Summary of Contents for Bosch Rexroth HYQUIP A18VO

- Page 1 Axial Piston Variable Pump RE 92270-01-B/01.11 Replaces: 09.09 A18V(L)O English Series 10 Instruction manual...

- Page 2 © This document, as well as the data, specifica tions and other information set forth in it, are the exclusive property of Bosch Rexroth AG. It may not be reproduced or given to third parties without its consent.

-

Page 3: Table Of Contents

RE 92270-01-B/01.11 | A18V(L)O Series 10 Bosch Rexroth AG 3/52 Contents Contents About this manual ..................4 1.1 Related documents ...................4 1.2 Abbreviations used ...................5 General safety instructions ................6 2.1 Intended use .....................6 2.2 Improper use .....................6 2.3 Personnel qualifications ................7 2.4 Safety instructions in this document ............7... -

Page 4: About This Manual

4/52 Bosch Rexroth AG A18V(L)O Series 10 | RE 92270-01-B/01.11 About this manual About this manual This manual contains important information on the safe and appropriate installation, transport, commissioning, maintenance, removal and simple troubleshooting of the axial piston variable pump A18V(L)O Series 10. -

Page 5: Abbreviations Used

RE 92270-01-B/01.11 | A18V(L)O Series 10 Bosch Rexroth AG 5/52 About this manual Abbreviations used As umbrella term for "axial piston variable pump A18V(L)O", the designation "axial piston unit" will be used in the following. Table 2: Abbreviations Abbreviation Meaning... -

Page 6: General Safety Instructions

For example, in exprotection areas or in safetyrelated parts of a control system (functional safety). Bosch Rexroth AG shall accept no liability whatsoever for damage resulting from improper use. The user shall bear all risks arising from improper use. -

Page 7: Personnel Qualifications

RE 92270-01-B/01.11 | A18V(L)O Series 10 Bosch Rexroth AG 7/52 General safety instructions Similarly, the following predictable fault usages are also considered to be not as intended: • Using the axial piston unit in explosive environments unless the component or system has been certified as compliant with the ATEX directive 94/9/EG •... -

Page 8: Adhere To The Following Instructions

8/52 Bosch Rexroth AG A18V(L)O Series 10 | RE 92270-01-B/01.11 General safety instructions The signal words have the following meaning: Signal word Application DANGER! imminently Indicates an hazardous situation which, if not avoided, will certainly result in death or serious injury. -

Page 9: Operator's Obligations

RE 92270-01-B/01.11 | A18V(L)O Series 10 Bosch Rexroth AG 9/52 General safety instructions During transport • Make sure that the lifting device has adequate lifting capacity. The weight can be found in chapter "5 Transport and storage". During installation • Before installation, make sure that all fluids have been removed from the axial piston unit to prevent mixing with the hydraulic fluid used in the system. -

Page 10: Delivery Contents

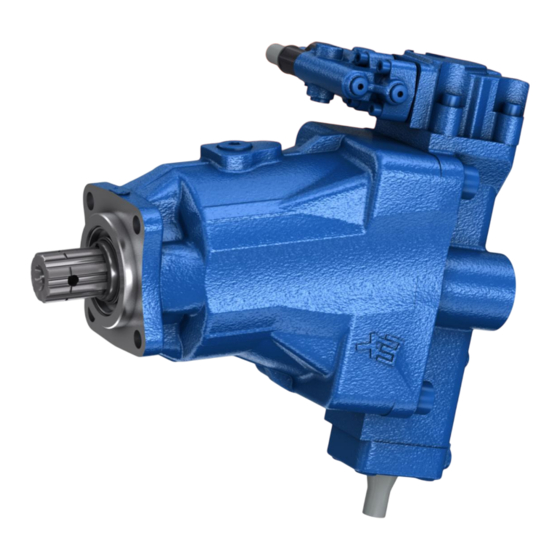

10/52 Bosch Rexroth AG A18V(L)O Series 10 | RE 92270-01-B/01.11 Delivery contents 3 Delivery contents Fig. 1: Axial piston unit A18VO Fig. 2: Axial piston unit A18VLO Included in the delivery contents are: • Axial piston unit as per order confirmation The following parts are also installed on delivery: •... -

