Table of Contents

Advertisement

Quick Links

Knowhow is the difference

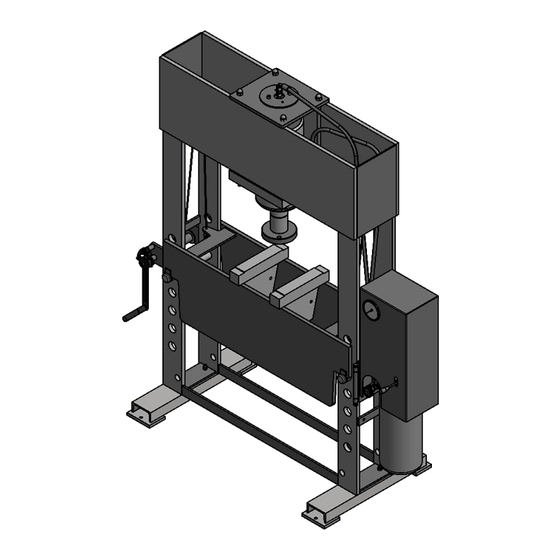

Operation Manual for Compac

Workshop Press

Model EP40 G6/G7, EP40D G6/G7,

EP60 G6/G7, EP60D G6/G7

Original instructions

Please carefully read all information within this manual, before using this product,

Upon request, this operation manual is also available in other languages at no additional cost.

(EN)

1/29

2018-03-21 S5

EP40-EP40D G6_G7 - EP60- EP60D G6_G7 (EN) 2018_03_21 R2 S5-V2.docx

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Compac EP40 G6

- Page 1 Knowhow is the difference Operation Manual for Compac Workshop Press Model EP40 G6/G7, EP40D G6/G7, EP60 G6/G7, EP60D G6/G7 Original instructions Please carefully read all information within this manual, before using this product, Upon request, this operation manual is also available in other languages at no additional cost.

-

Page 2: Use Of Compac Workshop Press

The Compac workshop press is such a press if it is used for ordinary repair work in a workshop or for testing tools, without any structural changes made to the workshop press. -

Page 3: Table Of Contents

Knowhow is the difference Indhold Use of COMPAC workshop press ......................2 Specifications ............................4 Electrical Specifications ......................... 4 To the owner/user ..........................5 Warranty............................. 5 Safety ..............................6 Safety symbols ........................... 6 The required safety and information labels on the press ................ 7 Safety instructions .......................... -

Page 4: Specifications

Knowhow is the difference Specifications Max. Stroke Tractive force Net weight Piston speed Oil, quantity Capacity length Type mm/sec litres 40,000 4,000 EP40D G6/G7 (40 tons) (4 tons) 60,000 6,000 kg EP60D G6/G7 (60 tons) (6 tons) 40,000 EP40 G6/G7 (40 tons) 60,000 (60 EP60... -

Page 5: To The Owner/User

Compac Hydraulik A/S disclaims any responsibility for improper use, alterations in construction, use of non-original parts and repairs and adjustments made by unauthorized personnel. Compac Hydraulik A/S reserves the right to make changes to the product without notice, if it can be done without significant changes to the technical specifications. -

Page 6: Safety

Knowhow is the difference Safety Important: Read and understand the operating manual before transport, installation and operation! All operators must read, understand and follow all instructions and safety warnings within this operation manual and on the safety labels placed on the product before using the shop press. All operating personnel must be able to operate the press safely and care for it in accordance with this operation manual. -

Page 7: The Required Safety And Information Labels On The Press

Knowhow is the difference RISK OF TIPPING Safety symbol indicates that the product may risk tipping over and cause serious injury or death The required safety and information labels on the press (EN) 7/29 2018-03-21 S5 EP40-EP40D G6_G7 - EP60- EP60D G6_G7 (EN) 2018_03_21 R2 S5-V2.docx... - Page 8 Knowhow is the difference Pos 1 Pos 2 Pos 3 Pos 4 (EN) 8/29 2018-03-21 S5 EP40-EP40D G6_G7 - EP60- EP60D G6_G7 (EN) 2018_03_21 R2 S5-V2.docx...

- Page 9 Knowhow is the difference Pos 5 Pos 6 WARNING When performing work with the press and operating the winch, fingers, hands and other body parts must not be at risk of becoming trapped ! The operator may not use the press: •...

- Page 10 Knowhow is the difference 1. Rating plate 2. WARNING. The foot must not rest on cross members or columns 3. Oil type AWS Hyspin 32 (Or the equivalent) 4. WARNING. Risk of being caught between table and pin 5. WARNING. Operation of the press 6.

