Summary of Contents for Atlas Copco QPNC83

- Page 1 ENGLISH Code 2200780127 Edit. 09/2020 INSTRUCTION AND MAINTENANCE MANUAL DRYERS QPNC83 (E5) - QPNC106 (E6) (R513A) READ THIS MANUAL CAREFULLY BEFORE CARRYING OUT ANY OPERATIONS ON THE DRYER. Cod. 2200780127 04 - Edition 09/2020 - 1...

-

Page 2: Table Of Contents

ENGLISH CONTENTS PART A: INFORMATION FOR THE USER GENERAL CHARACTERISTICS INTENDED USE OPERATION GENERAL SAFETY STANDARDS DESCRIPTION OF DANGER SIGNALS DANGER ZONES SAFETY DEVICES POSITION OF PLATES DRYERS ROOM 10.0 TRANSPORT AND HANDLING 11.0 UNPACKING 12.0 INSTALLATION 13.0 DIMENSIONS AND TECHNICAL DATA 14.0 MACHINE ILLUSTRATION 15.0... -

Page 3: General Characteristics

ENGLISH 1.0 GENERAL CHARACTERISTICS The dryer is a chilling machine with direct expansion and dry evaporator. The air to be dried is sent to the heat exchanger in which the water vapour present is condensed: the condensate gathers in the separator and is discharged outside through a steam trap. 2.0 INTENDED USE The dryer has been built to dry the compressed air for industrial use. -

Page 4: Description Of Danger Signals

ENGLISH 5.0 DESCRIPTION OF DANGER SIGNALS 1) Dangerous 2) Air not fit for 3) High pressure 4) Fan rotating 5) Hot parts electricvoltage breathing 6.0 DANGER ZONES 6.1 DANGER ZONES Risks present on the whole machine FIG. 2 7.0 SAFETY DEVICES 7.1 SAFETY DEVICES 1) Cooling fan shield 2) Earth... -

Page 5: Position Of Plates

The machine must be transported as shown in the following figures. FIG. 5 NET WEIGHT TYPE Kg. (lb.) QPNC83 44 (97) QPNC106 44 (97) 11.0 UNPACKING CUTTING THE METAL STRAPPING IS A DANGEROUS OPERATION, DO NOT ABANDON THE CUT PIECES IN THE ENVIRONMENT. -

Page 6: Installation

ENGLISH 12.0 INSTALLATION 12.1 POSITIONING After unpacking the equipment and preparing the dryers room, put the machine into position, checking the following items: ⚫ ensure that there is sufficient space around the machine to allow maintenance (see Fig. 6). ENSURE THAT THE OPERATOR CAN SEE THE WHOLE MACHINE FROM THE CONTROL PANEL AND CHECK THE PRESENCE OF ANY UNAUTHORIZED PERSONS IN THE VICINITY OF THE MACHINE. -

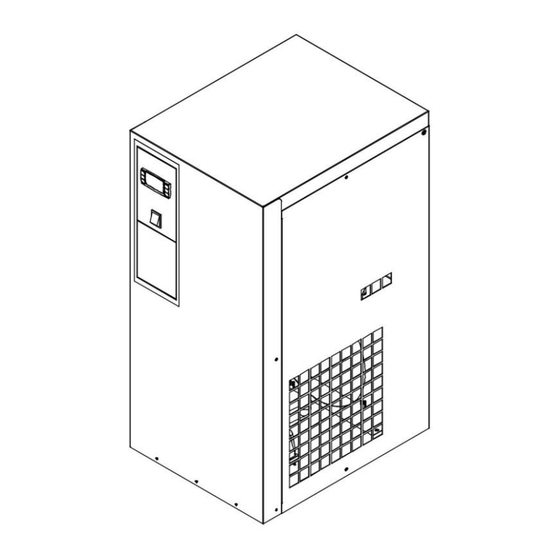

Page 7: Dimensions And Technical Data

ENGLISH 13.0 DIMENSIONS AND TECHNICAL DATA (E5 - E6) ELECTRICAL CABLE AIR INLET AIR OUTLET CONDENSATE DRAINING Refrigerant gas 100 (2) in (mm) TYPE R-513A TYPE 83 (E5) 83 (E5) 1” GAS F. 1” GAS F. 370 (14,57) 515 (20,28) 764 (30,08) According to ISO 817 106 (E6) - Page 8 ENGLISH 14.2 COMMAND AND CONTROL PANEL BEFORE CARRYING OUT THE OPERATION TEST, READ CAREFULLY AND ACQUIRE A GOOD KNOWLEDGE OF THE COMMAND FUNCTIONS. Ref. 1) Digital controller Ref. 7) Stop - Running button FIG. 9 Alarms Power ON Fan ON Dryer ON PDP indicator ICON...

