Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for SAMSON PUMPS TRUCK MASTER 350

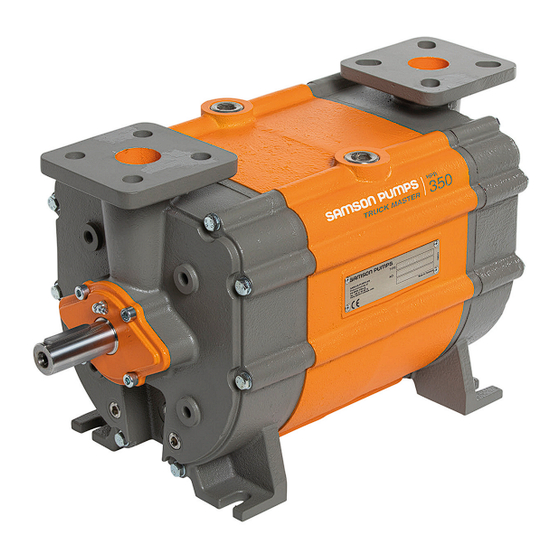

- Page 1 LIQUID RING PUMP ATEX APPROVED Zone 0 Internal / Zone 1 External TRUCK MASTER ® INSTRUCTION MANUAL FOR SAMSON LIQUID RING PUMP TRUCK MASTER 350 • Installation and start-up • Technical data • Design of a system • Service • System layout •...

-

Page 2: Table Of Contents

CONTENTS Introduction ..........................4 Declaration of conformity ......................4 Explanation of warning symbols ....................5 Disposal ..........................5 ATEX Directive 2014/34/EU ....................6 Field of application ........................7 Technical data .......................... 8 Dimensions ..........................8 Specifications .......................... 9 Power consumption and output ..................... 10 2.3.1 Vacuum .......................... - Page 3 Overhaul of pump ......................... 30 Winterization ......................... 30 Troubleshooting ........................31 Spare parts and tools ......................32 Marking and identification ..................... 32 How to order ......................... 33 Spare parts ..........................34 Gasket set ..........................38 Special tool set ........................39 Truck Master 350...

-

Page 4: Introduction

concepts and methodology DS/EN ISO 80079-36:2016 Explosive atmospheres - Part 36: Non-electrical equipment for explosive atmospheres - Basic method and requirements DS/EN ISO 80079-37:2016 Explosive atmospheres - Part 37: Non-electrical equipment for explosive atmospheres - Non-electrical type of protection constructional safety "c", control of ignition sources "b", liquid immersion "k" The standard above only applies to the extent that it is relevant for the purpose of the pump. The product must not be used before the complete system, which it must be incorporated in, has been conformity assessed and found to comply with all relevant health and safety requirements of 2006/42/EC and other relevant directives. The product must be included in the overall risk assessment. EU TYPE-Examination Certificate Number ExVeritas 19 ATEX 0452X Certification body Identification Number 2804 Viborg, 06.02.2020 ________________________________________ Jan S. Christiansen – Manager, Technical dept. DOC4046C DOC4046C E-Mail info@samson-pumps.com Samson Pumps A/S Petersmindevej 21 www.samson-pumps.com Phone | +45 87 50 95 70 DK-8800 Viborg... -

Page 5: Explanation Of Warning Symbols

1.3 Disposal Samson’s liquid ring pump is manufactured so that most of the device can be reused/recycled. Samson Pumps offer users of the company’s pumps the option of returning used pumps to be restored or scrapped. Alternatively, the pump must be taken apart and sorted into its separate components, by the customer (see section 7 for the pump’s material). -

Page 6: Atex Directive 2014/34/Eu

1.4 ATEX Directive 2014/34/EU The pump may be incorporated into a larger system, if the internal atmosphere has an area classification of: Zone 0 (for ATEX category 1 pumps) These systems will be certified in accordance with the ATEX Directive 2014/34/EU For the certification to be valid, the pump must be installed as described in this manual. -

Page 7: Field Of Application

Do not operate the pump so that cavitation can occur! For further information see instruction manual for the Samson Pumps vacuum limiter It must be ensured that the inlet gas cannot react with the service liquid and create aggressive bonds that break down the pump's components. -

Page 8: Technical Data

2 TECHNICAL DATA 2.1 Dimensions G3/8" G1" DOC1627452_2A DOC1627452_2A... -

Page 9: Specifications

Automatic lubrication* SKF LAGD 125/WA2 Weight 84 kg It is required to install liquid separator to ensure the pump is supplied as much water as needed. See System layout Zone 0/1. Zone 0/1 - Requirement. Automatic lubrication Truck Master 350... -

