Table of Contents

Advertisement

Quick Links

Product Literature

Lennox Industries Inc.

Dallas, Texas

This boiler cannot be used with all types of

chimneys. Read these instructions carefully

before installing.

C.S.A. Certified for

Natural gas or Propane

H

Tested for 50 psi. ASME

Working Pressure

installation

instRuctions

GWB8-IE

GAS FIRED BOILER

Retain these instRuctions foR

futuRe RefeRence

These instructions must be affixed on

or adjacent to the boiler.

Improper installation, adjustment,

alteration, service, or maintenance

!

can cause injury or property damage.

Refer to this manual. For assistance

or additional information consult a

qualified installer, service agency, or

the gas supplier.

GAS-FIRED HOT WATER BOILERS

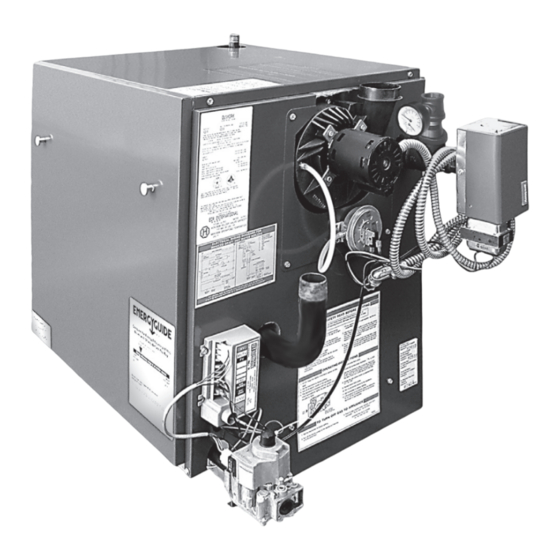

These Gas-Fired Water boilers are low pressure,

sectional cast iron boilers Design Certified by

CSA (Canadian Standards Association) for use

with Natural and Propane Gases. They are

constructed and hydrostatically tested for a

maximum working pressure of 50 psi (pounds

per square inch) in accordance with A.S.M.E.

(American Society of Mechanical Engineers)

Boiler and Pressure Vessel Code Section IV

Standards for Cast Iron Heating Boilers.

WARNING

P/N# 14683451, Rev. C [06/2011]

Advertisement

Table of Contents

Summary of Contents for Lennox GWB8-IE

- Page 1 Product Literature Lennox Industries Inc. Dallas, Texas GWB8-IE GAS FIRED BOILER Retain these instRuctions foR futuRe RefeRence These instructions must be affixed on or adjacent to the boiler. WARNING Improper installation, adjustment, alteration, service, or maintenance can cause injury or property damage.

-

Page 2: Table Of Contents

TABLE OF CONTENTS Safety Symbols ......................2 Installation Instructions ....................3 Boiler Ratings And Capacities ................... 3 Before You Start ......................4 Locating The Boiler ......................5 Fresh Air For Combustion....................6 Installation System Piping ....................7 Chimney & Vent Pipe Connection ..................10 Gas supply Piping ...................... -

Page 3: Installation Instructions

INSTALLATION INSTruCTIONS These instructions must be affixed on or adjacent to the boiler. This boiler cannot be used with all types of chimneys. Read WARNING these instructions carefully before installing. These Gas-Fired Hot Water Boilers are low pressure, sec- Improper installation, adjustment, alteration, tional cast iron boilers Design Certified by C.S.A. -

Page 4: Before You Start

BOILEr rATINgS & CApACITIES Boilers must stand on a noncombustible floor. If installed on Canada Only - For altitudes in the range of 2,000-4,500 a combustible floor, please refer to the Repair Parts manual feet (610 - 1350m) above sea level, boilers may be field for the appropriate Combustible Floor Base part number. -

Page 5: Locating The Boiler

LOCATINg ThE BOILEr If the boiler is part of a planned heating system, locate Figure 2 - minimum Clearances To Combustible it where shown on your plan. If boiler is to be part of an Construction existing system, it is usually best to put it where the old one was. -

Page 6: Fresh Air For Combustion

FrESh AIr FOr COmBuSTION • All Outdoor Air. Provide permanent opening(s) Provide combustion air and ventilation air in accordance communicating directly or by ducts with outdoors. with the section “Air for Combustion and Ventilation,” of the National Fuel Gas Code, ANSI Z223.1/NFPA 54, or Sections о... -

Page 7: Installation System Piping

INSTALLATION SySTEm pIpINg WARNING To avoid burns, scalding, or water damage due to discharge of steam and/or hot water during operation, a discharge line shall be installed to relief valve outlet connection. The discharge line shall: • connect to relief valve outlet and piped down to safe point of disposal. •... - Page 8 INSTALLATION SySTEm pIpINg Figure 4 - Relief Valve Discharge Piping rELIEF VALVE dISChArgE pIpINg Check local codes Figure 6 - Forced Hot Water Typical Piping With for maximum distance from Zone Control Valve floor or other allowable safe point of discharge Figure 5 - Forced Hot Water Typical Piping...

