Subscribe to Our Youtube Channel

Summary of Contents for Bosch A4VSG

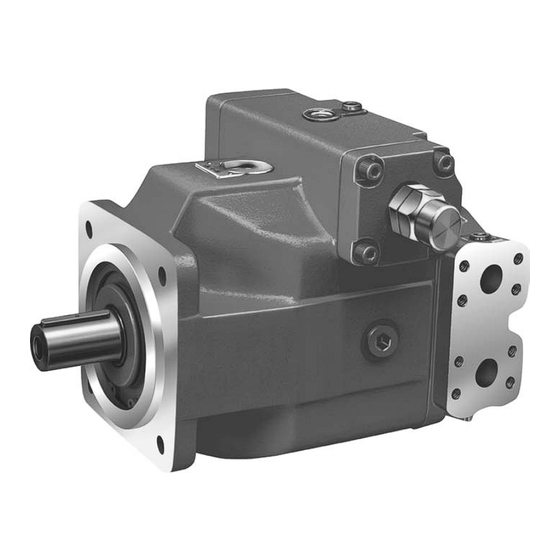

- Page 1 Axial Piston Variable Pump A4VSG Series 10, 11 and 30 Instruction manual Replaces: –.– RE 92100-01-B/09.2012 English...

- Page 2 © This document, as well as the data, specifications and other information set forth in it, are the exclusive property of Bosch Rexroth AG. It may not be reproduced or given to third parties without its consent.

-

Page 3: Table Of Contents

7.4.5 Installation on a gearbox 7.4.6 Installation with cardan shaft 7.4.7 Completing installation 7.4.8 Hydraulically connecting the axial piston unit 7.4.9 Electrically connecting the axial piston unit Peforming flushing cycle RE 92100-01-B/09.2012, A4VSG Series 10, 11 and 30, Bosch Rexroth AG... - Page 4 11.3 Removing the axial piston unit 11.4 Preparing the components for storage or further use Disposal Extension and conversion Troubleshooting 14.1 How to proceed for troubleshooting 14.2 Malfunction table Technical data Alphabetical index Bosch Rexroth AG, RE 92100-01-B/09.2012 Series 10, 11 and 30,...

-

Page 5: About This Manual

1 About this manual 1.1 Validity of the documentation This documentation applies to the following products: • Axial piston variable pump A4VSG Series 10, 11 and 30 This documentation is intended for machine/system manufacturers, fitters and service technicians. This documentation contains important information on the safe and appropriate transport, installation, commissioning, operation, maintenance, removal and simple troubleshooting of the axial piston unit. -

Page 6: Display Of Information

• Type and source of danger: identifies the type and source of the danger • Consequences: describes what occurs if the safety instructions are not complied with • Precautions: states how the danger can be avoided Bosch Rexroth AG, RE 92100-01-B/09.2012 Series 10, 11 and 30,... -

Page 7: Warning / Caution

Protective plug Made out of plastic, not pressure-resistant, only for transportation As umbrella term for A4VSG "axial piston variable pump" the designation "axial piston unit" will be used in the following. RE 92100-01-B/09.2012, A4VSG Series 10, 11 and 30, Bosch Rexroth AG... -

Page 8: Abbreviations

Rexroth document in the English language VDI 2230 Directive for the systematic calculation of high duty bolted joints and joints with one cylindrical bolt from the VDI (Verein Deutscher Ingenieure – Association of German Engineers) Bosch Rexroth AG, RE 92100-01-B/09.2012 Series 10, 11 and 30,... -

Page 9: Safety Instructions

Any use other than that described as intended use shall be considered as improper and is therefore impermissible. Bosch Rexroth AG shall accept no liability whatsoever for damage resulting from improper use. The user shall bear all risks arising from improper use. -

Page 10: Personnel Qualifications

• fully understanding in particular the interrelationships regarding safety devices, • having knowledge on the function and assembly of hydraulic components. Bosch Rexroth offers training support for special fields. You can find an overview of the training contents on the internet at: http://www.boschrexroth.de/didactic. -

Page 11: Product-Specific Safety Instructions

Operating the unit above the permissible maximum pressure can cause components to burst and hydraulic fluid to escape under high pressure. ▶ Changes to the factory settings must only be made by Bosch Rexroth specialist personnel. ▶ In addition, a pressure-relief valve is needed as back-up in the hydraulic system. - Page 12 Always set up the relevant part of the machine/system so that it is free of electrical voltage before you install the product or when connecting and disconnecting plugs. Protect the machine/system against being energized. Bosch Rexroth AG, RE 92100-01-B/09.2012 Series 10, 11 and 30,...

