HEIDENHAIN TNC 640 Manual

Contouring control for machining centers and milling/turning machines

Hide thumbs

Also See for TNC 640:

- User manual (948 pages) ,

- Operating instructions manual (64 pages) ,

- User manual (903 pages)

Summary of Contents for HEIDENHAIN TNC 640

- Page 1 TNC 640 Contouring Control for Machining Centers and Milling/Turning Machines March 2014...

- Page 2 This brochure describes the functions and specifi cations of the TNC 640 with NC software 34059x-04...

-

Page 3: Table Of Contents

– Dynamic Precision Machining with five axes – The TNC 640 permits optimum tool movement – Guided tool tip – Swivel head and rotary table controlled by the TNC 640 Intelligent machining – Dynamic collision monitoring (DCM) – Dynamic Efficiency –... -

Page 4: The Tnc 640

TNC 640. It is just as easy to ters. While the controls have undergone machine, in plain language dialog—the... - Page 5 Universally applicable High speed milling Machining centers and automated The TNC 640 is particularly well suited for • Fast block processing machining milling, turning, HSC and 5-axis machining • Short control-loop cycle time • Tool management on machines with up to 18 axes. The TNC •...

-

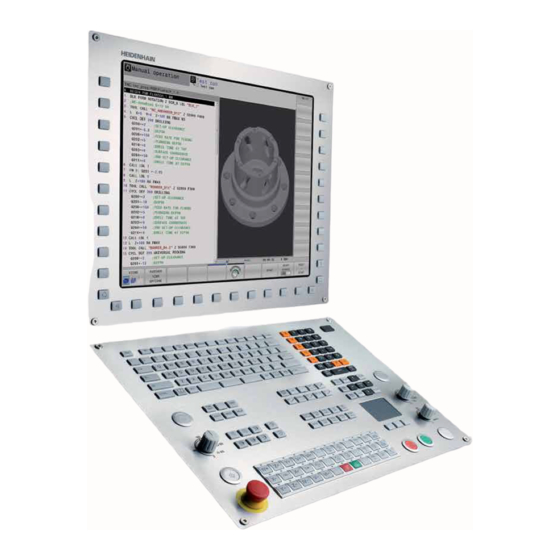

Page 6: Well Designed And User Friendly

Well designed and user friendly – The TNC 640 in dialog with the user The screen The large 19-inch TFT color fl at panel display with shows a clear overview of all relevant information for programming, operating and inspecting the machine tool and control: Program blocks, notes, error messages, etc. - Page 7 Durable status The high-quality stainless steel design of the TNC 640 features a special protection coating and is therefore highly resistant to PLC function keys (soft keys) for machine soiling and wear. functions...

-

Page 8: The Functional User Interface

The combination of the straightforward and Attractive view Fast function overview ergonomically designed keyboard and the The user interface of the TNC 640 has a With smartSelect you enjoy dialog well-designed screen layout are the es- modern appearance, with lightly rounded guidance for selecting functions quickly sence of reliable and fatigue-free operation. - Page 9 TNC 640 are shown in different Info line colors. The color syntax highlighting In the info line, the TNC 640 shows the improves your overview when editing NC respective submode condition and helps programs. It enables you to see at a you to orient yourself.

-

Page 10: Multi-Operation Machining

Multi-operation machining – Milling and turning on one machine (option) Does your workpiece, after complex milling The TNC 640 offers you powerful functions Programming as accustomed operations, also need to be set up on a that enable you to switch the NC program You can program the turning operations—... - Page 11 Frequently recurring operations that machine. comprise several steps are also stored in the TNC 640 as cycles. You program them In the more sophisticated contour turning under conversational guidance and are cycles, the TNC 640 uses the same tech- supported by valuable help graphics that niques as are used for milling.