Page 11: Product Description

RE 92270-01-B/01.11 | A18V(L)O Series 10 Bosch Rexroth AG 11/52 Product description 4 Product description Performance description The axial piston variable pump generates, controls and regulates a hydraulic fluid flow. It is designed for use in commercial vehicles. Refer to the data sheet and order confirmation for the technical data, operating conditions and operating limits of the axial piston unit. - Page 12 12/52 Bosch Rexroth AG A18V(L)O Series 10 | RE 92270-01-B/01.11 Product description 4.2.2 Functional description Pump Torque and a rotational speed are applied to the drive shaft (1) by an engine. The cylinder (4) is picked up and turned by the drive shaft and the pistons (3). The cylinder then glides over the lens plate (6), in which two kidneyshaped control...

-

Page 13: Product Identification

RE 92270-01-B/01.11 | A18V(L)O Series 10 Bosch Rexroth AG 13/52 Product description Product identification The axial piston unit can be identified from the name plate. The following example shows an A18VLO name plate: Rexroth DE - 89275 Elchingen CNR: X1234567890Y... -

Page 14: Transport And Storage

14/52 Bosch Rexroth AG A18V(L)O Series 10 | RE 92270-01-B/01.11 Transport and storage 5 Transport and storage Transporting the axial piston unit CAuTION! Risk of damage! Striking or impulsive forces could damage the axial piston unit. Do not strike the coupling or drive shaft of the axial piston unit. -

Page 15: Storing The Axial Piston Unit

RE 92270-01-B/01.11 | A18V(L)O Series 10 Bosch Rexroth AG 15/52 Transport and storage Transport with lifting strap Place the lifting strap around the axial piston unit in such a way that it passes over neither the attachment parts (e.g. valves) nor such that the axial piston unit is hung from attachment parts (see Fig. - Page 16 16/52 Bosch Rexroth AG A18V(L)O Series 10 | RE 92270-01-B/01.11 Transport and storage Table 4: Storage time with factory corrosion protection Standard corrosion Long-term Storage conditions protection corrosion protection Closed, dry room, uniform Maximum 12 months Maximum 24 months temperature between +5 °C and +20 °C.

-

Page 17: Installation

RE 92270-01-B/01.11 | A18V(L)O Series 10 Bosch Rexroth AG 17/52 Installation 6 Installation Prior to installation, the following documents must be available: • Installation drawing for axial piston unit (can be obtained from your responsible contact person at Rexroth) •... - Page 18 18/52 Bosch Rexroth AG A18V(L)O Series 10 | RE 92270-01-B/01.11 Installation Make certain that the intake fluid line and the case drain line flow into the reservoir below the minimum fluid level in all operating conditions. This will prevent air from being drawn in and foam from being formed.

-

Page 19: Installation Position

RE 92270-01-B/01.11 | A18V(L)O Series 10 Bosch Rexroth AG 19/52 Installation Installation position The following installation positions are permissible. The shown piping layout illustrates the basic layout. The case drain chamber is internally connected to the suction chamber. A case drain line between the case and reservoir is not required. However, when using the DRS controller, a case drain line from port "T"... - Page 20 20/52 Bosch Rexroth AG A18V(L)O Series 10 | RE 92270-01-B/01.11 Installation 6.3.2 Above-reservoir installation Abovereservoir installation is when the axial piston unit is installed above the minimum fluid level of the reservoir. Risk of damage due to lack of lubrication!

-

Page 21: Installing The Axial Piston Unit

RE 92270-01-B/01.11 | A18V(L)O Series 10 Bosch Rexroth AG 21/52 Installation Installing the axial piston unit DANGER! Systems which are not shut down pose a risk of injury! Working on operating systems poses a danger to life and limb. The work steps described in this chapter must only be performed on systems which are at a standstill. - Page 22 22/52 Bosch Rexroth AG A18V(L)O Series 10 | RE 92270-01-B/01.11 Installation 6.4.2 Dimensions The installation drawing contains the dimensions for all connections and ports on the axial piston unit. Also observe the manuals provided by the manufacturers of the other components when selecting the required tools.

- Page 23 RE 92270-01-B/01.11 | A18V(L)O Series 10 Bosch Rexroth AG 23/52 Installation Transport the axial piston unit to the installation location. Install the coupling onto the input according to the instructions of the coupling manufacturer. The axial piston unit may not be bolted down until the coupling has been correctly installed.

