Summary of Contents for Pfannenberg PTF Series

- Page 1 Operating Manual Top Filterfans / Top Exhaust Filter PTF / PTFA series 230 / 115 V Original instruction manual – Version 2.1, November 2023 V2.1...

-

Page 2: Table Of Contents

About this manual ................................4 Use and safekeeping ..............................4 Exclusion of liability ................................ 4 Target group .................................. 5 Explanation of the notes ..............................6 Marking of contents................................ 7 1.5.1 Handling instructions ..............................7 1.5.2 Links and cross references ............................7 Safety .................................... - Page 3 Service and maintenance..............................31 Safety information ................................ 31 Cleaning/replacing filter mats ............................32 Rectification of operating faults ............................. 34 General ..................................34 Decommissioning ................................35 Dismantling and disposal ............................... 36 Safety information ................................ 36 Dismantling .................................. 37 Disposal ..................................37 Spare parts and accessories ............................

-

Page 4: About This Manual

Pfannenberg reserves the right to change this document, including the exclusion of liability, at any time without notice and is not liable for any consequences of this change. -

Page 5: Target Group

Target group The different activities for handling the unit must be allocated to the target groups. The necessary personnel qualifications are subject to different legal requirements according to the application site. The owner must ensure that the applicable laws are observed. The admissible personnel and their minimum qualification are defined below insofar as this is not regulated by law. -

Page 6: Explanation Of The Notes

Explanation of the notes The warnings are indicated by signal words which express the degree of danger. The warnings must be heeded to avoid accidents, injuries and property damages. Explanation of the warnings in this manual: DANGER Brief description of the danger The signal word DANGER indicates an imminent danger. -

Page 7: Marking Of Contents

Marking of contents 1.5.1 Handling instructions Handling instructions are indicated in this manual as follows: Requirements Requirements and additional warnings Required tools and materials Tools and materials required for handling Procedure <Handling steps> … – <Intermediate result / Further instructions> …... -

Page 8: Safety

Intended use The Pfannenberg top filterfans and top exhaust filters of the PTF and PTFA series are stationary filterfans for ventilation and heat dissipation from switch cabinets and electronics housings. This is done by feeding in ambient air with a temperature below the permitted switch cabinet interior temperature. -

Page 9: Foreseeable Misuse

Foreseeable misuse The following points describe a foreseeable misuse of the unit: • Use of the unit as a storage place, work platform. • Use of the unit as a climbing aid. • Attachment of transport aids. • Installation in unsuitable locations. •... -

Page 10: Terms Of Warranty

The following must be observed to assert warranty claims and to return the unit: • Enclose a detailed description of the defect and the SRO (RMA) number assigned by Pfannenberg. • Enclose proof of purchase (copy of delivery note or invoice). -

Page 11: Unit Description

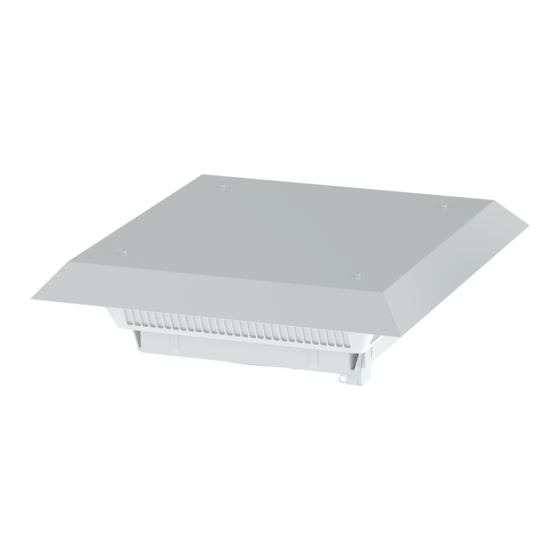

Unit description Unit structure The Pfannenberg top filterfans and top exhaust filters of the PTF and PTFA series are designed for dissipating heat from switch cabinets. • Efficient heat transport by optimum air guidance. • Tool-less assembly, quick fastening system (not for PTF1200). -

Page 12: Scope Of Delivery

PTF 1200 G00098 Fig. 2: Unit structure PTF 1200 Unit cover Fastening screws (4x) Fan motor/motor assembly Electrical connection Filter mats Equipotential bonding connection Housing The top filterfans PTF 1200 consist of the unit cover, the steel housing, the motor assembly and the filter mats. They are assembled by screwing to the switch cabinet. -