-

Page 13: Personal Protective Equipment

The personal protective equipment is the responsibility of the user of the axial piston unit. Observe the safety regulations and provisions of your country. All components of the personal protective equipment must be intact. RE 92100-01-B/09.2012, A4VSG Series 10, 11 and 30, Bosch Rexroth AG... -

Page 14: General Instructions On Damage To Equipment And The Product

(gap leakage). The bearings are thus insufficiently lubricated at switch on. ▶ Make sure that the suction and boost lines are always filled with hydraulic fluid during commissioning and operation. Bosch Rexroth AG, RE 92100-01-B/09.2012 Series 10, 11 and 30,... - Page 15 Dispose of the axial piston unit, hydraulic fluid and packaging in accordance with the national regulations in your country. ▶ Dispose of the hydraulic fluid in accordance with the applicable safety data sheet for the hydraulic fluid. RE 92100-01-B/09.2012, A4VSG Series 10, 11 and 30, Bosch Rexroth AG...

- Page 16 The warranty applies only to the delivered configuration. The entitlement to warranty cover will be rendered void if the product is incorrectly installed, commissioned or operated, or if it is used or handled improperly. Bosch Rexroth AG, RE 92100-01-B/09.2012 Series 10, 11 and 30,...

-

Page 17: Delivery Contents

• Axial piston unit as per order confirmation The following parts are also installed on delivery: • Protective covers (1) • Protective plug/threaded plug (2) • For version with through drive, metallic protective cover and mounting bolts RE 92100-01-B/09.2012, A4VSG Series 10, 11 and 30, Bosch Rexroth AG... -

Page 18: About This Product

5.2 About this product The A4VSG is a variable pump with axial piston rotary group in swashplate design for hydrostatic drives in closed circuits. Flow is proportional to drive speed and displacement. -

Page 19: Functional Description

Check whether the application on your machine requires additional safety measures, in order to bring the driven consumer into a safe position (immediate stop). If necessary, make sure that these are properly implemented. RE 92100-01-B/09.2012, A4VSG Series 10, 11 and 30, Bosch Rexroth AG... -

Page 20: Product Identification

11 Serial number shaft) – here: clockwise 12 Material number of the axial piston unit 5 Bar code 13 Ordering code 6 Power setting (optional) 14 Customer material number 7 Speed Bosch Rexroth AG, RE 92100-01-B/09.2012 Series 10, 11 and 30,... -

Page 21: Transport And Storage

(from size 500) or to a drive shaft. Alternatively, transport is also possible with a lifting strap. Only use the lifting strap if you are unable to achieve the required installation position with transport using the ring screws. RE 92100-01-B/09.2012, A4VSG Series 10, 11 and 30, Bosch Rexroth AG... - Page 22 20 %. You can hoist the axial piston unit as shown in Fig. 5 with the ring screw screwed into the drive shaft. Fig. 5: Mounting ring screw in drive shaft Bosch Rexroth AG, RE 92100-01-B/09.2012 Series 10, 11 and 30,...

-

Page 23: Storing The Axial Piston Unit

• Do not store the axial piston unit on the drive shaft or fitting, e.g. sensors or valves. • For further storage conditions, see Table 7. ▶ Check the axial piston unit monthly to ensure proper storage. RE 92100-01-B/09.2012, A4VSG Series 10, 11 and 30, Bosch Rexroth AG... - Page 24 Bosch Rexroth Service partner. In the event of questions regarding repair and spare parts, contact your responsible Bosch Rexroth Service partner or the service department of the manufacture's plant for the axial piston unit, see chapter 10.5 "Spare parts" on page 50.

- Page 25 Package the axial piston unit airproof together with desiccant in corrosion protection film. Store the axial piston unit so that it is protected against jolts, see "Requirements" on page 23 in this chapter. RE 92100-01-B/09.2012, A4VSG Series 10, 11 and 30, Bosch Rexroth AG...

-

Page 26: Installation

Please consult your responsible contact person at Bosch Rexroth. ▶ To achieve favorable noise values, decouple all connecting lines from all vibration- capable components (e.g. reservoir) using elastic elements. Bosch Rexroth AG, RE 92100-01-B/09.2012 Series 10, 11 and 30,... - Page 27 ▶ Use lint-free cloths for cleaning. ▶ Use suitable mild detergents to remove lubricants and other difficult-to-remove contamination. Cleaning agents must not enter the hydraulic system. RE 92100-01-B/09.2012, A4VSG Series 10, 11 and 30, Bosch Rexroth AG...

