Summary of Contents for Bosch Rexroth Hyquip 10 Series

- Page 1 Axial Piston Variable Pump RE 94010-01-B/09.10 Replaces: 11.08 A7VK English Series 10 Instruction manual...

- Page 2 © This document, as well as the data, specifications and other information set forth in it, are the exclusive property of Bosch Rexroth AG. It may not be reproduced or given to third parties without its consent.

-

Page 3: Table Of Contents

RE 94010-01-B/09.10 | A7VK Series 10 Bosch Rexroth AG 3/44 Contents Contents About this document ..................4 1.1 Related documents ...................4 1.2 Abbreviations used ...................4 General safety instructions ................5 2.1 Intended use .....................5 2.2 Improper use .....................5 2.3 Personnel qualifications ................6 2.4 Safety instructions in this manual .............6... -

Page 4: About This Document

4/44 Bosch Rexroth AG A7VK Series 10 | RE 94010-01-B/09.10 About this document About this document This manual contains important information on the safe and appropriate installation, transport, commissioning, maintenance, removal and simple troubleshooting of the A7VK series 10 axial piston variable pump. -

Page 5: General Safety Instructions

For example, in ex- protection areas or in safety-related parts of a control system (functional safety). Bosch Rexroth AG shall accept no liability whatsoever for damages resulting from improper use. The user shall bear all risks arising from improper use. -

Page 6: Personnel Qualifications

6/44 Bosch Rexroth AG A7VK Series 10 | RE 94010-01-B/09.10 General safety instructions Similarly, the following predictable faulty usages are also considered to be not as intended: • Using the axial piston unit in an explosive environment • Pumping non-approved fluids as per the data sheet RE 94010, e.g. water. -

Page 7: Adhere To The Following Instructions

RE 94010-01-B/09.10 | A7VK Series 10 Bosch Rexroth AG 7/44 General safety instructions The signal words have the following meaning: Signal word Application DANGER! Indicates a large, impending danger which, if not avoided, will certainly result in death or serious injury. -

Page 8: Operator's Obligations

8/44 Bosch Rexroth AG A7VK Series 10 | RE 94010-01-B/09.10 General safety instructions During transport • Make certain that the lifting device has adequate lifting capacity. The weight can be found in chapter "5 Transport and storage". During installation • Before installation, make sure that all fluids have been removed from the axial piston unit to prevent mixing with the hydraulic fluid used in the system. -

Page 9: Delivery Contents

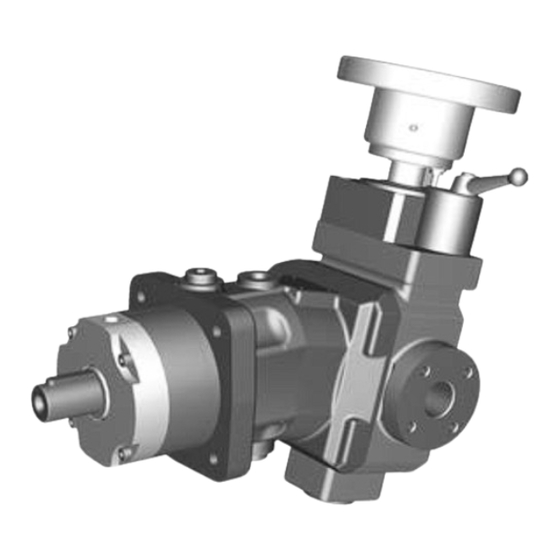

RE 94010-01-B/09.10 | A7VK Series 10 Bosch Rexroth AG 9/44 Delivery contents Delivery contents Fig. 1: Axial piston unit A7VK open design, clockwise rotation Fig. 2: Axial piston unit A7VK closed design Included in the delivery contents are: • 1 axial piston unit The following parts are also installed on delivery: •... -

