Table of Contents

Advertisement

Quick Links

Operation and Maintenance Manual

Enerpac EVO-Master

Coordinated Lifting Network Controller

Document Number: L4648

Document Revision: A

Document Revision Date: 19-APRIL-2022

Document Language: ENGLISH EN

To reduce the risk of injury, user must read and understand this document before use.

SIMATIC HMI

SIEMENS

SYSTEM

RESET

OK

ALARMS

START

CYCLE

PAUSE

MOTOR

ON

CYCLE

STOP

STOP

CYCLE

MOTOR

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Enerpac EVO-Master

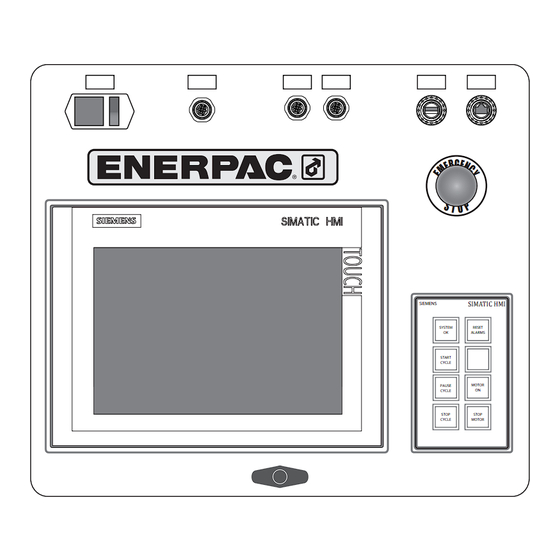

- Page 1 Operation and Maintenance Manual Enerpac EVO-Master Coordinated Lifting Network Controller Document Number: L4648 Document Revision: A Document Revision Date: 19-APRIL-2022 Document Language: ENGLISH EN SIMATIC HMI SIEMENS SYSTEM RESET ALARMS START CYCLE PAUSE MOTOR CYCLE STOP STOP CYCLE MOTOR To reduce the risk of injury, user must read and understand this document before use.

-

Page 3: Warranty

Enerpac for quality tools, services and solutions. For additional information, visit www.enerpac.com. WARRANTY Refer to the Enerpac Global Warranty document for terms and conditions of the product warranty. Such warranty information can be found at www.enerpac.com. NAMEPLATE Avenida Valdelaparra 27 Building 1... -

Page 4: Table Of Contents

6.1 SPECIFICATIONS ..........................8 7. INITIAL SETUP .............................. 8 7.1 ELECTRIC CONNECTIONS ......................... 8 7.2 EVO-MASTER PANEL ........................... 8 7.3 KEYPAD ..............................8 7.4 INSTALLATION OF SFP IN A NETWORK SYSTEM................9 7.5 INSTALLATION OF EVO IN A NETWORK SYSTEM................10 8. - Page 5 9.7 EVO OFFSET SCREEN........................22 9.8 EVO CALIBRATION SCREEN ......................23 EVO MANUAL SCREEN ........................24 9.10 EVO PRELOAD SCREEN ........................24 9.11 EVO AUTOMATIC SCREEN ....................... 25 9.12 EVO TILTING SCREEN ........................25 9.13 EVO STAGE LIFT SCREEN ........................ 26 9.14 EVO DATA RECORDING SCREEN ....................

-

Page 6: Safety

WARNING damage to the product and/or damage to other property. Enerpac cannot be responsible for any damage or injury Failure to observe and comply with the following from unsafe use, lack of maintenance, or incorrect precautions could result in death or serious personal operation. - Page 7 • Do not use electric pumps in an explosive • Immediately replace worn or damaged parts. atmosphere. Adhere to all local and national Use only genuine Enerpac parts from approved electrical codes. A qualified electrician must do distributors or service centers. Standard grade...

