Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for BlastPro BRB-1500

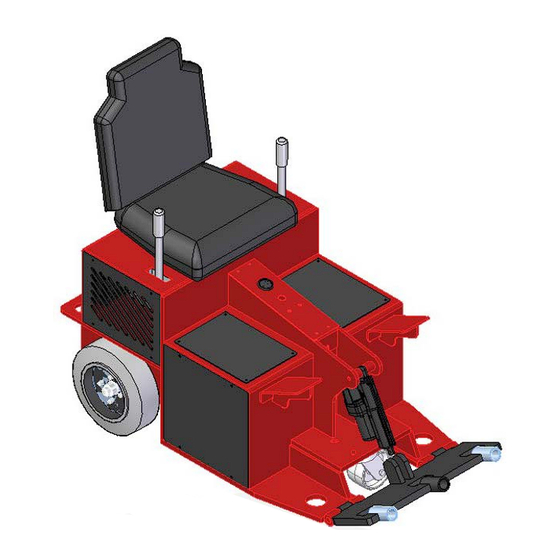

- Page 1 BRB-1500 MACHINE MANUAL...

-

Page 2: Table Of Contents

Table of Contents SECTION 1.1: APPLICATIONS ................4 SECTION 1.2: SPECIFICATIONS ...............4 SECTION 1.3: MANUFACTURER ...............4 SECTION 2.1: GENERAL ..................6 SECTION 2.2: MAINTENANCE AND WEAR PART REPLACEMENT MODES ..6 SECTION 2.3: WORK SITE ASSESSMENT AND INSPECTION ......7 SECTION 2.4: PERSONAL PROTECTIVE EQUIPMENT (PPE) ......9 SECTION 2.5: OPERATIONAL SAFETY.............9 SECTION 3.1: START-UP .................11 FIGURE 3.1.1 ....................12... -

Page 3: Section 1.1: Applications

MACHINE MANUAL BRB-1500 SPECIFICATIONS SECTION 1.1: APPLICATIONS SECTION 1.2: SPECIFICATIONS SECTION 1.3: MANUFACTURER ® © 2013 Blastpro Manufacturing Inc. -

Page 4: Section 1.2: Specifications

Coatings may include glue, epoxies and cementitious overlays. Coverings may include carpet, ceramic tile, and VCT. A wide variety of tools are available from Blastpro® for your specific application. In general, the BRB-1500 uses sharpened spring steel blades along with the weight of the machine itself to perform the scraping function. -

Page 5: Section 2.1: General

MACHINE MANUAL BRB-1500 SAFETY SECTION 2.1: GENERAL SECTION 2.2: MAINTENANCE AND WEAR PARTS REPLACEMENT MODES SECTION 2.3: WORK SITE ASSESSMENT AND INSPECTION SECTION 2.4: PERSONAL PROTECTIVE EQUIPMENT SECTION 2.5: OPERATIONAL SAFETY ® © 2013 Blastpro Manufacturing Inc. - Page 6 BRB-1500. Make these operating instructions accessible to all operating and maintenance personnel. Never weld, modify, cut or grind components of the BRB-1500 without prior written consent from the manufacturer. Never use aggressive cleaning chemicals to clean the machine.

- Page 7 THREAT TO THOSE WHO INHALE OR COME INTO CONTACT WITH THE DUST. THE WORK AREA MUST BE CHECKED FOR THESE MATERIALS BEFORE WORK BEGIN. BLASTPRO MANUFACTURING, INC. DOES NOT WARRANT ITS EQUIPMENT TO BE SUITABLE FOR, OR APPROVED FOR, REMOVING DANGEROUS ® © 2013 Blastpro Manufacturing Inc.

- Page 8 The operator must be aware of their surroundings and use common sense. THE OPERATOR IS NOT TO OPERATE THE EQUIPMENT IF HE IS TIRED, DISTRACTED, OR UNDER THE INFLUENCE OF DRUGS, ALCOHOL, MEDICATION THAT DECREASES AWARENESS. ® © 2013 Blastpro Manufacturing Inc.

-

Page 9: Section 2.4: Personal Protective Equipment (Ppe)

MACHINE MANUAL BRB-1500 SAFETY SECTION 2.4: PERSONAL PROTECTIVE EQUIPMENT (PPE) All personnel working with, or in the vicinity of the BRB-1500 should, at a minimum, utilize the following PPE: Protective boots or shoes Eye protection with side shields ... -

Page 10: Section 3.1: Start-Up

MACHINE MANUAL BRB-1500 OPERATION SECTION 3.1: START-UP SECTION 3.2: SHUT DOWN SECTION 3.3: BLADE SELECTION SECTION 3.4: TRANSPORT ® © 2013 Blastpro Manufacturing Inc. - Page 11 5. Push rocker switch on the right control lever to raise the blade. 6. Push levers forward to move forward; pull backward to reverse. Varying positions of the left and right control levers will turn the BRB-1500 left and right.