Page 13: Functional Description

PTF 1200 (air outlet) shall be combined with 2 filter kits model PFA 60.000 (air inlet) rated Type 12, or with Pfannenberg filter fan kits PFA or DPFA rated Type 12 having an area equal to or larger than the 2 filter kits model PFA 60.000. -

Page 14: Ptfa Top Exhaust Filter

The PTFA should be operated together with an opening to the air inlet which lets through sufficient air for the application and should be located in the lower third of the the switch cabinet or electronic housing to be ventilated. Pfannenberg filterfans (PF) for actively sucking in the air are typically used for this. -

Page 15: Safety Information

3.4.3 Safety information CAUTION Danger of irritation to the eyes Irritation of the eyes and muscles is possible after long exposure to the air stream. • Avoid standing in the air stream for long periods of time. 3.4.3.1 Safety devices The fan motor is equipped with a thermal or electronic winding protection device for protection against overloading. -

Page 16: Technical Data

Technical data 3.6.1 PTF 6x.xxx / PTFA 60.000 Designation Unit PTF 60.500 PTF 60.700 PTF 61.000 PTF 61.000S Type — Top filterfan Rated voltage (±10 %) 50/60 Hz 4× 4× Power consumption 50/60 Hz 80/100 75/100 120/160 110/160 120/160 28/29 29/24 Current consumption 50/60 Hz... - Page 17 Designation Unit PTFA 60.000 PTFA 60.000L Type — Top exhaust filter Weight Protection category — IP33 / IP54 °C -40 … +70 Operating temperature range °F -40 … +158 °C -40 … +75 Storage temperature range °F -40 … +167 Steel sheet, powder-coated cover Design Snap-in injection molded thermoplastic housing (ABS-FR), self-extinguishing,...

-

Page 18: Ptf 1200

3.6.2 PTF 1200 Designation Unit PTF 1200 Type — Top filterfan Rated voltage (±10 %) 50/60 Hz Power consumption 50/60 Hz Current consumption 50/60 Hz 1.40 2.20 Protection (external) Connection type — X-COM plug Air delivery volume IP54 m³/h 1000 free-blowing Air delivery volume IP54... - Page 19 ±2 G00108-01 Fig. 7: Dimensions Operating Manual | Top Filterfans / Top Exhaust Filter | – 230 / 115 V | 086150000a 19/40 V2.1...

-

Page 20: Assembly And Initial Commissioning

Assembly and initial commissioning Safety information DANGER Danger of fatal injury due to electric shock! Parts may be under voltage when the unit is opened and can cause an electric shock if touched. Observe the following points when working on the open unit: •... -

Page 21: Transport

Transport Observe the following to avoid personal injury and property damage: • Work may only be performed by qualified specialists. • Observe the safety information. Transport the unit in the original packing in operating position whenever possible. Observe the weight data in chapter "Technical data", Page 16. -

Page 22: Assembly

Assembly 4.5.1 General CAUTION Risk of cutting and injury! Risk of cutting and injury due to production-related, sharp sheet metal edges on the unit. • Use personal protective equipment (cut-proof gloves). • Handle with care. The following general requirements must be ensured for safe and reliable operation of the top filterfan: •... -

Page 23: Ptf / Ptfa 6X.xxx

4.5.2 PTF / PTFA 6x.xxx G00103 Fig. 8: Assembly cut-out/assembly Dimens Material thickness switch cabinet C ≥ 1.5 … ≤ 2 mm Material thickness switch cabinet C ≥ 2 … ≤ 3 mm 291 mm, tolerance: +1 mm, –0 mm 291 mm, tolerance: +2 …... - Page 24 Prerequisites DANGER – Danger to life due to electric shock. Make sure that the unit is voltage-free. • All general requirements are met, see "General", Page 22. Required tools and materials • • Switch cabinet mill if necessary • Protective covers Procedure Ensure that the switch cabinet has a protective cover to protect against chips.

-

Page 25: Ptf 1200

4.5.3 PTF 1200 229 mm 185 mm 30 mm G00103 Fig. 9: Assembly cut-out/assembly NOTE The general tolerances in accordance with ISO 2768-1, tolerance class "m” apply. Prerequisites DANGER – Danger to life due to electric shock. Make sure that the unit is voltage-free. •... -

Page 26: Electrical Connection

Electrical connection DANGER Danger of fatal injury due to electric shock! Parts may be under voltage when the unit is opened and can cause an electric shock if touched. Observe the following points when working on the open unit: • Work on the electrical system may only be carried out by authorized electricians. -

Page 27: Mains Connection

4.6.2 Mains connection DANGER Danger of fatal injury due to electric shock! Unconnected or incorrectly installed protective conductor systems can generate hazardous voltages and cause electrical shocks resulting in serious accidents. • Work may only be carried out by qualified specialists. •... - Page 28 4.6.2.1 Mains connection PTF 6x.xxx Fig. 10: Mains connection PTF 6x.xxx Mains terminal strip Cable 1.5 to 2.5 mm², stripping length 8 to 9 mm Strain relief (cable tie) Screwdriver (flat, max. 3.5 mm) NOTE Protective conductors in the mains connection cable are not regarded as potential equalization conductors. Prerequisite DANGER –...

