Table of Contents

Advertisement

Quick Links

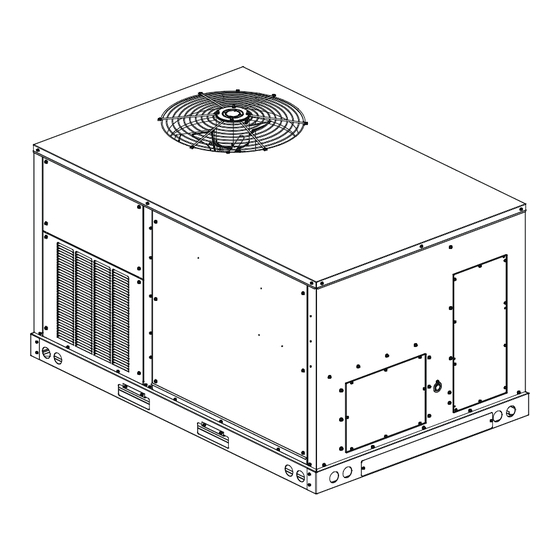

Packaged Air Conditioner And Heat Pump Unit 3-6 Ton

Direct Drive High Efficiency Light Commercial DHC/DHH

Models

Installation Instructions

NOTE: This equipment is only approved for use with

R-32 refrigerant.

Our continuing commitment to quality products may mean a change in specifications without notice.

IOD-1074

08/ 2024

©2024

19001 Kermier Rd., Waller, TX 77484

www.daikincomfort.com

INSTALLATION INSTRUCTIONS

ONLY PERSONNEL THAT HAVE BEEN TRAINED TO INSTALL,

ADJUST, SERVICE, MAINTENANCE OR REPAIR

(HEREINAFTER, "SERVICE") THE EQUIPMENT SPECIFIED IN

THIS MANUAL SHOULD SERVICE THE EQUIPMENT.

THIS EQUIPMENT IS NOT INTENDED FOR USE BY

PERSONS (INCLUDING CHILDREN) WITH REDUCED

PHYSICAL, SENSORY OR MENTAL CAPABILITIES, OR

LACK OF EXPERIENCE AND KNOWLEDGE, UNLESS THEY

HAVE BEEN GIVEN SUPERVISION OR INSTRUCTION

CONCERNING USE OF THE APPLIANCE BY A PERSON

RESPONSIBLE FOR THEIR SAFETY.

CHILDREN SHOULD BE SUPERVISED TO ENSURE THAT

THEY DO NOT PLAY WITH THE EQUIPMENT.

THE MANUFACTURER WILL NOT BE RESPONSIBLE FOR

ANY INJURY OR PROPERTY DAMAGE ARISING FROM

IMPROPER SUPERVISION, SERVICE OR SERVICE

PROCEDURES. IF YOU SERVICE THIS UNIT, YOU ASSUME

RESPONSIBILITY FOR ANY INJURY OR PROPERTY

DAMAGE WHICH MAY RESULT. IN ADDITION, IN

JURISDICTIONS THAT REQUIRE ONE OR MORE LICENSES

TO SERVICE THE EQUIPMENT SPECIFIED IN THIS

MANUAL, ONLY LICENSED PERSONNEL SHOULD

SERVICE THE EQUIPMENT. IMPROPER SUPERVISION,

INSTALLATION, ADJUSTMENT, SERVICING, MAINTENANCE

OR REPAIR OF THE EQUIPMENT SPECIFIED IN THIS

MANUAL, OR ATTEMPTING TO INSTALL, ADJUST, SERVICE

OR REPAIR THE EQUIPMENT SPECIFIED IN THIS MANUAL

WITHOUT PROPER SUPERVISION OR TRAINING MAY

RESULT IN PRODUCT DAMAGE, PROPERTY DAMAGE,

PERSONAL INJURY OR DEATH.

Do not bypass safety devices.

WARNING

WARNING

Advertisement

Table of Contents

Need help?

Do you have a question about the DHC Series and is the answer not in the manual?

Questions and answers