- Page 12 9. Depress E-stop. 10. Cover the BRB-1500 to protect it from dust and moisture. CAUTION: Many of the components on the BRB-1500 are not meant to be exposed to high levels of moisture. It is critical, especially if the machine is stored in a location exposed to the elements, that it be protected from rain, splashing or other high levels of water.

- Page 13 FIGURE 3.3.1 For carpet, rubberized and elastomeric coatings, a carpet blade should be utilized. The 90° wings on each end of the blade will help keep the removed material manageable. SEE FIGURE 3.3.2. FIGURE 3.3.2 ® © 2013 Blastpro Manufacturing Inc.

-

Page 14: Section 3.4: Transport

MACHINE MANUAL BRB-1500 OPERATION Blastpro offers a carbide tipped tool for tile removal. This can be inserted into the 3-hole tool adapter on the blade holder. SEE FIGURE 3.3.3 FIGURE 3.3.3 SECTION 3.4: TRANSPORT Only use factory installed tie-down/lifting lugs when transporting or moving the equipment. - Page 15 Verify that the blade holder is lowered and that the front swivel caster is off of the truck or trailer bed. Never allow personnel to stand under the machine when it is being lifted. ® © 2013 Blastpro Manufacturing Inc.

-

Page 16: Section 4.1: Maintenance Intervals

BRB-1500 MAINTENANCE SECTION 4.1: MAINTENANCE INTERVALS SECTION 4.2: TROUBLESHOOTING SECTION 4.3: MOTOR CONTROLLER FAULT CODES SECTION 4.4: BATTERY CHARGING SECTION 4.5: RECOMMENDED SPARE PARTS SECTION 4.6: RECOMMENDED TOOLS SECTION 4.7: PARTS LIST AND DRAWINGS ® © 2013 Blastpro Manufacturing Inc. - Page 17 MAINTENANCE SECTION 4.1: MAINTENANCE INTERVALS Daily, or at the beginning of each shift If additional assistance is required consult your Blastpro representative, authorized Blastpro distributor, or qualified electric systems professional. Always wear leather gloves and use caution when handling blades.

-

Page 18: Section 4.2: Troubleshooting

Batteries do not receive a Extension cord is too Use a shorter or bigger full charge long or too small extension cord. Always use the shortest possible cord. ® © 2013 Blastpro Manufacturing Inc. -

Page 19: Section 4.3: Motor Controller Fault Codes

Disengage the engaged after brake switch. machine start 02A48/0$A48 Machine will not Improperly Charge battery move after battery charged or replace charge. battery. defective battery. 02A29 Reduced ground Excessively Charge drive speed. low battery. battery. ® © 2013 Blastpro Manufacturing Inc. -

Page 20: Section 4.4: Battery Charging

Note: Even after relatively short periods of charging, about 2-3 hours, the battery indicator may initially read 100% charge. This is an indication of the surface charge of the battery, and will decrease quickly to the actual percentage of ® © 2013 Blastpro Manufacturing Inc. -

Page 21: Section 4.5: Recommended Spare Parts

SECTION 4.6: RECOMMENDED TOOLS “Recommended Tools” is a list of the minimum tools necessary to maintain and/or operate the BRB-1500 during normal operation. This list is not meant to be exhaustive or to indicate the tools required for more intensive maintenance. -

Page 22: Section 4.7: Parts List

REAR TRANSAXLE COVER BP92000017 SIDE BATTERY COVER BP92000020 HYDRAULIC CYLINDER BP92000023 STEERING SHAFT BP9200008 RTN ASSEMBLY BP92000026 RTN BRACKET BP92000019 HANDLE LINKAGE BP9200008 RTN ASSEMBLY BP85000012 JOYSTICK 3-POSITION SWITCH BP85000011 JOYSTICK STANDARD BP92000011 ZT WIRING HARNESS ® © 2013 Blastpro Manufacturing Inc. - Page 23 MACHINE MANUAL BRB-1500 MAINTENANCE ® © 2013 Blastpro Manufacturing Inc.

- Page 24 MACHINE MANUAL BRB-1500 MAINTENANCE ® © 2013 Blastpro Manufacturing Inc.

Need help?

Do you have a question about the BRB-1500 and is the answer not in the manual?

Questions and answers