Air Monitor OAM II Installation And Operation Manual

Outdoor airflow measurement

Hide thumbs

Also See for OAM II:

- Installation and operation manual (44 pages) ,

- Application manual (8 pages)

Summary of Contents for Air Monitor OAM II

- Page 1 OAM II OAM II Outdoor Airflow Measurement Outdoor Airflow Measurement Installation and Operation Manual Installation and Operation Manual For use with products shipped 6-2019 and later DOC-0001938 Rev.K...

- Page 2 • Air Monitor assumes no responsibilities for this product except as stated in the warranty. • If the customer or any third party is harmed by the use of this product, Air Monitor assumes no responsibility for any such harm owing to any defects in the product which were not predictable, or for any indirect damages.

-

Page 3: Table Of Contents

2.2.3.2 Louvered Inlets ................................17 2.2.3.3 Rain Hood Inlets ................................19 2.2.3.4 Ducted Inlets .................................19 2.2.3.5 Multiple Inlets (OAM II transmitter in Single Mode) ...................20 2.2.3.6 Inlets with an Aspect Ratio > 6:1 ..........................20 2.2.3.7 Very Large Inlets ................................20 2.2.4 Airflow Sensor Process Connections ...........................20 2.3 AIRFLOW STATION ..................................21... - Page 4 OAM II OUTDOOR AIRFLOW MEASUREMENT SYSTEM SECTION 5.0 SYSTEM SET - UP MENU ........................30 5.1 FLOW CONFIGURATION ................................30 5.2 DISPLAY CONFIGURATION ..............................32 5.3 ANALOG OUTPUT CONFIGURATION ..........................33 5.4 FILTERS AND LOCKDOWN ...............................34 5.5 FIELD CHARACTERIZATION ..............................34 5.6 CUSTOM ID CONFIGURATION ...............................36 SECTION 6.0 COMMUNICATIONS.........................

-

Page 5: Section 1.0 General Information

The OAM II can be used with most single, dual, and split inlets found on air handlers and built-up systems. Depicted on the next page are the most commonly encountered inlet configurations. With larger inlets or multiple inlets to one air handler, multiple sensors would be connected in parallel using manifolds. - Page 6 OAM II OUTDOOR AIRFLOW MEASUREMENT SYSTEM 1.2 TYPICAL AIRFLOW MEASUREMENT SYSTEM INSTALLATIONS (CONTINUED) The example above illustrates a single OA inlet. The OAM II would be configured for single channel operation for this application. The example above illustrates a dual OA inlet (two inlets providing outside air to separate air handlers). In this application, the OAM II would be configured for dual channel operation.

-

Page 7: Standard Features And Specifications

OAM II OUTDOOR AIRFLOW MEASUREMENT SYSTEM 1.3 STANDARD FEATURES AND SPECIFICATIONS* OAM II TRANSMITTER PERFORMANCE SYSTEM ACCURACY AMCA certified accuracy of ±5% or better in the velocity range of 150 to 2400 feet per minute¹ VELOCITY RANGE 100 to 3000 SFPM TEMPERATURE SENSOR ±0.1°F at 32°F... - Page 8 OAM II OUTDOOR AIRFLOW MEASUREMENT SYSTEM 1.3 STANDARD FEATURES AND SPECIFICATIONS (CONTINUED)* OAM II FLOW ELEMENT FLOW SENSOR DESIGN UNI-SENSOR Integral outside reference and inlet airflow sensor, proprietary design PERFORMANCE FREE INLET (HOOD) 150 to 3000 SFPM flow range based on configuration...

-

Page 9: Model Numbering Codification

OAM II OUTDOOR AIRFLOW MEASUREMENT SYSTEM 1.4 MODEL NUMBERING CODIFICATION Model Number Coding = OAM II-AFS-ABCD-EEFFG-HHIIJ (-HHIIJ only for dual channel configs) A = Model Configurations EE = Ch 1: Flow Range 2 = Single Channel 1B = Flow range 150 to 2400 SFPM... -

Page 10: Checking That You Received Everything

1.7 SERIAL NUMBER The serial number of your OAM II transmitter is located outside of the enclosure. The serial number is a unique identifier for your product. Please have it available when contacting Air Monitor for assistance regarding your product. -

