Table of Contents

Advertisement

Quick Links

Repair/Parts

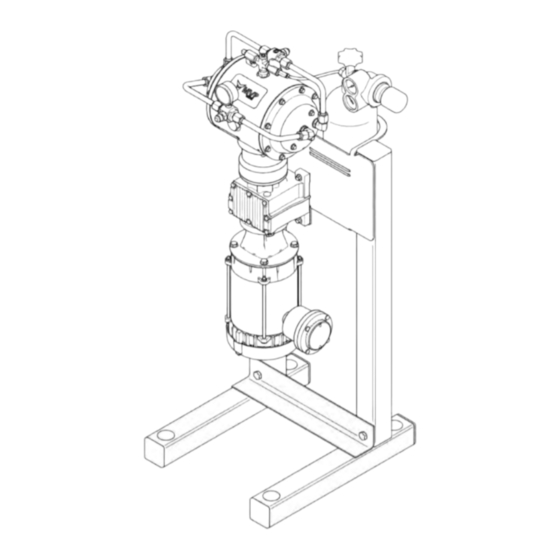

MODEL MVP-6CFM

VAPOR RECOVERY PUMP

Designed for hydrocarbon extraction processing.

For LP-Gas Recovery

Electric-Powered

Dual-Diaphragm

Explosion-Proof Motor

Stainless Steel Wetted Parts

Rated Maximum Allowable

Withstand Pressure (MAWP): LPG-350-PSI

For professional use only.

Important Safety Instructions

Read all warning and instruction in this manual

and in the pump Operation manual.

Save these instructions.

3A5263F EN

Advertisement

Table of Contents

Summary of Contents for Master MVP-6CFM

- Page 1 Repair/Parts MODEL MVP-6CFM VAPOR RECOVERY PUMP 3A5263F EN Designed for hydrocarbon extraction processing. For LP-Gas Recovery Electric-Powered Dual-Diaphragm Explosion-Proof Motor Stainless Steel Wetted Parts Rated Maximum Allowable Withstand Pressure (MAWP): LPG-350-PSI For professional use only. Important Safety Instructions Read all warning and instruction in this manual and in the pump Operation manual.

-

Page 2: Table Of Contents

1 Phase MVP-6CFM-3PH 1 HP 3 Phase Related Manuals Manual Number Title 3A5262 Model MVP-6CFM Vapor Recovery Pump, Operation Approvals Motor Approvals Explosion-proof for Class I, Division 1 (C1D1) hazardous areas Class I Group C&D, Class II Group F&G, T3C 3A5263F... -

Page 3: Warnings

Warnings Warnings The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. - Page 4 Warnings WARNING EQUIPMENT MISUSE HAZARD Misuse can cause death or serious injury. • Do not operate the unit when fatigued or under the influence of drugs or alcohol. • Do not exceed the maximum working pressure or temperature rating of the lowest rated system component.

- Page 5 Warnings WARNING BURN HAZARD Equipment surfaces can become very hot during operation. To avoid severe burns: • Do not touch hot equipment. PERSONAL PROTECTIVE EQUIPMENT Wear appropriate protective equipment when in the work area to help prevent serious injury, including eye injury, hearing loss, inhalation of fumes, and burns. This protective equipment includes but is not limited to: •...

-

Page 6: Troubleshooting

Troubleshooting Troubleshooting • Follow the Pressure Relief Procedure, page 7 before checking or servicing the equipment. • Check all possible problems and causes before disassembly. Problem Cause Solution Pump cycles but will not prime and/or Pump head center section has no Check CO supply, adjust CO to 70... -

Page 7: Repair

Repair Repair This equipment stays pressurized until pressure is relieved manually. To help prevent serious injury from pressurized vapor, follow the Pressure Relief Procedure when you stop pumping for an extended To avoid serious injury or death from fumes or period of time, and before you clean, check, or fluids: service the equipment. -

Page 8: Check Valve Repair

Repair Check Valve Repair 6. Use a 2.5 mm hex wrench or star screwdriver to remove the inlet check valve screw. Repeat for the outlet check valve. Manifold tubing may become hot during operation. Prior to removal, ensure that tubing has cooled enough to handle safely. -

Page 9: Diaphragm Repair

Repair Diaphragm Repair Manifold tubing may become hot during operation. Prior to removal, ensure that tubing has cooled enough to handle safely. Disassemble the Diaphragms NOTE: Diaphragm kit is available. See Parts section. 1. Follow the Pressure Relief Procedure, page 7 Remove power from the motor. - Page 10 Repair Reassemble the Diaphragms 8. Repeat to install the other diaphragm assembly. 9. Attach the diaphragm covers and vapor caps. Apply medium-strength (blue) thread locker to the TIP: If you are also repairing or servicing the screw threads. See Torque Instructions, page center section (drive shaft, piston, etc.), see to tighten.