Page 10: Product Description

10/44 Bosch Rexroth AG A7VK Series 10 | RE 94010-01-B/09.10 Product description Product description Risk of damage! CAuTION! The use of additives in the hydraulic fluid may affect the service life of the axial piston unit. Before commencing series production with the axial piston unit, the customer should check that the hydraulic fluid, including any additives used, is fully compatible with the axial piston unit. - Page 11 RE 94010-01-B/09.10 | A7VK Series 10 Bosch Rexroth AG 11/44 Product description Drive shaft Cylinder Tapered pistons Stroke piston Handwheel with position indicator Lens plate Adjustment spindle Drive flange For axial piston units of bent-axis design, the tapered pistons (2) are arranged at an angle to the drive shaft (1).

-

Page 12: Product Identification

12/44 Bosch Rexroth AG A7VK Series 10 | RE 94010-01-B/09.10 Product description Product identification The axial piston unit can be identified from the name plate. The following example shows an A7VK name plate: Rexroth DE - 89275 Elchingen CNR: X1234567890Y... -

Page 13: Transport And Storage

RE 94010-01-B/09.10 | A7VK Series 10 Bosch Rexroth AG 13/44 Transport and storage Transport and storage Transporting the axial piston unit CAuTION! Risk of damage! Striking or impulsive forces could damage the axial piston unit. Do not strike the coupling or drive shaft of the axial piston unit. - Page 14 14/44 Bosch Rexroth AG A7VK Series 10 | RE 94010-01-B/09.10 Transport and storage 5.1.1 Transporting with lifting device For transporting, the axial piston unit can be connected to a lifting device via a ring screw or a lifting strap. Transport with ring screw The drive shaft can be used to transport the axial piston unit as long as only outward (pulling) axial forces occur.

-

Page 15: Storing The Axial Piston Unit

RE 94010-01-B/09.10 | A7VK Series 10 Bosch Rexroth AG 15/44 Transport and storage Storing the axial piston unit Requirement • The storage areas must be free from corrosive materials and gasses. • The storage areas must be dry. • Ideal storage temperature: +5 °C to +20 °C •... - Page 16 16/44 Bosch Rexroth AG A7VK Series 10 | RE 94010-01-B/09.10 Transport and storage After removal If a dismounted axial piston unit is to be stored, it must be preserved against corrosion for the duration of the storage. If a removed axial piston unit has to be put into storage, it must be properly cleaned prior to a new preservation (depending on the hydraulic fluid used).

-

Page 17: Installation

RE 94010-01-B/09.10 | A7VK Series 10 Bosch Rexroth AG 17/44 Installation 6 Installation Prior to installation, the following documents must be available: • Installation drawing for axial piston unit (can be obtained from your responsible contact person at Rexroth) •... - Page 18 18/44 Bosch Rexroth AG A7VK Series 10 | RE 94010-01-B/09.10 Installation For the closed design, the case drain fluid in the case interior must be drained to the reservoir via the highest case drain port. Use the line size which is appropriate for the port. For the open design, a case drain line is not necessary.

-

Page 19: Installation Position

RE 94010-01-B/09.10 | A7VK Series 10 Bosch Rexroth AG 19/44 Installation Installation position The following installation positions are permissible. Other installation positions are possible after consulting with your responsible Rexroth Service contact. Preferred installation position: drive shaft horizontal. Fig. 7:... -

Page 20: Installing The Axial Piston Unit

20/44 Bosch Rexroth AG A7VK Series 10 | RE 94010-01-B/09.10 Installation Installing the axial piston unit DANGER! Systems which are in operation pose a risk of injury! Working on operating systems poses a danger to life and limb. The work steps described in this chapter must only be performed on systems which are at a standstill. - Page 21 RE 94010-01-B/09.10 | A7VK Series 10 Bosch Rexroth AG 21/44 Installation 6.4.2 Dimensions The installation drawing contains the dimensions for all connections and ports on the axial piston unit. Also observe the manuals provided by the manufacturers of the other components when selecting the required tools.

