Advertisement

Quick Links

INSTALLATION AND MAINTENANCE INSTRUCTIONS

NC-100 Control Module

SPECIFICATIONS

Normal Operating Voltage:

External Supply Voltage (between Terminals T10 and T11)

Maximum:

Temperature Range:

Humidity:

Dimensions:

Accessories:

RELAY CONTACT RATINGS:

CURRENT RATING

2 A

3 A

2 A

0.46 A

0.7 A

0.9 A

0.5 A

0.3 A

BEFORE INSTALLING

This information is included as a quick reference installation guide. Refer to

the control panel installation manual for detailed system information. If the

modules will be installed in an existing operational system, inform the opera-

tor and local authority that the system will be temporarily out of service. Dis-

connect power to the control panel before installing the modules.

NOTICE: This manual should be left with the owner/user of this equipment.

GENERAL DESCRIPTION

NC-100 Supervised Control Modules are intended for use in addressable, two-

wire systems, where the individual address of each module is selected using

the built-in rotary switches. This module is used to switch an external power

supply, which can be a DC power supply, to notification appliances. It also su-

pervises the wiring to the connected loads and reports their status to the panel

as NORMAL, OPEN, or SHORT CIRCUIT. The NC-100 has two pairs of output

termination points available for fault-tolerant wiring and a panel-controlled

LED indicator. This module can be used to replace a C304 module that has

been configured for supervised wiring operation.

COMPATIBILITY REQUIREMENTS

To ensure proper operation, these modules shall be connected to listed com-

patible system control panels only.

MOUNTING

The NC-100 mounts directly to 4-inch square electrical boxes (see Figure 2A).

The box must have a minimum depth of 2

cal boxes (SMB500) are available. The module can also mount to the DNR(W)

housing.

WIRING

NOTE: All wiring must conform to applicable local codes, ordinances, and

regulations. When using control modules in nonpower limited applications,

the CB500 Module Barrier must be used to meet UL requirements for the sepa-

ration of power-limited and nonpower-limited terminals and wiring. The bar-

rier must be inserted into a 4˝×4˝×2

must be placed into the barrier and attached to the junction box (Figure 2A).

The power-limited wiring must be placed into the isolated quadrant of the

module barrier (Figure 2B).

NO-460-005

15 to 32VDC

80 Volts (RMS or DC)

32°F to 120°F (0°C to 49°C)

10% to 93% Non-condensing

4.675" H x 4.275" W x 1.4" D (Mounts to a 4˝ square by 2

SMB500 Electrical Box; CB500 Barrier

MAXIMUM VOLTAGE

25 VAC

30 VDC

30 VDC

30 VDC

70.7 VAC

125 VDC

125 VAC

125 VAC

1

/

inches. Surface mounted electri-

8

1

/

˝ junction box, and the control module

8

1

/

˝ deep box.)

8

LOAD DESCRIPTION

PF = 0.35

Resistive

Resistive

(L/R = 20ms)

PF = 0.35

Resistive

PF = 0.75

PF = 0.35

1.

Install module wiring in accordance with the job drawings and appropri-

ate wiring diagrams.

2.

Set the address on the module per job drawings.

3.

Secure module to electrical box (supplied by installer), see Figure 2A.

Wire should be stripped to the appropriate length (recommended strip length

is

1

/

" to

3

/

"). Exposed conductor should be secured under the clamping plate

4

8

and should not protrude beyond the terminal block area. Caution: Do not loop

wire under terminals. Break wire run to provide supervision of connections.

IMPORTANT: When using the NC-100 control module for audio applications,

remove Jumper (J1) and discard. The Jumper is located on the back as shown

in Figure 1B. J1 must be removed whenever power supply monitoring feature

is not required.

NOTE: All references to power limited represent "Power Limited (Class 2)".

All references to Class A also include Class X.

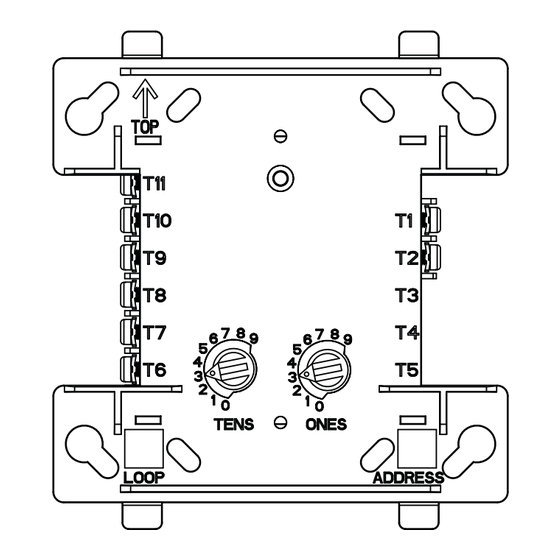

FIGURE 1A. CONTROLS

AND INDICATORS:

C0909-01

1

12 Clintonville Road

Northford, CT 06472-1653

Phone: 203.484.7161

APPLICATION

Non-coded

Non-coded

Coded

Non-coded

Non-coded

Non-coded

Non-coded

Non-coded

FIGURE 1B:

J1

C0910-00

I56-3501-005

Advertisement

Summary of Contents for Honeywell Notifier NC-100

- Page 1 INSTALLATION AND MAINTENANCE INSTRUCTIONS 12 Clintonville Road Northford, CT 06472-1653 NC-100 Control Module Phone: 203.484.7161 SPECIFICATIONS Normal Operating Voltage: 15 to 32VDC External Supply Voltage (between Terminals T10 and T11) Maximum: 80 Volts (RMS or DC) Temperature Range: 32°F to 120°F (0°C to 49°C) Humidity: 10% to 93% Non-condensing Dimensions:...

- Page 2 FIGURE 2A. MODULE MOUNTING FIGURE 2B: WITH BARRIER: ISOLATED QUADRANT C1050-00 FIGURE 3. TYPICAL NOTIFICATION APPLIANCE CIRCUIT CONFIGURATION, NFPA STYLE Y (CLASS B): CONNECT MODULES TO 24 VDC CIRCUIT LISTED COMPATIBLE DO NOT LOOP WIRE ON TERMINALS 10 & 11. BREAK WIRE RUN TO PROVIDE SUPERVISION OF CONNECTIONS.

Need help?

Do you have a question about the Notifier NC-100 and is the answer not in the manual?

Questions and answers