Table of Contents

Advertisement

INSTRUCTION MANUAL

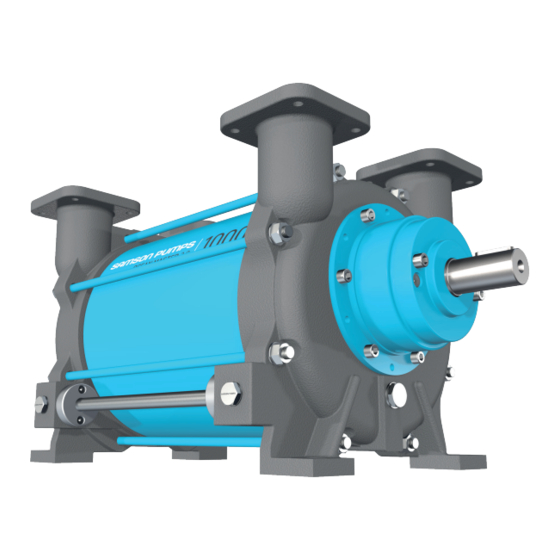

LIQUID RING PUMP

OCEAN MASTER 1000

INSTRUCTION MANUAL FOR SAMSON LIQUID RING PUMP

OCEAN MASTER 1000

• Technical data

• Design of a system

• Installation and start-up

The English version of the instruction manual is the legally binding version.

DOC9063L

• Service

• Troubleshooting

• Spare parts

Advertisement

Table of Contents

Summary of Contents for SAMSON PUMPS OCEAN MASTER 1000

- Page 1 INSTRUCTION MANUAL LIQUID RING PUMP OCEAN MASTER 1000 INSTRUCTION MANUAL FOR SAMSON LIQUID RING PUMP OCEAN MASTER 1000 • Service • Technical data • Design of a system • Troubleshooting • Installation and start-up • Spare parts The English version of the instruction manual is the legally binding version.

-

Page 2: Table Of Contents

Ocean Master 1000 CONTENTS Introduction ..........................4 Declaration of conformity ......................4 Explanation of warning symbols ....................5 Field of application ........................5 Disposal ..........................5 Technical data .......................... 6 Dimensions ..........................6 Specifications .......................... 7 Power consumption and output ....................8 2.3.1... - Page 3 Ocean Master 1000 Service, operation, maintenance and inspection intervals..........20 Check grease cartridges - Only belt drive ................20 Winterization ......................... 20 Lubrication of bearings - Only belt drive ................20 Inspection and cleaning of service liquid’s supply pipe ............20 Troubleshooting ........................21...

-

Page 4: Introduction

Ocean Master 1000 1 INTRODUCTION 1.1 Declaration of conformity D D e e c c l l a a r r a a t t i i o o n n o o f f C C o o n n f f o o r r m m i i t t y y... -

Page 5: Explanation Of Warning Symbols

1.4 Disposal Samson’s liquid ring pump is manufactured so that most of the device can be reused/recycled. Samson Pumps offer users of the company’s pumps the option of returning used pumps to be restored or scrapped. Alternatively, the pump must be taken apart and sorted into its separate components, by the customer (see section 7 for the pump’s material). -

Page 6: Technical Data

Ocean Master 1000 2 TECHNICAL DATA 2.1 Dimensions Ø13,5 Ø80 Ø162,5 DOC1619221A Pos. Description Size Water inlet hose stud Ø20 G 3/4” Drain plug B, F G 3/4” DOC1619221A Housing plug C, E G 1/2” Shell plug G 3/8” DOC9063L... -

Page 7: Specifications

Ocean Master 1000 2.2 Specifications A failure to meet these specifications may result in damage to the pump Description Minimum Maximum Ambient temperature, operation Below 0°C - see chapter 5.3 -20°C 55°C Ambient temperature, storage -20°C 55°C Humidity 100% Intake temperature, suction side 60°C... -

Page 8: Power Consumption And Output

Ocean Master 1000 PERFORMANCE 2.3 Power consumption and output OCEAN MASTER 1000 2.3.1 Performance m3/h 1100 1000 30,00 27,50 25,00 22,50 20,00 17,50 15,00 12,50 10,00 7,50 5,00 2,50 - 1,00 - 2,00 - 3,00 - 4,00 - 5,00 - 6,00... -