Page 10: Power Consumption And Output

2.3 Power consumption and output 2.3.1 Vacuum Vacuum Flow [m³/h] Flow 1200 [rpm] Consumption [kW] Torque [Nm] Flow [m³/h] Flow 1500 [rpm] Consumption [kW] Torque [Nm] Flow [m³/h] Flow 1650 [rpm] Consumption [kW] Torque [Nm] Flow [m³/h] Flow 1800 [rpm] Consumption [kW] Torque... -

Page 11: Correction Factor - Temperature

50°C 100% saturated and service liquid temperature of 15°C. Suction pressure % Vacuum Correction factor wet gas K 1,34 1,28 1,15 1,13 1,09 1,08 1,07 The performance of the pump can thereby be calculated as: Truck Master 350... -

Page 12: Handling And Transport

2.4 Handling and transport The pump must not be used if it is damaged or the identification plate is missing ATEX marking must correspond to the area the pump is operating in The pump must be transported in such way that it is not exposed to vibrations and impacts that can overload the bearings. -

Page 13: Pump Storage And Draining Procedure

When emptying the pump, it is important that all chambers inside the pump are emptied. The pump can be fitted with valves in the draining connections. See below. DOC1627383 DOC1627383 Truck Master 350... -

Page 14: Design Of A System

3 DESIGN OF A SYSTEM DOC1627390 Pos. Description Liquid ring pump Non return valve 4-way valve Vacuum limiter Service liquid valve Fan cooler Liquid separator Dome valve... -

Page 15: Function And Design Of A Liquid Separator

The round velocity reducer can be placed inside any tank geometry. Air flow [m³/h] øD minimum [mm] DOC1627391 øD so the velocity is below 3 m/s H=4 to 6*Ød depending on the geometry. A smooth diameter conversion will give a low factor. Truck Master 350... -

Page 16: Air Cooling With Fan Cooler

3.2 Air cooling with fan cooler Compression of air inside the liquid ring pump will create heat that is transferred to the service liquid. Therefore, it can be necessary to install a fan cooler depending on the expected use, the climate etc. The time it takes to heat up the water also depends on for example ambient temperature, suction pressure, amount of water and the cooling effect in the truck itself. -

Page 17: Fan Cooler

First, we have to reduce the radiator effect based on a temperature difference of 12°C. = 2,4 kW out Truck The total cooling effect required is thereby: = 6 - 2,4 = 3,6 kW out Pump out Truck Truck Master 350... - Page 18 Summary Pump model Description Truck Master 350 Heat input from technical specifications 6 kW in Pump Ambient temperature 28°C Maximum Working Temperature of the water. This is determined by you. The temperature 40°C has influence on the pump performance Temperature difference Δ...

-

Page 19: Water Consumption

Therefore, it will be recommended to make a combination of a filter and dome valve as illustrated below. The filter will prevent particles lifted by the foam to enter the pump. DOC1627393 Truck Master 350... -

Page 20: System Layout (Zone 0/1)

3.6 System layout (Zone 0/1) To safeguard the pump so that it can operate in potentially explosive areas, the components used in the safety device must stop the pump in the event of abnormal operation The maximum working pressure must not exceed specifications, by installing a safety valve The pump must be fitted with the safety device components specified in drawing below. - Page 21 Min. 2 L/min. max. delay 30 sec. Flow meter safety device Min. 2 L/min. max. delay 30 sec. Stop valve Stop valve Drain valve Max. 70°C Temperature transmitter DE safety device Max. 70°C Temperature transmitter NDE safety device Truck Master 350...

-

Page 22: Safety Integrity Level (Sil) According Iec 61508

3.6.1 Safety Integrity Level (SIL) according IEC 61508 Safety action SIL requirement Description of Hazard Position (Sensor) required to safety function Increased temperature due to absence of Pos 6 (Level) & pos 8 (Flow) Stop of pump SIL2 service liquid for mechanical shaft seal, NDE Increased temperature due to absence of Pos 6 (Level) &... -

Page 23: Cavitation

Due to economical aspect it is more efficient to drain the liquid separator and refill with fresh water instead of protecting with glycol and drain the separator more rarely. Truck Master 350... -

Page 24: Pipe System

3.10 Pipe system The exhaust from the liquid separator will have the same zone classification as the pump’s suction side The pipes that are connected to the pump’s suction and outlet sides must be at least the same dimension as the pump. The length of the pipe system affects the pump’s capacity and should be calculated to account for pressure drop in longer pipe installations. -

Page 25: Installation And Start-Up

(C). The M12 bolts must be tightened with 60 Nm (B). In order to prevent tensions in the pump, the pipe connections (A) must be tensionless while tightening the bolts. DOC1627384_1 Truck Master 350 DOC1627384_1... -

