Table of Contents

Advertisement

Quick Links

Installation

Operation

Co

Maintenance

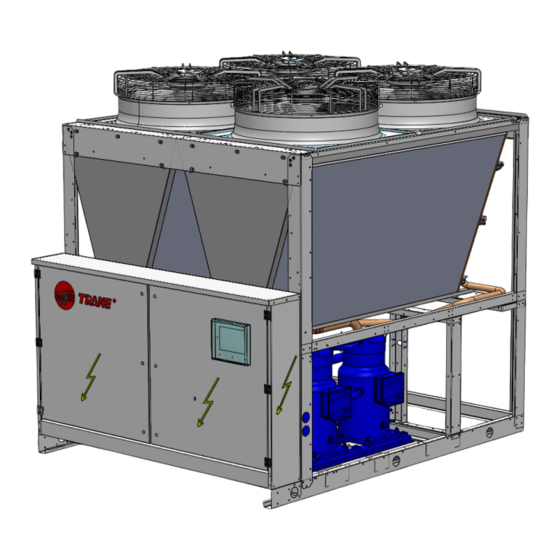

RAUS/RAUX condensing units

Air cooled chillers and heat pumps condensing units with scroll

compressors

RAUS 410 – 760 Cooling capacity 143 - 268 kW

RAUX 370 – 660 Cooling capacity 130 - 232 kW

June 2022

Heating capacity 133 -234 kW

CG-SVX054B-GB

Original instructions

Advertisement

Table of Contents

Summary of Contents for Trane RAUS Series

- Page 1 Installation Operation Maintenance RAUS/RAUX condensing units Air cooled chillers and heat pumps condensing units with scroll compressors RAUS 410 – 760 Cooling capacity 143 - 268 kW RAUX 370 – 660 Cooling capacity 130 - 232 kW Heating capacity 133 -234 kW June 2022 CG-SVX054B-GB Original instructions...

-

Page 2: Table Of Contents

INDEX OVERVIEW ..................................3 SAFETY REGULATIONS ...............................3 OPERATING LIMITS..............................6 INSTALLATION ................................8 ACOUSTIC PROTECTION ............................10 ELECTRICAL POWER SUPPLY ..........................10 HOW TO SIZE REFRIGERANT LINES ........................11 LIQUID RECEIVER ..............................19 REMOTE TERMINALS CONTROL AND EXPANSION VALVE ................. 22 ELECTRICAL PANEL ............................23 OPERATOR RESPONSABILITIES ........................ -

Page 3: Overview

1.2 WARRANTY The warranty for Trane machines is 12 months from the date the machine is operated for the first time but no more than 18 months from the date of the invoice. The warranty is reduced to 6 months from the start up date for units running continuously, that is more than 12 hours a day. - Page 4 2.2 GENERAL PRECAUTIONS The operator must only intervene on the unit commands; he or she must not open any panels except for the one which gives access to the command module. The installer must only intervene on the connections between the plant and the machine; he or she must not open any machine panels nor carry out any commands.

- Page 5 • if the unit is to be moved after a year of being in the site or if it has to be dismantled contact Trane. VERY IMPORTANT No refrigerant high pressure safety valve is installed on RAUX (RAUS mounts a refrigerant safety valve instead).

-

Page 6: Operating Limits

OPERATING LIMITS 3.1 STORAGE The units can be stored within the following environmental conditions: Min ambient temperature -10°C Max ambient temperature 53°C Max relative humidity 95% not condensable CAUTION: The storage in a very high humidity space (condensation) can damage electronic components. 3.2 OPERATING LIMITS RAUS / RAUX unit operation is permitted within the limits indicated in the diagram provided in 3.3. - Page 7 RAUX 370-660 – CHILLER MODE OAT = Outdoor Air Temperature [°C] ET = Evaporating Temperature [°C] -------- = Low air temperature kit needed (down to -10°C) RAUX 370 -660 – HEAT PUMP MODE OAT = Outdoor Air Temperature [°C] CT = Condensing Temperature [°C] -------- = Low air temperature kit needed (down to -15°C) Page 7...

-

Page 8: Installation

INSTALLATION 4.1 MOVING AND POSITIONING THE UNIT The units have been designed to be lifted from above by means of eyebolts and holes in the base members. Use retractor bars to keep the lifting wires or chains away from the unit. Figure 1 Correct lifting procedure Lifting procedures provided with the unit have to be respected. - Page 9 4.2 MINIMUM SPACE REQUIREMENTS Dimensional drawing shall be respected to avoid: • Noise • Incorrect heat exchange and ventilation • Difficult maintenance or inaccessibility to components It is fundamental to respect minimum distances on all RAUS / RAUX units, in order to ensure optimum ventilation for the condenser coils.

