Table of Contents

Advertisement

Quick Links

D771 MiniPurge

Manual

ML 435

IMPORTANT NOTE

It is essential for safety that the installer and user of the Expo system observe

the following instructions:

Please refer to the standard for principles and definitions.

(N.B. These instructions apply only to the Pressurizing system. It is the responsibility of the manufacturer

of the Pressurized Motor Enclosure to provide appropriate instructions for the Enclosure.)

Contents

ML435 v1

Issued 30/05/08 ©

15

Page 1 of

Advertisement

Table of Contents

Summary of Contents for EXPO MiniPurge D771

-

Page 1: Table Of Contents

Manual ML 435 IMPORTANT NOTE It is essential for safety that the installer and user of the Expo system observe the following instructions: Please refer to the standard for principles and definitions. (N.B. These instructions apply only to the Pressurizing system. It is the responsibility of the manufacturer of the Pressurized Motor Enclosure to provide appropriate instructions for the Enclosure.) -

Page 3: D771 Minipurge - General System Specification

1. D771 MiniPurge - General System Specification Pressurized Motor Housing Pressurized Motor Enclosure : A range of Electrical Motor housings Classification : Zone 1 Group IIC Total Purge Flow Rate : To be determined by customer and to include flow to compensate for leakage. Estimated Purge Time : To be determined by motor manufacturer dependent on the flow rate selected &... - Page 4 Purge Time : User selectable. 3-off time increments available. 10, 15 or 20 Minutes (-0 + 25%). Giving a maximum available purge time period of 45 minutes. Default set to 45 Minutes. Approvals :ATEX Certificate: Sira 01ATEX1295X 0518 II 2 (2) G D Ex [px] II T6 Ex pD II 21 T85ºC Tamb -20ºC +55ºC...

-

Page 5: Quick User Guide

If an obvious problem has not been highlighted and corrected then follow the checks in the section “Fault Finding”. If the checks have been made and the system will still not work then please contact your local distributor or EXPO. ML435 v1 Issued 30/05/08 ©... -

Page 6: Application Suitability

“Pressurization” is a method of protection used in Zone 1 and Zone 2 Hazardous Locations to ensure that the interior of an electrical enclosure, for example the motor housing, is free of flammable gas. With the utilisation of the Expo MiniPurge system, the motor may be used safely in a hazardous environment. -

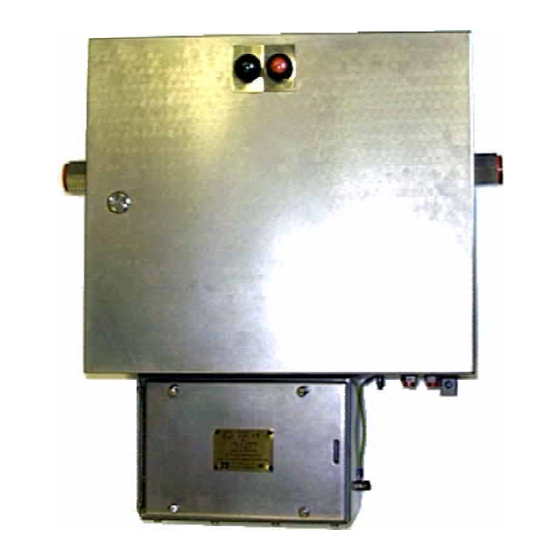

Page 7: Main Components

action on loss of pressurization by the MiniPurge is “Alarm and Automatic Disconnect of Power” (A&T – Alarm and Trip). This can be changed by the customer to “Alarm Only” (AO), please refer to Section titled ‘Main Components’ - “Alarm Only” circuit. ... - Page 8 functions: turn on the electrical supply to the PE, turn off the high purge flow and start the “Leakage Compensation” mode. It will also provide a hold-on signal to maintain the system in “Leakage Compensation” mode with the power switch on even when the Purge Timer has reset ready for the next purge cycle whenever it is required.