-

Page 12: Quick And Reliable Machining With High Contour Accuracy

Quick and reliable machining with high contour accuracy – Uniformly digital control design Thanks to its digital design, the TNC 640 Highest contour accuracy and surface The Advanced Dynamic Prediction feature has control over the machine’s entire drive quality (ADP) expands the conventional look-ahead system. - Page 13 In the uniformly digital control concept of This achieves a high degree of availability machined contour—apart from the NC the TNC 640, all components are con- for the entire system. It can be diagnosed program. You simply enter in the control nected to each other via purely digital and is immune to noise—for everything...

-

Page 14: Dynamic Precision

The hypernym Dynamic Precision stands All the deviations are together responsible The machine tool builder can use the for a number of HEIDENHAIN solutions for for dimensional errors and faults in the options comprised by Dynamic Precision milling that can dramatically improve the workpiece surface. -

Page 15: Machining With Five Axes

Machining with five axes – The TNC 640 permits optimum tool movement Modern machines often work with four or 3-D contour machining at its finest The TNC 640 looks ahead and thinks with five positioning axes. This makes it possible The TNC 640’s short block processing... -

Page 16: Guided Tool Tip

CAM systems use postprocessors to Regardless of what type of 5-axis generate 5-axis programs. In principle, such programs you wish to run, the TNC 640 programs contain either all coordinates of makes all the compensating movements in the machine’s existing NC axes, or NC the linear axes that result from movements blocks with surface normal vectors. - Page 17 • During peripheral milling, machining is adjust it manually with an electronic mainly by the side of the tool. The tool tip handwheel. The TNC 640 makes sure that also travels on a straight path, but the tool remains on the contour and does additionally the tool’s circumference...

-

Page 18: Swivel Head And Rotary Table Controlled By The Tnc 640

The and programming work. Here the TNC 640 workpiece drawing. Clearly arranged TNC supports you with application-oriented helps you to save a great deal of support graphics assist you during input. - Page 19 Machining cylindrical surfaces* Manual axis motion in the tool direction Linear feed rate for rotary tables in With the TNC 640 it is quite easy to on 5-axis machines mm/min* program contours (consisting of straight The safe retraction of a tool is very...

-

Page 20: Intelligent Machining

It is also active in manual operation. If, for example, during setup the machine operator takes a collision course, the TNC 640 detects it, stops axis movement, and issues an error message. * These functions must be implemented in the... - Page 21 Of course the TNC 640 also shows the The tool is automatically considered a When using the dynamic collision machine operator—both with an error cylinder of the tool radius (defined in the monitoring, please note: message and graphically—which machine tool table). For tilting devices, the machine •...

-

Page 22: Dynamic Efficiency

– Dynamic Efficiency With the concept of Dynamic Efficiency, Dynamic Efficiency comprises three Each solution in itself offers decisive HEIDENHAIN offers innovative TNC software TNC functions: advantages in the machining process. But functions that help the user to make heavy •... -

Page 23: Active Chatter Control (Acc)

Strong milling forces come into play during To reduce the inclination to chattering, roughing (power milling). Depending on the HEIDENHAIN now offers an effective tool spindle speed, the resonances in the antidote with the Active Chatter Control machine tool and the chip volume (metal- (ACC) control function. -

Page 24: Adaptive Feed Control (Afc)

Besides the feed rate for each block or “control” mode. Of course, various overl- Tool monitoring cycle, HEIDENHAIN controls have always oad reactions can be provided for, which The TNC's adaptive feed rate control allowed the programmer to enter a manual... -

Page 25: Machining Any Contour Slots With Trochoidal Milling

Intelligent machining – Machining any contour slots with trochoidal milling The benefit of trochoidal milling is its ultra- With trochoidal milling, on the other hand, The slot to be machined is described in efficient machining of slots of all kinds. large cutting depths are possible since a contour subprogram as a contour train. -

Page 26: Minimize Setup Times

Minimize setup times – The TNC 640 makes setup easy Before you can begin machining, you must Delicate manual traverse Workpiece alignment first clamp the tool and set up the machine, For setup, you can use the direction keys With HEIDENHAIN touch probes (see page... - Page 27 The TNC 640 features probing cycles for In the datum management you can save automatic presetting. Once found, you can any number of datums and assign an save these datums individual basic rotation to each one.