-

Page 10: Acoustic Protection

4.6 PRECAUTIONS AGAINST THE PRESENCE OF FOLIAGE AND FOREIGN BODIES Avoid installing the unit in the immediate vicinity of plants that can prevent proper intake and discharge air. 4.7 CONTROL OF COMPRESSOR FASTENING The compressors are fitted on shock absorbers. For fixing through spring anti-vibration mounts, it is necessary to remove blockages put to fasten the compressors, as indicated on the label on compressors body. -

Page 11: How To Size Refrigerant Lines

HOW TO SIZE REFRIGERANT LINES In the dimensioning of refrigerant lines of air conditioning systems equipped with two sections, the designer has to take into account that, due to the pressure loss of the refrigerant circuits, cooling capacity decrease and compressors power input increase may occur. - Page 12 7.2 LENGTH The length of the suction line produces pressure losses higher than those ones found in the circuit of a machine with a single section. Obviously consequently there is a lower pressure in the intake to the compressor. This may cause, as already mentioned, a decrease of the output power and increase of that absorbed, with consequent reduction of the COP.

- Page 13 Those fictitious lengths are shown in the table 2 and shall be considered effective for fully open valves. Table 2: Equivalent lengths (in meters) for concentrated drops. The table1 is referred to a condensation temperature of 40°C. In case of different condensation temperatures the following correcting values shall be applied to the cooling capacity. Cond.

- Page 14 pressure drops that would occur on the line using the diameter corresponding to the cooling capacity of the unit. The equivalent length is about 60 meters, then with a pressure drops of 0.02 K / m the total pressure drops are equal to: T = 60x0,02 = 1.2 K These pressure drops are higher than the maximum specified by ASHRAE.

- Page 15 Table 3: Minimum capacity (kW) ensuring the oil flowing in vertical sections of the suction line (R410a refrigerant). The cooling capacity shown in table 3 refer to 40°C of condensing temperature: in case of different temperature values of the liquid line, the capacities must be adjusted according to the following factors: Liquid temperature (°C) Correction factor...

- Page 16 It might be guessed that in order to guarantee the proper speed ensuring the correct oil flow, if the compressor is working at partial loads, the diameter shall be reduced, therefore a too much high speed is obtained when the compressor is working at full load. This is cause of excessive pressure drops.

- Page 17 If the two evaporators are installed at different levels there are two possible solutions shown in figure2. On the discharge line, there is the same problem due to the oil flow on the suction line. The solution to the problem is the same. In this case, the most important issue could be the oil drop towards the compressor.

- Page 18 7.4 PRECAUTIONS FOR REFRIGERANT LINE SIZING • Suction line must always be insulated to avoid condensate formation. • The liquid line must be insulated if the outdoor temperature is higher than the liquid temperature. (approximately 5°C less than the condensing temperature) •...

-

Page 19: Liquid Receiver

– V Receiver V1: volume of the unit’s heat exchanger (please contact Trane to obtain this information) V2: Volume of the remote heat exchanger. If V receiver has positive sign, the receiver shall be placed so as to be filled in heat pump mode and discharged in chiller, otherwise it shall be placed so as to be filled in chiller mode and emptied in the heat pump. - Page 20 8.2 INSTALLATION DIAGRAM AND PLACING OF THE LIQUID RECEIVER RAUS 410 - 760 REFRIGERANT R410A CONNECTION BY THE CUSTOMER INDEX INDEX CARTER HEATER EXPANSION VALVE COMPRESSOR SIGHT GLASS HP PRESSURE SWITCH HP TRANSDUCER SERVICE VALVE FILTER HP GAUGE SHUT OFF VALVE (OPTION) SAFETY VALVE Rliq LIQUID RECEIVER...

- Page 21 RAUX 370-660 REFRIGERANT R410A GAS LINE LIQUID LINE EQUALIZATION LINE Liquid receiver in heat pump mode Liquid receiver in CONNECTION BY THE CUSTOMER chiller mode CONNECTION BY THE CUSTOMER INDEX INDEX CARTER HEATER MECHANICAL EXPANSION VALVE COMPRESSOR SIGHT GLASS HP PRESSURE SWITCH HP TRANSDUCER SERVICE VALVE FILTER...