Page 11: Section 2.0 Installation

Factory Set-Up Information Sheet provided with the unit. Review this information and verify that the OAM II set-up is correct for your application. If any problems or discrepancies are detected, contact Air Monitor’s Customer Service Department at 1-800-AIRFLOW prior to proceeding. -

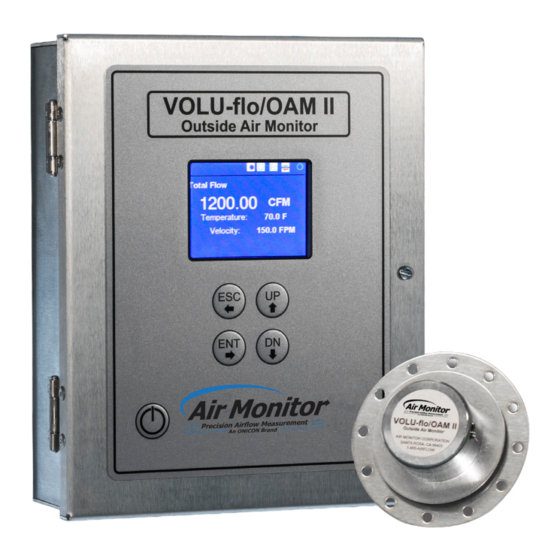

Page 12: Transmitter Dimensions

OAM II OUTDOOR AIRFLOW MEASUREMENT SYSTEM NEMA 4X ENCLOSURE NEMA 1 ENCLOSURE 2.1.2 Transmitter Dimensions 6.6" 7.0" VOLU-flo/OAM II Outside Air Monitor VOLU-flo/OAM II Outside Air Monitor 9.1" 10.3" 11.4" 11.2" Air Monitor Precision Airflow Measurement An ONICON Brand ON/OFF 8.3"... -

Page 13: Transmitter Wiring Connections

OAM II OUTDOOR AIRFLOW MEASUREMENT SYSTEM 2.1.4 Transmitter Wiring Connections RESET TERM BIAS TERM BIAS RTD 1 RTD 2 AO1 / AO2 AO3 / AO4 BACnet 24 V INPUT PWR Rb2 Rb1 Ra Rb2 Rb1 Ra + com / + com... - Page 14 OAM II OUTDOOR AIRFLOW MEASUREMENT SYSTEM 2.1.4 Transmitter Wiring Connections (Continued) A. Power/Signal Connections Input Power Requirements: • 24 VAC, 15VA @ 24 VAC, 40 VA with heater • 24 VDC, 10W @ 24 VDC, 35W with heater INPUT POWER...

-

Page 15: Airflow Sensor

Total Pressure Drop In wc 2.2.1 Uni-Sensor Each OAM II is factory configured for one of three operating configurations. Each configuration is intended for use in specific applications. The number of uni-sensors required is based on the OAM II configuration and the installation type. -

Page 16: Airflow Sensor Installation

OAM II OUTDOOR AIRFLOW MEASUREMENT SYSTEM 2.2.3 Airflow Sensor Installation INLET C L UNI-SENSOR SIDE VIEW FRONT VIEW 2.2.3.1 Moisture Prevention In installations where the setup may be prone to moisture condensation in the lines, a drip leg is recommended. An example is shown below. -

Page 17: Louvered Inlets

4” between the louver and the edge of the damper blades when damper is fully open. The recommended distance between tip of the OAM II uni-sensor and the edge of the 100% open damper blade should be at least 2”. The louver depth will dictate the length of the uni-sensor probe (louver depth +2”). - Page 18 OAM II OUTDOOR AIRFLOW MEASUREMENT SYSTEM 2.2.3.2 Louvered Inlets (Continued) In order to use a louver, it must meet the inlet pressure drop shown in the graph on page 16. Below is an example of a louver pressure drop graph. Refer to louver manufacturers data for their associated pressure drop curves.