-

Page 28: Automated Machining

Automated machining – The TNC 640 measures, manages and communicates The difference in requirements placed on Inspecting workpieces for proper Milling cutter measurement and the classical machine for tool and mold- machining and dimensional accuracy automatic compensation of tool data... - Page 29 Pallet management For machining centers with automatic tool The TNC 640 can assign the appropriate changers, the TNC 640 offers a central tool part program and datum shift to parts memory for any number of milling and mounted on pallets and brought to the turning tools.

-

Page 30: Programming, Editing, Testing

Programming, editing, testing – The TNC 640 opens endless possibilities The TNC 640 is just as universal in Programming at the machine application as it is fl exible in machining and HEIDENHAIN controls are workshop And if you are used to G-code program- programming. -

Page 31: Graphic Support In Any Situation

Program-run graphics The two-dimensional programming To be on the safe side before running a On the TNC 640, you can run the program- graphics give you additional security: while program, the TNC can graphically simulate run graphics or verification graphics even you are programming, the TNC 640 draws the machining progress. -

Page 32: Programming In The Workshop

– Straightforward function keys for complex contours Programming 2-D contours Straight and circular contour elements The TNC 640 can look ahead over a radius- To program a line segment, for example, compensated contour for up to 99 blocks simply press the key for linear traverse. The... -

Page 33: Programming Contours Unconventionally

Not all workpieces are dimensioned for (option) conventional NC programming. Thanks to The TNC 640 provides special contour FK, the control’s free contour programming elements to enable you to defi ne recesses feature, in such cases you simply type in and undercuts. -

Page 34: Field-Proven Cycles For Recurring Operations

Programming in the workshop – Field-proven cycles for recurring operations Comprehensive fi xed cycles for Cycles for complex contours The TNC 640 maintains a fi nishing Clearing pockets with combined contours allowance on the wall and fl oor surfaces milling, drilling and boring is aided greatly by Subcontour List cycles during roughing. - Page 35 TNC 640, you can program very diverse easily be described mathematically. Here cycles and saving them in the TNC 640. machining patterns simply and extremely you can use the basic arithmetical ope- However, the end user can write his own fl exibly—of course with graphic support.

-

Page 36: Field-Proven Turning Cycles

Naturally, contours elements recess and undercut interface, however, is inspired in its look the TNC 640 fully automatically takes the are available, which you can insert between and functionality by the familiar and proven angle of the turning tool into account. - Page 37 Recessing Thread machining Orientation of the turning tool In this area, as well, the TNC 640 Simple and expanded cycles are available On milling/turning machines it can be distinguishes itself with ample flexibility for longitudinal and transverse machining of necessary to incline the tool during turning and functionality.

-

Page 38: Reusing Programmed Contour Elements

Many machining operations repeat at any place in your current program. This position or in a different size, the TNC 640 themselves either on the same workpiece gives you convenient access to pre-pro- offers you a simple solution: coordinate or on different workpieces. -

Page 39: Fast Availability Of All Information

TNC TNC hard disk. screen. TNCguide integrated in the control, e.g. on the TNC 640 ... … or at the programming station. -

Page 40: Open For Communication

Open for communication – The TNC 640 understands DXF fi les (option) Why program complex contours when As a rule, DXF fi les contain multiple layers, The TNC also supports you when defi ning your drawing is already in DXF format with which the designer organizes the the workpiece preset. - Page 41 You can defi ne the following locations as Contour selection is exceptionally user This can be done very easily: Using the reference point: friendly. You select any element by clicking mouse, simply select the desired area. In a • The beginning, end or mid-point of a line it with the mouse.