-

Page 22: Remote Terminals Control And Expansion Valve

As mentioned in the previous paragraph, the liquid receiver location for RAUX versions shall be evaluated in accordance to the refrigerant charge delta of the two cycles. If the higher refrigerant charge is required for the chiller mode the liquid receiver shall be placed in a location that ensure the proper filling during the operation in heat pump mode and the proper emptiness during chiller mode. -

Page 23: Electrical Panel

The electrical panel supply is 400V/3ph+n/50Hz suitable for TN-S system and no additional power supply is necessary. If the unit is powered by a TN-C, TT or IT power supply system the Trane catalogue option “power supply without neutral 400V/3ph/50Hz” must have been ordered and implemented in the unit’s electrical cabinet. -

Page 24: Operator Responsabilities

11 OPERATOR RESPONSABILITIES It is important that the operator is properly trained and familiar with the equipment before working on the unit. In addition to reading this manual, the operator must study the manual operation of the microprocessor and the wiring diagram to understand the sequence of start- up, operation, shutdown sequences, and the criterion of operation of all safety devices. -

Page 25: Check List - Mandatory Operation Control Before Start-Up

SITE: ADDRESS: POSTCODE: COUNTRY: THE INTENDED PURPOSE OF RAUS / RAUX UNITS IS NOT FOR INDUSTRIAL PROCESS APPLICATION. PLEASE CONTACT TRANE TECHNICAL DEPARTMENT IN CASE OF INDUSTRIAL PROCESS APPLICATION. GENERAL COMPLIANCE THE UNIT DISPLAYS DENTS OR DAMAGES ON THE EXTERNAL CASING OCCURRED DURING THE TRANSPORTATION OR POSITIONING. - Page 26 AN ELECTRONIC SUPERVISOR (OR ANY ADDITIONAL CONTROLLER) HAS BEEN INSTALLED. THE CONNECTION WIRES ARE SHIELDED. REMOTE CONTROL DEVICES OR INTERFACES ARE CONNECTED TO THE ELECTRICAL PANEL IN CONFORMITY WITH TRANE WIRING DIAGRAMS ELECTRONIC DEVICES ARE INTACT AND DON’T DISPLAY ANY DAMAGE. THE ELECTRICAL ABSORPTION IS STANDARD.

- Page 27 13.1 REFRIGERANT CHARGE 13.1.1 Refrigerant replacement procedure with unit stopped and in vacuum (refrigerant charge in the liquid phase) Open the shut off valve as far as possible so that it closes the service coupling. Connect the refrigerant cylinder to the service coupling without tightening the coupling.

- Page 28 13.1.2 Refrigerant replacement procedure with unit running (refrigerant charge in the vapour phase) Caution: charge vapour only. Do not charge liquid because it may damage the compressor. Connect the refrigerant cylinder to the service valve without tightening the coupling. Drain the connection piping and tighten the coupling.

-

Page 29: Maintenance

Every unit comes with a logbook, in which the user or the person delegated to machine maintenance can keep all the required notes, in order to keep a historical log of the Trane unit. A lack of notes in the logbook could be considered proof of careless maintenance. - Page 30 “dirty” or corrosive environment. Cleaning with cleansers or detergents is strongly discouraged due to the all- aluminum construction; straight water should prove sufficient, if not please contact Trane. Any breach in the tubes can result in refrigerant leaks IMPORTANT: Only in extreme cases should any type of chemical cleaner or detergent be used on microchannel coils.

- Page 31 14.4 ORDINARY MAINTENANCE Activities list week Month (note 1) Year (note 2) General: Data collection operation (Note 3) Visually inspect the unit for any damage and / or looseness Verifying the integrity of the thermal insulation Clean and paint where needed Electric: Check the correct operation of the equipment on the unit Check the wear of contactors - Replace if necessary...

-

Page 32: Recommended Spare Parts

15 RECOMMENDED SPARE PARTS There follows a list of the recommended parts for several years’ running. Trane is at your disposal to recommend a personalised list of accessories according to the commissioned order, including the part number of the equipment. -

Page 33: Troubleshooting

16 TROUBLESHOOTING Who can take corrective action U Symptom Cooling Heating = User Probable cause Possible remedy S = specialised personnel Probe faulty service Check and replace if necessary. A The unit does Lack of consent of the high or low See points D-E not start pressure... - Page 34 Who can take corrective action U Symptom Cooling Heating = User Probable cause Possible remedy S = specialised personnel Pressure switch out of order Check and replace. Machine completely void of See point G. refrigerant Finned coil clogged, airflow rate is Remove dirt from the coil.

- Page 35 Who can take corrective action U Symptom Cooling Heating = User Probable cause Possible remedy S = specialised personnel Expansion device that is not working Verify and replace. properly Water circulation pump blocked Unlock the pump. M Frost in the compressor intake Water circulation pump defective Check the pump and replace if necessary.

-

Page 36: Improper Uses

17 IMPROPER USES The unit is projected and built up to grant the maximum safety in its proximity, as well as to resist to the aggressive environmental conditions. The fans are protected by grilles. Residual risks are indicated with warning labels. SAFETY SYMBOLS DANGER: DANGER:... - Page 37 Trane – by Trane Technologies (NYSE: TT), a global climate innovator – creates comfortable, energy efficient indoor environments through a broad portfolio of heating, ventilating and air conditioning systems and controls, services, parts and supply. For more information, please visit trane.eu or tranetechnologies.com.

Need help?

Do you have a question about the RAUS Series and is the answer not in the manual?

Questions and answers