-

Page 8: Compliance Statement

• Always follow the inspection and maintenance instructions contained in this manual. Perform EVO-Master controller can be connected to up to 4 maintenance and inspection activities at the Split Flow Pumps (only for pumps with solenoid valves) specified time intervals. -

Page 9: Features & Components

MOTOR PAUSE CYCLE STOP STOP CYCLE MOTOR Figure 1: Major Features and Components of EVO-Master 5.2 Keypad 1. System ok light 4. Stop cycle button 7. Stop motor button 2. Start cycle button 5. Reset alarms button 3. Pause cycle button 6. -

Page 10: Technical Product Data

EVOs. When working with SFPs, Enerpac recomends to purchase SFPKPT kit (pressure transducer removable kit) together with EVO-Master. This kit allows to connect Figure 4: Type of Power Cords Supplied pressure transducers to the SFP. Pressure transducers are necessary for an optimal operation of the EVO- 7.2 EVO-Master Panel... -

Page 11: Installation Of Sfp In A Network System

• Reset Alarms: of the network, the EVOCOMM-25 from the previous pump - Off: No active alarms. must be connected to the IN plug of the EVO-Master - Red: Active alarms. controller and the next pump must be connected with a EVOCOMM-25 coming from the OUT plug. -

Page 12: Installation Of Evo In A Network System

7.5.2 Connection into a EVO Network Figure 7: SFP Initial Screen When EVO-Master controller is connected to up to 4 EVOs network, it must be connected directly to an EVO This is the first screen shown by the system in remote by the communication cable EVOCOMM-25. -

Page 13: Sfp Selection Screen

8.3.2 SFP Movements Pop Up Figure 8: SFP Selection Screen EVO-Master controller can be connected to different hydraulic equipments from Enerpac. In this screen, the operator can select the system to work with (in this case, SFP). -

Page 14: Sfp Screen's Header

8.5 SFP Work Parameters Screen 8.3.4 SFP Screen Slides Figure 13: SFP Screen Slides Figure 15: SFP Work Parameters Screen In the screens of each section there is an arrow which In this screen the user must define some features and allows to merge a slide with the shortcuts to the screens security parameters of the system. -

Page 15: Sfp Spans Screen

Special Parameters button: Pushing this button, the user can access to the special parameters LOAD screen (refer to paragraph 8.5.1 for further details). The system will require an user name (parameters) and password (200). 8.5.1 SFP Special Parameters Screen Calibration Calibration allowed not allowed... -

Page 16: Sfp Offset Screen

HPU selection buttons: The user must select the Information of sensors and cylinders is available either HPUs which will be involved in the movement or on the product label or online at www.enerpac.com. operation. Movement values: There are some values that the system can show during the movement. -

Page 17: Sfp Manual Screen

When the stroke sensor wire is connected to the This screen belongs to the movements section. In this section the user must select the type of movement cylinder‘s rod, or if an internal stroke sensor is used, which is going to be executed. the system reads the extended length of the sensor (A value). -

Page 18: Sfp Preload Screen

Final Load parameter: The user must type the final load that the cylinder must reach to finish the cycle. Enerpac recommends setting the final load value to less than 10% of the expected load. Figure 27: SFP Tilting Screen 8.11 SFP Automatic Screen... -

Page 19: Sfp Stage Lift Screen

8.13 SFP Stage Lift Screen is selected, the background color of the button will become green. Deviation button: This button shows the deviation screen. In this screen the user can check the details of the current tilting movement. CAUTION At the end of each cycle, all the cylinders will finish at the same time. -

Page 20: Sfp Language Screen

To access this user, it is required to Time period: The user must type the frequency of enter the ID “enerpac” and password “100”. the data recording. The units used are seconds. - Expert: The expert has same access rights as... -

Page 21: Evo Screens

ID and Password to log into the user profile. The system is submitted with the default user profile which is recorded with the user name: enerpac and password: 100. 9.2 EVO Selection Screen Figure 39: EVO Setup Pop Up In this pop up the user can access to Work Parameters, Spans, Offset and Calibration screens. -

Page 22: Evo Screen's Header

9.4 EVO Screen’s Header In this pop up the user can access to Manual, Preload, Automatic, Tilting and Stage Lift screens. Tapping on each button the user can access the screens of movements section. The background color of this section is gray. Every screen of this section will have a gray background. - Page 23 9.5.1 EVO Special Parameters Screen WARNING The maximum expected load of the cylinders must always be lower than the capacity of the cylinders. Refer to the features of the cylinder to know the maximum capacity of each cylinder. Special Parameters button: Pushing this button, the user can access to the special parameters screen (refer to paragraph 9.5.1 for further details).