- Page 29 4.6.2.2 Mains connection PTF 1200 Fig. 11: Mains plug PTF1200 Mains plug Cable 1.5 to 4 mm², stripping length 8 to 9 mm Mating plug Screwdriver (flat, max. 3.5 mm) NOTE Protective conductors in the mains connection cable are not regarded as potential equalization conductors. Prerequisite DANGER –...

-

Page 30: Equipotential Bonding Connectors (Only In Ptf 1200)

4.6.3 Equipotential bonding connectors (only in PTF 1200) Functional equipotential bonding (M6-thread), for a signal reception with low interference between the unit and the switch cabinet. G00106 Fig. 12: Equipotential bonding PTF 1200 NOTE Potential equalization provided by customer If the device is to be integrated into the customer’s existing potential equalization for EMC reasons, a conductor can be connected at the connecting point of the function potential equalization. -

Page 31: Service And Maintenance

Service and maintenance Safety information DANGER Danger of fatal injury due to electric shock! Parts may be under voltage when the unit is opened and can cause an electric shock if touched. Observe the following points when working on the open unit: •... -

Page 32: Cleaning/Replacing Filter Mats

Cleaning/replacing filter mats G00107 Fig. 13: Cleaning/replacing filter mats Phillips screwdriver Filter mats (4×) Lid screws (4×) Labeling of the filter mat Operating Manual | Top Filterfans / Top Exhaust Filter | – 230 / 115 V | 086150000a 32/40 V2.1... - Page 33 ATTENTION Damage to components Damage to the filter mats due to improper cleaning. • Avoid high-pressure water jets. • Do not wring out filter mats. • Replace oily or greasy filter mats immediately. NOTE The time intervals for cleaning or replacing the filter mats depend strongly on the contamination of the ambient air. Prerequisites •...

-

Page 34: Rectification Of Operating Faults

Rectification of operating faults General Fault Possible causes Remedial measures Fan not running No power supply. Check power supply. Unit does not sufficiently dissipate the Application limits exceeded. Check ambient air temperature and heat. internal load. Dirty filter Clean filter, replace if necessary. Fan defective. -

Page 35: Decommissioning

NOTE Old units are also professionally disposed of by Pfannenberg. Delivery to one of our manufacturing facilities shall be free of charge. Operating Manual | Top Filterfans / Top Exhaust Filter | – 230 / 115 V | 086150000a 35/40 V2.1... -

Page 36: Dismantling And Disposal

They must be taken to a separate electrical and electronic waste collection depot. For further information about disposal, scan the QR code or call www.pfannenberg.com/disposal. Safety information All work may only be performed by persons with certified qualifications under consideration of: •... -

Page 37: Dismantling

Observe the valid work safety and environmental protection regulations. Disposal NOTE Old units are also professionally disposed of by Pfannenberg. Delivery to one of our manufacturing facilities shall be free of charge. Dismantled components should be recycled unless return or disposal agreements have been made: •... -

Page 38: Spare Parts And Accessories

Spare parts and accessories NOTE Always state the Pfannenberg part number when ordering spare parts and accessories. Designation 18611600193 Filter mat (20 pieces) PTF 1200 18611600143 Filter mat (20 pieces) PTF 61.000(S), PTF 60.700, PTFA 60.000L 18611600124 Filter mat (20 pieces) PTF 60.500, PTFA 60.000... -

Page 39: 10 Index

10 Index Functional description About this document PTF top filterfan ............13 Handling instructions ............7 PTFA top exhaust filter ..........14 Accessories ..............38 Assembly Mains connection ............. 27 PTF 1200 ..............25 Misuse ................9 PTF 60.xxx ..............23 PTF 61.xxx .............. - Page 40 All the contained information has been carefully checked. However, we shall assume no liability with regard to the completeness and accuracy of the information. Company details: Pfannenberg GmbH Werner-Witt-Strasse 1 21035 Hamburg Tel. +49 40 734 12-0 www.pfannenberg.com © Pfannenberg 2023 V2.1...

Need help?

Do you have a question about the PTF Series and is the answer not in the manual?

Questions and answers