- Page 22 22/44 Bosch Rexroth AG A7VK Series 10 | RE 94010-01-B/09.10 Installation Fix the axial piston unit at the installation location. If necessary, details on the required tools and tightening torques for the fixing screws are available from the machine or system manufacturer.

- Page 23 RE 94010-01-B/09.10 | A7VK Series 10 Bosch Rexroth AG 23/44 Installation Risk of personal injury and property damage! CAuTION! Operating the axial piston unit with seal screws can result in injuries or damage to the axial piston unit. Before commissioning, remove all seal screws and replace them with suitable, pressure-proof, metal locking screws.

- Page 24 24/44 Bosch Rexroth AG A7VK Series 10 | RE 94010-01-B/09.10 Installation 6.4.7 Hydraulically connecting the axial piston unit The machine or system manufacturer is responsible for dimensioning the lines. The axial piston unit must be connected to the rest of the hydraulic system in accordance with the hydraulic circuit diagram of the machine or system manufacturer.

- Page 25 RE 94010-01-B/09.10 | A7VK Series 10 Bosch Rexroth AG 25/44 Installation Notes on routing the lines Observe the following notes when routing the inlet, pressure and case drain lines. Make certain that the feed line (pipe or hose) is as short and straight as possible.

- Page 26 26/44 Bosch Rexroth AG A7VK Series 10 | RE 94010-01-B/09.10 Installation Port overview Fig. 11: A7VK port overview, open design, clockwise rotation Fig. 12: A7VK port overview, open design, counter-clockwise rotation Fig. 13: A7VK port overview, closed design...

- Page 27 RE 94010-01-B/09.10 | A7VK Series 10 Bosch Rexroth AG 27/44 Installation Table 6: Ports, A7VK series 10 Designation Port for Standard Maximum State pressure [bar] Service line DIN 3852 Clockwise: Counter- clockwise: Service line DIN 3852 Clockwise: Counter- clockwise: Service line...

- Page 28 28/44 Bosch Rexroth AG A7VK Series 10 | RE 94010-01-B/09.10 Installation Risk of mix-ups with threaded The axial piston units are used in application areas with metric as well as with connections Imperial systems of units. Both the system of units and the size of threaded hole and threaded plug (e.g.

-

Page 29: Commissioning

RE 94010-01-B/09.10 | A7VK Series 10 Bosch Rexroth AG 29/44 Commissioning Commissioning wARNING! Danger while working in the danger zone of a machine or system! It is not permissible to work in the danger zone of a machine or system. -

Page 30: First Commissioning

30/44 Bosch Rexroth AG A7VK Series 10 | RE 94010-01-B/09.10 Commissioning First commissioning CAuTION! Risk of damage to the product! Any contamination of the hydraulic fluid leads to wear and malfunctions. In particular, contaminants, such as welding beads or metal cuttings in the hydraulic lines, may damage the axial piston unit. - Page 31 RE 94010-01-B/09.10 | A7VK Series 10 Bosch Rexroth AG 31/44 Commissioning Danger of environmental contamination! CAuTION! The discharge or spillage of hydraulic fluid while filling the axial piston unit can lead to environmental pollution and contamination of the groundwater. When filling and changing the hydraulic fluid, always place a drip tray under the axial piston unit.

-

Page 32: Recommissioning After Standstill

32/44 Bosch Rexroth AG A7VK Series 10 | RE 94010-01-B/09.10 Commissioning 7.1.3 Performing functional test wARNING! Risk of injury in case of incorrectly connected machine or system! Interchanging the ports will cause malfunctions resulting in danger for persons and equipment. -

Page 33: Running-In Phase

RE 94010-01-B/09.10 | A7VK Series 10 Bosch Rexroth AG 33/44 Operation Running-in phase The bearings and sliding surfaces are subject to a running-in phase. The increased friction at the start of the running-in phase results in increased heat development which decreases with increasing operating hours. The volumetric and mechanical-hydraulic efficiency increases as well through the conclusion of the running-in phase of approx. -