Page 26: Connecting The Service Liquid

4.3 Connecting the service liquid The service liquid must be connected to the pump at the hose connections, see illustration below. DOC1627453A DOC1627453A 4.4 Transmission The pump can be connected direct or through belt transmission. For belt transmission, it must be ensured that the permissible radial force is not exceeded. -

Page 27: Earth Connection Requirements

The pump must be protected from the creation of sparks in connection with static electricity, in accordance with the applicable regulations for use in the current categories. The pump is prepared for earth connection with an M8 bolt. DOC1627452_1B DOC1627452_1B Truck Master 350... -

Page 28: Prior To Start-Up

4.6 Prior to start-up • Do not start the pump without service liquid, as this will damage the mechanical shaft seals • Do not start the pump if it is completely filled with service liquid • Do not start the pump before the grease cartridges have been activated, as this can damage the pump •... -

Page 29: Service, Operation, Maintenance And Inspection Intervals

Any leaks must be repaired before operation may continue. 5.3 Draining the liquid separator While the pump is stopped, the liquid separator must be drained to remove contaminants. Truck Master 350... -

Page 30: Check Grease Cartridges

The pump may not be started before the instruments have been re-installed. 5.8 Overhaul of pump The pump must be serviced after 10,000 duty hours. This is done by sending the pump to Samson Pumps, or approved and certified partner, upon agreement. The pump must be cleaned before shipment. -

Page 31: Troubleshooting

Leakage from the • Damaged shaft seal • Bearings may become • Stop the pump bearing housing’s drain damaged and contact the manufacturer holes • Potential risk of explosive gas leak Truck Master 350... -

Page 32: Spare Parts And Tools

7 SPARE PARTS AND TOOLS 7.1 Marking and identification The pump is equipped with an identification plate as shown below. CERTIFICATE NO. Ex MARKING NOTIFIED BODY NO. CE CONFORMITY MARK ORDER CONFIRMATION NO. / A NO. MANUFACTURING DATE / SERIAL NO. PRODUCT CODE TM 350 R 0 S S B 1 0 T X5 Configuration example:... -

Page 33: How To Order

Pump housing: Cast iron EN-GJL-250; EN1561 Shell: Cast iron EN-GJL-250; EN1561 Flow plates: Stainless steel AISI 316 Generation of pump: 1 or 2 Gaskets: Oakenstrong Colour: Grey primer Truck Master Orange On request Documentation: ATEX Zone 0 Truck Master 350... -

Page 34: Spare Parts

7.3 Spare parts... - Page 35 * - Included in gasket set. DOC1627450 Truck Master 350...

- Page 36 922000042 Mechanical shaft seal NBR / AISI 316 / Carbon 930000078 Ball bearing Chrome steel W.Nr. 1.3505 1600003 Gasket set Truck Master 350 1622072 Bearing cover DE Cast iron EN-GJL-250, EN 1561 1600003 Gasket set Truck Master 350 1622036 Shell...

- Page 37 Pos. Part number Description Qty. Material 1600003 Gasket set Truck Master 350 910300125 Socket set screw Steel DIN 916 910300182 Plug Steel DIN 906 1622026 Spacer for ball guide SS W.Nr. 1.4401 1624020 Sticker Warning! Plastic foil FasCal 400 915000225...

-

Page 38: Gasket Set

7.4 Gasket set DOC11592 Pos. Part number Description Qty. Material 922200051 Radial shaft seal 45x65x8 Rubber NBR DIN 3760A 922200022 Radial shaft seal 35x50x7 Rubber NBR DIN 3760A 922200020 Radial shaft seal 35x47x7 (<2012) Rubber NBR DIN 3760A 1622027 Gasket for shell / flow plate 0,4 mm Paper Oakenstrong 1622066 Gasket for shell / flow plate 0,8 mm... -

Page 39: Special Tool Set

Plastic POM 1629098 Assembly bush Plastic POM 1629194 Guide pin M8 SS AISI 316 1629192 Bearing mounting tool Plastic / Aluminum 910300428 Socket set screw SS DIN 916 1629196 Mandrel radial shaft seal Ø40 + Ø45 Plastic POM Truck Master 350... - Page 40 Notes:...

- Page 41 Notes: Truck Master 350...

- Page 42 Notes:...

- Page 43 Notes: Truck Master 350...

- Page 44 SAMSON PUMPS Samson Pumps is the only company in the world to specialise exclusively in liquid ring vacuum pumps. Samson pumps are made in Denmark and used around the globe. We offer worldwide delivery, and we export to more than 80 countries around the world.

Need help?

Do you have a question about the TRUCK MASTER 350 and is the answer not in the manual?

Questions and answers