Table of Contents

Advertisement

Quick Links

DC3SEA SERIES

THREE-PHASE

AIR CONDITIONING

INSTALLATION & SERVICE REFERENCE

IMPORTANT SAFETY INSTRUCTIONS

The following symbols and labels are used throughout this

manual to indicate immediate or potential safety hazards.

It is the owner's and installer's responsibility to read

and comply with all safety information and instructions

accompanying these symbols. Failure to heed safety

information increases the risk of personal injury, property

damage, and/or product damage.

NOTE: This equipment is approved to use only with R-32

refrigerant.

High Voltage!

Disconnect all power before servicing or

installing this unit. Multiple power sources may

be present. Failure to do so may cause property

damage, personal injury or death.

Do not bypass safety devices.

Scroll equipped units should never be used to evacuate

the air conditioning system. Vacuums this low can cause

internal electrical arcing resulting in a damaged or failed

compressor.

Do not use means to accelerate the defrosting process

or to clean, other than those recommended by the

manufacturer. The appliance shall be stored in a room

without continuously operating ignition sources. For

example: Open flames, an operating gas appliance or an

operating electric heater. Do not pierce or burn. Be aware

that refrigerants may not contain an odor.

Our continuing commitment to quality products may mean a change in specifications without notice.

© 2024

IOD-4062A

7/2024

WARNING

WARNING

CAUTION

WARNING

19001 Kermier Rd. Waller, TX 77484

www.daikincomfort.com

INSTALLATION INSTRUCTIONS

Only personnel that have been trained to install, adjust,

service, maintenance or repair (hereinafter, "service")

the equipment specified in this manual should service the

equipment.

This equipment is not intended for use by persons

(including children) with reduced physical, sensory or

mental capacities, or lack of experience and knowledge,

unless they have been given supervision or instruction

concerning use of the appliance by a person responsible

for their safety.

Children should be supervised to ensure that they do not

play with the equipment.

The manufacturer will not be responsible for any injury

or property damage arising from improper supervision,

service or service procedures. If you service this unit, you

assume responsibility for any injury or property damage

which may result. In addition, in jurisdictions that require

one or more licenses to service the equipment specified in

this manual, only licensed personnel should service the

equipment. Improper supervision, installation, adjustment,

servicing, maintenance or repair of the equipment specified

in this manual, or attempting to install, adjust, service

or repair the equipment specified in this manual without

proper supervision or training may result in product

damage, property damage, personal injury or death.

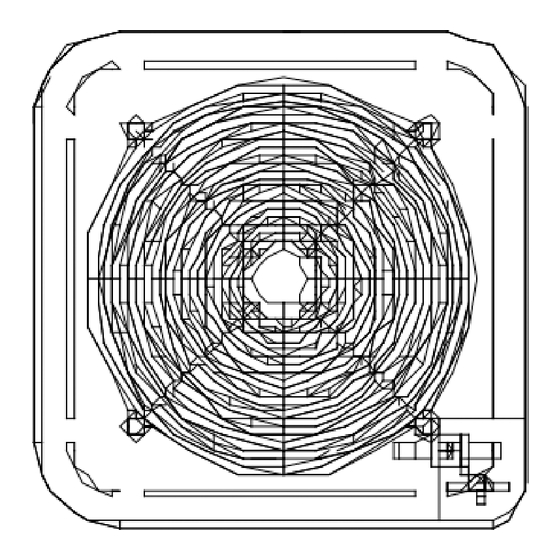

INSTALLATION CLEARANCES

Special consideration must be given to location of the

condensing unit(s) in regard to structures, obstructions,

other units, and any/all other factors that may interfere

with air circulation. Where possible, the top of the unit

should be completely unobstructed; however, if vertical

conditions require placement beneath an obstruction there

should be a minimum of 60 inches between the top of

the unit and the obstruction(s). Ensure there is not a

potential for refrigerant to pool should a leak occur in the

unit. The specified dimensions meet requirements for air

circulation only. Consult all appropriate regulatory codes

prior to determining final clearances. Another important

consideration in selecting a location for the unit(s) is the

angle to obstructions. Either side adjacent the valves be

placed toward the structure provided the side away from

the structure maintains minimum service clearance. Corner

installations are strongly discouraged.

WARNING

Advertisement

Table of Contents

Summary of Contents for Daikin DC3SEA Series

- Page 1 INSTALLATION INSTRUCTIONS DC3SEA SERIES WARNING THREE-PHASE Only personnel that have been trained to install, adjust, AIR CONDITIONING service, maintenance or repair (hereinafter, “service”) the equipment specified in this manual should service the INSTALLATION & SERVICE REFERENCE equipment. This equipment is not intended for use by persons...