- Page 24 24/52 Bosch Rexroth AG A18V(L)O Series 10 | RE 92270-01-B/01.11 Installation Risk of damage to persons and property! CAuTION! Operating the axial piston unit with plastic plugs can result in injuries or damage to the axial piston unit. Before commissioning, remove all plastic plugs and replace them with suitable, pressureproof, metal threaded plugs.

- Page 25 RE 92270-01-B/01.11 | A18V(L)O Series 10 Bosch Rexroth AG 25/52 Installation 6.4.7 Hydraulically connecting the axial piston unit The machine or system manufacturer is responsible for dimensioning the lines. The axial piston unit must be connected to the rest of the hydraulic system in accordance with the hydraulic circuit diagram of the machine or system manufacturer.

- Page 26 26/52 Bosch Rexroth AG A18V(L)O Series 10 | RE 92270-01-B/01.11 Installation With the pressure lines, make certain that the pipes, hoses and connecting elements are approved for the operating pressure range. Always route the case drain lines so that the housing is constantly filled with hydraulic fluid and to ensure that no air gets through the shaft seal ring even during extended standstill periods.

- Page 27 RE 92270-01-B/01.11 | A18V(L)O Series 10 Bosch Rexroth AG 27/52 Installation Port overview Fig. 14: Port overview of A18VO Series 10 with DRS control Fig. 15: Port overview of A18VLO Series 10 with DRS.E control...

- Page 28 28/52 Bosch Rexroth AG A18V(L)O Series 10 | RE 92270-01-B/01.11 Installation Fig. 16: Port overview of A18VO Series 10 with EP2 control Table 7: Ports A18V(L)O Series 10 Designation Port for Standard Maximum State pressure [bar] Service line DIN ISO 228...

- Page 29 RE 92270-01-B/01.11 | A18V(L)O Series 10 Bosch Rexroth AG 29/52 Installation Tightening torques The following tightening torques apply: • Threaded hole of the axial piston unit: The maximum permissible tightening torques M are maximum values of the G max female threads and must not be exceeded. For values, see the following table.

- Page 30 30/52 Bosch Rexroth AG A18V(L)O Series 10 | RE 92270-01-B/01.11 Installation For axial piston units with electric control or mounted sensors, note for example: • the permissible voltage range • the permissible current • the correct connections • the recommended electric control units.

-

Page 31: Commissioning

RE 92270-01-B/01.11 | A18V(L)O Series 10 Bosch Rexroth AG 31/52 Commissioning 7 Commissioning wARNING! Danger while working in the danger zone of a machine or system! It is not permissible to work in the danger zone of a machine or system. -

Page 32: First Commissioning

32/52 Bosch Rexroth AG A18V(L)O Series 10 | RE 92270-01-B/01.11 Commissioning First commissioning CAuTION! Risk of damage to the product! Any contamination of the hydraulic fluid leads to wear and malfunctions. In parti cular, contaminants, such as welding beads or metal cuttings in the hydraulic lines, may damage the axial piston unit. - Page 33 RE 92270-01-B/01.11 | A18V(L)O Series 10 Bosch Rexroth AG 33/52 Commissioning The axial piston unit should be filled with a filling unit (10 µm filter grade). The axial piston unit must not be operated while it is being filled with the filling unit.

- Page 34 34/52 Bosch Rexroth AG A18V(L)O Series 10 | RE 92270-01-B/01.11 Commissioning Check the suction pressure at port "S" of the axial piston pump at nominal speed and maximum flow. Refer to data sheets RE RE 92270 and RE 92280 for the permissible value.

-

Page 35: Recommissioning After Standstill

RE 92270-01-B/01.11 | A18V(L)O Series 10 Bosch Rexroth AG 35/52 Commissioning Recommissioning after standstill Depending on the installation conditions and ambient conditions, changes may occur in the system which make recommissioning necessary. Among others, the following criteria may make recommissioning necessary: •... -

Page 36: Operation

36/52 Bosch Rexroth AG A18V(L)O Series 10 | RE 92270-01-B/01.11 Operation 8 Operation The product is a component which requires no settings or changes during operation. For this reason, this chapter of the manual does not contain any information on adjustment options. Use the product only within the performance range provided in the technical data. -