-

Page 42: Fast Data Transfer With The Tnc

The transmitted programs are saved in the Programs for data transfer The TNC 640 can be integrated into internal memory of the TNC 640 and are With the aid of the free PC software networks and connected with PCs, run from it at high speed. -

Page 43: Display Any File Formats On The Tnc Screen

– Display any file formats on the TNC screen The new integrated PDF viewer enables The following further file formats can also the user to open PDF files directly on the be opened directly on the TNC with control. The PDF format is a widely used corresponding editors, and sometimes data format that can be generated out of a edited. -

Page 44: The Tnc 640 Programming Station

It’s well known that it is easy to create part Of course you can also test programs that The programming station software runs on programs on a TNC 640 at the machine, were written on a CAD/CAM system. The a PC. The PC screen shows you the TNC even while another part is being machined. -

Page 45: Workpiece Measurement

The ruby ball tips are available in several diameters, and the styli in different lengths. * The touch probes must be interfaced to the TNC 640 by the machine tool builder. SE 640 TS 230... -

Page 46: Tool Measurement

TNC 640. tooth, are necessary. HEIDENHAIN offers the TT trigger tool touch probes as well as... -

Page 47: Inspecting And Optimizing Machine Accuracy

HEIDENHAIN touch probe. But first you (measure for the static tilting accuracy), as and reproducible accuracy even over long define the resolution of the measurement well as the actual compensation values. -

Page 48: Positioning With The Handwheel

• Soft keys for machine functions defi ned The panel-mounted handwheels from by the machine tool builder HEIDENHAIN can be integrated in the machine operating panel or mounted at another location on the machine. An adapter permits connection of up to three HR 150 electronic handwheels. -

Page 49: Overview

A total of 14 additional NC axes or 13 additional NC axes plus second spindle • Digital current and speed control Program entry • HEIDENHAIN conversational • DIN/ISO programming Direct loading of contours or machining positions from DXF files and saving as conversational contouring program or as point table Position entry •... - Page 50 Collision monitoring Dynamic Collision Monitoring (DCM) Graphic depiction of the active collision objects FK free contour • FK free contour programming in HEIDENHAIN conversational format with graphic support for programming workpiece drawings not dimensioned for NC Program jumps • Subprograms •...

- Page 51 Complete list of all current error messages • Context-sensitive help function for error messages • TNCguide: The integrated help system. User information available directly on the TNC 640 • Graphic support for programming cycles • Comment and structure blocks in the NC program •...

- Page 52 • Keeping the tool normal to the contour • Tool radius compensation normal to the tool direction • Manual traverse in the active tool-axis system HEIDENHAIN DNC 526451-01 Communication with external PC applications over COM component...

- Page 53 Option Option As of NC Remark number software 340 59x- Display step 632986-01 Display step to 0.01 µm or 0.000 01° DCM collision 526452-01 Dynamic Collision Monitoring (DCM) DXF converter 526450-01 Load and convert DXF contours Adaptive Feed Control 579648-01 Adaptive Feed Control (AFC) Python OEM process...

- Page 54 • 2 x Gigabit Ethernet interface 1000BASE-T • 5 x USB (1 x front USB 2.0, 4 x USB 3.0) HEIDENHAIN-DNC for communication between a Windows application and TNC (DCOM interface) Diagnostics • Fast and simple troubleshooting through integrated diagnostic aids Ambient temperature •...

- Page 55 (up to 18 axes + 2 spindles) • Milling/turning operation (up to 18 axes + 2 spindles) – Option – Program entry • HEIDENHAIN conversational format • According to ISO • DXF converter...

- Page 56 Dr.-Johannes-Heidenhain-Straße 5 83301 Traunreut, Germany { +49 8669 31-0 | +49 8669 5061 E-mail: info@heidenhain.de Vollständige und weitere Adressen siehe www.heidenhain.de For complete and further addresses see www.heidenhain.de www.heidenhain.de HEIDENHAIN Vertrieb Deutschland FARRESA ELECTRONICA S.A. 83301 Traunreut, Deutschland 08028 Barcelona, Spain 02-384 Warszawa, Poland ...

Need help?

Do you have a question about the TNC 640 and is the answer not in the manual?

Questions and answers