-

Page 24: Evo Spans Screen

Effective area: The user must type the surface area of the pushing side of the cylinder. Information of sensors and cylinders is available either Calibration Calibration on the product label or online at www.enerpac.com. allowed not allowed Pressure span: The user must type the pressure transducer’s maximum range. -

Page 25: Evo Calibration Screen

“A” value normally represents the absolute extension of When the stroke sensor wire is connected to the the stroke sensor between 0 and full extension. When cylinder‘s rod, or if an internal stroke sensor is used, the user presses and holds the Offset button (A=0), the the system reads the extended length of the sensor current “A”... -

Page 26: Evo Manual Screen

9.9 EVO Manual Screen Reset relative position button: When this button is pushed, the relative position of the cylinder is reset to zero. Refer to point 8 of this section for further details about the relative position. Flow button: The user can type the flow of the HPU and control the speed of the movement. -

Page 27: Evo Automatic Screen

Final Load parameter: The user must type the final load that the cylinder must reach to finish the cycle. Enerpac recommends setting the final load value to less than 10% of the expected load. Figure 58: EVO Tilting Screen 9.11 EVO Automatic Screen... -

Page 28: Evo Stage Lift Screen

In this screen the user can check the details of the Retract Delta value: The user must type the current tilting movement. distance cylinders should retract to create a space where operators could insert a central block. This There are two important elements in this screen: central block will support the load for the next Key formula: This area shows the formula used to movement. -

Page 29: Evo Language Screen

- Operator: This user has general access to operate the system. To access this user, it is required to Check for alarms in the EVO-Master. If any alarm enter the ID “enerpac” and password “100”. has came up, check and solve the root cause and push the reset alarm button (Figure 2, item 5). -

Page 30: Manual Mode

20 kN (2 ton), to ensure the cylinders withstand that load WARNING value. Enerpac recomends to always set the layout of the This mode allows to have a real reference of the position cylinders in such a way that the calibration is allowed. -

Page 31: Tilting Mode

the stroke that plungers extend per step, creating Start motor in the HPU’s electric cabinet. space where operators can insert two outer blocks Press Start Cycle button (Figure 2, item 2). under the spreading plate. When the cylinders reach the delta position, the Type Negative Delta parameter. -

Page 32: Maintenance

load. Remove the central block if it is at the same level than the outer blocks. Plungers must be retracted for this step. 10. Switch on the motor in the HPU’s electric cabinet. 11. Press the Start Cycle button (Figure 2, item 2). 12. -

Page 33: Alarm Guide

For repair service, contact your local Authorized Enerpac Service Center. The following alarm charts are divided depending on the kind of the equipment is connected with the EVO-Master controller, Split Flow Pump (SFP) or EVO system. -

Page 34: Evo Alarms

• The safety output is off upon start up • Reset Alarm Controller 24V DC • The EVO-Master DC protection has • Open the EVO-Master and reactivate the DC Protection Failure been tripped, due to an excessive protection channel. consumption,... - Page 35 ALARMS CHART for EVO SYSTEM ALARM POSSIBLE CAUSE SOLUTION Maximum Total Load • The total sum of cylinder loads • Check the parameter, considering the load weight (selected non-selected) and the cylinder characteristics. If it is incorrect, exceeded the value entered in the change it.

- Page 36 ALARMS CHART for EVO SYSTEM ALARM POSSIBLE CAUSE SOLUTION HPU #: Motor OFF • A start cycle operation has been • Reset alarm. attempted with the motor off. • Start the motor. HPU #: Frequency Inverter • Frequency Inverter error. •...

- Page 37 NOTES ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________...

- Page 38 NOTES ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________...

- Page 39 NOTES ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________...

- Page 40 © 2022 Enerpac Tool Group, All Rights Reserved. www.enerpac.com...

Need help?

Do you have a question about the EVO-Master and is the answer not in the manual?

Questions and answers