Page 37: Maintenance And Repair

RE 92270-01-B/01.11 | A18V(L)O Series 10 Bosch Rexroth AG 37/52 Maintenance and repair 9 Maintenance and repair Cleaning and care CAuTION! Damage to the surface caused by solvents and aggressive detergents! Aggressive detergents may damage the seals on the axial piston unit and cause them to age faster. -

Page 38: Maintenance

38/52 Bosch Rexroth AG A18V(L)O Series 10 | RE 92270-01-B/01.11 Maintenance and repair 9.2.1 Checking the inspection hole Risk of property damage! CAuTION! If hydraulic fluid leaks from the inspection hole, the axial piston unit as well as the power takeoff may drain and be damaged. -

Page 39: Repair

RE 92270-01-B/01.11 | A18V(L)O Series 10 Bosch Rexroth AG 39/52 Maintenance and repair Repair Rexroth offers a comprehensive range of services for the repair of Rexroth axial piston units. Repairs to the axial piston unit may only be performed by authorized, skilled and instructed personnel. -

Page 40: Decommissioning

40/52 Bosch Rexroth AG A18V(L)O Series 10 | RE 92270-01-B/01.11 Decommissioning 10 Decommissioning The axial piston unit is a component that does not require decommissioning. For this reason, this chapter of the manual does not contain any information. For details about how to remove or replace your axial piston unit, please refer to chapter "11 Removal and replacement". -

Page 41: Preparing The Components For Storage Or Further Use

RE 92270-01-B/01.11 | A18V(L)O Series 10 Bosch Rexroth AG 41/52 Removal and replacement Danger of environmental contamination! CAuTION! The discharge or spillage of hydraulic fluid while removing the axial piston unit can lead to environmental pollution and contamination of the groundwater. -

Page 42: Disposal

42/52 Bosch Rexroth AG A18V(L)O Series 10 | RE 92270-01-B/01.11 Disposal 12 Disposal Observe the following points when disposing of the axial piston unit: Completely empty the axial piston unit. Dispose of the hydraulic fluid according to the national regulations of your country. -

Page 43: Troubleshooting

RE 92270-01-B/01.11 | A18V(L)O Series 10 Bosch Rexroth AG 43/52 Troubleshooting 14 Troubleshooting The following table may assist you in troubleshooting. The table makes no claim for completeness. In practical use, problems which are not listed here may also occur. -

Page 44: Malfunction Table

44/52 Bosch Rexroth AG A18V(L)O Series 10 | RE 92270-01-B/01.11 Troubleshooting 14.2 Malfunction table Table 10: Malfunction table for variable pumps Malfunction Possible cause Remedy Unusual noises Drive speed too high. Machine or system manufacturer. Wrong direction of rotation. Ensure correct direction of rotation. - Page 45 RE 92270-01-B/01.11 | A18V(L)O Series 10 Bosch Rexroth AG 45/52 Troubleshooting Table 10: Malfunction table for variable pumps Malfunction Possible cause Remedy No or insufficient pressure Faulty mechanical input Machine or system manufacturer. (e.g. defective coupling). Drive power too low.

-

Page 46: Technical Data

46/52 Bosch Rexroth AG A18V(L)O Series 10 | RE 92270-01-B/01.11 Technical data 15 Technical data The technical data for your axial piston unit can be found on data sheets RE 92270 (A18VO) and RE 92280 (A18VLO). The data sheets can be found on the internet under www.boschrexroth.com/axialkolbenpumpen... -

Page 47: Alphabetical Index

RE 92270-01-B/01.11 | A18V(L)O Series 10 Bosch Rexroth AG 47/52 Alphabetical index Alphabetical index Abbreviations 5 Hydraulic fluid 32 Abovereservoir installation 20 Address directory 46 Air bleed port 19, 20 Identification 13 Assembly 11 Inspection 37 Inspection hole 38 Installation 17, 21 Belowreservoir installation 19... - Page 48 48/52 Bosch Rexroth AG A18V(L)O Series 10 | RE 92270-01-B/01.11 Alphabetical index Recommissioning After standstill 35 Related documents 4 Removal 40 Performing 40 Preparing 40 Repair 39 Replacement 40 Ring screw 14 Runningin phase 35 Safety instructions 6, 7 Spare parts 39...

Need help?

Do you have a question about the Rexroth HYQUIP A18VO and is the answer not in the manual?

Questions and answers