- Page 9 INSTALLATION SySTEm pIpINg If you are installing an entire new heating system, first Low Design Water Temperature Systems (Below install all of your radiation units (panels, radiators or 140° F) And Large Water Content Systems: cabinets) and the Supply and Return Mains - then make the connections at the boiler.

-

Page 10: Chimney & Vent Pipe Connection

ChImNEy & VENT pIpE CONNECTION If the boiler is the only appliance connected to the Check Your Chimney vent, Type B vent pipe is recommended for the vent This is a very important part of your heating system. It connector. must be clean, the right size, properly constructed and in GOOD CONDITION. - Page 11 ChImNEy & VENT pIpE CONNECTION Figure 9 - Type B Gas Ven Liner Chimney Thimble Vent System Cleanout Boiler CHECK YOUR CHIMNEY For boilers for connection to gas vents or Chimney chimneys, vent installations shall be in accordance with “Venting of Equipment”, of the National Fuel Gas Code, ANSI Z223.1/ NFPA 54, or “Venting systems and Air Supply for Appliances”, of the Natural Gas and...

- Page 12 ChImNEy & VENT pIpE CONNECTION Insofar as is practical, close all building doors and After it has been determined that each appliance windows and all doors between the space in which the remaining connected to the common venting system appliances remaining connected to the common venting properly vents when tested as outlined above, return system are located and other spaces of the building.

-

Page 13: Gas Supply Piping

gAS SuppLy pIpINg All pipe compound must be resistant to liquefied CAUTION petroleum gas. Install ground joint union in gas supply line between WHAT TO DO IF YOU SMELL GAS shut-off valve and boiler controls. Do not try to light any appliance. Install a sediment trap upstream of gas controls. -

Page 14: Electrical Wiring

gAS SuppLy pIpINg Table 8a - NATURAL GAS Pipe Capacity - BTU Per Hour Input Length Includes Fittings Pipe - Ft. ½" ¾" 1" 1¼" 92,000 190,000 350,000 625,000 63,000 130,000 245,000 445,000 50,000 105,000 195,000 365,000 Table 8b - PROPANE GAS Pipe Capacity - BTU Per Hour Input Length Includes Fittings... -

Page 15: Sequence Of Operation

SEquENCE OF OpErATION Sequence of Operation - Refer to Figure 13 Thermostat calls for heat, powering the 1K relay coil and closing contacts 1K1 and 1K2. Circulator pump is powered through terminals C1 and Induced draft blower and transformer primary are powered through terminals B1 and B2. -

Page 16: Wiring Diagrams

WIrINg dIAgrAmS Figure 13 - Intermittent Ignition NOTICE NOTICE If any of the original wire as supplied with The circulator harness is factory wired to the this appliance must be replaced, it must be aquastat. This harness needs to be connected to the circulator in the field. -

Page 17: Equipment & Optional Accessories

EquIpmENT & OpTIONAL ACCESSOrIES Relief Valve Air Eliminating Fitting (Air Purger) You must have a relief valve on your boiler. Water expands An Air Purger is used to remove excess air from the as it is heated. If there is no place for the water to system. - Page 18 EquIpmENT & OpTIONAL ACCESSOrIES Blower (Draft Inducer) Rollout Switch The blower provides a means for pulling air through the (Flame Rollout Safety Shutoff) boiler and exhausting the flue gasses into the vent system. The rollout switch is a temperature-sensitive fuse link The blower shuts off when the burners are not firing.

-

Page 19: Starting Your Boiler

STArTINg yOur BOILEr How A Hot Water System Operates WARNING Your entire heating system (boiler, piping and radiation units) is filled with water. As the water in the boiler is BEFORE OPERATING smell all around the heated, it is pumped from the top of the boiler through appliance area for gas. -

Page 20: Checking And Adjusting

STArTINg yOur BOILEr Operating Instructions. WARNING STOP! Read Safety Information on previous page Wait five (5) minutes to clear out any gas. If Set the thermostat to lowest setting. you then smell gas STOP! Follow WHAT TO Turn off all electric power to the appliance. DO IF YOU SMELL GAS on previous page. - Page 21 ChECkINg ANd AdjuSTINg Adjust Limit Controls Figure 15 - Pilot Flame Adjustment Instructions for each control are included with the controls. Recommended Boiler Water Temperatures Type of Heating Unit Limit Control Setting Flame Standing Radiators......... 180° F Sensor Baseboard and Convector Radiators..... 180° F These settings can be changed after you have had some idea how the system works.