-

Page 28: Installation Position

With installation positions 3, 4, 9 and 10, it is to be expected that the control or regulation is influenced. Because of gravity, dead weight and case pressure, minor characteristic displacements and actuating time changes may occur. Bosch Rexroth AG, RE 92100-01-B/09.2012 Series 10, 11 and 30,... -

Page 29: Below-Reservoir Installation (Standard)

T; R(L) plug 3 (drive shaft, horizontal) ; R(L) plug 4 (drive shaft, horizontal) ; R(L) plug 5 (drive shaft, vertically downward) R(L) 6 (drive shaft vertically upward) T; R(L) plug RE 92100-01-B/09.2012, A4VSG Series 10, 11 and 30, Bosch Rexroth AG... -

Page 30: Above-Reservoir Installation

If an attachment pump is fitted, please note the suction height and minimum inlet pressure stated in the data sheet for the attachment pump. For an overview of attachment pumps, please refer to data sheet RE 92100. Fig. 9: Above-reservoir installation A4VSG with installation position 7–12 T, R(l),... -

Page 31: Installing The Axial Piston Unit

The direction of rotation as specified on the name plate determines the direction of rotation of the axial piston unit as viewed on the drive shaft, see chapter 5.3 "Product identification" on page 20. RE 92100-01-B/09.2012, A4VSG Series 10, 11 and 30, Bosch Rexroth AG... -

Page 32: Dimensions

The drive shaft of the axial piston unit is equipped with a female thread. Use this female thread to pull the coupling element onto the drive shaft. The size of the female thread can be seen in the installation drawing. Bosch Rexroth AG, RE 92100-01-B/09.2012 Series 10, 11 and 30,... -

Page 33: Installation On A Gearbox

Bring the axial piston unit to the installation position and secure. If necessary, details on the required tools and tightening torques for the mounting bolts can be obtained from the system manufacturer. RE 92100-01-B/09.2012, A4VSG Series 10, 11 and 30, Bosch Rexroth AG... -

Page 34: Completing Installation

Ports intended for connecting lines are covered by protective plugs or threaded plugs, which serve as transport protection. All ports required for the function must be connected (see Table 10 "Ports A4VSG Series 10, 11 and 30" on page 38). If this requirement is disregarded, malfunction or damage may result. -

Page 35: Hydraulically Connecting The Axial Piston Unit

(pressure, flow, hydraulic fluid, temperature) with the necessary safety factors. Connect only hydraulic lines that are appropriate for the axial piston unit port (pressure level, size, system of units). RE 92100-01-B/09.2012, A4VSG Series 10, 11 and 30, Bosch Rexroth AG... - Page 36 The system of units, the kind of seal and the size of female thread and threaded plugs (e.g. locking screw) must all match. Due to the limited options for visually detecting differences, there is a risk of mix-ups. Bosch Rexroth AG, RE 92100-01-B/09.2012 Series 10, 11 and 30,...

- Page 37 For all female threads, use a threaded plug from the same system of units and of the correct size. Port overview R(L) Fig. 12: Port overview A4VSG, MA control, size 40 R(L) Fig. 13: Port overview A4VSG, HD control, size 500 RE 92100-01-B/09.2012, A4VSG Series 10, 11 and 30, Bosch Rexroth AG...

- Page 38 38/60 Installation R(L) Fig. 14: Port overview A4VSG with mounted boost pump, HDT control, size 125 R(L) Fig. 15: Port overview A4VSG, HS control, size 250 Table 10: Ports A4VSG Series 10, 11 and 30 Designation Port for Control device (optional)

- Page 39 Must be connected for version for HFC hydraulic fluids. Plugged for HD.A, HD.B, HD.D, EPA, EPB, EPD. Plugged for sizes 40 to 355. O = Must be connected (plugged on delivery) X = Plugged (in normal operation) RE 92100-01-B/09.2012, A4VSG Series 10, 11 and 30, Bosch Rexroth AG...

- Page 40 10 Nm or M10 x 1 to 17 Nm for M12 x 1.5. For the delivery condition "dry" and for reduced M , 10 Nm for M10 x 1 and 17 Nm for M12 x 1.5, the maximum permissible pressure is 420 bar. Bosch Rexroth AG, RE 92100-01-B/09.2012 Series 10, 11 and 30,...

-

Page 41: Electrically Connecting The Axial Piston Unit

RE 92100 or data sheet for control (see Table 1 "Required and supplementary documentation" on page 5). The mating connector is not always included in the delivery contents. RE 92100-01-B/09.2012, A4VSG Series 10, 11 and 30, Bosch Rexroth AG... -

Page 42: Peforming Flushing Cycle

Fig. 16: HIRSCHMAnn connector 7.5 Peforming flushing cycle In order to remove foreign particles from the system, Bosch Rexroth recommends a flushing cycle for the entire system before the first commissioning. To avoid internal contamination, the axial piston unit must not be included in the flushing cycle. -

Page 43: Commissioning

The axial piston unit should be filled with a filling unit (10 µm filter grade). The axial piston unit must not be operated while it is being filled by the filling unit. RE 92100-01-B/09.2012, A4VSG Series 10, 11 and 30, Bosch Rexroth AG... - Page 44 Use only a hydraulic fluid that conforms to the following requirements: You can find details of the minimum requirements on hydraulic fluids in Bosch Rexroth data sheets RE 90220, RE 90221 and RE 90222. The titles of the data sheet can be found in Table 1 "Required and supplementary documentation"...