-

Page 11: Center Section Repair

Repair Center Section Repair 5. Slide the piston assembly (102) out of the center. 6. Leave the gearbox coupler (114) attached to the gearbox shaft (118) unless it is damaged. If you need to remove it, first remove the screws (128) and the access cover (126) on the alignment housing. - Page 12 Repair Reassemble the Center Section 1. Clean and dry the center housing (101), the 5. If removed, install the gearbox coupler (114) in center of the piston (102) and the drive shaft the alignment housing (116) until the coupler (112). seats securely on the shaft.

- Page 13 Repair Apply medium-strength (blue) thread locker to threads. Torque to 15–25 ft-lb (20–34 N•m). Lips must face IN toward the center. Apply anti-seize lubricant liberally on the radial surfaces of the drive shaft assembly. Install the drive shaft assembly with the groove facing up.

- Page 14 Repair Replace Center Bearing 7. Remove the bearing (D). Use the lower holes on the medium-sized jaw, and the outer holes on the puller. NOTE: Follow this procedure only if you suspect that the center bearing is damaged. It is not necessary to replace the bearing for normal pump service.

- Page 15 Repair Disconnect the Motor and Gearbox NOTE: Normally, the motor remains connected to the 5. Remove the screws (128) and the access gearbox. Disconnect the motor only if you suspect cover (126) on the alignment housing. Turn the that the motor or gearbox must be replaced. gearbox coupler (114) until you have access to the screw (115) on the coupler.

- Page 16 Repair Center Section Leak Testing 1. Perform the Pressure Relief Procedure, page 7 2. Close the center section vent valve (22). 3. Open the shutoff valve on the CO cylinder. 4. Open the CO supply line valve (22). 5. Fill the equipment to 60 psi (0.41 MPa, 4.1 bar) with CO and close the shutoff valve on the CO cylinder.

-

Page 17: Torque Instructions

Torque Instructions Torque Instructions If diaphragm cover or vapor cap fasteners have been loosened, it is important to torque them using the following procedure to improve sealing. NOTE: Cover and cap screws have a thread-locking adhesive patch applied to the threads. If this patch is excessively worn, the screws may loosen during operation. -

Page 18: Parts

Parts Parts 3A5263F... - Page 19 Parts Parts/Kits Quick Reference Use this table as a quick reference for kits. Go to the kit table on page 20 for a full description of kit contents. Qty. Qty. Ref. Kit Ref Description Ref. Kit Ref Description — — — See page MODULE, drive;...

- Page 20 Parts Drive Section 3A5263F...

- Page 21 Parts Kit Ref Description Kit Ref Description HOUSING, center, GEARBOX includes plugs assembly; — — — 118a COUPLER, motor drive (Refs. 123, 124) SCREW, cap, hex head, PISTON, assembly M6 x 16 mm includes BOLT, bearing; SCREW, cap, hex head, Refs.

-

Page 22: Kits And Accessories

Parts Kits and Accessories Ref. Description Qty. 25D050 Kit, stand legs, includes: Ref. Description Qty. Ref 28 1 ea Ref 27 25D028 Kit, VFD, 1–Phase 2 ea Ref 42, 43 4 ea Ref 29, 30, 31, 32 25D029 Kit, VFD, 3–Phase 6 ea 25D034 Kit, coupler, includes:Ref 113... -

Page 23: Technical Data

Technical Data Technical Data Metric Model MVP-6CFM Vapor Recovery Pump LP-Gas vapor recovery rate 6 cfm 0.17 m /min Butane recovery rate 1 lb/min 0.45 kg/min Butane recovery and re-condense rate 12 GPH 45.42 L/hour Maximum pumping outlet pressure, continuous 60 psi 0.41 MPa, 4.1 bar... -

Page 24: Mvp Standard Warranty

MVP reserves the right to make changes at any time without notice. Original Instructions. This manual contains English. MM 3A5263 MVP Headquarters: Santa Cruz Master Vapor Pumps LLC • 849 Almar Ave., Suite C, #209 • Santa Cruz CA 95060 • USA Copyright 2017, Master Vapor Pumps LLC. MasterVaporPumps.com...

Need help?

Do you have a question about the MVP-6CFM and is the answer not in the manual?

Questions and answers