Page 9: Consumption

Ocean Master 1000 2.3.2 Consumption 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 30,00 27,50 25,00 POWER 22,50 20,00 17,50 15,00 12,50 10,00 7,50 5,00 2,50 - 1,00 - 2,00 - 3,00 - 4,00... -

Page 10: Handling And Transport

Ocean Master 1000 2.4 Handling and transport The pump must not be used if it is damaged or the identification plate is missing The pump must be transported in such way that it is not exposed to vibrations and impacts that can overload the bearings. -

Page 11: Pump Storage And Draining Procedure

Ocean Master 1000 2.5 Pump storage and draining procedure A failure to comply with the requirements for storing the pump may result in internal damage to the device If the temperature is below freezing point of the service liquid, it could damage the pump... -

Page 12: Design Of A System

Ocean Master 1000 3 DESIGN OF A SYSTEM DOC1627418_1 Pos. Description Liquid ring pump 4-way valve Pressure gauge Regulating valve Water pump Pipe connection - Critical pipe Stop valve DOC9063L... -

Page 13: Piping

Ocean Master 1000 3.1 Piping In a fish handling system, where the pump is working without liquid separator, the piping can be critical. The pipe pos 6 will be a combination of a discharge and a suction pipe and the design of this pipe is very important. -

Page 14: Service Liquid Pump

Ocean Master 1000 3.3 Service liquid pump The water pump must be able to have a flow on 3000 l/h at a pressure at 1 bar(g) in order to get the full performance of the liquid ring pump. 3.4 Pump performance The pump performance can easily be found using the performance curves. -

Page 15: Pressure Drop

Ocean Master 1000 3.5 Pressure drop The pressure drop in the system depends on the flow and on the other side the flow will depend on the pressure drop. It is a mathematical iteration process, therefore in practice we need to start the calculation with a guess. -

Page 16: Service Liquid Requirement

Ocean Master 1000 3.6 Service liquid requirement If sea water is used as sealing water, it is recommended to flush the pump with fresh water (inlet A or B) after use and drain the pump (outlet C) afterwards. See illustration below. -

Page 17: Installation And Start-Up

Ocean Master 1000 4 INSTALLATION AND START-UP 4.1 Securing the pump Installation requirements must be observed, otherwise there is a risk of damage The pump must be installed on a stable foundation, which must be level and stable, so that the pump is not twisted or exposed to a profile distortion. -

Page 18: Drive

Ocean Master 1000 4.4 Drive The pump can be connected through direct or belt drive. Angular misalignment The unit (pump & motor) must be installed on a stable foundation, which must be level and stable, so that the unit is not twisted or exposed to a profile distortion. -

Page 19: Prior To Start-Up

Ocean Master 1000 4.5 Prior to start-up • Do not start the pump without service liquid, as this will damage the mechanical shaft seals • Do not start the pump if it is completely filled with service liquid • Do not start the pump before the grease cartridges have been activated, as this can damage the pump (if equipped) •... -

Page 20: Service, Operation, Maintenance And Inspection Intervals

Ocean Master 1000 5 SERVICE, OPERATION, MAINTENANCE AND INSPECTION INTERVALS A failure to observe the inspection intervals described in table below may result in damage to the pump Section Operation Interval Check grease cartridges (if equipped) - Only belt drive... -

Page 21: Troubleshooting

Ocean Master 1000 6 TROUBLESHOOTING Problem Cause Effect Corrective measure The pump is unable to • Service liquid valve is • Reduced output • Check service liquid create a vacuum closed valve • The pump can become • The pump is not damaged during •... -

Page 22: Spare Parts And Tools

Ocean Master 1000 7 SPARE PARTS AND TOOLS 7.1 Marking and identification The pump is equipped with an identification plate as shown below. CE CONFORMITY MARK ORDER CONFIRMATION NO. / A NO. MANUFACTURING DATE / SERIAL NO. PRODUCT CODE Configuration example:... -

Page 23: How To Order

Ocean Master 1000 7.2 How to order Example: 1000 Model: 1000 1000 Rotation: Clockwise Counter clockwise Rotor type: Welded AISI 316 Pump housing: Cast iron EN-GJL-250; EN1561 Shell: Cast iron EN-GJL-250; EN1561 Stainless steel AISI 316 Flow plates: Stainless steel AISI 316... -

Page 24: Spare Parts - Generation 0

Ocean Master 1000 7.3 Spare parts - GENERATION 0 DOC9063L... - Page 25 Ocean Master 1000 * - Included in gasket set. DOC1627408_3 DOC1627408_3 DOC9063L...