-

Page 19: Rain Hood Inlets

SPLIT RAINHOOD INLET SEPARATE MIN. & TOTAL OA The use of Air Monitor’s expanded metal is recommended for all non-louvered inlets. For Min Outside Air and Economizer applications segment the inlets to prevent flow entering in from the other side which will impact the readings. -

Page 20: Multiple Inlets (Oam Ii Transmitter In Single Mode)

2.2.4 Airflow Sensor Process Connections Air Monitor recommends that signal tubing between the transmitter enclosure and all sensors be stainless steel or copper of the appropriate size. Use tees or manifolds to combine multiple sensors into single high and low pressure lines running to the transmitter’s channel fittings for each channel. -

Page 21: Airflow Station

Airflow Stations (AFS) are built to order and provided fully assembled. The number of airflow sensors provided varies based on the size and shape of the station. When multiple OAM II stations are provided for a single system, only one temperature sensor (RTD) will be included. -

Page 22: Plenum Inlets

4” between the screen and the edge of the damper blades when damper is fully open. The distance between tip of the OAM II uni-sensor and the edge of the 100% open damper blade should be at least 2”. -

Page 23: Temperature Sensors Installation

OAM II OUTDOOR AIRFLOW MEASUREMENT SYSTEM 2.4.1 Temperature Sensors Installation • Remove the RTD from the transmitter enclosure (taped in bag at bottom). • Select a convenient mounting location(s) near the inlet or inside the air handler/duct to mount the RTD(s). -

Page 24: Section 3.0 Operation

Flow data will be displayed after a brief pause. Information shown on this screen (flow, temperature, velocity, etc.) will vary based on the OAM II operating configuration. In addition, system status data is provided at the top of the display window and the user defined locations tag is displayed at the bottom. -

Page 25: Configuration

The user interface consists of 4 push-buttons used for programming the transmitter. The displayed information is dependent on the factory configuration of the OAM II. The transmitter configurations are: Single Channel, Single System – Two transducers in series (stacked) to extend the range Min/Economizer (split) –... -

Page 26: Entering The Programming Menus

OAM II OUTDOOR AIRFLOW MEASUREMENT SYSTEM 3.4 ENTERING THE PROGRAMMING MENUS Press ENT at any time to access the programming menus. If the password has been Password set previously, the following screens will be displayed. Password Menu Enter the password and you will be brought to the menus selection Enter screen. -

Page 27: Section 4.0 Main Menu

OAM II OUTDOOR AIRFLOW MEASUREMENT SYSTEM SECTION 4.0 MAIN MENU Main menu functions are used to configure transmitter settings common to Main Menu all configurations. Flow Settings Display Settings Network Configuration Set Password Restore Factory Settings Product Information Sensor Status... -

Page 28: Network Configuration

OAM II OUTDOOR AIRFLOW MEASUREMENT SYSTEM 4.3 NETWORK CONFIGURATION This menu allows the user to set up the serial communications network. It can be Network Configuration used to configure the device for BACnet MS/TP or MODBUS RTU networks. When the network is enabled, the user will see the following icon next to the “System... -

Page 29: Product Information

OAM II OUTDOOR AIRFLOW MEASUREMENT SYSTEM 4.6 PRODUCT INFORMATION This screen provides detailed information about the transmitter hardware. Product Information Work Order: 123456-F Serial Number: 123456789 Part Number: 106-065-00 Eqpt Type: Dual Date of Mfg: 10/29/2018 Model: XDCR Heater: No Firmware Version: 2.0.0 Build 101... -

Page 30: Section 5.0 System Set - Up Menu

OAM II OUTDOOR AIRFLOW MEASUREMENT SYSTEM SECTION 5.0 SYSTEM SET - UP MENU System set-up menu functions are specific to the operating channel(s). System Setup Menu Flow Configuration Display Configuration Analog Output Configuration Filters and Lockdown Field Characterization Custom ID Configuration ENT - Accept ESC - Leave UP/DN - Change 5.1 FLOW CONFIGURATION... - Page 31 OAM II OUTDOOR AIRFLOW MEASUREMENT SYSTEM 5.1 FLOW CONFIGURATION (CONTINUED) Dual The separate inlets for Dual and Split Min/Max are shown in the menu pages to the left. Each inlet is configurable in the same way as described above for the System 1 Flow Configuration single channel configuration.