-

Page 22: Initial Operational Boiler Test Check-Out Procedure

INITIAL OpErATIONAL BOILEr TEST ChECk-OuT prOCEdurE XEB Series Cast Iron Gas-Fired Cast Iron Boilers Check off each step as completed. Verify base insulation is securely fastened to base panels. Verify air purged from hydronic heating system. Purge air from gas piping; check gas piping for leaks. ... - Page 23 INITIAL OpErATIONAL BOILEr TEST CErTIFICATE & SIgNEd rECEIpT Boiler Identification: Boiler Manufacturer: Model #: _______________________________________________ Dunkirk Boilers Serial #: 85 Middle Road ________________________________________________ Dunkirk, NY 14048 t: _____________________ : ________ /________ /_________ Measured BTUH inpu Operational Test Date ☐ Installation Instructions in the XEB Installation, Operation and Maintenance Manual have been followed. ☐...

-

Page 24: Maintaining Your Boiler

mAINTAININg yOur BOILEr Relief Valve Water System This valve should open automatically if the system pressure If system is to remain out of service during freezing exceeds the pressure rating (usually 30 psi) of the relief weather, always drain it completely (water left in to freeze valve. -

Page 25: Service Hints

SErVICE hINTS You may avoid inconvenience and service calls by checking these points before you call for service: WARNING WHAT TO DO IF YOU SMELL GAS Do not try to light any appliance. Do not touch any electrical switches; do not use any phones in your building. Immediately call your gas supplier from a neighbor’s phone. - Page 26 NOTES...

- Page 28 Gas-Fired Hot Water Induced Draft Boilers REPAIR PARTS & OPTIONAL KITS P/N 240008172 REV A [06/2011]...

- Page 29 rEpAIr pArTS LIST Jacket Sections and Base Parts...

- Page 30 jACkET ANd BASE Jacket Sections and Base Parts PART NUMBERS FOR DESCRIPTION 2 Section 3 Section 4 Section 5 Section 6 Section 7 Section Jacket, Right Side Panel 730001050 730001050 730001050 730001050 730001050 730001050 Blower Cover Plate 630001170 630001170 630001170 630001170 630001170 630001170...

- Page 31 BOILEr CONTrOLS ANd pIpINg rEpAIr pArTS Boiler Controls and Piping Repair Parts NOTE: Circulator and ball valves do not come pre-installed.

- Page 32 BOILEr CONTrOLS ANd pIpINg rEpAIr pArTS Boiler Controls and Piping Repair Parts Part Description ¾” ASME Relief Valve 14622011 ¾” x 5½” Nipple 1310010 Temperature Pressure Gauge - 1260006SP (3½” Stem) 1¼” x 5½” Nipple 14607019 1¼” x ¾" x 1¼" Tee 1510001 L8148A Comb Hi Limit &...

- Page 33 NATurAL gAS VALVE Natural Gas Valve FOr uSE WITh NATurAL gAS ONLy NOTE: Actual gas valve may look different than gas valve shown. NATURAL GAS BURNER & MANIFOLD PARTS PART NUMBERS FOR DESCRIPTION 2 Section 3 Section 4 Section 5 Section 6 Section 7 Section 24 Volt Gas Valve,...

- Page 34 prOpANE gAS VALVE Propane Gas Valve For Use With Propane Gas Only NOTE: Actual gas valve may look different than gas valve shown. PROPANE GAS BURNER & MANIFOLD PARTS PART NUMBERS FOR DESCRIPTION 2 Section 3 Section 4 Section 5 Section 6 Section 7 Section 24 Volt Gas Valve,...

- Page 35 ORDERING INSTRUCTIONS Order Parts through your nearest supplier. When ordering parts, first obtain Model Number from data plate on your boiler. Include following information when ordering: Part No. ______________________________________________________________ Part Description ________________________________________________________ Boiler Model No. ________________________________________________________...

- Page 36 Product Literature Lennox Industries Inc. Dallas, Texas...

Need help?

Do you have a question about the GWB8-IE and is the answer not in the manual?

Questions and answers