position - do not "let it fly" | Disengage cam lock pin BEFORE cutting | |

| Blade chipping | Hone as directed in manual (~25 cuts, then daily) | Do not cut stranded bamboo | Do not cut high pressure laminate | Check veneer thickness (max=1⁄16") |

| Pin openings wallowed out / oblong where cam axle passes through | Do not lift or carry cutter by the handle | Return handle slowly to open position - do not "let it fly" | Check veneer thickness (max= 1⁄16") | Review approved materials list |

| Not cutting to edge of material | Check fence alignment - adjust if needed | Do not "angle" material beyond the blade edge | Ensure angle fence(s) are installed with WIDE edge inward (620 model) |

SAFETY PRECAUTIONS

safety signs are located near specific hazards.

General precautions are listed on CAUTION safety signs.

- This notation appears before warnings in the text. It means that the step that follows must be carried out to avoid the possibility of personal injury or death. These warnings are intended to help the technician avoid any potential hazards encountered in the normal service procedures. We strongly recommend that the reader takes advantage of the information provided to prevent personal injury or injury to others.

THE FOLLOWING PRECAUTIONS ARE SUGGESTED TO HELP PREVENT ACCIDENTS. A CAREFUL OPERATOR IS THE BEST OPERATOR. MOST ACCIDENTS CAN BE AVOIDED BY OBSERVING CERTAIN PRECAUTIONS.READ AND TAKE THE FOLLOWING PRECAUTIONS BEFORE OPERATING THIS EQUIPMENT TO HELP PREVENT ACCIDENTS. EQUIPMENT SHOULD BE OPERATED ONLY BY THOSE WHO ARE RESPONSIBLE AND INSTRUCTED TO DO SO.

CALIFORNIA PROPOSITION 65 WARNING:

This product can expose you to chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm.

- Read all operating and maintenance instructions before operating or servicing the flooring cutter.

- A flooring cutter is only as safe as its operator. Give complete and undivided attention to the operation of the flooring cutter.

- Know how to stop the flooring cutter instantly.

NEVER operate the flooring cutter if any cutter components have been removed.

- Keep inexperienced and unauthorized people away from the flooring cutter at all times.

- Keep the flooring cutter in good operational condition. Loose or damaged parts are dangerous.

- Avoid loose clothing that could get caught in moving parts.

Keep hands and feet away from moving parts.

- Keep all warning, caution and safety instruction labels in good condition. Replace missing, damaged or illegible labels.

- Clear the work area around the cutter to prevent tripping or falling onto the cutter.

- Operate on level ground to prevent the flooring cutter from flipping over.

- DO NOT OPERATE this flooring cutter under the influence of alcohol or while taking medication that impairs your reactions.

- Use only factory authorized parts for replacement.

- Wear safety glasses when operating the flooring cutter.

- Always use caution when replacing the cutter blade.

- Only operate the cutter with the approved materials. If extreme force is required to cut a material, it may result in personal injury and/or damage to the flooring cutter.

- Wear proper protective clothing while operating flooring cutter, including eye, ear, and clothing.

- Handle all solvents and cleaning agents with care and follow manufacturer's instructions on safety and disposal.

SAFETY DECALS

If your safety decals are damaged, they can be replaced by contacting Customer Service.

Blade Warning Label

Handle Warning Label

Phone 800-888-0127 / 641-753-0127

Fax 800-477-6341 / 64 1-753-6341

www.MARSHALLTOWN.com

Documents / Resources

References

Download manual

Here you can download full pdf version of manual, it may contain additional safety instructions, warranty information, FCC rules, etc.

Download Marshalltown BULLET MARKSMAN (ES00-1113) - Shear Manual

Advertisement

Tip: put the cutter on the edge of a sturdy table.

Tip: put the cutter on the edge of a sturdy table.

Need help?

Do you have a question about the BULLET MARKSMAN and is the answer not in the manual?

Questions and answers