-

Page 11: Safety Instructions

Knowhow is the difference Safety instructions Failure to observe the following may result in serious body injury or death, as well as possible damage to property. The work press is intended only for normal shop use and not as a production press. The press's maximum load is stated in the CE certificate and on the press's product label. -

Page 12: Component Overview

Knowhow is the difference Component overview Pos. Name V-Block Winch Frame Cylinder Pressure gauge Motor Protective motor switch/ Electrical connection Control lever up down Pressure regulation Oil container Nagel Table Compression and tension flange Only for the types EP40D, EP60D Piston Oil filling Description of Operation... -

Page 13: Transport And Installation Of The Press

Knowhow is the difference Transport and installation of the press RISK OF TIPPING OVER With regard to safe transport of the shop press, please be aware that the press's center of gravity is very high. When shipped, the press is secured to the transport pallet with screws and metal strips, which should only be removed when setting up the press. -

Page 14: Pre-Commissioning Preparation

Knowhow is the difference Pre-commissioning preparation: An experienced operator must visually inspect the press for leakage and damage. Such inspection must furthermore take place at least once a year. The press comes filled with hydraulic oil. Connection of electricity The power connection must be carried out by a professionally trained electrician, furthermore, should be in accordance with the wiring instructions found inside of the motor's top cover. -

Page 15: Preparation Of Press Table And V Blocks

Knowhow is the difference NOTE: Because the table hangs freely from the winch during positioning, there is a risk of the table falling and causing damage or injury. Therefore, do not release the handle until one of the winch's locks is engaged with the turntable (see Fig. 4) before removing the pins. Preparation of press table and v blocks The table must be placed as close to the returned rod as possible, so that the piston always has the least possible projection (the shortest possible stroke length). -

Page 16: V-Block Or Straightening Plate

Knowhow is the difference If the object is angled or asymmetrical, there is a significant risk of injury or damage to the press's cylinder, piston or chassis (see Fig. 10). Do not press on work items that could burst or break, because this can injure persons or damage the press's cylinder, rod or frame. - Page 17 Knowhow is the difference Ensure that all cylinder bolts are retightened again before commencing any work. If the cylinder is able to move while under pressure, then there is a risk of injury or damage. Fig. 13 (EN) 17/29 2018-03-21 S5 EP40-EP40D G6_G7 - EP60- EP60D G6_G7 (EN) 2018_03_21 R2 S5-V2.docx...

-

Page 18: Setting Of Swivel-Type Pump

Knowhow is the difference Setting of swivel-type pump The pump can be firmly locked into position as shown in Fig. 15 or Fig. 16, depending upon the specific position that is most appropriate with respect to the operation and feeding in of the work items. If the pump is turned 90 degrees as shown in Fig. -

Page 19: Operation Of The Press

Knowhow is the difference Operation of the press Adjust the table to the required work height, and then place the v-blocks upon the table. Note! At pressures over 40% of the maximum capacity both v-blocks must be supporting the object. Pull the operating lever (H) up so that the piston moves returns to its start position. -

Page 20: Maintenance Instructions

Any required repair of the press must be performed by a hydraulic expert. Use of non-original parts may make the press unsafe for use and nullifies the warranty. Therefore, use only original parts from Compac for reliable and safe operation. Oil level If it becomes necessary to refill oil in the press, see the section “Periodic maintenance and inspection”,... -

Page 21: Periodic Maintenance And Inspection

Only persons certified in professional repair and maintenance of hydraulic equipment may perform the following service and maintenance of the Compac press. Use only original parts from Compac. - Page 22 Knowhow is the difference Pos. Action Oil level Retaining rings Leakage Rust Rupture Cracks in surface Table and wire Moving parts Cylinder bolts Pressure hose Pins Labels Securing washer Electrical (EN) 22/29 2018-03-21 S5 EP40-EP40D G6_G7 - EP60- EP60D G6_G7 (EN) 2018_03_21 R2 S5-V2.docx...

- Page 23 Knowhow is the difference 3. Visual inspection Check the oil level in the oil tank Action 3A: The oil level must be 90 mm from the filling hole. Use only Castrol HYSPIN AWS 32 or the equivalent. Never overfill the oil tank.

- Page 24 Knowhow is the difference Cleaning and lubrication of moving parts Action 3H: Carefully clean the press, especially the moving parts. If cleaning with soap and water, all moving parts must then be greased well afterwards before use. Check of the moving cylinder function Action 3J: Loosen the bracket for the moving cylinder and move the cylinder from side to side.

- Page 25 Check the press markings Action 3M: Check that all labels and warnings are intact and legible. If not, obtain new labels and warnings by contacting Compac. Check the electrical installation of the press Action 3P: Inspection of electrical installation must be performed by a certified electrician.

- Page 26 Knowhow is the difference Defective wire (see 3G) Fig. 1 Defective pressure hose (see 3K) Fig. 2 (EN) 26/29 2018-03-21 S5 EP40-EP40D G6_G7 - EP60- EP60D G6_G7 (EN) 2018_03_21 R2 S5-V2.docx...

-

Page 27: Service Log

Knowhow is the difference Service log Date Performed by Remarks Next service d/m/y Stamp or signature d/m/y (EN) 27/29 2018-03-21 S5 EP40-EP40D G6_G7 - EP60- EP60D G6_G7 (EN) 2018_03_21 R2 S5-V2.docx... -

Page 28: Press Accessories

Knowhow is the difference Press accessories The press can be ordered with the following optional accessories. Optional Protective Guard If there is a danger of objects or tools being ejected from the pressing area, then a protective guard must be used or alternative protection which provides the same level safety. Shelf Mandrel Ball bearing... -

Page 29: Appendix - Supplied On Delivery Of The Press

Knowhow is the difference Mandrel set The press's standard pressure head is removed by unscrewing the small finger screw and pulling out the pressure head/nose. The set includes a pressure head/adaptor, the largest end of which should be facing up towards the piston, replacing the standard pressure head/nose. The selected mandrel is mounted in the adaptor and secured with the small screw on the side of the adapter.

Need help?

Do you have a question about the EP40 G6 and is the answer not in the manual?

Questions and answers