-

Page 9: Installation Of The System

Cable glands must be “Ex” certified if they are non-metallic. 6. Installation of the System This equipment is designed for use under normal industrial conditions of ambient temperature, humidity and vibration. Please consult Expo before installing this equipment in conditions that may cause stresses beyond normal industrial conditions. ... - Page 10 Air Supply Quality The MiniPurge system should be connected to a protective gas supply, which is suitable for purging and pressurization. The supply pipe connection to the MiniPurge is 1” NPT(F) but the supply pipe shall be sized for the maximum input purge flow rate for the application and regulated to 6 barg. The air supply to the filtration system must be clean, non-flammable, from a non-hazardous area and free from water and oil to BS ISO 8573-1: 2001 Class 2.2.1 or relevant local standards.

-

Page 11: Commissioning

• The “CLAPS Leakage Compensation Valve” can be set finally only when the enclosure has been installed in its permanent operating location. • Check that the system has been installed in accordance with Expo Instructions. • Disconnect the supply pipe from the inlet to the MiniPurge system and blow clean air through it for at least 10 seconds per meter of length to remove any debris, oil and condensation. - Page 12 • Check the Pressure Relief Valve is correctly set by disconnection the Minimum Pressure sensing “Green” pipe at the bulkhead fitting on the input to the MiniPurge , this will disable all of the pressure sensors. • Connect a manometer to the bulkhead fitting, with a 4mm nylon tube, from where the Minimum Pressure sensing “Green”...

-

Page 13: Maintenance Of The System

The maintenance recommended for the system consists of the following, supplemented by any additional requirements imposed by the local Code of Practice. Expo recommends that the commissioning tests be repeated at every six to 24 months, dependent on the environment. In addition the following checks are also recommended at that time: •... -

Page 14: Fault Finding

If the system is less than 12 months old, parts under warranty should be returned to Expo for investigation, with a full report of the fault and the system Serial Number. As with any pneumatic system the greatest enemies are water, oil and dirt in the air supply. For this reason the air system must always incorporate a dust and water filter to provide air to instrument quality. -

Page 15: Recommended Spares List

Remove the clamp and retest. If the system ceases to time out, there an air leak in the reservoir circuit. Use soapy water to detect the leak and then rectify it. (Call Expo Ltd. if in doubt). Finally recheck the purge timer at its full setting. -

Page 16: Drawings And Diagrams

11. Drawings and Diagrams The following attached drawings are applicable to the D771 MiniPurge System: Title Drawing Number Sheet(s) D758 Control Unit GA D758-GA 1 of 2 and 2 of 2 Typical D758 Hook Up D758-HU 1 of 1 D758-3 P and I Diagram D758-PI 1 of 1... - Page 24 UNSPECIFIED NO DEC PLACE ±0.5 The contents of this drawing / document are Copyright © Expo Technologies Limited. They are to be treated as confidential 3rd ANGLE DIMENSIONS IN mm TOLERANCES 1 DEC PLACE ±0.2 and are returnable upon request. They are not to be copied or communicated in part or in whole without written consent PROJECTION 2 DEC PLACE ±0.1...

- Page 33 This document confirms that “MiniPurge” Pressurize and Purge Control Systems manufactured by Expo Technologies Ltd conform, as described, to the following European Directives and standards:- Electromagnetic Compatibility Directive MiniPurge systems with a /PO suffix in the type number are non-electrical and are outside the scope of the EMC Directive.

- Page 36 Expo Technologies Ltd., + 44 (0) 20 8398 8011 Summer Road, + 44 (0) 20 8398 8014 Thames Ditton, E-mail: sales@expoworldwide.com Surrey, England, KT7 0RH Expo Technologies Inc., Tel: (440) 247 5314 PO Box 486, Fax: (440) 247 5409 Chagrin Falls, E-mail: sales.na@expoworldwide.com...

Need help?

Do you have a question about the MiniPurge D771 and is the answer not in the manual?

Questions and answers