-

Page 2: Charging Instructions

This unit can be located at ground floor level or on flat sheets can be found at www.daikincomfort.com for roofs. At ground floor level, the unit must be on a solid, Daikin. Within website, please select the residential level foundation that will not shift or settle. To reduce the... -

Page 3: Rooftop Installations

ROOFTOP INSTALLATIONS WARNING If it is necessary to install this unit on a roof structure, ensure the roof structure can support the weight and that To avoid possible explosion, use only returnable (not disposable) service cylinders when removing refrigerant proper consideration is given to the weather-tight integrity from a system. -

Page 4: Refrigerant Lines

If a refrigerant leak is suspected, all naked flames shall All field joints created shall be accessible for inspection be extinguished and the area shall be ventilated. If a leak prior to being covered or enclosed. When installing is found which requires brazing, all refrigerant shall be refrigerant lines between evaporating and condensing unit, recovered from the system prior to performing hot work. -

Page 5: Burying Refrigerant Lines

Insulation is necessary to prevent condensation from Before conducting any hot work, ensure the area is in the forming and dropping from the suction line. Armflex (or open or has adequate ventilation. The ventilation shall satisfactory equivalent) with 3/8” min. wall thickness is continue during the period of hot work and should safely recommended. -

Page 6: Leak Testing (Nitrogen Or Nitrogen-Traced)

NOTE: Scroll compressors should never be used to evacuate or pump down a heat pump or air WARNING conditioning system. To avoid possible explosion, the line from the nitrogen cylinder must include a pressure regulator and a pressure relief valve. The pressure relief valve must be set to open at CAUTION no more than 450 psig. - Page 7 ELECTRICAL CONNECTIONS - THREE PHASE OPERATION For units designed for 3-phase operation, DO NOT OPERATE ON A SINGLE PHASE POWER SUPPLY. Measure the power supply to the unit. The supply voltage must be in agreement with the unit rating plate power requirements.

-

Page 8: System Start-Up

Low Voltage Connections Adequate refrigerant charge for the matching AHRI rated Condensing unit control wiring requires 24 Volt minimum, designated tested combination (DTC) evaporator coil and 25VA service from the indoor transformer. Low voltage 15 feet of lineset is supplied with the condensing unit. wiring for two-stage units depends on the thermostat used If using evaporator coils other than DTC coil, it may be and the number of control wires between the indoor unit... -

Page 9: Charge Verification

1. Break vacuum by fully opening liquid and suction Units matched with indoor coils equipped with a non- base valves. adjustable TXV should be charged by Subcooling only. 2. Set thermostat to call for cooling. Check indoor and Superheat on indoor coils with adjustable TXV valves are outdoor fan operation and allow system to stabilize factory set and no adjustment is normally required during for 10 minutes for fixed orifices and 20 minutes for... - Page 10 SATURATED SUCTION PRESSURE SATURATED LIQUID PRESSURE TEMPERATURE CHART TEMPERATURE CHART LIQUID SATURATED SUCTION SUCTION SATURATED SUCTION PRESSURE TEMPERATURE ºF PRESSURE TEMPERATURE ºF PSIG R-32 PSIG R-32 NOTE: Specifications And Performance Data Listed Herein Are Subject To Change Without Notice.

-

Page 11: Expansion Valve System

EXPANSION VALVE SYSTEM 1. Clamp a pipe clamp thermometer near the suction line 4-6” from the compressor on the suction line. a. Ensure the thermometer makes adequate contact NOTE: Units matched with indoor coils equipped for the best possible readings. with a TXV should be charged by Subcooling only. - Page 12 The refrigerant charge shall only be recovered into a cylinder labeled for use with R-32. Ensure that the refrigerant cylinder(s) are capable of holding the total system charge. Cylinders shall be complete with a pressure-relief valve and associated shut-off valves in good working order.

-

Page 13: Troubleshooting Information

TROUBLESHOOTING INFORMATION System Unsatisfactory Complaint No Cooling Operating Cooling Pressures POSSIBLE CAUSE Test Method DOTS IN ANALYSIS Remedy GUIDE INDICATE "POSSIBLE CAUSE" Power Failure • Test Voltage Blown Fuse • • • Impact Fuse Size & Type Loose Connection • •... -

Page 14: Split Systems

SPLIT SYSTEMS AIR CONDITIONING AND HEAT PUMP homeowner’s Routine Maintenance Recommendations We strongly recommend a bi-annual maintenance checkup be performed before the heating and cooling seasons begin by a qualified servicer. Replace or Clean Filter Clean Outside Coil (Qualified Servicer Only) IMPORTANT NOTE: Never operate unit without a filter installed as dust and lint will build up on WARNING... -

Page 15: Start-Up Checklist

START-UP CHECKLIST Condenser / Heat Pump (including all Inverter) Model Number Serial Number ELECTRICAL (Outdoor Unit) L1 - L2 Supply Voltage L2 - L3 L3 - L1 R - C Secondary Voltage (Measure Transformer Output Voltage) NOT ALL MODELS Compressor Amps Condenser Fan Amps TEMPERATURES (Indoor Unit) DB °F... - Page 16 CUSTOMER FEEDBACK Daikin Comfort Technologies is very interested in all product comments. Please fill out the feedback form on the following link: https://daikincomfort.com/contact-us You can also scan the QR code on the right to be directed to the feedback page.

Need help?

Do you have a question about the DC3SEA Series and is the answer not in the manual?

Questions and answers