Hyster J2.00-3.20XM Repair Manual

Ac motor

Hide thumbs

Also See for J2.00-3.20XM:

- Manual (20 pages) ,

- Safety precautions maintenance and repair (20 pages) ,

- Manual (90 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Hyster J2.00-3.20XM

- Page 1 AC MOTOR REPAIR J2.00-3.20XM (J40-65Z) [A416, B416] PART NO. 1534732 620 SRM 1053...

-

Page 2: Table Of Contents

General ................................AC Motor Repair ..............................Disassemble ..............................Assemble ................................ Drive End Bearing, Replace.......................... Disassemble, J2.00-3.20XM (J40-65Z) (B416) Traction Motor..............Assemble, J2.00-3.20XM (J40-65Z) (B416) Traction Motor................. Troubleshooting..............................This section is for the following models: J2.00-3.20XM (J40-65Z) [A416, B416] ©2007 HYSTER COMPANY... - Page 3 More Content includes Brake system, Capacities, and specifications, Frame, Hydraulic, System, Industrial battery, Main control, Valve, Mast repair, Fasteners, Schematics diagrams, Steering axle, Steering system, Wire harness repair And more) Click Here Get all the content after purchase Thank very much.

-

Page 4: General

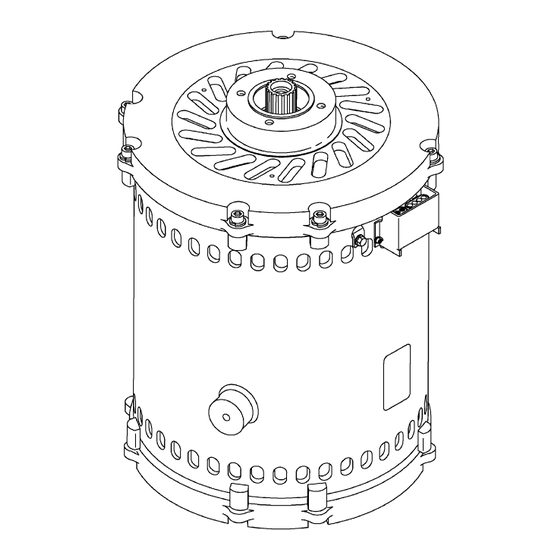

AC hydraulic and AC traction motors used on J2.00-3.20XM (J40-65Z) (A416) lift trucks. The AC traction motor used on J2.00-3.20XM (J40- 65Z) (B416) (see Figure 3) lift trucks is different from NOTE: AC HYDRAULIC PUMP MOTOR USED ON the AC traction and AC hydraulic motors used on OLDER MODEL J2.00-3.20XM (J40-65Z) (A416) -

Page 5: Ac Motor Repair

AC Motor Repair 620 SRM 1053 Figure 3. AC Traction Motor, J2.00-3.20XM (J40-65Z) (B416) Lift Truck Models NOTE: AC TRACTION MOTOR USED ON NEWER MODEL J2.00-3.20XM (J40-65Z) (A416) TRUCKS SHOWN. Figure 2. AC Traction Motor AC Motor Repair DISASSEMBLE weighs 46 kg (101 lb) and the AC traction motor weighs 109 kg (240 lb). - Page 6 9. Remove end bell from rotor assembly. See Fig- ure 6. NOTE: AC HYDRAULIC PUMP MOTOR USED ON OLDER MODEL J2.00-3.20XM (J40-65Z) (A416) TRUCKS SHOWN. 1. END BELL NOTE: AC TRACTION MOTOR USED ON NEWER 2.

-

Page 7: Assemble

620 SRM 1053 ASSEMBLE NOTE: The procedures described in the follow- ing paragraphs apply to AC traction and AC hy- draulic motors used on J2.00-3.20XM (J40-65Z) (A416) lift trucks and AC hydraulic motor used on J2.00-3.20XM (J40-65Z) (B416) lift trucks. CAUTION To avoid damage to the encoder bearing elec- tronics, use a bearing driver and arbor press. -

Page 8: Drive End Bearing, Replace

AC traction and AC hy- NOTE: When replacing one bearing, it is strongly rec- draulic motors used on J2.00-3.20XM (J40-65Z) ommended to replace both bearings and the seals. (A416) lift trucks and AC hydraulic motor used on 1. - Page 9 6. RUBBER GASKET and motor case. Marks will be used to correctly align the end bell on the motor case during as- Figure 10. AC Traction Motor, J2.00-3.20XM sembly. (J40-65Z) (B416) Lift Truck Models 9. Remove screws from end bell on drive side and 3.

-

Page 10: Assemble, J2.00-3.20Xm (J40-65Z) (B416) Traction Motor

4. ROTOR ASSEMBLY 8. WAVE WASHER* *ITEMS NOT SHOWN IN FIGURE 12, BUT LOCATION IS CORRECT. Figure 12. Seal and Bearing Removal ASSEMBLE, J2.00-3.20XM (J40-65Z) CAUTION (B416) TRACTION MOTOR Do not damage sealing surface on drive end of rotor shaft when installing bearing. -

Page 11: Troubleshooting

Troubleshooting 620 SRM 1053 NOTE: Before installing drive side end bell, cover 7. Using the alignment marks made during disas- snap ring groove with tape to protect seal from dam- sembly, line up the non drive side end bell with ®... - Page 12 620 SRM 1053 Troubleshooting PROBLEM POSSIBLE CAUSE PROCEDURE OR ACTION Stator open circuit. Broken coil windings. Raise drive wheel off the floor and verify voltage at motor terminals. Disconnect the battery and check resistance of windings.

- Page 13 NOTES ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________...

Need help?

Do you have a question about the J2.00-3.20XM and is the answer not in the manual?

Questions and answers