-

Page 32: Display Configuration

OAM II OUTDOOR AIRFLOW MEASUREMENT SYSTEM 5.2 DISPLAY CONFIGURATION Single Channel, Single System: Display Configuration Line 1 is Flow Line 1 Flow Line 2 can display Velocity/Temperature/DP/Absolute pressure/Velocity Std. Line 2 Temperature Line 3 can display Velocity/Temperature/DP/Absolute pressure/Velocity Std. Line 4 can display Velocity/Temperature/DP/Absolute pressure/Velocity Std/None... -

Page 33: Analog Output Configuration

OAM II OUTDOOR AIRFLOW MEASUREMENT SYSTEM 5.3 ANALOG OUTPUT CONFIGURATION This menu is used to configure the analog outputs. In split and dual modes the Analog Output Configuration outputs are assigned to the specific channels. Type 4-20 mA Output Type... -

Page 34: Filters And Lockdown

1/3 of the operating range. When making this measurement, it is essential that the velocity measurement be within the operating range of the OAM II system. This range is 150 to 3000 SFPM. Note that the range is stated in standard feet per minute. - Page 35 Allows the user to select the number of points. Data Points There are two columns shown on the menu; one for Reference (the test and balancer results) and one for OAM II Points. Data is stored in the system’s non-volatile memory. The following are general guidelines characterizing flow based on the number of data points.

-

Page 36: Custom Id Configuration

OAM II OUTDOOR AIRFLOW MEASUREMENT SYSTEM 5.5 FIELD CHARACTERIZATION (CONTINUED) 1 Point - Enter a flow velocity that is at or near the top of the operating range. Charaterization Calculator Number of Points Data Points must be Act. Velocity Only! -

Page 37: Section 6.0 Communications

OAM II OUTDOOR AIRFLOW MEASUREMENT SYSTEM SECTION 6.0 COMMUNICATIONS The OAM II is provided with BACnet MS/TP and MODBUS RTU as serial communications protocol options. BACnet is the default setting. The field configurable serial communications interface is described on the following pages. Refer to section 2.1.4 Transmitter Wiring Connections for detailed information on wiring connections. -

Page 38: Standard Bacnet Objects Supported

OAM II OUTDOOR AIRFLOW MEASUREMENT SYSTEM 6.1.3 Standard BACnet Objects Supported Object Identifier Writeable 0 – 4,194,303 Object Name OAM-II Writeable Alpha-numeric; 20 character limits. See “Custom ID” setting in the Service Menu. Object Type Device Read-only System Status Operational... -

Page 39: Bacnet Analog Inputs

OAM II OUTDOOR AIRFLOW MEASUREMENT SYSTEM 6.1.4 BACnet Analog Inputs Single Object Name Description Units Analog 1 Total Flow Cubic Feet Per Minute Analog 2 D.P. Inches of Water Analog 3 Temperature Degrees Fahrenheit Analog 4 Velocity Feet Per Minute... -

Page 40: Analog Input Object

OAM II OUTDOOR AIRFLOW MEASUREMENT SYSTEM 6.1.5 Analog Input Object Object Identifier Analog Input-0 to Analog Input-X1 Read-only Object Name Various Read-only Object Type Analog-Input Read-only Present Value REAL Read-only Status Flags F, F, F, F Read-only Event State Normal... -

Page 41: Modbus Registers

OAM II OUTDOOR AIRFLOW MEASUREMENT SYSTEM 6.2.1 MODBUS Registers Operating Mode Register Description Register Type Address Data Type Single Total Flow Input register 30000 Floating point Single Differential Pressure Input register 30002 Floating point Single Temperature Input register 30004 Floating point... - Page 42 OAM II OUTDOOR AIRFLOW MEASUREMENT SYSTEM 6.2.1 MODBUS Registers (Continued) Description Register Type Address Data Type Description System Velocity Units Read Input 30201 uint16_t 1 = FPM, 2 = FPS, 3 = MPM, 4 =MPS System Flow Units Read Input...

-

Page 43: Section 7.0 Maintenance

• Air Monitor does not recommend a specific time interval between re-calibrations. Calibrations should be scheduled to meet the needs of the facility where the OAM II is installed. For example, critical care facilities may wish to schedule annual re-calibrations while commercial/retail buildings may only schedule re-calibrations at 3-5 year intervals. - Page 44 11451 Belcher Road South • Largo, FL 33773 • USA • Tel +1 (727) 447-6140 www.airmonitor.com/hvac/ • hvacsales@airmonitor.com...

Need help?

Do you have a question about the OAM II and is the answer not in the manual?

Questions and answers