Page 34: Maintenance And Repair

34/44 Bosch Rexroth AG A7VK Series 10 | RE 94010-01-B/09.10 Maintenance and repair 9 Maintenance and repair Cleaning and care CAuTION! Damage to the surface caused by solvents and aggressive detergents! Aggressive detergents may damage the seals on the axial piston unit and cause them to age faster. -

Page 35: Maintenance

RE 94010-01-B/09.10 | A7VK Series 10 Bosch Rexroth AG 35/44 Maintenance and repair Maintenance The axial piston unit is low maintenance when used as intended. Changes in the case drain flow indicate wear in the axial piston unit. For this reason, for the closed design we recommend that the case drain quantity be measured and documented at regular intervals. -

Page 36: Decommissioning

36/44 Bosch Rexroth AG A7VK Series 10 | RE 94010-01-B/09.10 Decommissioning 10 Decommissioning The axial piston unit is a component that does not require decommissioning. For this reason, this chapter of the manual does not contain any information. For details about how to remove or replace your axial piston unit, please refer to chapter "11 Removal and replacement". -

Page 37: Preparing The Components For Storage Or Further Use

RE 94010-01-B/09.10 | A7VK Series 10 Bosch Rexroth AG 37/44 Removal and replacement Danger of environmental contamination! CAuTION! The discharge or spillage of hydraulic fluid while removing the axial piston unit can lead to environmental pollution and contamination of the groundwater. -

Page 38: Disposal

38/44 Bosch Rexroth AG A7VK Series 10 | RE 94010-01-B/09.10 Disposal 12 Disposal Observe the following points when disposing of the axial piston unit: Completely empty the axial piston unit. Dispose of hydraulic fluid in compliance with the national regulations of your country and in accordance with the safety data sheet for the hydraulic fluid. -

Page 39: Troubleshooting

RE 94010-01-B/09.10 | A7VK Series 10 Bosch Rexroth AG 39/44 Troubleshooting 14 Troubleshooting The following tables may assist you in troubleshooting. The tables make no claim for completeness. In practical use, problems which are not listed here may also occur. -

Page 40: Malfunction Table

40/44 Bosch Rexroth AG A7VK Series 10 | RE 94010-01-B/09.10 Troubleshooting 14.2 Malfunction table Table 8: Malfunction table - A7VK variable pump Malfunction Possible cause Remedy Unusual noises Drive speed too high. Machine or system manufacturer. Wrong direction of rotation. - Page 41 RE 94010-01-B/09.10 | A7VK Series 10 Bosch Rexroth AG 41/44 Troubleshooting Table 8: Malfunction table - A7VK variable pump Malfunction Possible cause Remedy No or insufficient pressure Faulty mechanical input Machine or system manufacturer. (e.g. defective coupling). Drive power too low.

-

Page 42: Technical Data

42/44 Bosch Rexroth AG A7VK Series 10 | RE 94010-01-B/09.10 Technical data 15 Technical data The technical data of your axial piston unit can be found in data sheet RE 94010. The data sheet can be found on the internet at www.boschrexroth.com/industrial-hydraulics-catalog... -

Page 43: Alphabetical Index

RE 94010-01-B/09.10 | A7VK Series 10 Bosch Rexroth AG 43/44 Alphabetical index Alphabetical index Abbreviations 4 Related documents 4 Address directory 42 Removal 36 Appendix 42 Performing 36 Preparing 36 Repair 35 Replacement 36 Carrying 13 Ring screw 14 Connecting... - Page 44 Bosch Rexroth AG Hydraulics Axial piston units Glockeraustraße 4 89275 Elchingen, Germany Tel. +49 (0) 73 08-82-0 Fax +49 (0) 73 08-72 74 info.brm-ak@boschrexroth.de www.boschrexroth.com/brm Printed in Germany RE 94010-01-B/09.10...

Need help?

Do you have a question about the Rexroth Hyquip 10 Series and is the answer not in the manual?

Questions and answers