-

Page 45: Testing The Hydraulic Fluid Supply

After starting the engine, check in particular the specified pressures, e.g. system pressure, boost pressure and case pressure. ▶ If necessary, disconnect the gauge and plug the ports with threaded plugs. RE 92100-01-B/09.2012, A4VSG Series 10, 11 and 30, Bosch Rexroth AG... -

Page 46: Running-In Phase

▶ Change the hydraulic fluid if the required cleanliness level is not reached. If a laboratory test is not carried out after the running-in phase, Bosch Rexroth recommends the hydraulic fluid be changed. 8.3 Recommissioning after standstill Depending on the installation conditions and ambient conditions, changes may occur in the hydraulic system which make recommissioning necessary. -

Page 47: Operation

Use the product only within the performance range provided in the technical data. The machine/system manufacturer is responsible for the proper project planning of the hydraulic system and its control. RE 92100-01-B/09.2012, A4VSG Series 10, 11 and 30, Bosch Rexroth AG... -

Page 48: Maintenance And Repair

Use only water and, if necessary, a mild detergent to clean the axial piston unit. Never use solvents or aggressive detergents. ▶ Remove coarse external dirt and keep sensitive and important components, such as solenoids, valves, indicators and sensors, clean. Bosch Rexroth AG, RE 92100-01-B/09.2012 Series 10, 11 and 30,... -

Page 49: Inspection

Maintenance and repair 49/60 10.2 Inspection In order to enable long and reliable operation of the axial piston unit, Bosch Rexroth recommends testing the hydraulic system and axial piston unit on a regular basis, and documenting and archiving the following operating conditions:... -

Page 50: Repair

50/60 Maintenance and repair 10.4 Repair Bosch Rexroth offers a comprehensive range of services for the repair of Rexroth axial piston units. Repairs on the axial piston unit and its fittings may only be performed by service centers certified by Bosch Rexroth. -

Page 51: Removal And Replacement

Completely empty the axial piston unit. Plug all openings. 11.4 Preparing the components for storage or further use ▶ Proceed as described in chapter 6.2 "Storing the axial piston unit" on page 23. RE 92100-01-B/09.2012, A4VSG Series 10, 11 and 30, Bosch Rexroth AG... -

Page 52: Disposal

Do not modify the axial piston unit or its fittings. This includes changes to the setting screws or wiring. The Bosch Rexroth warranty only applies for the delivered configuration. In case of conversion or extension, the entitlement under warranty will be rendered void. -

Page 53: Troubleshooting

Try to get a clear idea of the error cause. Directly ask the (machine) operator. ▶ Document the work carried out. ▶ If you cannot rectify the error, contact one of the contact addresses which can be found at: www.boschrexroth.com/addresses. RE 92100-01-B/09.2012, A4VSG Series 10, 11 and 30, Bosch Rexroth AG... -

Page 54: Malfunction Table

Wear of axial piston unit. Exchange axial piston unit, contact Bosch Rexroth Service. Mechanical damage to the axial piston unit. Exchange axial piston unit, contact Bosch Rexroth Service. Bosch Rexroth AG, RE 92100-01-B/09.2012 Series 10, 11 and 30,... - Page 55 Bosch Rexroth Service. Instability/vibrations Setpoint value not stable. Machine/system manufacturer. Resonance in the reservoir line. Machine/system manufacturer. Malfunction of the control devices or the Contact Bosch Rexroth Service. controller. RE 92100-01-B/09.2012, A4VSG Series 10, 11 and 30, Bosch Rexroth AG...

-

Page 56: Technical Data

Further information can be found in the online product catalog Industrial Hydraulics: www.boschrexroth.com/ics The order-related technical data of your axial piston unit can be found in the order confirmation. Bosch Rexroth AG, RE 92100-01-B/09.2012 Series 10, 11 and 30,... -

Page 57: Alphabetical Index

Operation Drive shaft ▶ P ▶ F Performance description Filling Piston Flushing cycle Port overview Functional description Pump – Control Functional test ▶ Q Qualifications ▶ H High-pressure side RE 92100-01-B/09.2012, A4VSG Series 10, 11 and 30, Bosch Rexroth AG... - Page 58 Technical data Tightening torques Tools Transport – By hand – With lifting strap – With ring screw Transporting Transport protection Troubleshooting ▶ U Unpacking ▶ w Warranty 16, 52 Weight Bosch Rexroth AG, RE 92100-01-B/09.2012 Series 10, 11 and 30,...

Need help?

Do you have a question about the A4VSG and is the answer not in the manual?

Questions and answers