- Page 9 ENGLISH 14.3 COMMAND AND CONTROL PANEL (Option “free contact”) BEFORE CARRYING OUT THE OPERATION TEST, READ CAREFULLY AND ACQUIRE A GOOD KNOWLEDGE OF THE COMMAND FUNCTIONS. FIG. 9a Reference Name Alarm icon Refrigerant compressor icon Fan icon Dryer ON PDP indicator Button to snooze or to reset the alarm SET button UP button...

- Page 10 ENGLISH REMOTE ALARM FUNCTION The controller allows to remotely control a number of alarms. This is managed by means of a free NC (Normally Closed) contact. The contact opens in case of an alarm or when the dryer is switched off. Refer to the table below to identify the availability of the function and refer to the related picture Fig.

-

Page 11: Partial Routine Maintenance

ENGLISH PART “B” THIS PART “B” OF THE INSTRUCTIONS MANUAL IS RESERVED FOR PROFESSIONALLY SKILLED PERSONNEL APPROVED THE MANUFACTURER. 16.0 PARTIAL ROUTINE MAINTENANCE BEFORE CARRYING OUT ANY MAINTENANCE JOBS IT IS OBLIGATORY TO STOP THE MACHINE AND DISCONNECT IT FROM THE POWER MAINS AND FROM THE COMPRESSED AIR DISTRIBUTION NETWORK. -

Page 12: Trouble-Shooting And Emergency Remedies

ENGLISH 16.3 CLEANING THE CONDENSER (Fig. 10) The condenser must be cleaned every month. Proceed as follows: - Switch off the machine by pressing the STOP button Ref. 3 Fig. 10 - Turn on the supply automatic differential switch Ref. 4 Fig. 10 - Remove the panels Ref. - Page 13 ENGLISH 17.1 TROUBLE-SHOOTING AND EMERGENCY REMEDIES N.B. OPERATIONS MARKED ◼ ◼ MUST BE CARRIED OUT BY PROFESSIONALLY SKILLED PERSONNEL APPROVED THE MANUFACTURER DISPLAY FLASHING WARNING NOTES Possible root causes Observations Dryer is working OK Warning icon NOT Fan control probe failed ◼◼...

- Page 14 ENGLISH SE ALARM After 6000Hrs, the controller will issue a “SE” warning. This is the maintenance due warning. How to reset the maintenance warning: follow steps 1 to 12 DOWN Push and hold buttons “SET” and PDP is flashing between standard view Message “SE”...

- Page 15 ENGLISH PROCEDURE TO SET THE SERVICE INTERVAL ON PDP DEVICE DOWN Push and hold buttons “SET” and PDP is showing standard view. Message “SE” appears on display. “DOWN” to enter in the menu. Current service interal is displayed. Select desired service interval using Push and release “SET”...

- Page 16 ENGLISH (Option “free contact”) 17.2 TROUBLE-SHOOTING AND EMERGENCY REMEDIES N.B. OPERATIONS MARKED ◼ ◼ MUST BE CARRIED OUT BY PROFESSIONALLY SKILLED PERSONNEL APPROVED THE MANUFACTURER Possible root Disply Flashing fault message Description Observations causes Dryer is working OK Dryer is working OK Warning icon NOT Fan control probe failed ◼◼...

- Page 17 ENGLISH EE ALARM EE alarm is shown when internal EPROM errors happens, if this warning will appear, the dryer will stop running. The error can be reset by pressing one of the four buttons of the controller, anyway please replace the controller itself. NOTE: In case of EE alarm please contact your tech support.

- Page 18 ENGLISH How to reset the maintenance warning: follow steps 1 to 12 DOWN Push and hold buttons “SET” and PDP is flashing between standard view Message “SE” appears on display. “DOWN” to enter in the menu. and “SE” alarm Message “rS” appears on display. Push and release button “SET”.

- Page 19 ENGLISH PROCEDURE TO SET THE SERVICE INTERVAL ON PDP DEVICE DOWN Push and hold buttons “SET” and PDP is showing standard view. Message “SE” appears on display. “DOWN” to enter in the menu. Current service interal is displayed. Select desired service interval using Push and release “SET”...

-

Page 20: Starting Up

ENGLISH 18.0 STARTING UP BEFORE CARRYING OUT ANYOPERATION ON THE MACHINE, ENSURE THAT THE ELECTRIC POWER SUPPLY HAS BEEN DISCONNECTED 18.1 PRELIMINARY CONTROLS Before starting the dryer, check: - The correct connection to the compressed air piping: remember to remove eventual caps on the drier inlet and outlet. - The correct connection to the condensate drainage system. - Page 21 ENGLISH CALIBRATIONS BYPASS VALVE FOR HOT GAS N.B.These valves have already been calibrated and they do not require any adjistment. A dew point different from the rated one generally depends on causes which are not attributable to their operation. Ref. 1) Closing cap Ref.

Need help?

Do you have a question about the QPNC83 and is the answer not in the manual?

Questions and answers