- Page 26 Pos. Part number Description Qty. Material Identification plate Stainless steel Direction arrow Aluminum 15054-P Gasket set Ocean Master 1000 15054-P Gasket set Ocean Master 1000 151.418 Gasket branch pipes Rubber 1619058 Stay bolt Steel 15054-P Gasket set Ocean Master 1000 157.320...

- Page 27 Grease nipple Steel 37** 1634773 Nipple Brass 38** 915000225 Automatic lubricator LAGD 125/WA2 Plastic / grease 15054-P Gasket set Ocean Master 1000 15054-P Gasket set Ocean Master 1000 1634848 Mechanical shaft seal Steel 1634849 Mechanical shaft seal Steel 922100085 O-ring Ø134,30x5,70...

-

Page 28: Spare Parts - Generation 2

Ocean Master 1000 7.4 Spare parts - GENERATION 2 DOC9063L... - Page 29 Ocean Master 1000 * - Included in gasket set. DOC1619221_3 DOC1619221_3 DOC9063L...

- Page 30 Description Qty. Material 107934 HSR Samson Rotor transfer domet 25x25mm Plastic foil 107944 Identification plate Stainless steel 15058-P Gasket set Ocean Master 1000 G2 1619206 Stay Bolt Steel 1619223 Pump Housing NDE Cast iron 1619232 Flow plate Stainless steel 1619233...

- Page 31 Steel 915000050 Grease nipple Steel 1634850 Mechanical shaft seal Steel 15058-P Gasket set Ocean Master 1000 G2 15058-P Gasket set Ocean Master 1000 G2 15058-P Gasket set Ocean Master 1000 G2 15058-P Gasket set Ocean Master 1000 G2 15058-P Gasket set Ocean Master 1000 G2...

-

Page 32: Gasket Set - Generation 0

Ocean Master 1000 7.5 Gasket set - GENERATION 0 DOC15054-P Pos. Part number Description Qty. Material 151.401 Gasket for bearing cover 0,4 mm Paper 151.404 Gasket for pump housing / flow plate 0,4 mm Paper 152.503 Gasket for shell / flow plate 0,5 mm... -

Page 33: Gasket Set - Generation 2

Ocean Master 1000 7.6 Gasket set - GENERATION 2 DOC15058-P Pos. Part number Description Qty. Material 152.503 Gasket for shell / flow plate 0,5 mm Paper 1619101 Gasket for shell / flow plate 0,8 mm Paper 152.531 Gasket for shell / flow plate 1,0 mm... -

Page 34: Adaptor - Generation 2

Ocean Master 1000 7.7 Adaptor - GENERATION 2 DOC1634868_2 DOC1634868_2 Pos. Part number Description Qty. Material 1654038 Adaptor, Machined Cast iron 1654057 Flange for adapter Cast iron 910000422 M20 Nut DIN 934 8.8 FZV Steel 910000423 M20 Washer DIN 125-A 8.8 HDG... -

Page 35: Special Tool Set - Generation 0

Ocean Master 1000 7.8 Special tool set - GENERATION 0 DOC1629189_1 DOC1629189_1 Pos. Part number Description Qty. Material 1629183 Bearing tool Steel 1629107 Bearing mounting tool set NDE Steel 1629108 Bearing mounting tool set DE Steel 1629178 Mandrel radial shaft seal Ø50 + Ø55... -

Page 36: Special Tool Set - Generation 2

Ocean Master 1000 7.9 Special tool set - GENERATION 2 DOC1629373_1 DOC1629373_1 Pos. Part number Description Qty. Material 1629374 Mandrel radial shaft seal Ø48 + Ø55 Plastic 1629375 Machined bearing cap Steel 1629107 Bearing mounting tool set NDE Steel 1629108... - Page 37 Ocean Master 1000 Notes: DOC9063L...

- Page 38 Ocean Master 1000 Notes: DOC9063L...

- Page 39 Ocean Master 1000 Notes: DOC9063L...

- Page 40 Gamma Series is designed to handle the harshest industrial vacuum jobs. At the core of Samson Pumps’ activity is the strong belief that our liquid ring vacuum pumps must be of superlative quality for our customers to focus on what they do best.

Need help?

Do you have a question about the OCEAN MASTER 1000 and is the answer not in the manual?

Questions and answers